Patents

Literature

32results about How to "Reduce the amount of alkali" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

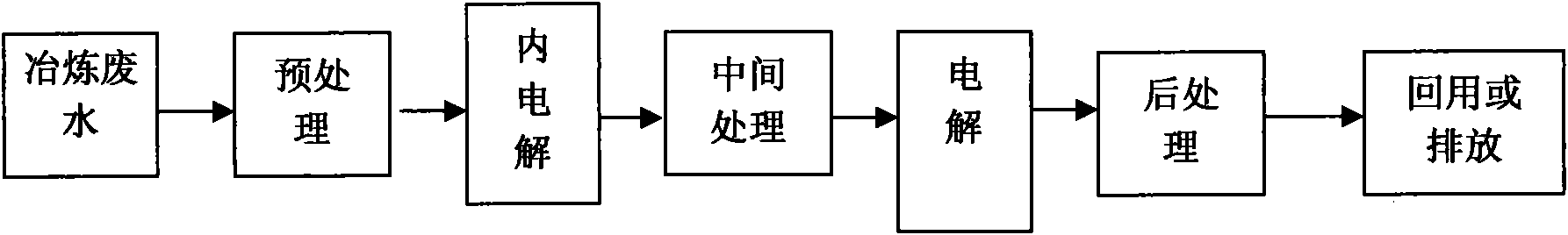

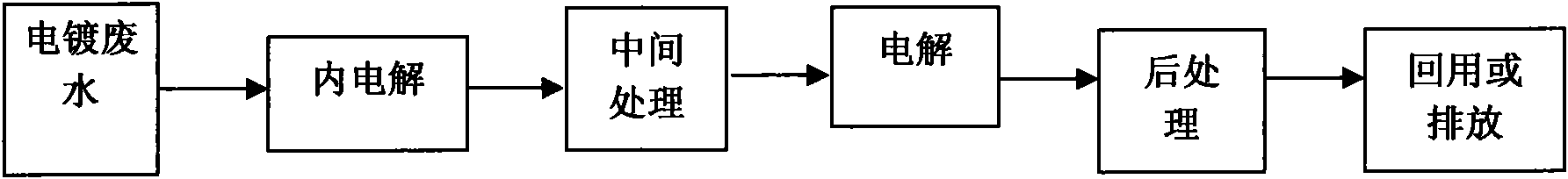

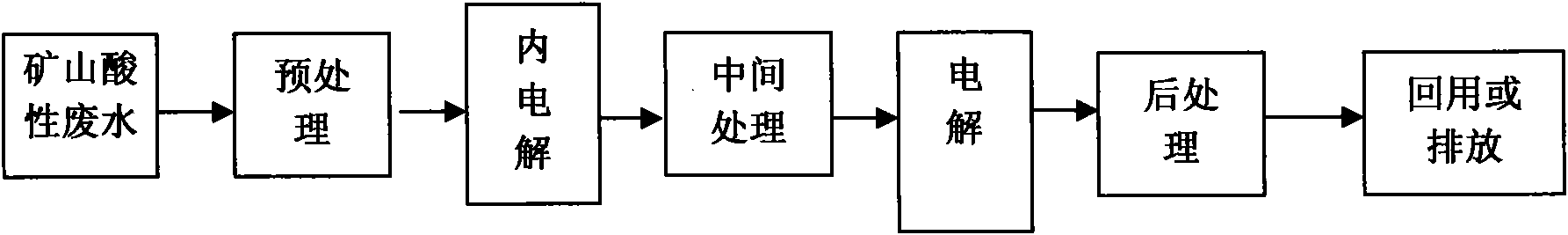

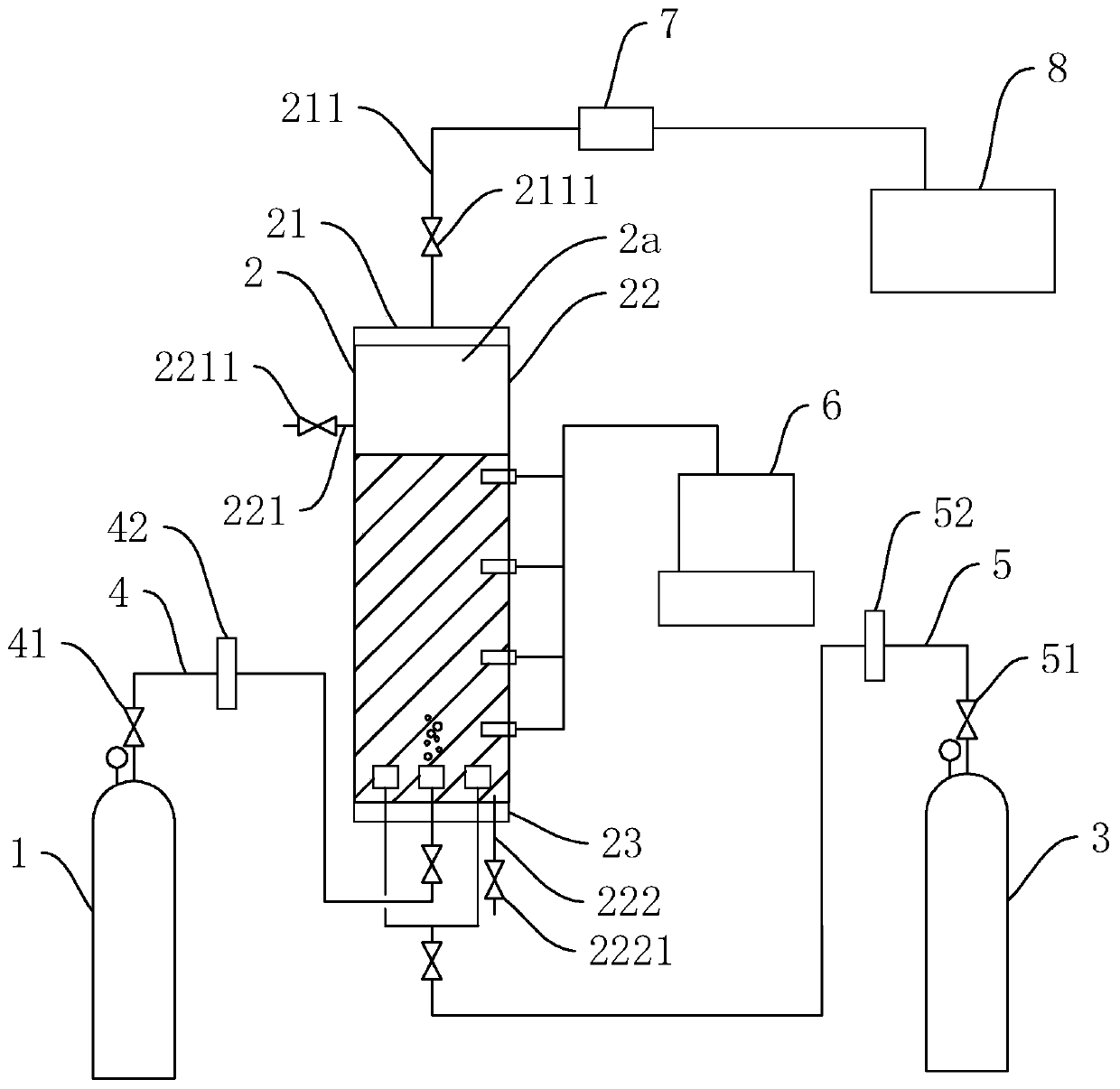

Method for processing waste water containing heavy metals by utilizing internal electrolysis-electrolysis method

InactiveCN101962240AIncrease reaction rateLower pHWater contaminantsWater/sewage treatmentElectrolysisEmission standard

The invention discloses a method for processing waste water containing heavy metals by utilizing an internal electrolysis-electrolysis method, which is characterized in that the waste water meeting the requirements of microelectrolysis processing is microelectrolyzed; the waste water is electrolyzed after the microelectrolysis reaches to the requirements thereof in a certain time so as to reach effluent standards or the requirements of recycle and the subsequent processing; the microelectrolysis bears a part of the task for processing the waste water containing the heavy metals and plays a preprocessing role of the electrolysis method; and the electrolysis method bears the remaining task for processing the rest waste water containing the heavy metals and plays the postprocessing role of the microelectrolysis. The invention organically integrates the microelectrolysis method and the electrolysis method, the two methods cooperate with each other and play roles together, and the processing method has the advantages of simple technique, processing efficiency enhancement of the waste water containing the heavy metals, and processing cost reduction.

Owner:KUNMING UNIV OF SCI & TECH

Stewing method for preparing bamboo wood dissolving pulp

InactiveCN102337689AIncrease productionQuality improvementPretreatment with water/steamPulping with inorganic basesLiquid wasteBlack liquor

The invention belongs to the technical field of dissolving pulp preparation and relates to a stewing method for preparing bamboo wood dissolving pulp, which comprises the following steps of: (a) introducing vapor to a boiler: preparing bamboo wood raw materials into slice materials, conveying the slice materials to a digester, and introducing low pressure vapor to the digester while conveying theslice materials; (b) vapor heating and pre-hydrolyzing: heating through the vapor after introducing the vapor to the boiler to pre-hydrolyze the slice materials; (c) neutralizing through white liquor: neutralizing the slice materials and vapor condensed water in the digester through the white liquor in a hot white liquor tank; (d) replacing through hot black liquor: replacing the neutralization liquid waste in the digester through the hot black liquor in a hot black liquor tank; (e) heating and stewing in a temperature control manner to prepare virgin pulp of the bamboo wood dissolving pulp; (f) replacing the washing black liquor, washing and cooling the virgin pulp; and (g) discharging at a low temperature. The invention has the advantages of reducing the production cost, increasing the production efficiency, effectively utilizing the stewing heat and improving the yield and the quality of the bamboo wood dissolving pulp.

Owner:CHONGQING LEE & MAN PAPER MFG

Method for eliminating interference of original matter in sewage on ammonia nitrogen water quality on-line monitor

InactiveCN102507473AEliminate the effects ofImprove accuracyColor/spectral properties measurementsCitrate sodiumEnvironmental chemistry

A method for eliminating interference of original matter in sewage on an ammonia nitrogen water quality on-line monitor solves the problem of interference of the original matter in the sewage and resulting in changes of absorbance in the determining process during the use of an on-line monitor used for monitoring ammonia nitrogen concentration in water and utilizing a Nessler's reagent method. The technical scheme of the method is that regarding distilled water as a reference sample, adding a screening agent and a Nessler's reagent into the distilled water, and determining the absorbance of the reference sample after color development; fetching a standard water sample as a standard sample, adding the distilled water, the screening agent and the Nessler's reagent into the standard water sample, and determining the absorbance of the standard sample after color development; fetching a water sample to be tested, adding the distilled water, the screening agent and the Nessler's reagent into the water sample to be tested, and determining the absorbance of the water sample to be tested after color development, wherein the screening agent is mixed solution of component A and strong base, the component A is potassium sodium tartrate or sodium citrate or potassium citrate, and the Nessler's reagent is mixed solution of mercuric iodide, potassium iodide and the strong base; and inputting determined data into a computer system to calculate the concentration of the ammonia nitrogen in the water sample to be tested.

