Acrylon wastewater deep treatment method based on dry method

A dry-process acrylic fiber and advanced treatment technology, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of wastewater treatment not up to standard, and overcome the narrow pH range, Reduce the amount of treated water and increase the flux of nanofiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

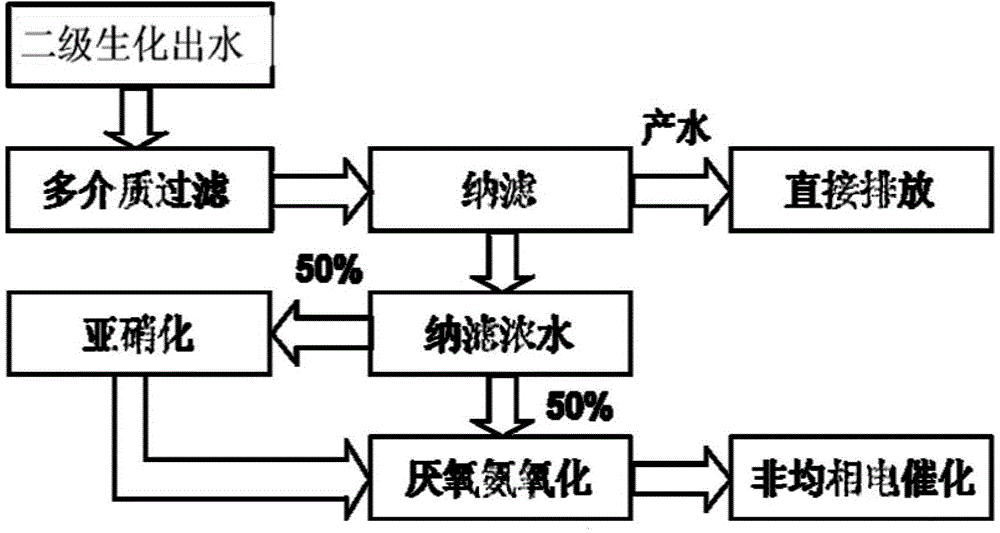

[0032] Such as figure 1 As shown, taking the waste water of the Fushun Petrochemical Acrylic Fiber Plant as the treatment target, the water quality of the dry acrylic fiber waste water after the second-level biochemical treatment of the wastewater: COD 200-400mg / L, BOD 5 0-20mg / L, SS is 0-100mg / L, ammonia nitrogen is 70-150mg / L, pH is 6.7-7.5, temperature is 30-35°C, treated water volume is 0.5m 3 , Is the pilot scale.

[0033] The multi-media filter is a filter with anthracite and quartz sand double-layer filter material as the core. The filling height ratio of the two filter materials is 4:3. The raw water enters the multi-media filter, and is dispersed to the filter bed through the internal water distributor of the multi-media filter to reduce the turbidity of the water, and the effluent enters the subsequent treatment process. Control filtration speed 8.8m / h, washing intensity 8-10L / S·m 2 , Air washing strength 10-15L / S·m 2 , The pressure is 0.6MPa. When the time reaches one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com