Treatment method of rubber processing wastewater difficult to biodegrade

A technology that is difficult to biodegrade and process wastewater, applied in the field of treatment of rubber processing wastewater, can solve the problems of destroying molecular structure, difficult to treat low-concentration rubber processing wastewater, and difficult to treat low-concentration rubber processing wastewater. Biochemical, COD and Ammonia Nitrogen Concentration Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

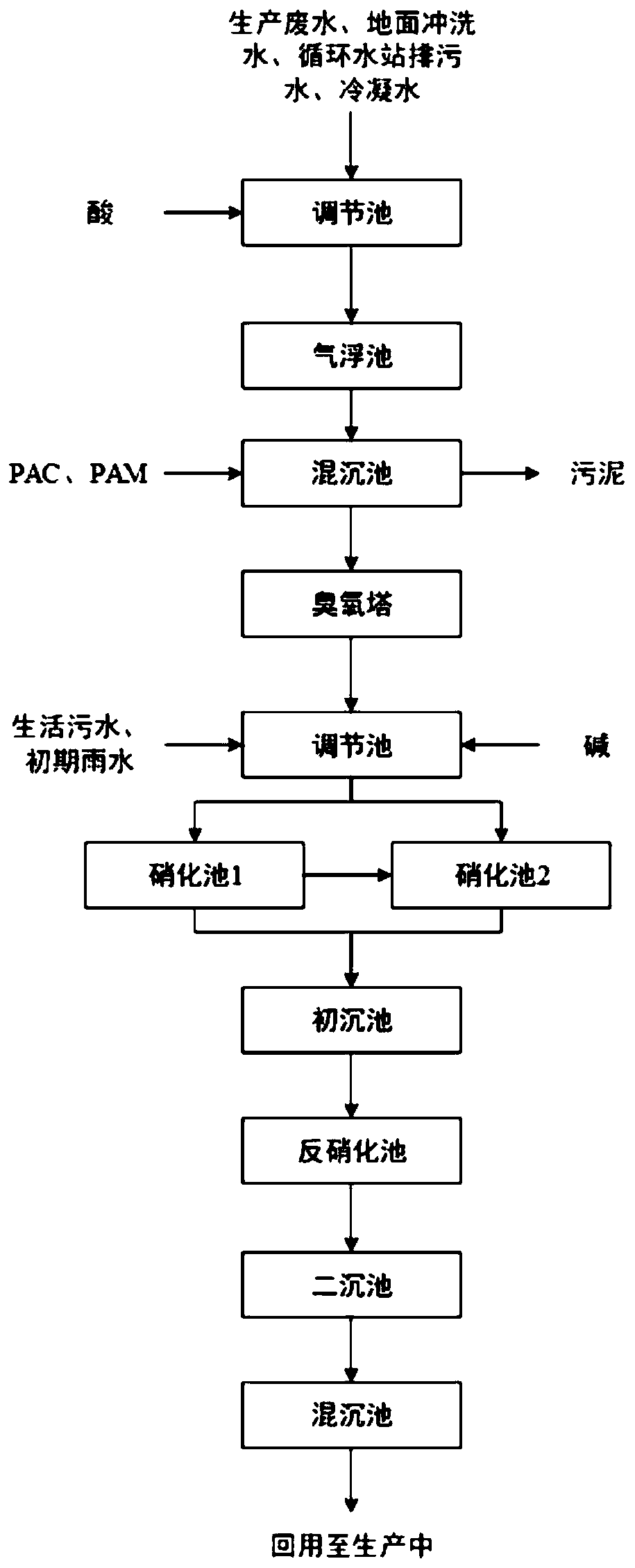

[0034] The present invention provides a method for treating difficult-to-biodegradable rubber processing wastewater. The production wastewater is sequentially subjected to sewage mixing, air flotation treatment, primary coagulation precipitation, ozone catalytic oxidation, secondary mixing, nitrification and denitrification, and secondary coagulation. Treatment of precipitation. The production waste water includes but is not limited to project production waste water, ground flushing water, circulating water station sewage and condensed water, and waste water containing non-biodegradable pollutants produced during the production process can be treated by the present invention.