Owner:BOHAI UNIV +1

Composite chelated iron desulfurizing agent and preparation method thereof

ActiveCN109758872AImprove stabilityIncrease the pH range of useDispersed particle separationSulfosalicylic acidSodium salt

The invention relates to desulfurizing agents for gaseous phase esulfurization, and discloses a composite chelated iron desulfurizing agent and a preparation method thereof. High valent soluble ferricsalt is added into deionized water to be kept stirred, atype A chelating agent and a type B chelating agent are sequentially added and to be kept stirred, a pH buffer agent is gradually added till the solid matters are completely dissolved, the pH buffer agent is added continuously till the pH value is adjusted to 8.0-13.5, and the mixed matters are continuously stirred and react for 4-8 hours, so that the composite chelated iron desulfurizing agent is obtained; the type A chelating agent is one or more of HEDTA, EGTA, DGA, 2-peracetic acid malonic acid, 2-peracetic acid isobutyric acid and sodium salt and potassium salt thereof, the type B chelating agent is one or more of sodium citrate, sulfosalicylic acid, sodium sulfosalicylate dihydrate, sodium gluconate, mannitol and oligose, the mole ratio of the type A chelating agent to the type B chelating agent is from (1:1)to (1:0.25), the mole ratio of the chelating agents to high valent water-soluble ferric salt is from (1:1)to (3:1), and the mass percentage of Fe in the desulfurizing agent is 1.0-6.0wt%. The composite chelated iron desulfurizing agent is high in saturated sulfur capacity and stability, and wide in pH application range.

Owner:浙江佳运能源技术有限公司

Preparation method of continuous Ni-Co-Al ternary precursor

InactiveCN107910550AUniform sizeImprove performanceCell electrodesSecondary cellsAmmonium hydroxideSodium hydroxide

The invention relates to a preparation method of a continuous Ni-Co-Al ternary precursor. The preparation method comprises the steps of preparing a metal salt solution of a certain concentration, an aluminum alkali, liquid sodium hydroxide and an ammonia solution; adding into a reaction kettle for reaction, wherein the liquid sodium hydroxide is added into the reaction kettle via an upper liquid inlet tube, the aluminum alkali is added into the reaction kettle via a lower liquid inlet tube, and the upper liquid inlet tube and the lower liquid inlet tube are connected in parallel to the reaction kettle; opening an overflowing valve so that a reaction liquid flows into an aging groove for aging until an internal liquid level of the reaction kettle is flush with the overflowing valve when a liquid level in the reaction kettle is raised to be approximate to a reaction kettle cover, and closing the overflowing valve; repeating accordingly; and washing and drying the aged product to obtain the Ni-Co-Al ternary precursor. By a method of the liquid sodium hydroxide injected via the two liquid inlet tubes, a part of liquid sodium hydroxide is guided into the reaction kettle via the upper liquid inlet tube, the pH in an existing technical reaction can be locally reduced, the crystal nucleus can be obviously reduced, the D0 is improved, and the overflowing valve is adjusted to be an intermittent opening state from a normally-open state.

Owner:HUNAN ZOOMWE NEW ENERGY TECH CO LTD

Hydrogenolysis method of cyclohexyl hydroperoxide

InactiveCN104326870AReduce dosageIncrease dosageOrganic compound preparationOxygen compounds preparation by reductionHydrogenHydrogen peroxide

The invention discloses a hydrogenolysis method of cyclohexyl hydroperoxide and belongs to the technical field of organic chemistry. The method comprises the following specific steps: washing a cyclohexane oxidation solution containing cyclohexyl hydroperoxide, isolating an organic phase, adding a Pd / Al catalyst into the organic phase, introducing hydrogen, reacting at the temperature of 50-120 DEG C and at the pressure of 0.1-1.5 MPa for 0.1-3h, filtering the catalyst, carrying out alkali cleaning by adding 5-30 wt% of alkali lye into the reaction liquid with introduced hydrogen, washing with water after alkali cleaning, carrying out liquid separation after water washing, and collecting the organic phase, wherein mass ratio of the catalyst to the organic phase is 1:10-10000 and diameter of the catalyst is 0.01-10mm. The Pd / Al catalyst is used to catalyze hydrogenolysis of cyclohexyl hydroperoxide; reaction condition is mild; selectivity is high; treatment after the reaction is convenient; dosage of the catalyst is low and the catalyst can be recycled; and conversion rate and selectivity are high.

Owner:SHANGHAI HONGLU CHEM TECH

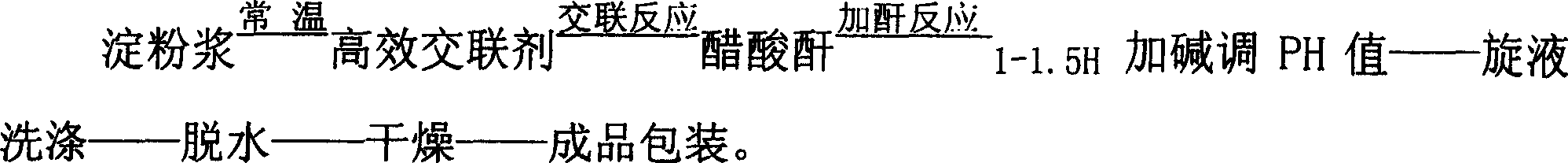

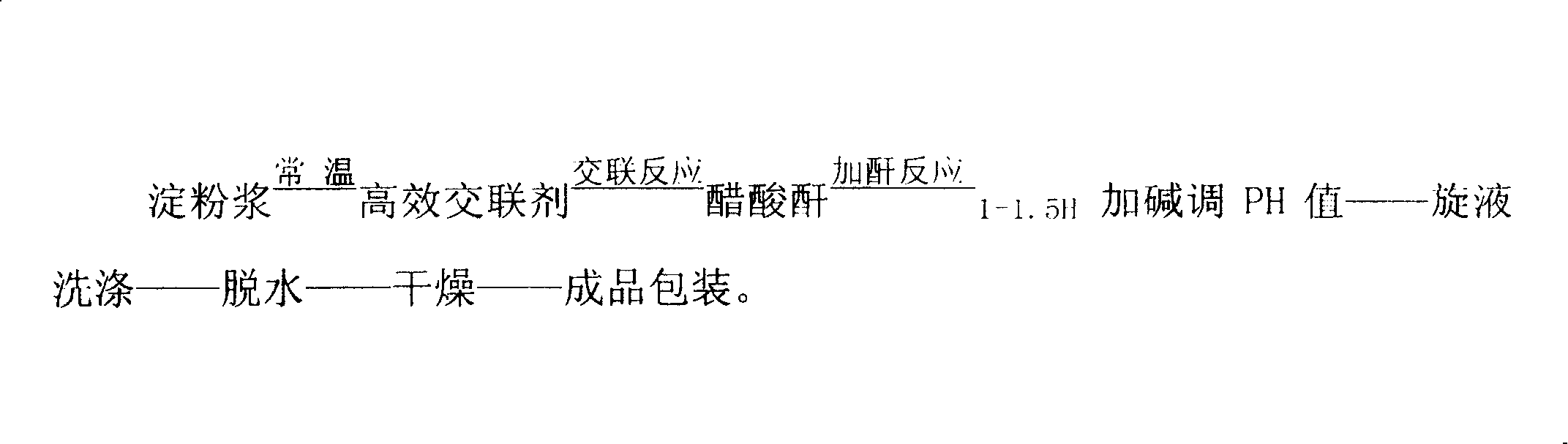

Method for manufacturing organic esterified starch

This invention is about production method of organic esterified starch, characterized with esterization after pre-cross bonding of starch slurry, then washing and desiccation drying.the cross linker consists of chloroacetic acid and gluconolactone in the weight proportion of 3:7. compared with the previous denaturized starch method, the invention we reported here is simple-manipulated, low-priced, lower temperature in starch esterization by 10deg C (in the range of 48deg C-52deg C now), Brinell viscosity is up to 5000-7000BU from2400-3300BU. We are leading in both of the two main index, gelatinization temperature and viscosity domesticly and in the world. This invention also has a large application scale and prominent economic profit.

Owner:李国桐 +2

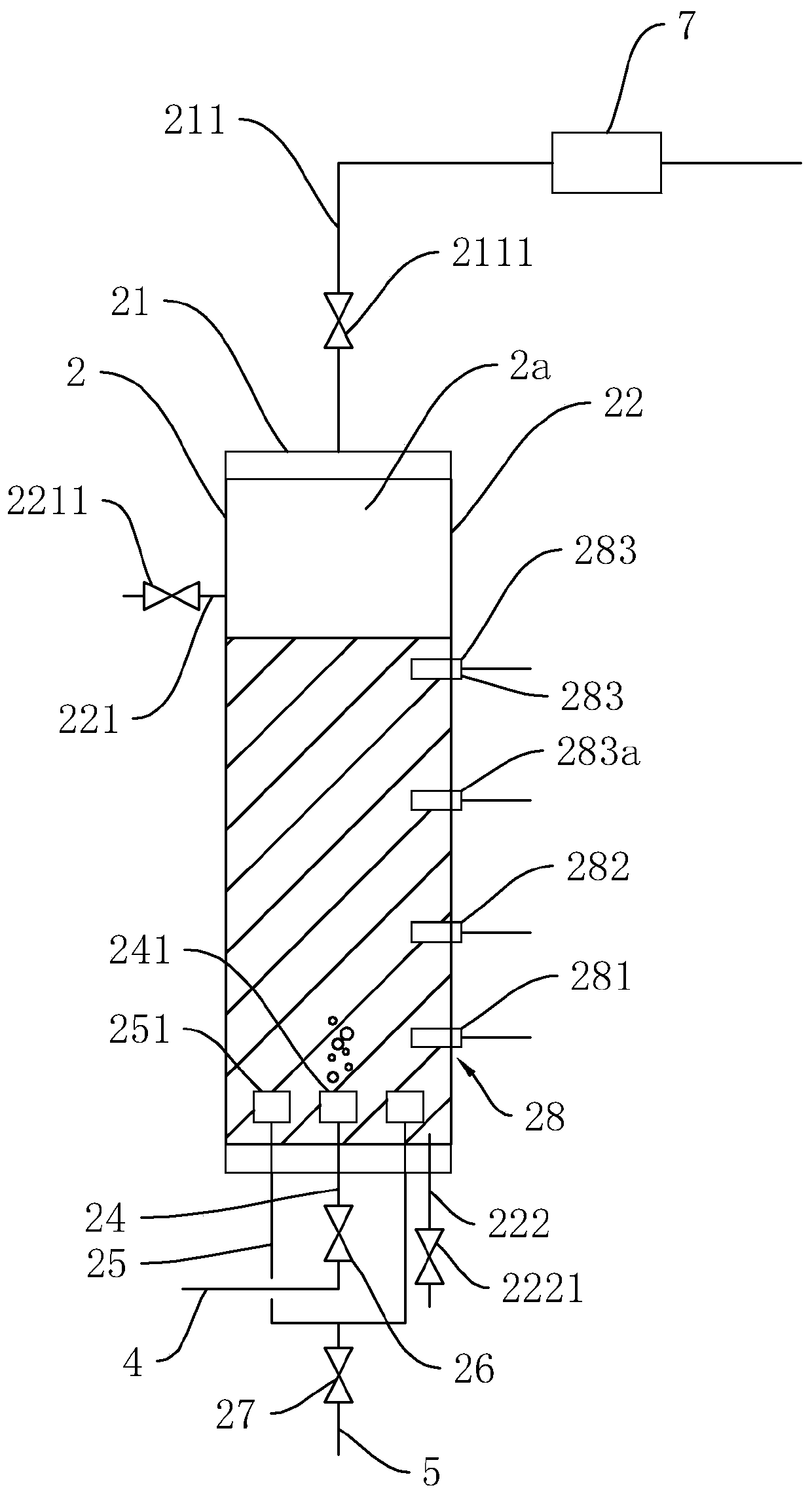

Wastewater phosphorus recovery pretreatment process

ActiveCN104030488AReduce the amount of alkaliReduce contentWater contaminantsWaste water treatment from animal husbandryCalcium biphosphateMagnesium ammonium phosphate

