Method for removing biochemical process tail water organic matters in wastewater by ultraviolet combined with chlorine

A technology for organic matter and sewage, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of toxic and harmful disinfection by-products, non-sustainable sterilization ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

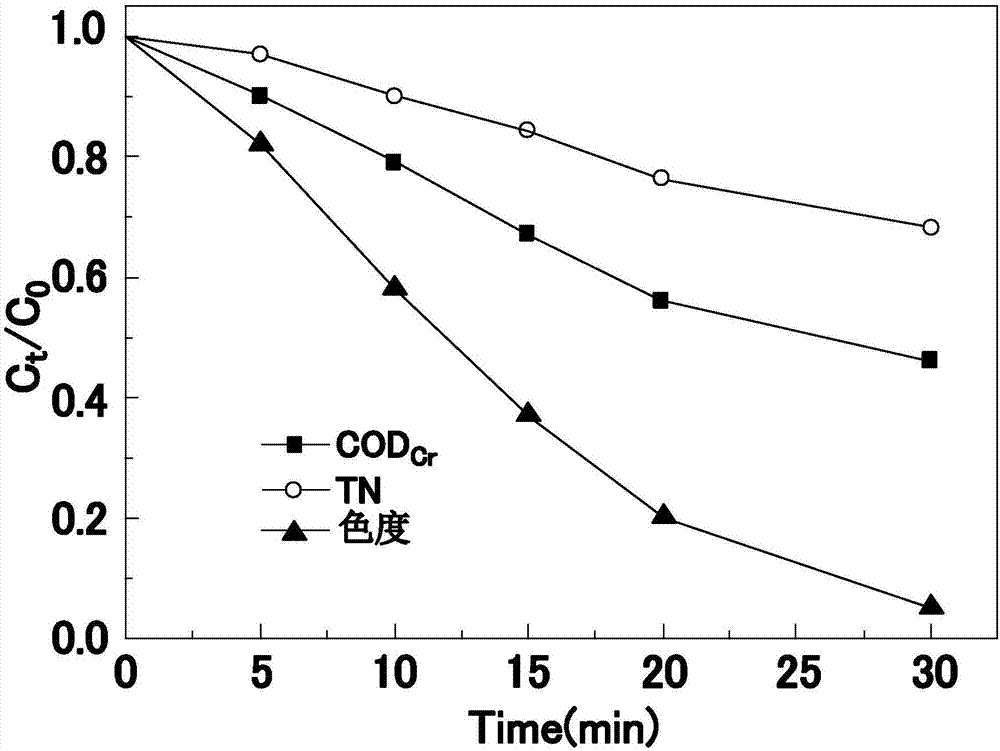

Embodiment 1

[0012] Example 1: The biochemical tail water is taken from the secondary sedimentation tank effluent (COD Cr 45 mg / L, TN 15 mg / L, chromaticity 30 times), chlorine dosage 105 mg / L (one-time dosage), pH 7.0, temperature 25 0 c. The reaction is carried out for 30 minutes according to the steps in the method for removing organic matter in sewage biochemical tail water by combining ultraviolet rays and chlorine in the present invention. COD in this embodiment Cr The removal rate is 56%, TN removal rate is 35%, and chroma removal rate is 96.5%.

Embodiment 2

[0013] Example 2: The biochemical tail water is taken from the secondary sedimentation tank effluent (COD Cr 60mg / L, TN 18 mg / L, chromaticity 25 times), dosage 142 mg / L (multiple dosage), pH 7.5, temperature 25 0 c. The reaction was carried out for 30 minutes according to the steps in the method for removing organic matter in sewage biochemical tail water with ultraviolet combined with chlorine of the present invention. COD in this embodiment Cr The removal rate is 65%, TN removal rate is 42%, and chroma removal rate is 98%.

Embodiment 3

[0014] Example 3: The biochemical tail water is taken from the secondary sedimentation tank effluent (COD Cr 150 mg / L, TN65 mg / L, chromaticity 150 times), dosage 300 mg / L (multiple dosage), pH 7.5, temperature 25 0 c. The reaction was carried out for 60 min according to the steps in a method for removing organic matter in sewage biochemical tail water with ultraviolet combined with chlorine of the present invention. COD in this embodiment Cr The removal rate is 68%, TN removal rate is 35%, and chroma removal rate is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com