[0035] The specific processing steps are as follows,

[0036] S100. Mix production wastewater containing non-biodegradable pollutants. The COD concentration in the wastewater is 1000-3000mg / L, and the ammonia nitrogen concentration is 100-400mg / L; the mixed wastewater is discharged into the regulating tank; ...

Embodiment 2

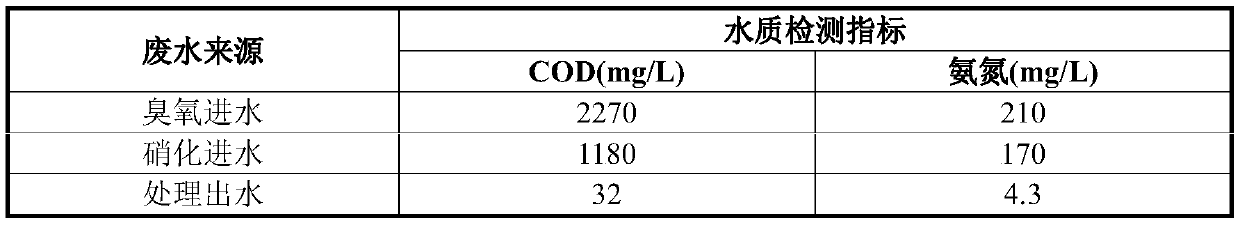

[0053] The basic implementation mode of this embodiment is the same as that of Embodiment 1. The difference is that this embodiment provides a treatment method of production wastewater from a rubber processing wastewater project in Jiangsu. The specific steps are as follows:

[0054] S100. Mix production wastewater, ground flushing water, circulating water station sewage, and condensate, and send it to the regulating tank to adjust the pH to 8 with sulfuric acid;

[0055] S200. After the effluent enters the air flotation tank and is treated by the diffuse air flotation device-the diffuse air flotation method, PAC and PAM are added for flocculation and sedimentation;

[0056] S300. The effluent in S200 is sent to the ozone tower for catalytic ozone oxidation; the catalyst is titanium dioxide; based on the volume of the influent water, the volume ratio of the catalyst is 30%, and the ozone concentration is 6.0 mg / min, the hydraulic retention time is 20min;

[0057] S400. After mixing t...

Embodiment 3

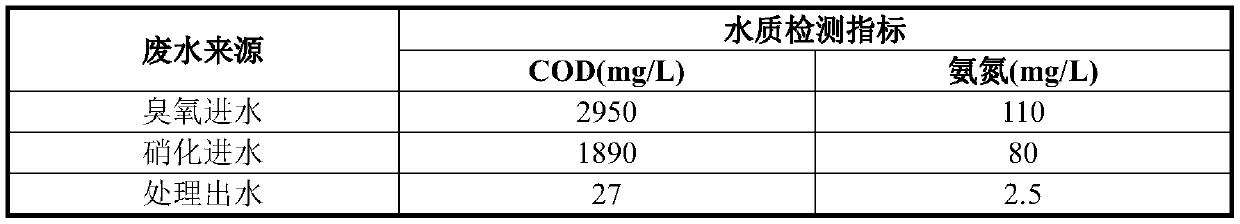

[0063] The basic implementation mode of this embodiment is the same as that of Embodiment 1. The difference is that this embodiment provides a treatment method of production wastewater from a rubber processing wastewater project in Jiangsu. The specific steps are as follows:

[0064] S100. Mix production wastewater, ground washing water, circulating water station sewage, and condensate, and send it to the regulating tank to adjust the pH to 6 with hydrochloric acid;

[0065] S200. After the effluent enters the air flotation tank and is treated by the electrolytic air flotation device-electrolytic air flotation method, PAM is added for flocculation and precipitation;

[0066] S300. The effluent in S200 is sent to the ozone tower for ozone catalytic oxidation; the catalyst is manganese dioxide; based on the volume of the influent water, the volume ratio of the catalyst is 30%, and the ozone concentration is 4.0mg / min, hydraulic retention time is 10min;

[0067] S400. After mixing the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com