The invention discloses a wastewater phosphorus recovery pretreatment process, belonging to the field of water pollution control and resource recycling. The wastewater phosphorus recovery pretreatment process comprises the following steps: performing CO2 air stripping of the phosphorus-containing wastewater in an air stripping tank (tower); leading the wastewater after air stripping into a sedimentation tank in an automatic-flow mode; removing the suspension organic matters, colloids and some sediments of the wastewater in the sedimentation tank; performing phosphorus recovery of the effluent of the sedimentation tank through magnesium ammonium phosphate or calcium phosphate crystallization reaction. By adopting the wastewater phosphorus recovery pretreatment process disclosed by the invention, the alkali added for phosphorus recovery can be greatly reduced, the content of impurities in the phosphorus recovery product is reduced, and meanwhile, the problem of scaling of facilities such as water pumps, pipe fittings and the like is effectively solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Papermaking cooking reagent

InactiveCN103774480ASpeed up wettingReduce the use of alkaliCellulose material pulpingSodium carboxymethylcelluloseCarboxymethyl cellulose

The invention discloses a papermaking cooking reagent, which is mainly prepared from the following raw materials by weight: 20-28 parts of methacrylic acid, 5-9 parts of dioctadecyl dimethyl ammonium chloride, 2-5 parts of an emulsifier, 1-3 parts of sodium hexametaphosphate, 1-2 parts of carboxymethyl cellulose, 0.5-3 parts of a defoaming agent, 3-6 parts of citric acid, 5-8 parts of sodium citrate, and 0.1-0.5 part of a light stabilizer. The papermaking cooking reagent provided by the invention can speed up the soaking and permeation of a cooking liquor to raw materials, and can reduce the alkali use dosage, as well as improve and protect the fiber strength. The cooked slurry is soft and loose, and has good elasticity. And the papermaking cooking reagent can prevent wrinkling of the finally prepared paper.

