Biogas residue biogas slurry processor

A processor and biogas slurry technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. To achieve the effect of high filtration rate of suspended organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

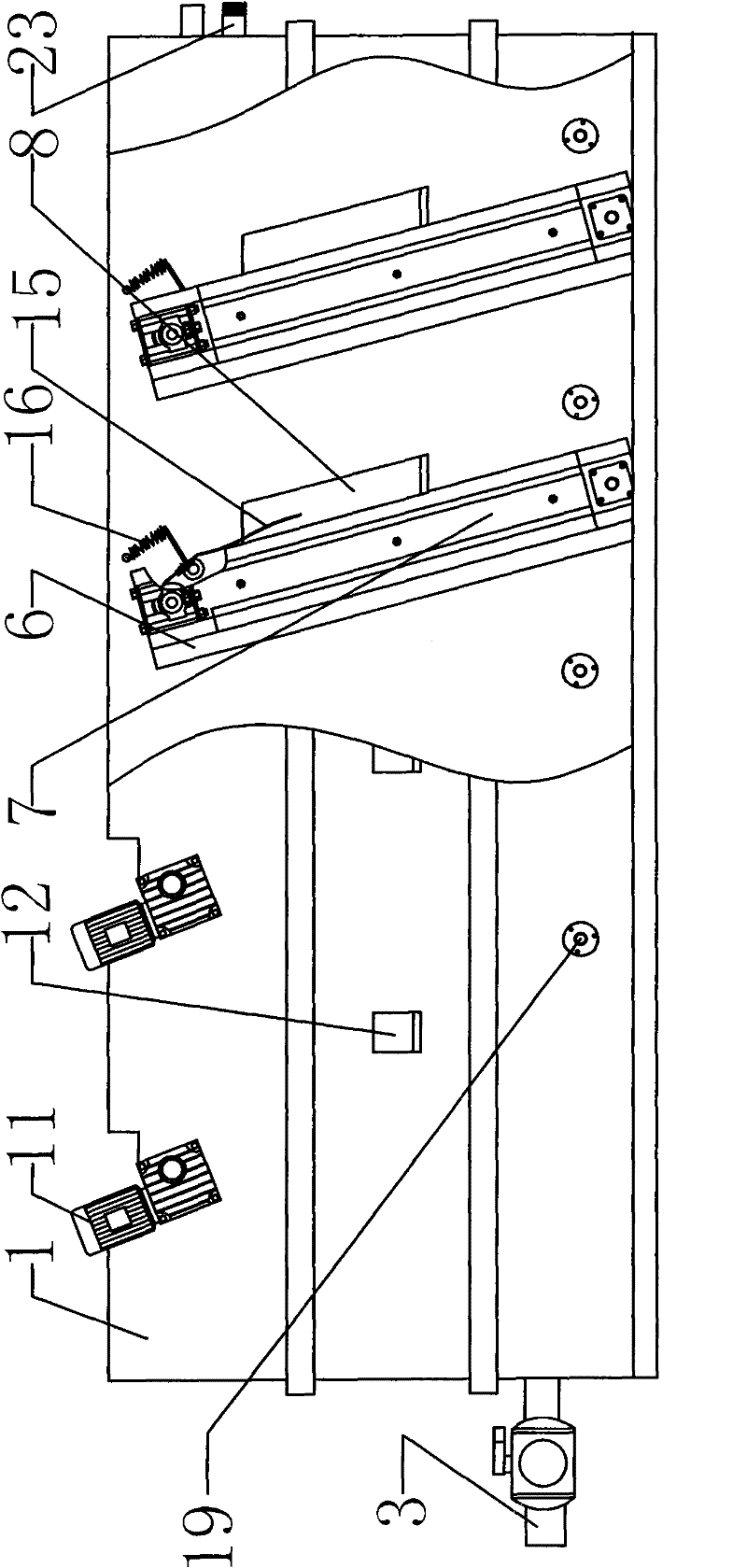

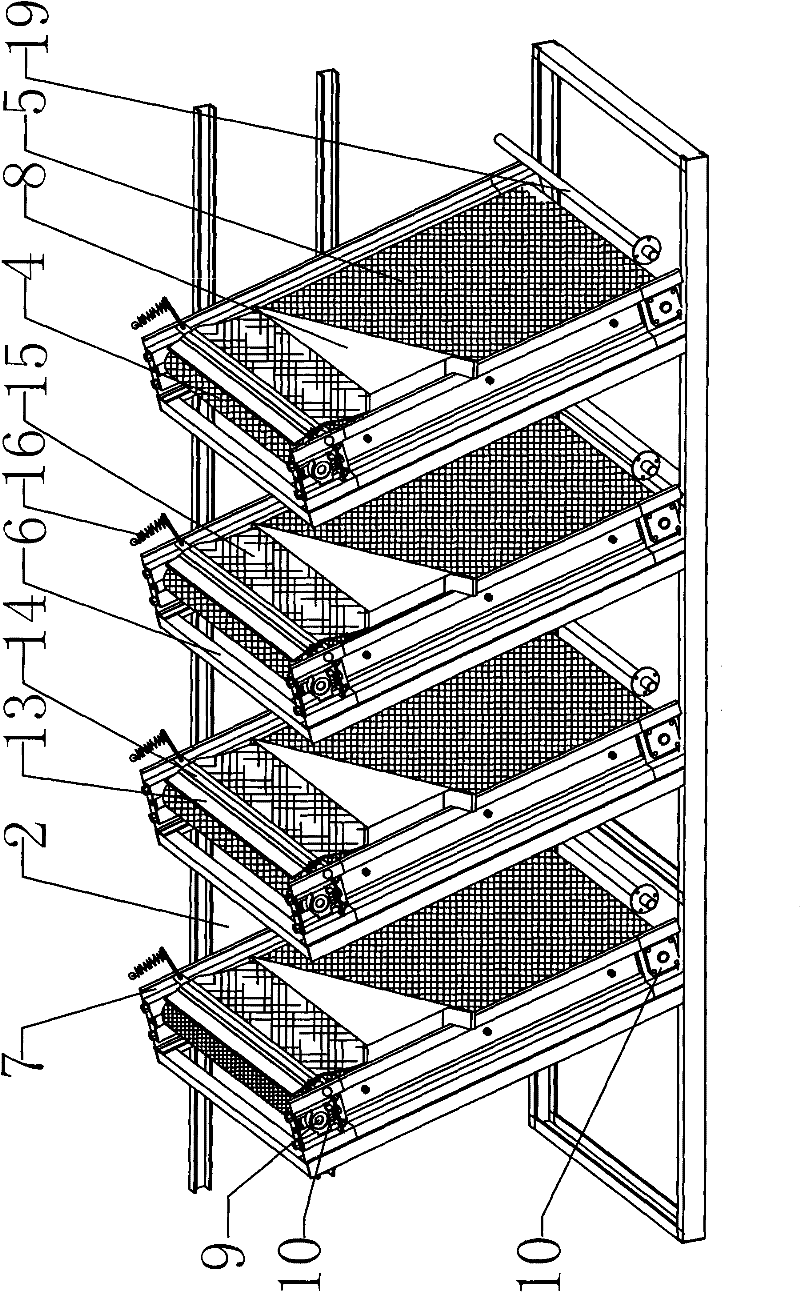

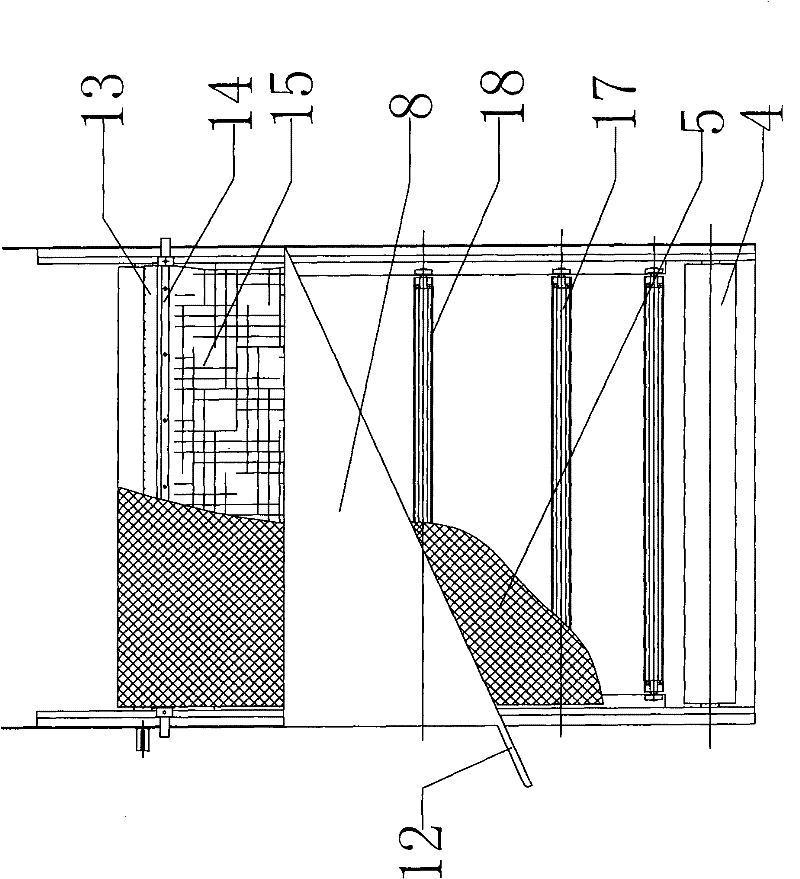

[0023] Such as figure 1 , 2 As shown in and 3, the biogas residue biogas slurry processor includes a box body 1 and a filter device, and the length direction of the box body 1 is respectively provided with a plurality of filter devices, and the box body space between each filter device forms a filter chamber section 2, the first The casing 1 of the first filter chamber section 2 is provided with a waste water inlet 23, and the bottom of the casing 1 of the last filter chamber section 2 is provided with a filtrate outlet 3, and each filter device is inclined towards the filtrate outlet direction and forms a horizontal line. Angle α, which is 70°. The filtering device includes a drum 4, a filter screen 5, a filter screen frame 6, a side plate 7, a sewage discharge tank 8 and a slag removal mechanism. The direction of the filtrate outlet 3 decreases step by step. The slag removal mechanism includes a scraper 13, a scraper shaft 14, a rubber plate 15 and a spring 16. Side plate...

Embodiment 2

[0025] Such as Figure 4 As shown, the aeration tube 19 of the present invention can be omitted, and as long as the stirring paddle 21 and the stirring motor 22 of the case cover 20 are arranged, the solution can be stirred and mixed. Other structures are with embodiment 1.

[0026] The invention works like this:

[0027] Turn on the motor 11 that drives the drum 4 to rotate, and inject waste water into the first filter chamber section 2. At this time, the drum 4 drives the filter screen 5 to filter the residue in the waste water, and uses the scraper 13 to scrape the filter residue into the sewage tank 8, From the second filter chamber section 2, put into each chamber section sewage treatment flocculant in proportion to purify, open the aeration pipe 19 at the bottom of the box body 1, and the stirring motor 22 at the upper end of the box cover 20, for each chamber section The solution is mixed and stirred, and the solution of each chamber segment treated with the flocculan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com