Biogas residue and biogas liquid treatment machine

A processing machine and biogas slurry technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as untimely treatment, wet filter residue, and mixing, and achieve suspended organic matter The effect of high filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

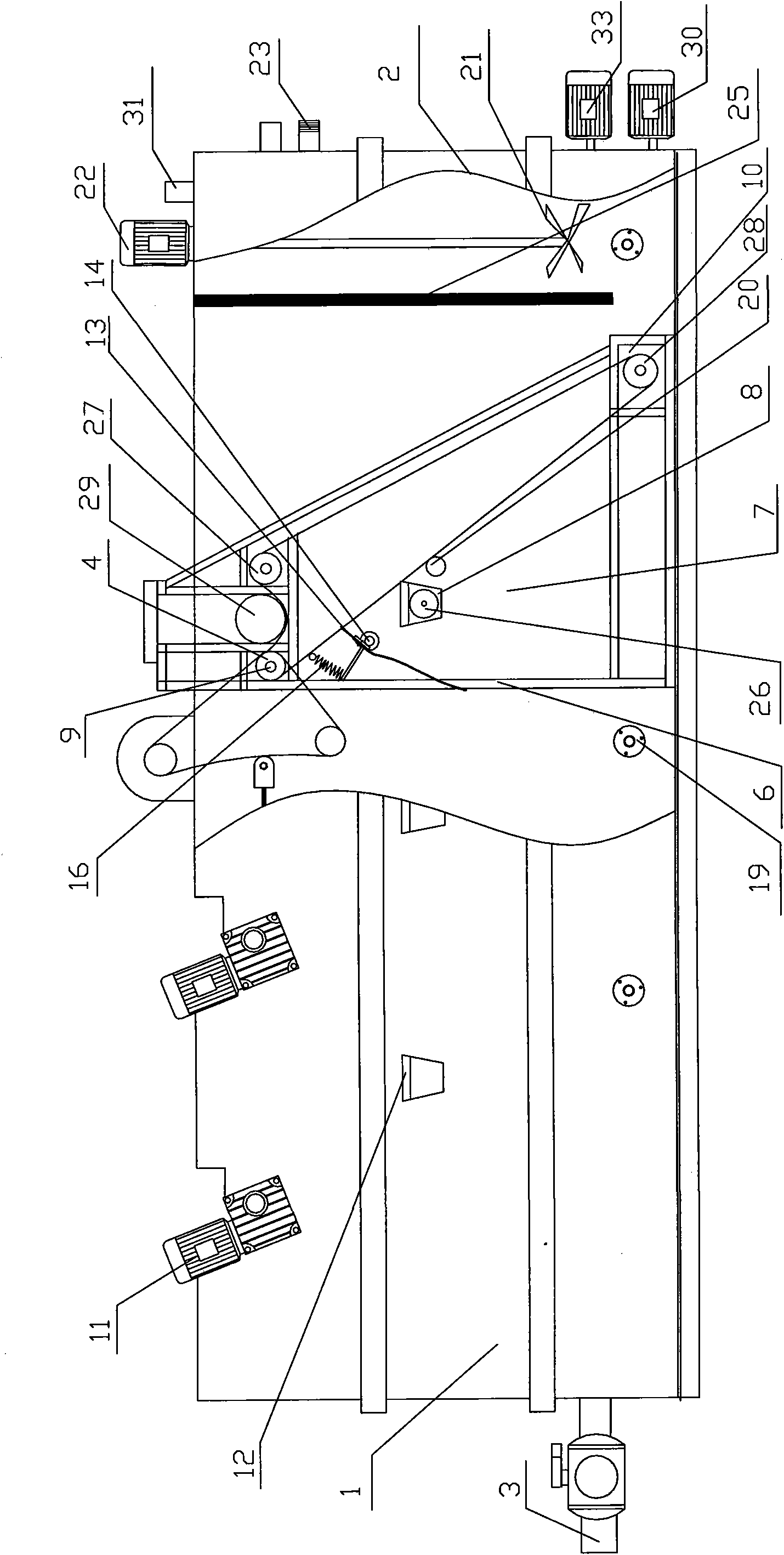

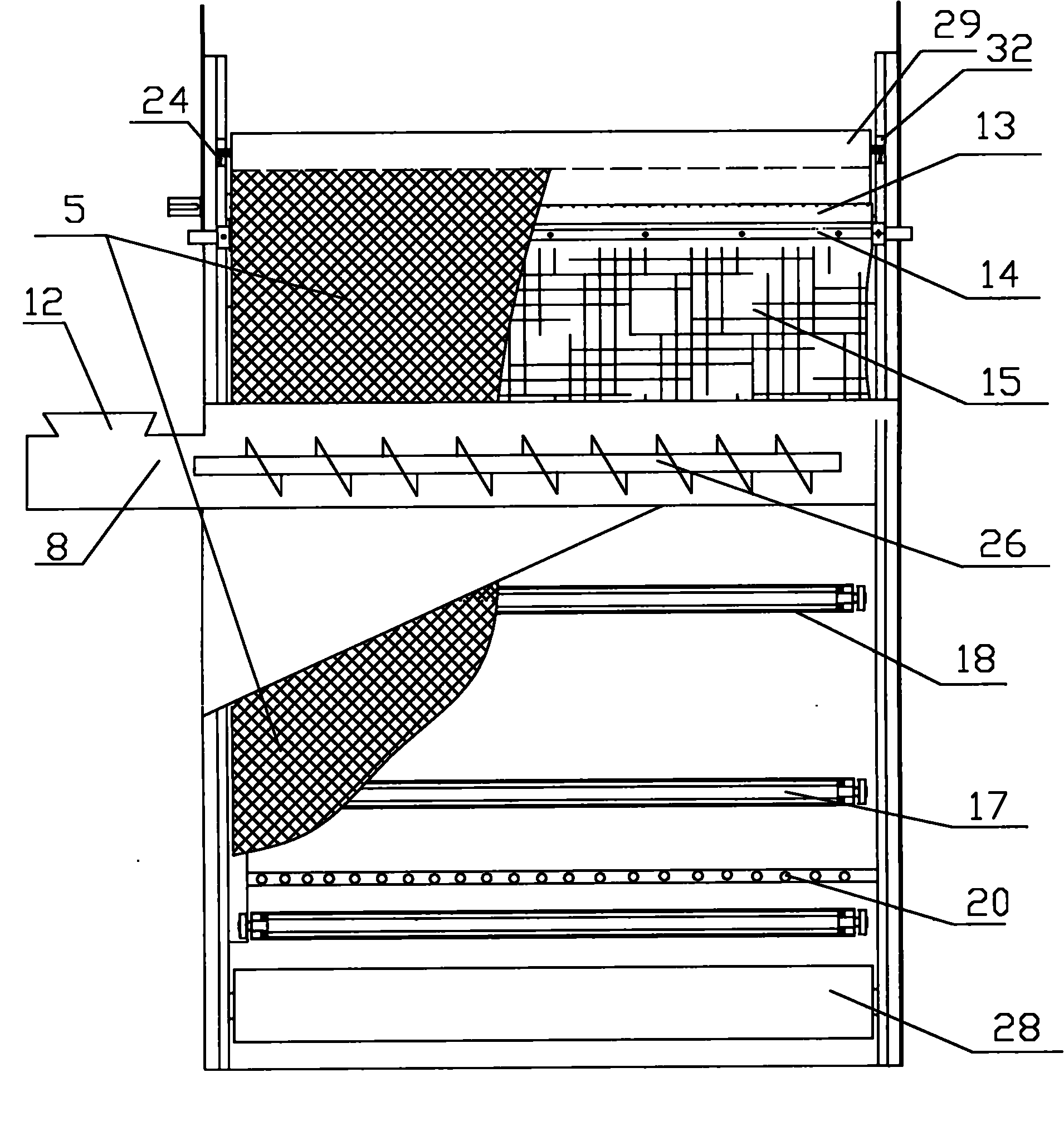

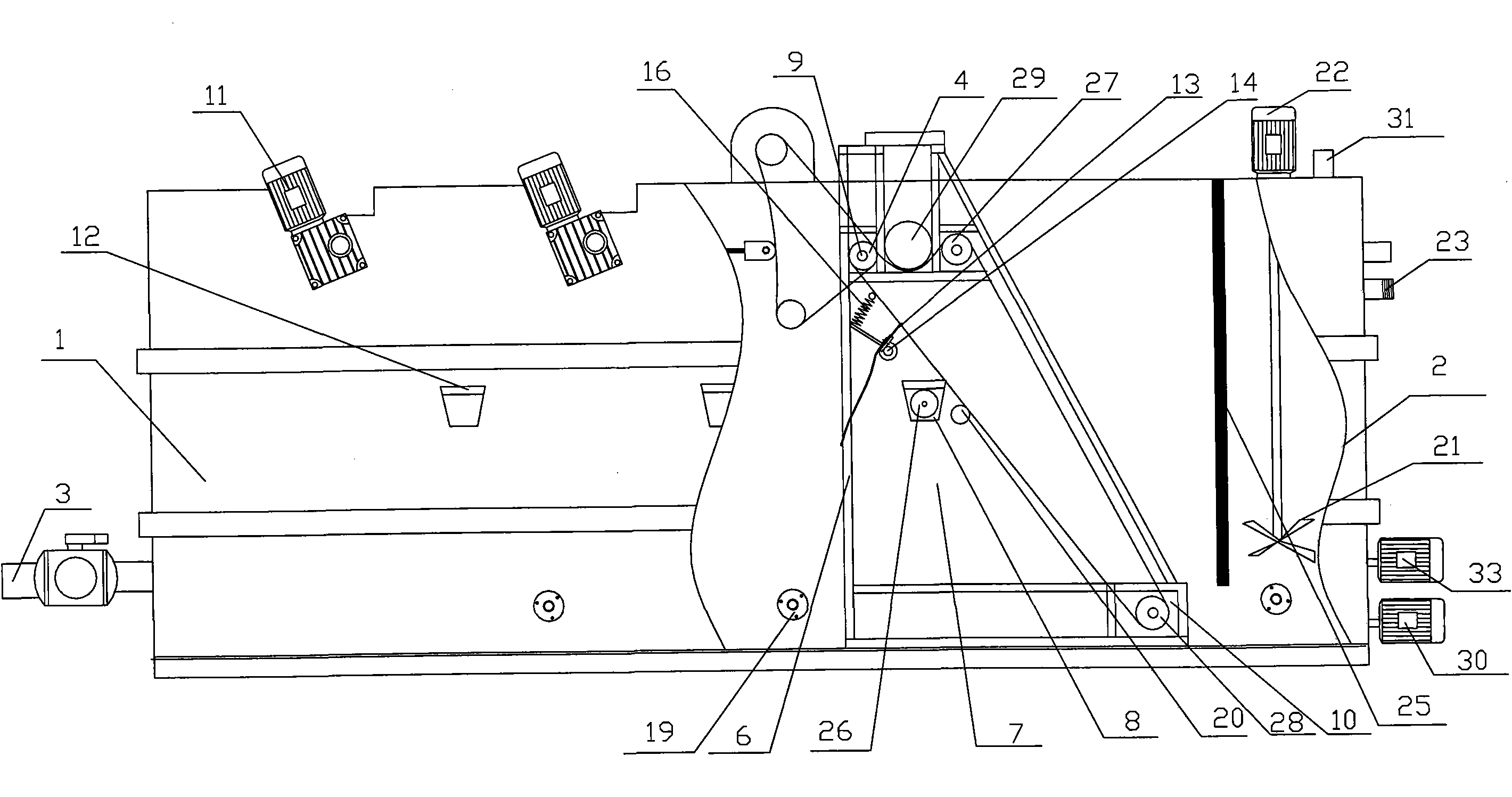

[0017] Such as figure 1 with 2 As shown, a biogas residue biogas slurry processor of the present invention includes a box body 1 and a filter device. The length direction of the box body 1 is respectively provided with a plurality of filter devices, and each filter device is inclined towards the filtrate outlet 3 and is aligned with the The horizontal line forms an angle where α is 70°, and the space of the box body 1 between each filter device forms a filter cavity segment 2, and the bottom of the box body 1 of each filter cavity segment 2 is provided with an aeration pipe 19, and the first filter cavity segment The side of the box body 1 of 2 is provided with a waste water inlet 23, the upper part of the first filter chamber section 2 box body 1 is provided with a dosing port 31, the bottom of the box body 1 of the last filter chamber section 2 is provided with a filtrate outlet 3, and the waste water inlet 23 and the first filter chamber section 2 are provided with a parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com