Owner:NANJING XIRUISI CHEM

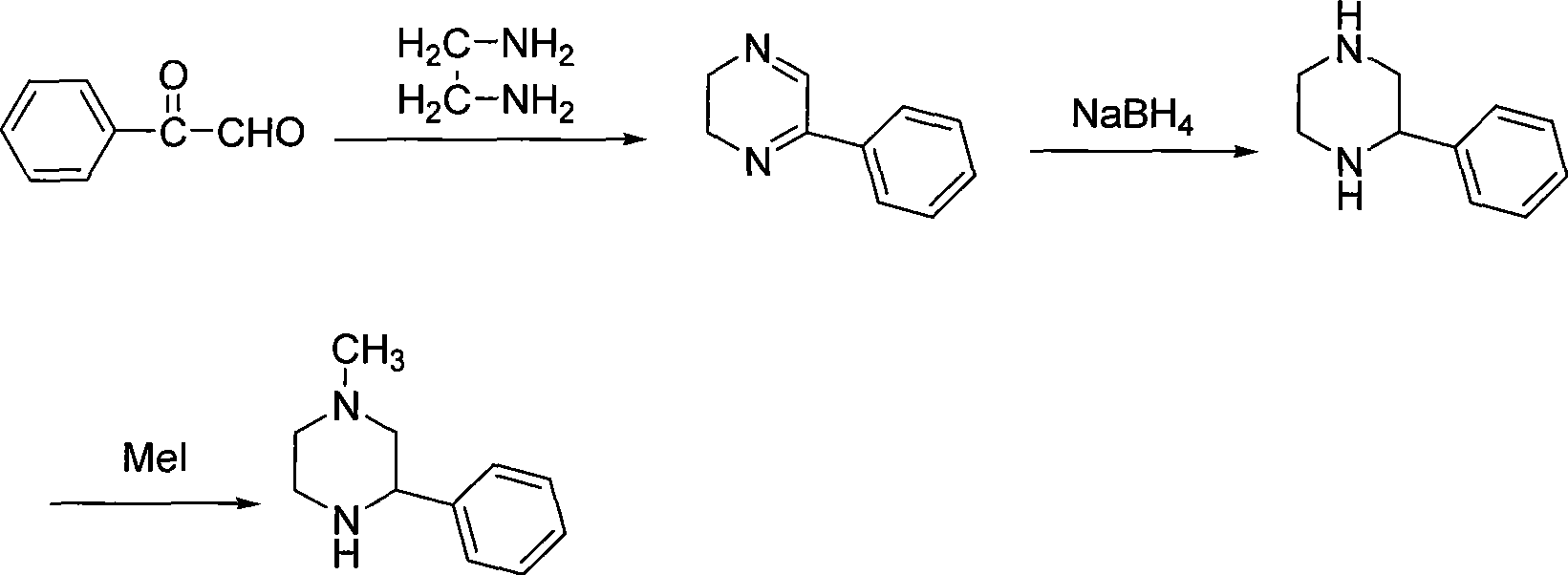

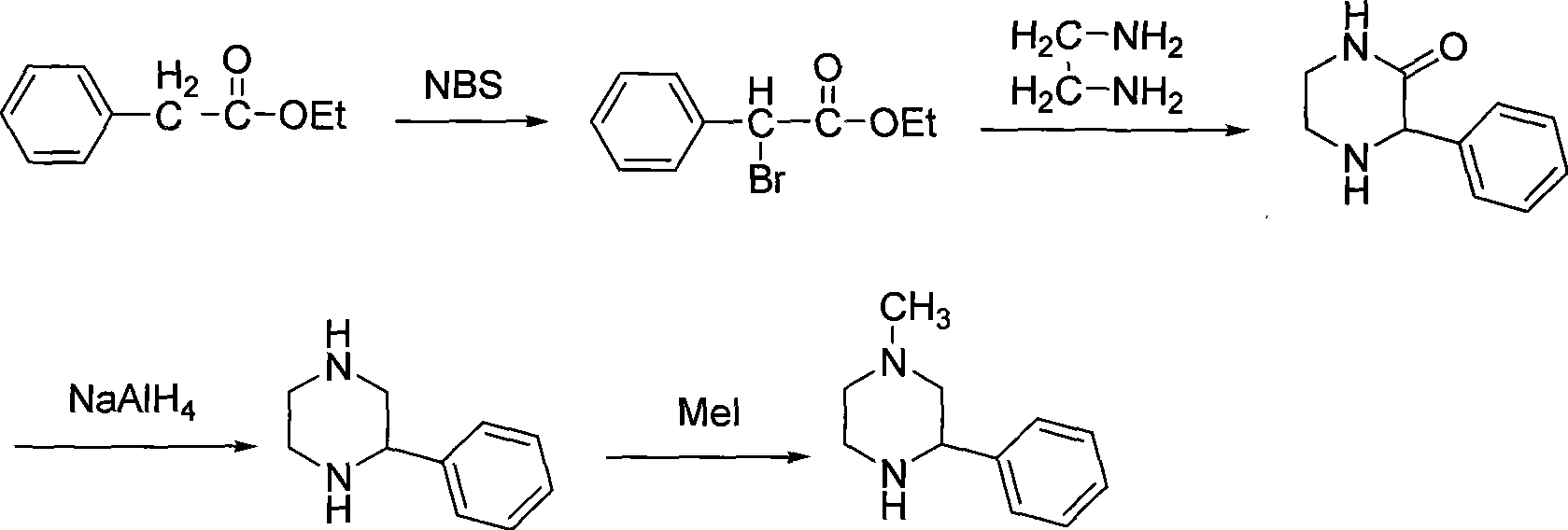

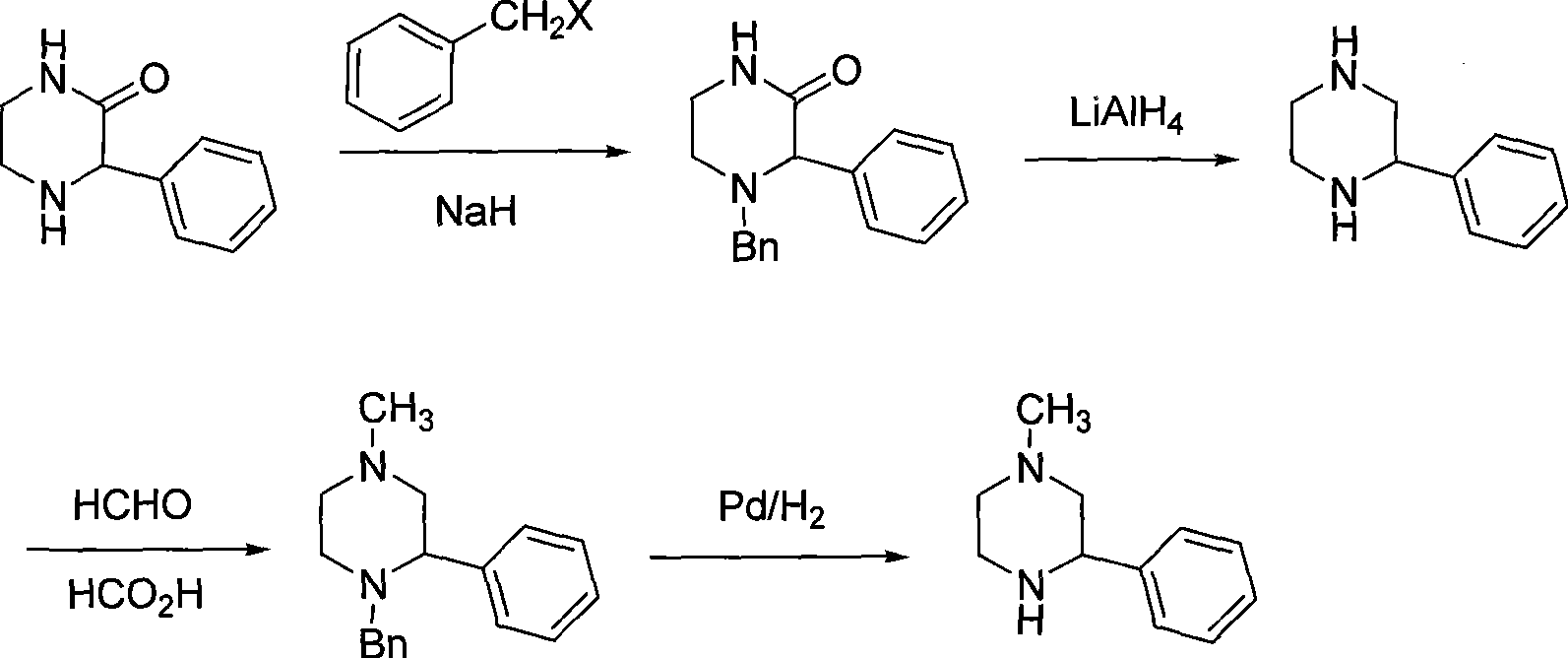

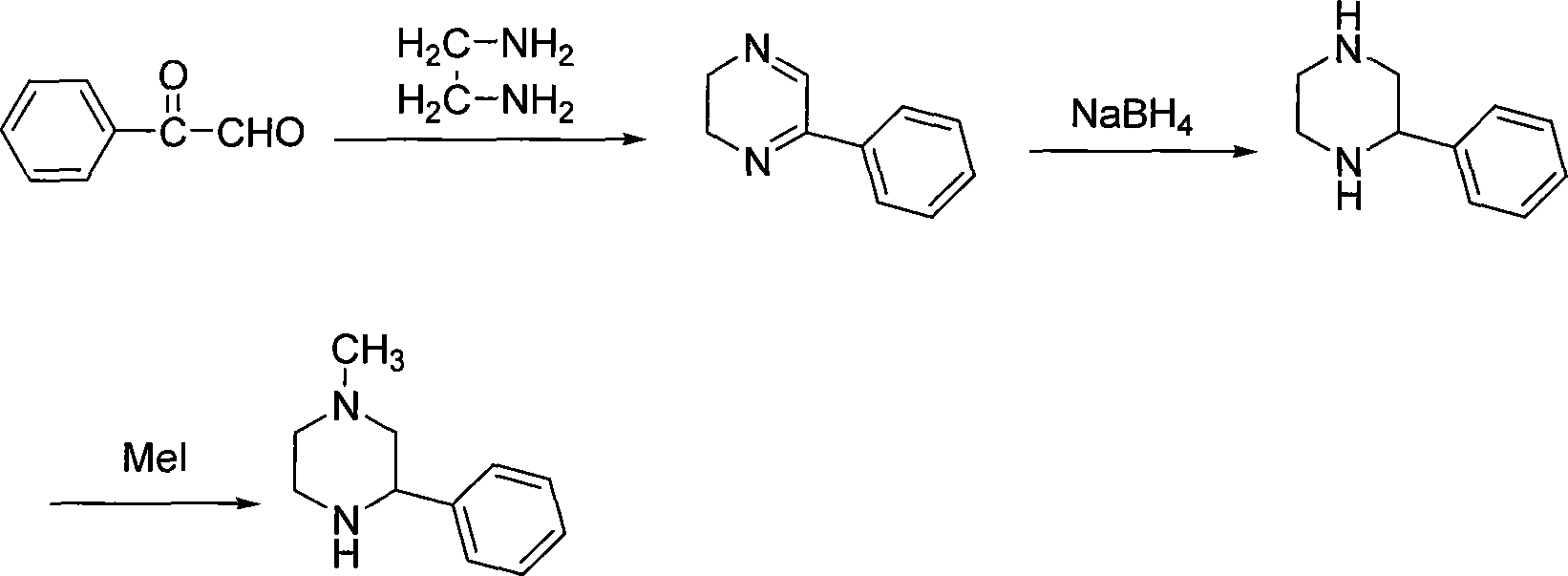

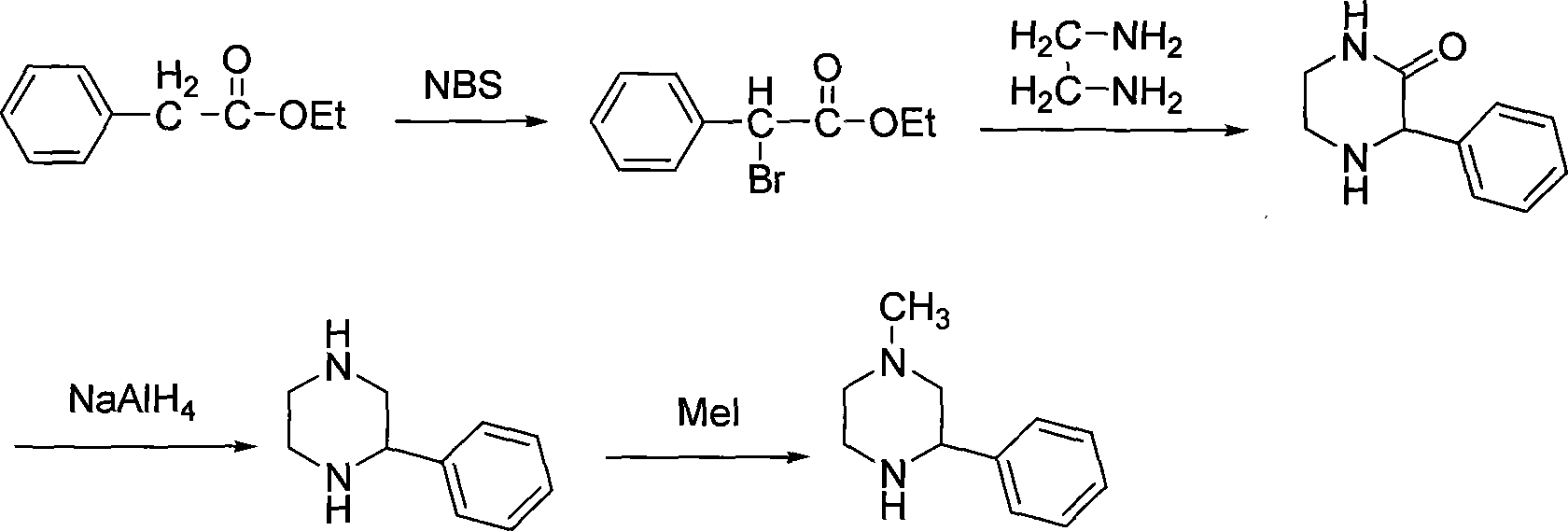

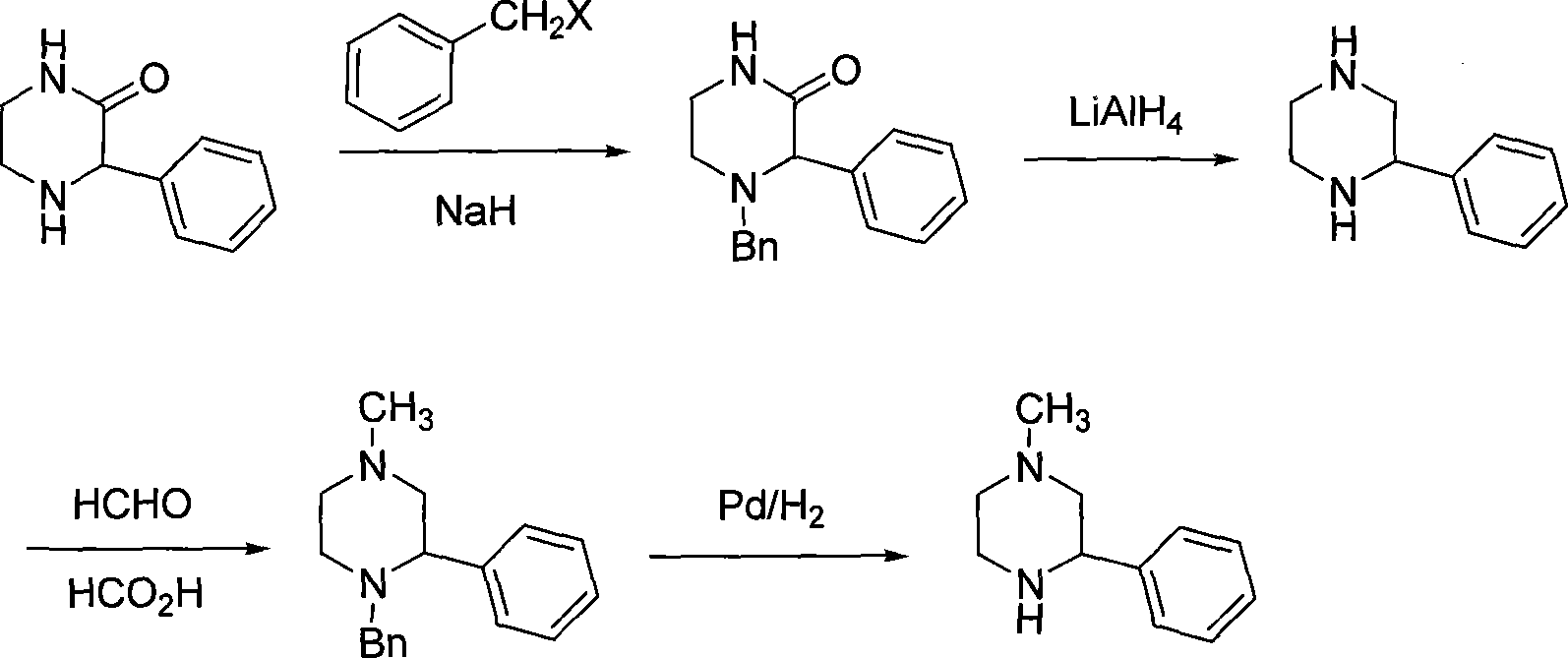

Preparation of medicament intermediate 1-methyl-3-phenyl piperazine

The invention relates to a method for preparing a medicine intermediate, namely 1-methyl-3-phenyl-piperazine. Epoxy phenylethane and N-methyl ethanolamine react for ring opening in a methylbenzene solution and further react with thionyl chloride to obtain N-(2- chloroethyl)-N-methyl-2-chloro-2-phenylethylamine hydrochloride, the hydrochloride reacts with toluene sulfonamide and sodium hydroxide in a DMF solution to obtain 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine, the 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine reacts with concentrated hydrochloric acid to remove sulfonyl, and a product is obtained through neutralization extraction and recrystallization. Compared with the prior art, the method for preparing the 1-methyl-3-phenyl-piperazine has the advantages of low cost of selected raw materials, cost conservation, few synthesis steps, convenient and safe operation, simple post-treatment, high reaction yield, high product purity, good quality, and suitability for industrialized application.

