Water purifying method for cultivation pond

A technology for water purification and aquaculture wastewater, applied in fish farming, oxidized water/sewage treatment, animal husbandry, etc., can solve the problems of polluted environment and high cost of water management, and achieve good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

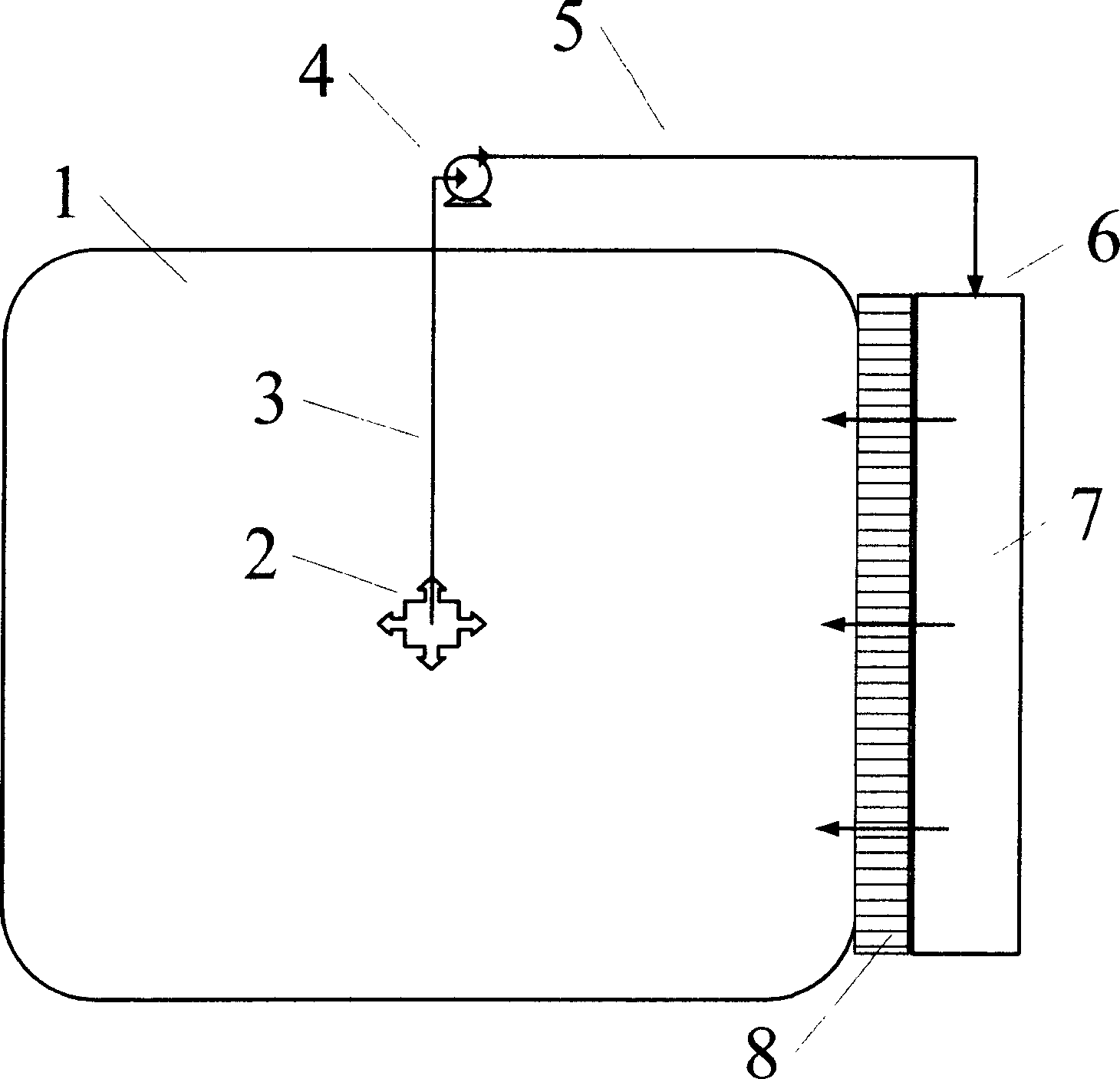

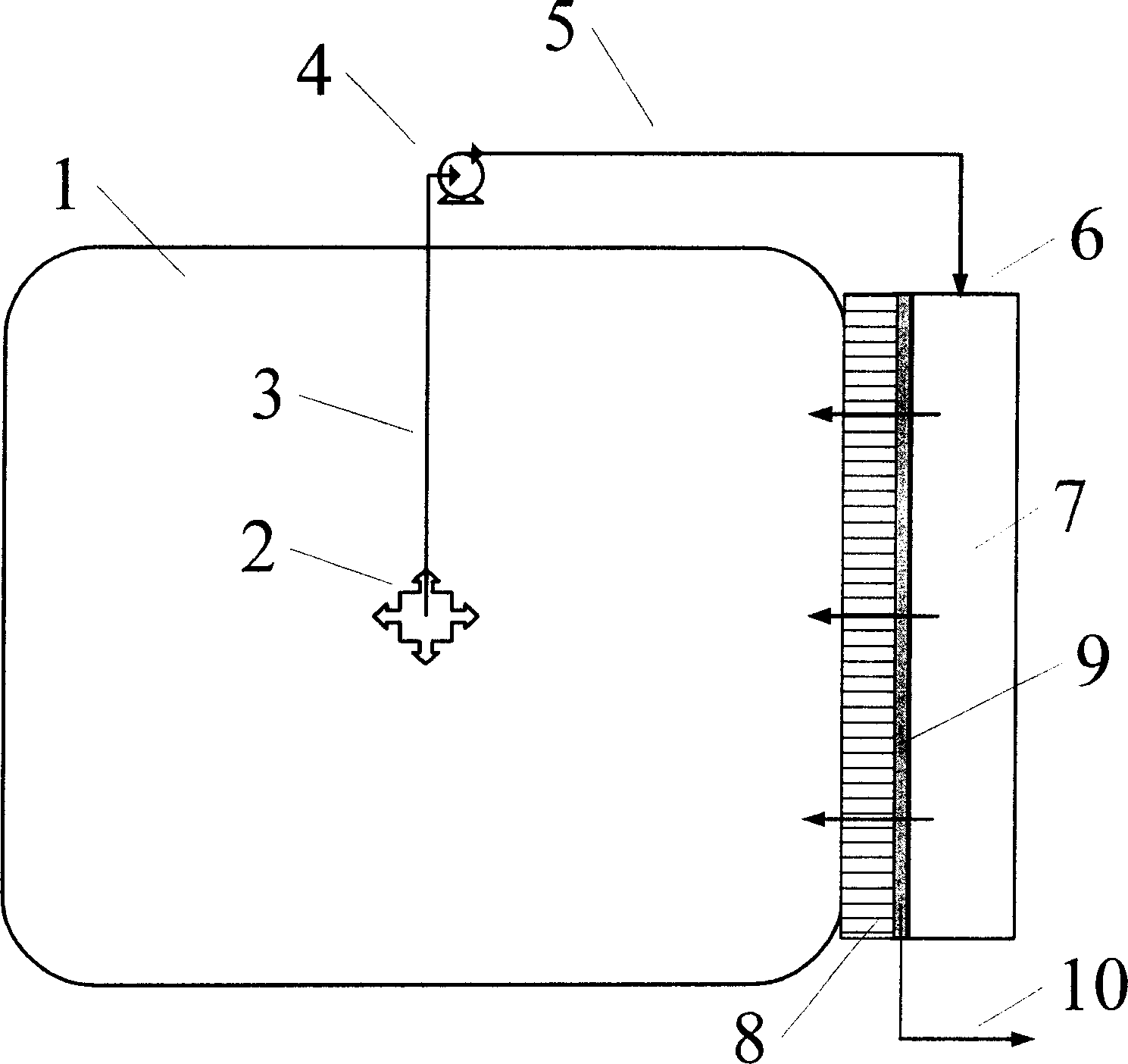

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , the water purification method of the present invention can pass through the sewage collection pipe device 2, the central sewage pipe 3, the water pump 4, the water delivery pipe 5, the water distribution device 6, and the shallow sedimentation tank arranged at the central bottom of the aquaculture pond 1 of the gentle pot bottom type. 7 and actinic slope 8 to achieve the natural light circulation water purification system. The sewage collection pipe device 2 is composed of 8 perforated sewage collection hard plastic pipes and 1 sewage discharge pipe, which is used to collect the residue at the bottom of the pool and the bottom layer of inferior quality. The central blowdown pipe 3 is a socket hard plastic pipe, which can make waste water and residues with higher organic loads be lifted into the shallow sedimentation tank 7 by the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com