Method for treating wastewater generated in acetone production process

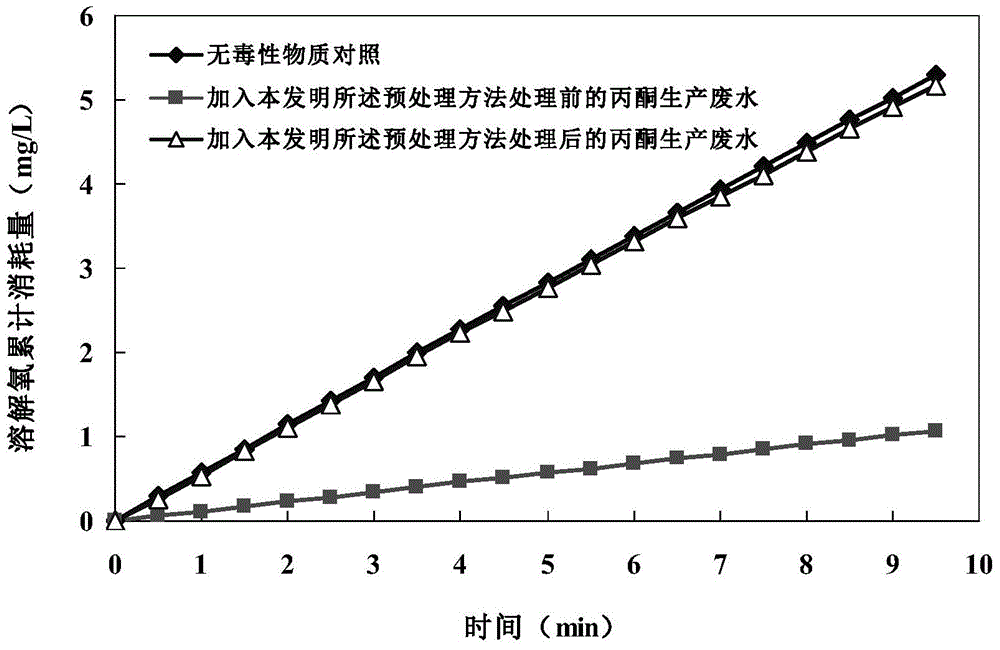

A technology of production process and treatment method, applied in biological water/sewage treatment, multi-stage water treatment, natural water treatment, etc. Difficulty in domestication of sludge, etc., to achieve the effect of high inhibition rate of activated sludge oxygen consumption rate, reduction of toxic effect of wastewater, and improvement of operation stability and treatment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for treating waste water generated in the acetone production process, including the following steps:

[0029] (1) Wastewater pretreatment: adjust the wastewater to a pH value of 2-7, then add a catalyst to it, and react at 20-60°C for 1-10min until the inhibition rate of the activated sludge oxygen consumption rate of the wastewater is reduced by 40%~90% drops below 10%, the concentration of the added catalyst is 5mg / L~100mg / L, the catalyst is ferrous sulfate, ferrous ammonium sulfate or ferrous chloride; adjusting the wastewater after the reaction The pH value is between 6.5 and 7.5.

[0030] (2) Aerobic biological treatment: Add nitrogen source nutrients, phosphorus source nutrients and micronutrients to the pretreated wastewater, and then carry out aerobic biological treatment;

[0031] (3) Removal of suspended organic matter: After aerobic biological treatment, the wastewater enters the sedimentation tank or air flotation tank to separate mud and water after coag...

Embodiment 2

[0045] Adjust the pH value of wastewater from acetone production to 2 with sulfuric acid, add 0.2g / L of ferrous sulfate, and after reacting at 60°C for 10 minutes, adjust the pH value to 7.5 with NaOH, and the inhibition rate of oxygen consumption rate of wastewater activated sludge decreases from 90% to 9 %. After adding ammonium sulfate, potassium hydrogen phosphate, and micronutrients to the wastewater, after aerobic treatment with activated sludge method (HRT=24h), the COD of wastewater decreases from 3500mg / L to 340mg / L, after coagulation and sedimentation treatment , The effluent COD drops below 80mg / L.

Embodiment 3

[0047] The pH value of wastewater from acetone production was adjusted to 7 with hydrochloric acid, and 0.05g / L ferrous ammonium sulfate was added. After reacting at 20°C for 1 min, the inhibition rate of oxygen consumption rate of wastewater activated sludge decreased from 40% to 1%. After adding ammonium phosphate and micronutrients to the wastewater, it is treated by aerobic biological fluidized bed (HRT=18h), the COD of the wastewater is reduced from 2000mg / L to 210mg / L. After coagulation and precipitation treatment, the COD of the effluent drops To below 80mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com