Owner:上海津力药业股份有限公司

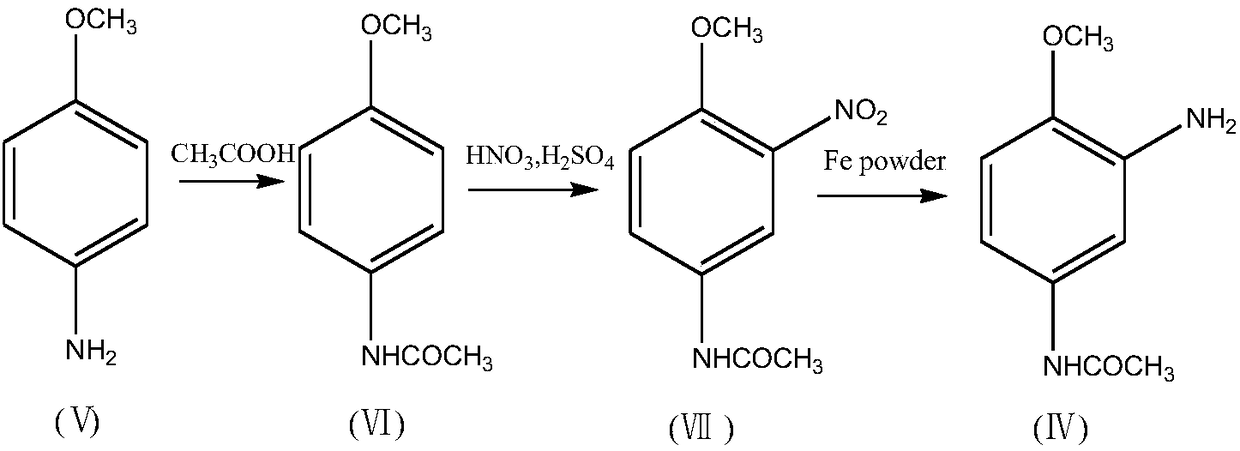

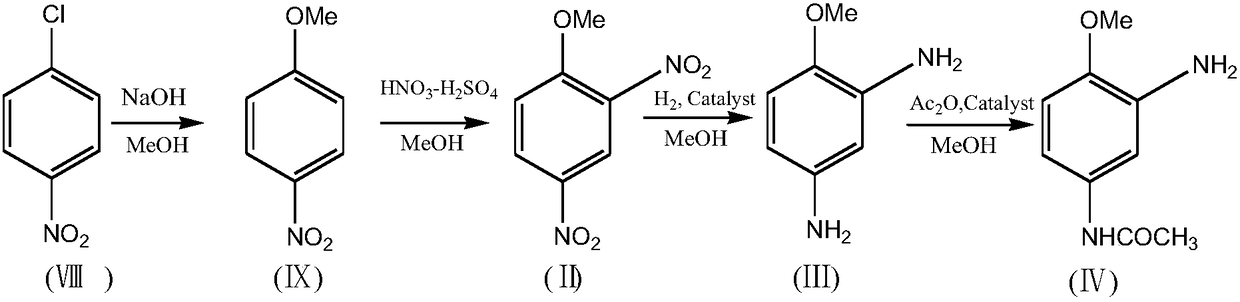

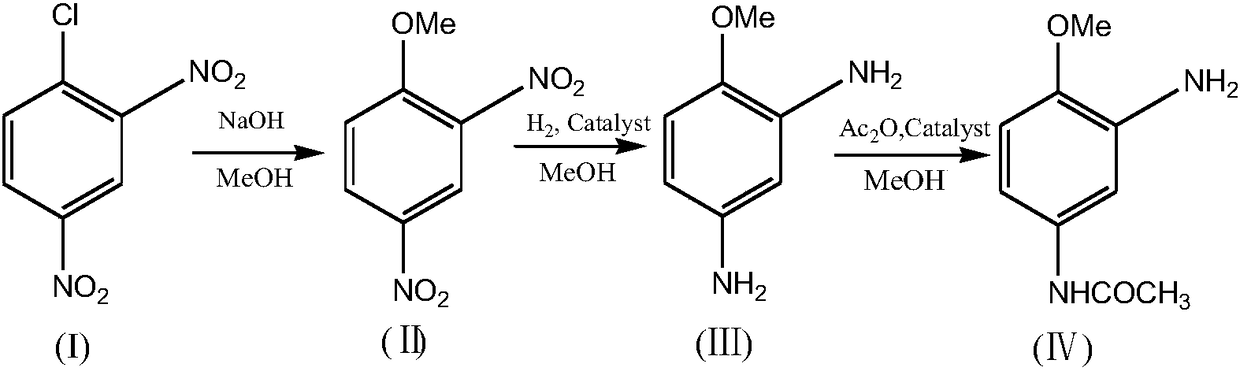

Process for synthesizing 2-amino-4-acetylaminoanisole

InactiveCN108299205AReduce instantaneous moisture contentReduce the amount of alkaliOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideHydrogen

The invention discloses a process for synthesizing 2-amino-4-acetylaminoanisole. The process comprises the steps of preparing 2,4-dinitroanisole from 2,4-dinitrochlorobenzene, which serves as a raw material, in methanol, in the presence of sodium hydroxide or potassium hydroxide, carrying out reduction in the presence of action of Pd / C catalyst by taking hydrazine monoformate as a hydrogen sourceso as to prepare a 2,4-diaminoanisole-methanol solution, and then, subjecting 2,4-diaminoanisole and acetic anhydride to a partial acylation reaction in the presence of an acid binding agent, therebypreparing the 2-amino-4-acetylaminoanisole. According to the process disclosed by the invention, the energy consumption is low, the cost is low, the volume of solid waste and waste liquid is small, the process is environmentally friendly, the operation is simple, the reaction conditions are mild, the industrial safety coefficient is big, the total yield of a target compound is 85% or more (by initial reactants), the HPLC purity is 99.0% or more, and the target compound is high in yield and good in quality, so that the process is more applicable to industrial production.

Owner:张翔

Low-cost waste water phosphorus fertilizer production technology

InactiveCN105084943AReduce the amount of alkaliReduce contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSuspended organic matterMagnesium ammonium phosphate

The invention provides a low-cost waste water phosphorus fertilizer production technology, and belongs to the field of water pollution control and resource regeneration. A low-cost waste water phosphorus fertilizer production device is composed of four treatment units including a first-stage blowing stripping pond, a first-stage settlement pond, a second-stage blowing stripping reaction pond and a second-stage settlement pond. The technology includes the following steps that biogas slurry waste water from an anaerobic pool is firstly subjected to CO2 blowing stripping in the first-stage blowing stripping pond, and the blowing stripping pH value is controlled; then, the waste water enters the first-stage settlement pond in a self-flowing mode, and suspended organic matter, colloid and part of precipitates are separated and removed; outflow water of the first settlement pond enters the second blowing stripping reaction pond for deep aerated blowing stripping and magnesium ammonium phosphate (MgNH4PO4.6H2O) crystallization reaction, and the pH value of the reaction is controlled; the waste water enters the second-stage settlement pond in a self-flowing mode for gravity settling, solid and liquid are separated, and magnesium ammonium phosphate precipitates are recycled. The waste water phosphorus fertilizer production technology can greatly reduce the amount of alkali thrown during waste water magnesium ammonium phosphate production, and the content of impurities in the product is reduced. Meanwhile, the problem that water pumps, pipe accessories and other facilities scale is effectively solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

