A kind of pta production waste water comprehensive treatment reuse method

A technology for production wastewater and comprehensive treatment, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of secondary pollution, affecting the hydrotreating unit, and less amount of extractant PX, etc. High recovery rate of wastewater treatment, significant economic benefits, and the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

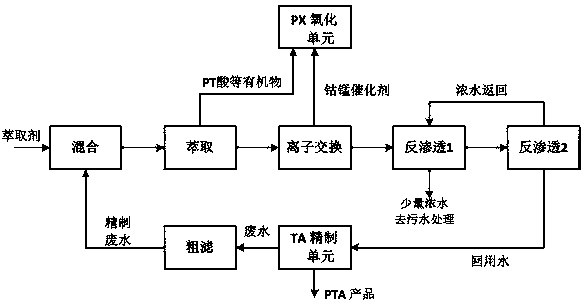

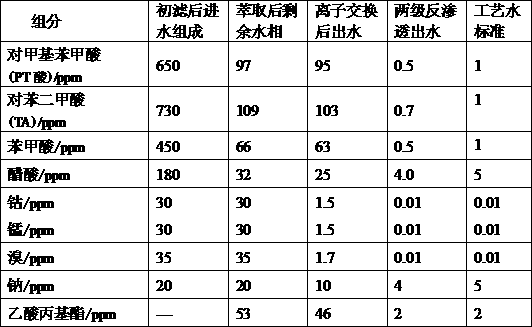

Embodiment 1

[0030] The production capacity of a PTA plant is 600 kt / a, and the operating conditions of the hydrogenation reaction are: reaction temperature 280~286°C, pressure 6.8~8.1MPa. The wastewater from the TA refining unit of the PTA plant is pre-filtered to remove large solid suspended solids (containing TA, PT acid and other organic matter) in the water, and the filtered solid aromatic acid organic matter is returned to the oxidation unit for use. The filtered refined wastewater and propyl acetate extractant are mixed in the mixer and then transported to the extractor. The extraction residence time is 15~30 minutes, the temperature is 17~25°C, and the extraction agent / wastewater=0.6~1.0 (mass Compare). The wastewater and propyl acetate extractant are mixed and mass-transferred in the extractor, and the fine solid aromatic acid organic matter is transferred from the water phase to the extractant phase; the aromatic acid organic matter in the extraction phase is separated from the e...

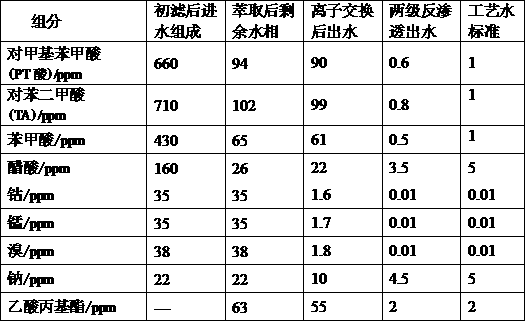

Embodiment 2

[0035] The production capacity of a PTA plant is 600 kt / a, and the operating conditions of the hydrogenation reaction are: reaction temperature 280~286°C, pressure 6.8~8.1MPa. The wastewater from the TA refining unit of the PTA plant is pre-filtered to remove large solid suspended solids (containing TA, PT acid and other organic matter) in the water, and the filtered solid aromatic acid organic matter is returned to the oxidation unit for use. The filtered refined wastewater and propyl acetate extractant are mixed in the mixer and then transported to the extractor. The extraction residence time is 15-30 minutes, the temperature is 25-30°C, and the extraction agent / wastewater=0.6-1.0 (mass Compare). The wastewater and propyl acetate extractant are mixed and mass-transferred in the extractor, and the fine solid aromatic acid organic matter is transferred from the water phase to the extractant phase; the aromatic acid organic matter in the extraction phase is separated from the e...

Embodiment 3

[0040] The production capacity of a PTA plant is 600 kt / a, and the operating conditions of the hydrogenation reaction are: reaction temperature 280~286°C, pressure 6.8~8.1MPa. The wastewater from the TA refining unit of the PTA plant is pre-filtered to remove large solid suspended solids (containing TA, PT acid and other organic matter) in the water, and the filtered solid aromatic acid organic matter is returned to the oxidation unit for use. The filtered refined wastewater and butyl acetate extractant are mixed in the mixer and then transported to the extractor. The extraction residence time is 10~30 minutes, the temperature is 30~35°C, and the extraction agent / wastewater=0.7~1.0 (mass Compare). The waste water and butyl acetate extractant are mixed and mass-transferred in the extractor, and the fine solid aromatic acid organic matter is transferred from the water phase to the extractant phase; the aromatic acid organic matter in the extraction phase is separated from the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com