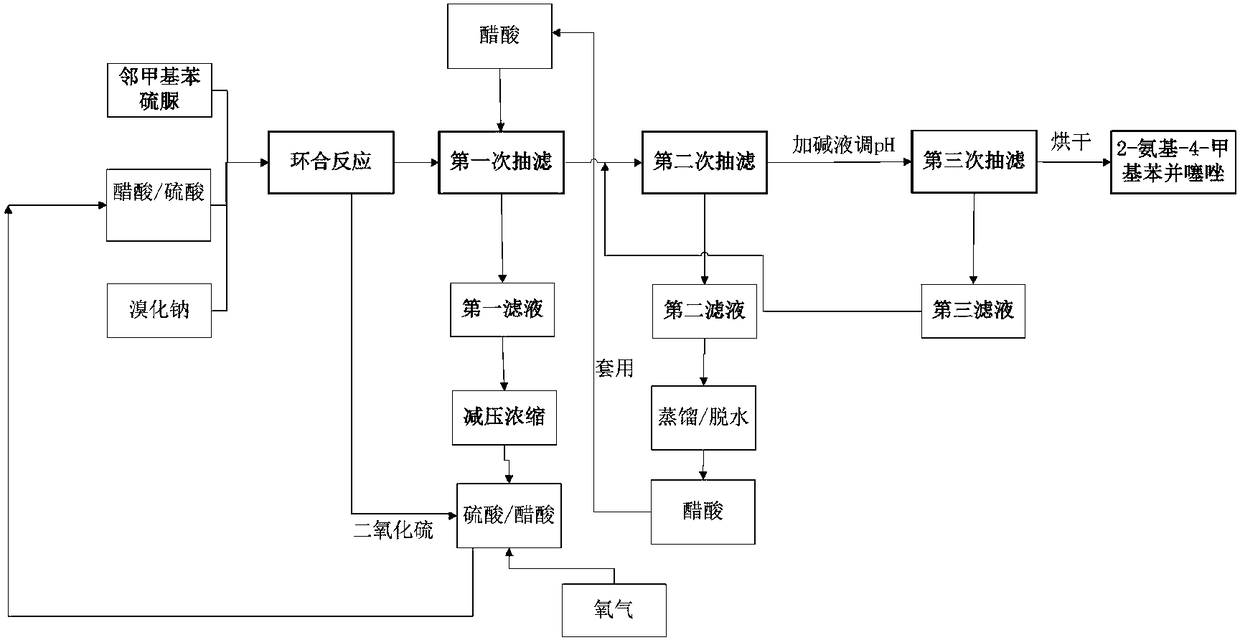

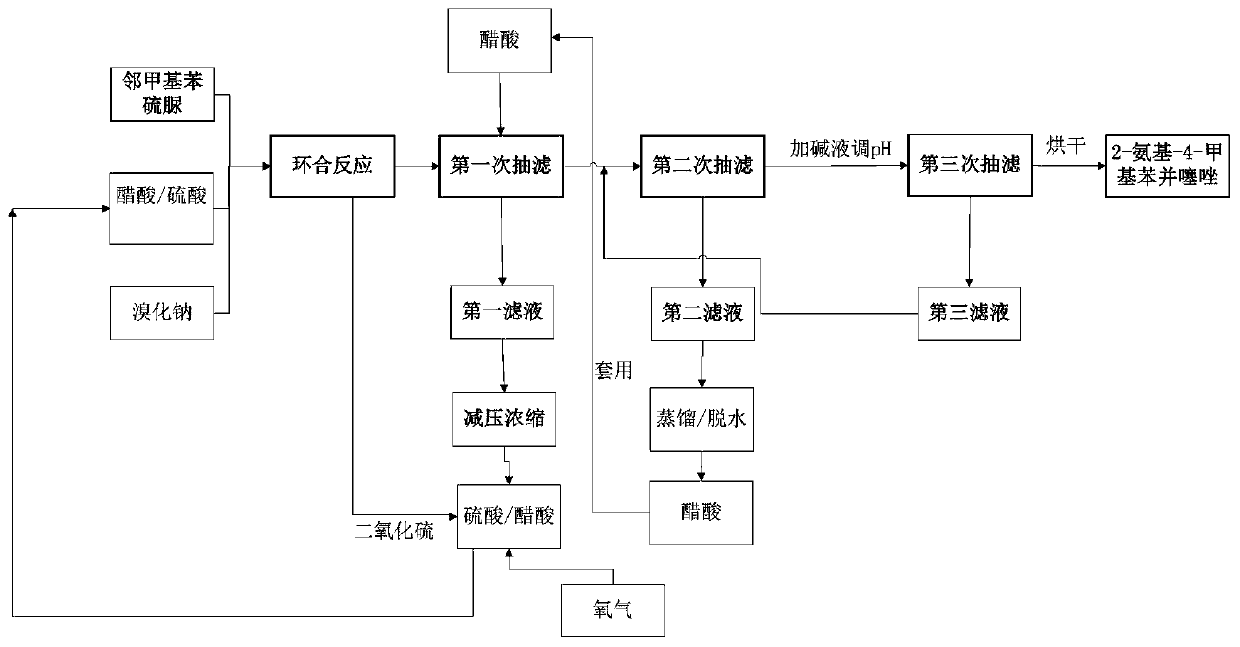

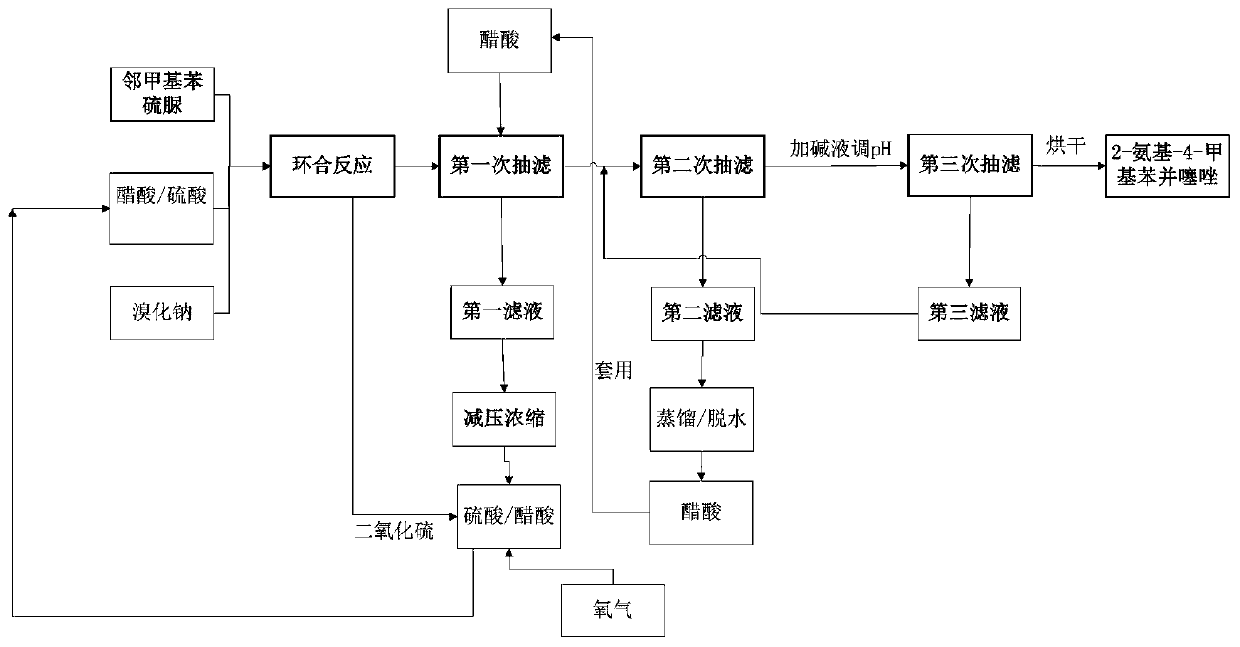

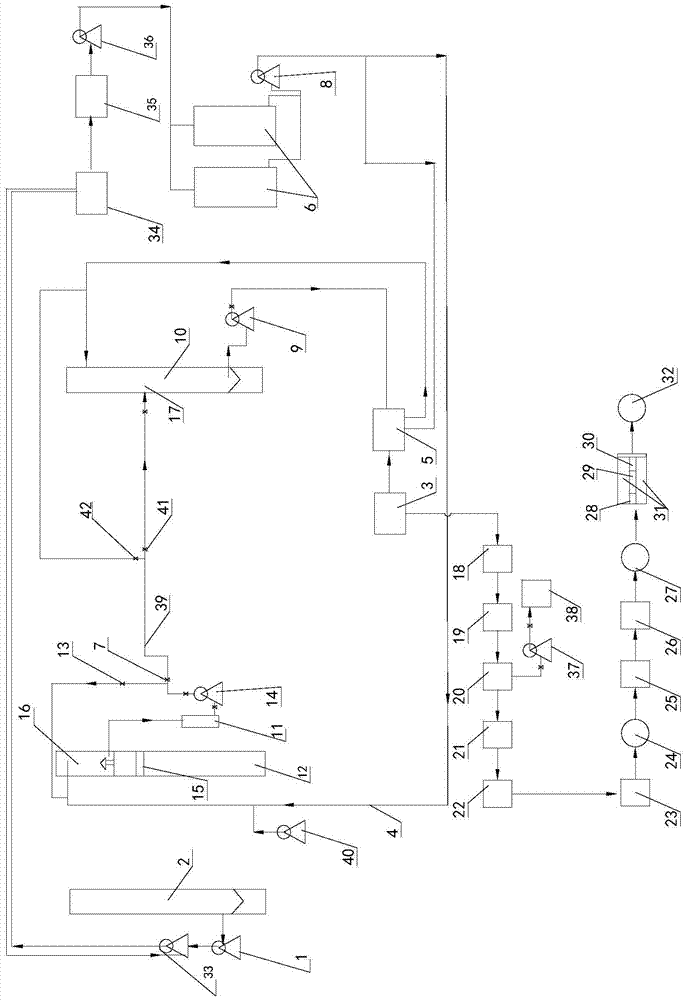

Preparation method of 2-amino-4-methylbenzothiazole

ActiveCN108558790AReduce the amount requiredReduce oxidationOrganic chemistry2-amino-4-methylbenzothiazoleWastewater

The invention relates to a preparation method of 2-amino-4-methylbenzothiazole. The preparation method comprises the steps of cyclization reaction, filtering and washing, recycling and the like. By the method, operation risks are reduced, the utilization rate of sulfuric acid is increased, zero emission of gas is realized basically, the emission amount of waste water is reduced effectively, and thus, the yield of synthesis is stable.

Owner:浙江禾本科技股份有限公司

Production method for papermaking cooking reagent

InactiveCN103774477ASpeed up wettingImprove permeabilityPulping with inorganic basesSlurryPermeation

The invention discloses a production method for a papermaking cooking reagent. The method includes: firstly weighing all raw materials for standby use; heating deionized water to boiling, then adding methacrylic acid, hydroxymethyl cellulose and sodium citrate, stirring the materials uniformly, conducting heat preservation at 65-70DEG C, then adding citric acid to adjust the pH value to 5-7; adding dioctadecyl dimethyl ammonium chloride, an emulsifier and sodium hexametaphosphate, then conducting shearing dispersion, performing cooling, then adding a light stabilizer, a defoaming agent and a penetrating agent, and stirring the materials evenly to obtain the papermaking cooking reagent. The method provided by the invention has the advantages of simple process and convenient manufacturing. The cooking reagent prepared by the method can speed up the soaking and permeation effects of a cooking liquor on raw materials, can reduce the alkali consumption, and improve and protect the fiber strength. The decocted slurry is soft and loose, and has good elasticity. And the finally prepared paper can be prevented from wrinkling.

Owner:NANJING XIRUISI CHEM

Enzymatic straw material pulping process

InactiveCN1190555CGood effectQuality assuranceChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

Method for eliminating interference of original matter in sewage on ammonia nitrogen water quality on-line monitor

InactiveCN102507473BEliminate the effects ofImprove accuracyColor/spectral properties measurementsReference samplePotassium sodium tartrate

A method for eliminating interference of original matter in sewage on an ammonia nitrogen water quality on-line monitor solves the problem of interference of the original matter in the sewage and resulting in changes of absorbance in the determining process during the use of an on-line monitor used for monitoring ammonia nitrogen concentration in water and utilizing a Nessler's reagent method. The technical scheme of the method is that regarding distilled water as a reference sample, adding a screening agent and a Nessler's reagent into the distilled water, and determining the absorbance of the reference sample after color development; fetching a standard water sample as a standard sample, adding the distilled water, the screening agent and the Nessler's reagent into the standard water sample, and determining the absorbance of the standard sample after color development; fetching a water sample to be tested, adding the distilled water, the screening agent and the Nessler's reagent into the water sample to be tested, and determining the absorbance of the water sample to be tested after color development, wherein the screening agent is mixed solution of component A and strong base, the component A is potassium sodium tartrate or sodium citrate or potassium citrate, and the Nessler's reagent is mixed solution of mercuric iodide, potassium iodide and the strong base; and inputting determined data into a computer system to calculate the concentration of the ammonia nitrogen in the water sample to be tested.

Owner:BOHAI UNIV +1

A kind of preparation method of 2-amino-4-methylbenzothiazole

The invention relates to a preparation method of 2-amino-4-methylbenzothiazole. The preparation method comprises the steps of cyclization reaction, filtering and washing, recycling and the like. By the method, operation risks are reduced, the utilization rate of sulfuric acid is increased, zero emission of gas is realized basically, the emission amount of waste water is reduced effectively, and thus, the yield of synthesis is stable.

Owner:浙江禾本科技股份有限公司

Method and apparatus for reducing cyanogen content of coking wastewater

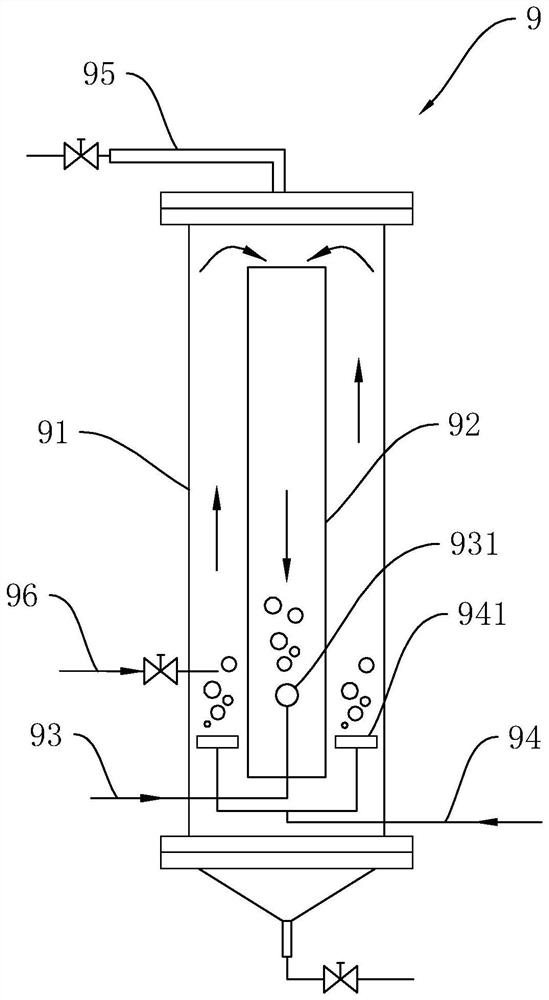

InactiveCN106938873ALow running costLess investmentFatty/oily/floating substances removal devicesWater contaminantsWater volumeCoke oven

The invention relates to a method and an apparatus for reducing the cyanogen content of coking wastewater. The apparatus comprises a regenerating tower, a circulating ammonia pump, a raw material ammonia water pipeline, an alkali tank, a 42% alkali pump and a 2.5-5% alkali pump; the regenerating tower is connected with a desulphurization lean solution pump, the outlet of the desulphurization lean solution pump is connected with the circulating ammonia water pump, and the circulating ammonia water pump is connected with a coke oven; one end of the raw material ammonia water pipeline is connected with the raw material ammonia water pump, the other end of the raw material ammonia water pipeline is connected with the alkali washing section of a desulfurization tower, and the raw material ammonia water pipeline is connected with the 42% alkali pump; and the bottom of the alkali washing section of the desulfurization tower is connected with the alkali tank, and the alkali tank is respectively connected with an ammonia distiller and the alkali washing section of the desulfurization tower through the 2.5-5% alkali pump. Raw material ammonia water substitutes distilled ammonia wastewater and is mixed with a concentrated alkali, and the obtained mixture is sent to the alkali washing section of the desulfurization tower in order to remove hydrogen sulfide and hydrogen cyanide. The stability of the ammonia water volume of the alkali washing section is guaranteed; and the ammonia content of the raw material ammonia water is high, so the raw material ammonia water has a better desulphurization effect than the distilled ammonia wastewater.

Owner:ANGANG STEEL CO LTD

Preparation of medicament intermediate 1-methyl-3-phenyl piperazine

ActiveCN101440067BReduce the amount of alkaliDoes not require high vacuum distillationOrganic chemistryEpoxyPhenylpiperazine

The invention relates to a method for preparing a medicine intermediate, namely 1-methyl-3-phenyl-piperazine. Epoxy phenylethane and N-methyl ethanolamine react for ring opening in a methylbenzene solution and further react with thionyl chloride to obtain N-(2- chloroethyl)-N-methyl-2-chloro-2-phenylethylamine hydrochloride, the hydrochloride reacts with toluene sulfonamide and sodium hydroxide in a DMF solution to obtain 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine, the 1-methyl-4-p-toluenesufonyl-3-phenylpiperazine reacts with concentrated hydrochloric acid to remove sulfonyl, and a product is obtained through neutralization extraction and recrystallization. Compared with the prior art, the method for preparing the 1-methyl-3-phenyl-piperazine has the advantages of low cost of selected raw materials, cost conservation, few synthesis steps, convenient and safe operation, simple post-treatment, high reaction yield, high product purity, good quality, and suitability for industrialized application.

Owner:上海津力药业股份有限公司

An energy-saving and environment-friendly electrochemical corrosion expansion method for electronic aluminum foil

ActiveCN104611760BRealize secondary useProcess energy saving and environmental protectionElectrolytic capacitorsSpecific volumeAluminum foil

The present invention discloses an electronic aluminum foil energy conservation and environmental protection electrochemical corrosion expansion method, the method can not only significantly improve the efficiency of electric erosion, improves electrochemical corrosion expansion surface ratio ( namely specific volume of anode aluminum foil), reduces and combined hole and large hole, but also can save electric energy, reduce chemical consumption, increase the rate of utilization of waste liquid, and reduce waste liquid emissions, and also can further improve the stability and consistency of the products.

Owner:GUANGDONG HUAFENG NEW ENERGY TECH CO LTD +1

A kind of preparation method of coal-based fulvic acid

A preparation method of coal-based fulvic acid relates to the technical field of fine chemical production, in particular to a preparation method of fulvic acid. The purpose is to solve the problems of harsh reaction conditions, serious environmental pollution and low yield in the existing humic acid oxidation degradation production technology. Method: 1. Suspend coal powder in water, add H 2 o 2 、NaNO 3 and solid acid catalyst, stirring and reacting; 2. Add NaOH aqueous solution to the reaction system and continue stirring to obtain a mixed solution; 3. Centrifuge the mixed solution, and the obtained liquid is sodium humate solution; 4. Add sodium humate solution Add strong acid type cation exchange resin for neutralization, and filter to obtain fulvic acid solution; 5. Concentrate the fulvic acid solution under reduced pressure, and spray dry to obtain powdery fulvic acid. The yield of fulvic acid prepared by this method is relatively high, which can reach more than 30%. The purity of fulvic acid is high, which can reach more than 90%. The invention is used for preparing fulvic acid.

Owner:HARBIN UNIV OF SCI & TECH

Wastewater Phosphorus Recovery Pretreatment Process

ActiveCN104030488BReduce the amount of alkaliReduce contentWater contaminantsWaste water treatment from animal husbandryCalcium biphosphateSuspended organic matter

A pretreatment process for wastewater phosphorus recovery, belonging to the field of water pollution control and resource regeneration, which includes the following steps: firstly, phosphorus-containing wastewater is stripped with CO2 in a stripping tank (tower); the stripped wastewater enters the sedimentation in a self-flowing form The wastewater is removed in the sedimentation tank for suspended organic matter, colloids and part of the precipitated products; the effluent of the sedimentation tank is then reclaimed phosphorus through ammonium magnesium phosphate or calcium phosphate crystallization reaction. The pretreatment process for wastewater phosphorus recovery provided by the present invention can greatly reduce the amount of alkali added during phosphorus recovery, reduce the content of impurities in phosphorus recovery products, and effectively solve the problem of fouling of facilities such as water pumps and pipe fittings.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

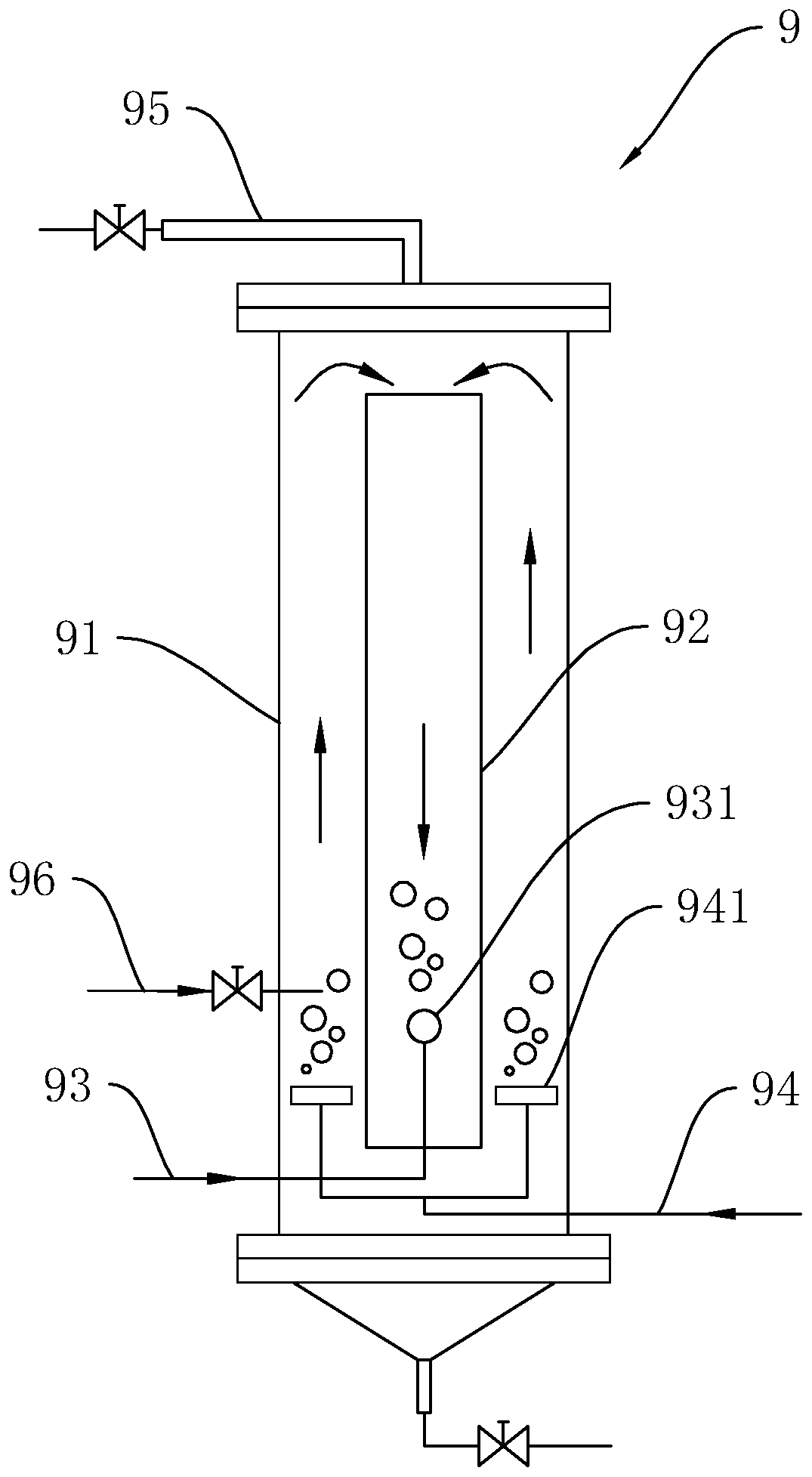

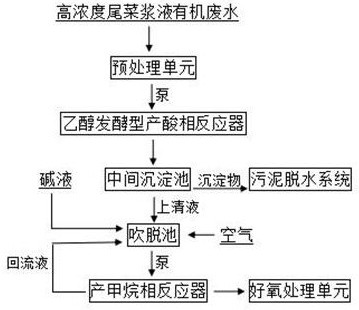

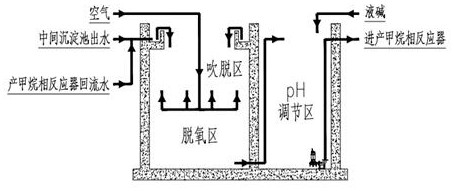

Multistage anaerobic system for treating waste vegetable pulp

PendingCN112723681AGuaranteed uptimeEfficient removalSludge treatmentWater contaminantsProcess engineeringPre treatment

The invention discloses a multistage anaerobic system for treating waste vegetable pulp. The multistage anaerobic system comprises a pretreatment unit, an ethanol fermentation type acid-producing phase reactor, an intermediate sedimentation tank, a sludge dewatering system, an air stripping tank, a methane-producing phase reactor and an aerobic treatment unit, wherein the pretreatment unit is connected with the ethanol fermentation type acid-producing phase reactor through a pipeline, and a pump body is arranged in the pipeline to provide power; the ethanol fermentation type acid-producing phase reactor is communicated with the intermediate sedimentation tank; the bottom of the intermediate sedimentation tank is communicated with a sludge dewatering system, the top of the intermediate sedimentation tank is communicated with an air stripping tank, the air stripping tank is communicated with a methane-producing phase reactor through a pipeline, a pump body is arranged in the pipeline to provide power, and a return pipe is arranged between the air stripping tank and the methane-producing phase reactor; and the methane-producing phase reactor is communicated with an aerobic treatment unit. Under the condition that a metal coagulant is not added, pollutants in the high-concentration organic wastewater can be removed, and the treatment effect is stable and efficient.

Owner:山东问清环境科技有限公司

A kind of preparation method of environment-friendly anti-hard water fulvic acid potassium

ActiveCN109437987BSolve pollutionSolve environmental pollutionOrganic fertilisersFlocculationPtru catalyst

An environment-friendly preparation method of potassium fulvic acid potassium which is resistant to hard water aims to solve the problem that the potassium fulvic acid humate product prepared by the existing method is poor in hard water resistance. Method: 1. Suspend coal powder in water, add H 2 o 2 、NaNO 3 and solid acid catalyst, stirring reaction, 2. Add KOH to the reaction system, then adjust the pH value of the solution to 9.0 with ammonia water, continue to stir, and centrifuge, the obtained liquid is potassium fulvic acid solution; 3. Potassium fulvic acid The solution was concentrated in vacuum, and solid potassium fulvic acid was obtained by spray drying. The potassium fulvic acid prepared by the invention has high anti-hard water activity, and under the condition of no anti-coagulation additive, no flocculation phenomenon occurs when the dilute solution prepared in 30-degree hard water is placed for 120 hours. The invention is used for preparing potassium fulvic acid.

Owner:HARBIN UNIV OF SCI & TECH

Environment-friendly hard water resisting potassium fulvic acid preparation method

The invention discloses an environment-friendly hard water resisting potassium fulvic acid preparation method and aims at solving the problem that a potassium fulvic acid product prepared by an existing method has poor hard water resistance. The method comprises the following steps: 1, suspending pulverized coal in water, adding H2O2, NaNO3 and a solid acid catalyst and performing stirring reaction; 2, adding KOH into a reaction system, then using ammonium hydroxide to adjust the pH value of a solution to 9.0, continuing stirring and centrifugally separating, wherein obtained liquid is a potassium fulvic acid solution; 3, vacuum concentrating the potassium fulvic acid solution and using a spray drying mode to obtain solid potassium fulvic acid. The potassium fulvic acid prepared by the preparation method disclosed by the invention has very high hard water resistance activity; without any anti-coagulation additive, a dilute solution prepared from 30 DEG C hard water has no coagulation phenomenon after being placed for 120 hours. The preparation method disclosed by the invention can be applied to preparing potassium fulvic acid.

Owner:HARBIN UNIV OF SCI & TECH

A kind of compound chelated iron desulfurizer and preparation method thereof

ActiveCN109758872BImprove stabilityIncrease the pH range of useDispersed particle separationEGTASalicylic acid

The invention relates to a desulfurizer for gas-phase desulfurization, and discloses a composite chelated iron desulfurizer and a preparation method thereof. The high-valent soluble iron salt is added into deionized water to keep stirring, and the A-type chelating agent and the B-type chelating agent are added in sequence, and the stirring is maintained. Gradually add a pH buffer until the solid matter is completely dissolved, continue to add a pH buffer to adjust the pH to 8.0-13.5, and continue to stir the reaction for 4-8h to obtain a composite chelated iron desulfurizer. The A-type chelating agent is HEDTA, EGTA, DGA, 2 One or more of oxyacetoxymalonic acid, 2-oxyacetoxybutyric acid and its sodium salt, potassium salt, the B-type chelating agent is sodium citrate, sulfosalicylic acid, sulfosalicylic acid One or more of sodium, sodium gluconate, mannitol, and oligosaccharides, the molar ratio of the A-type chelating agent and the B-type chelating agent is 1:1-1:0.25; the chelating agent and the high-valent water-soluble iron salt The molar ratio of Fe is 1:1-3:1; the mass fraction of Fe in the desulfurizer is 1.0-6.0wt%, and the composite chelated iron desulfurizer of the present application has a high saturated sulfur capacity, good stability and a wide range of pH use.

Owner:浙江佳运能源技术有限公司

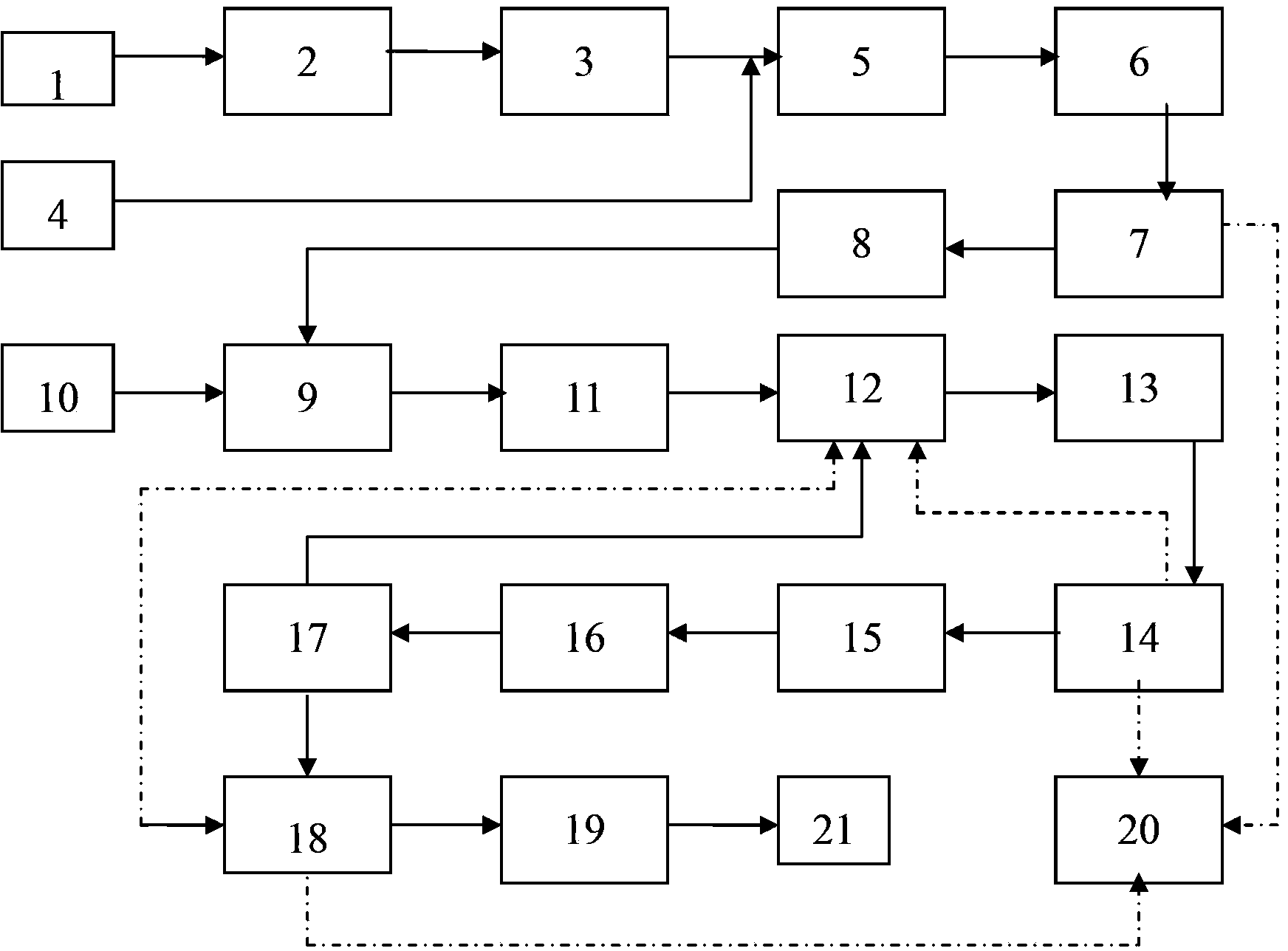

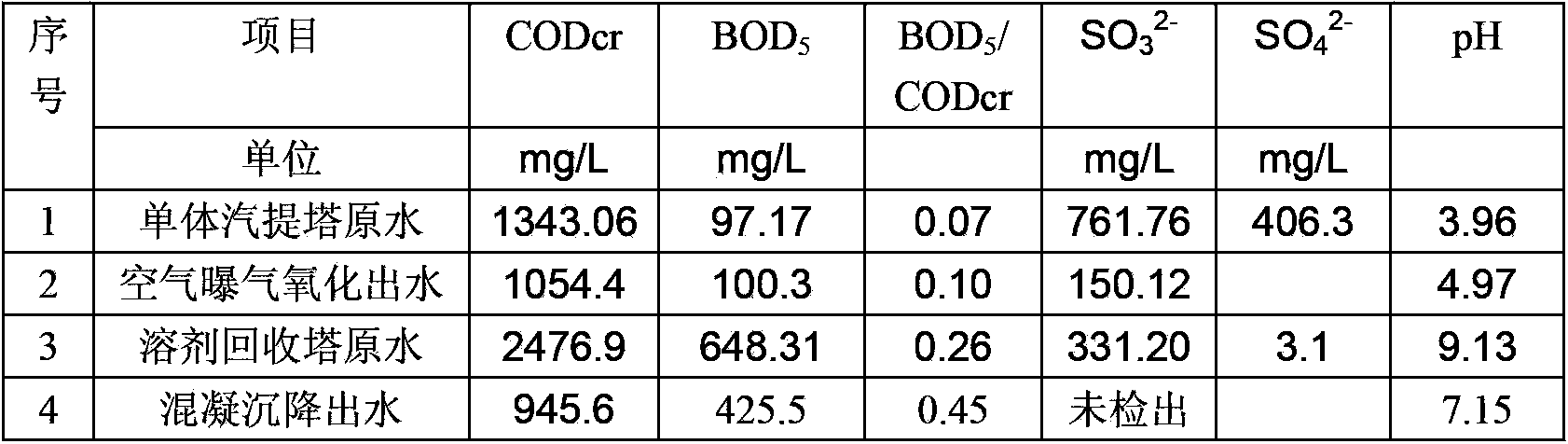

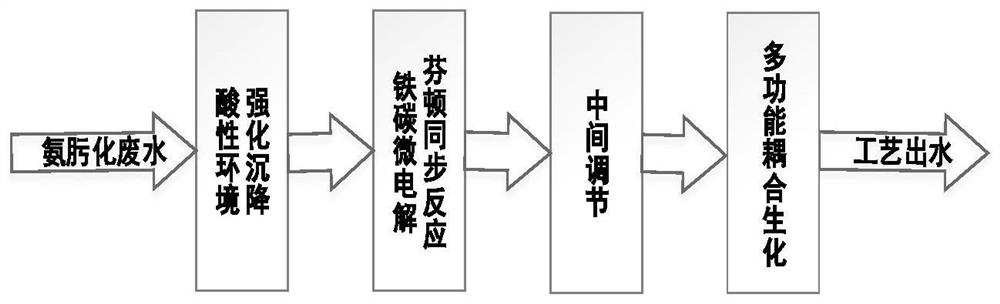

Acrylonitrile/acrylon production comprehensive wastewater treatment technique

ActiveCN103086576BImprove biodegradabilityReduce the amount of alkaliMultistage water/sewage treatmentNature of treatment waterWater qualityAcrylonitrile

Owner:BEIJING CCESS ENVIRONMENT TECH CO LTD

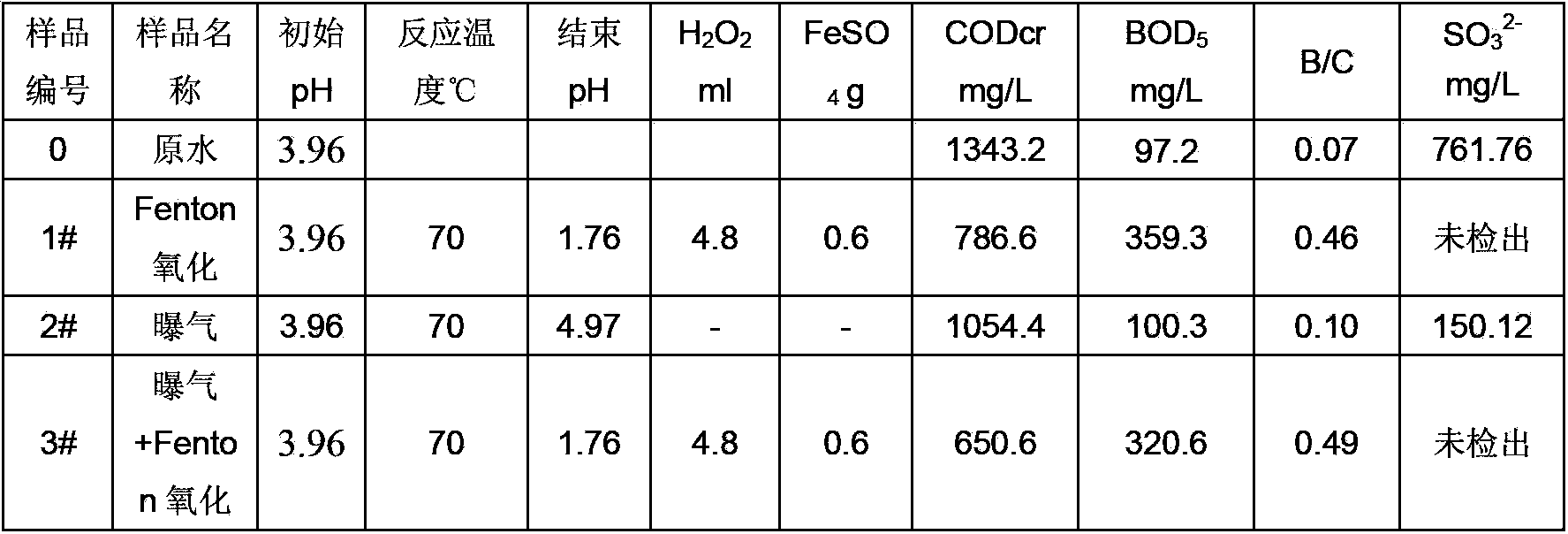

Ammoximation wastewater treatment method and application thereof

PendingCN114426368AReduce dosageEnhanced coagulation and settlement effectWater treatment parameter controlWater treatment compoundsAmmoniaFenton oxidation

The invention provides an ammoximation wastewater treatment method and application thereof. The treatment method of the ammoximation wastewater provided by the invention comprises the following steps: S1, carrying out coagulating sedimentation on the ammoximation wastewater to obtain wastewater subjected to coagulating sedimentation; s2, carrying out iron-carbon micro-electrolysis-Fenton oxidation synchronous treatment on the wastewater subjected to coagulating sedimentation to obtain wastewater subjected to synchronous treatment; and S3, carrying out biochemical treatment on the synchronously treated wastewater. The processes are combined and synergistic, so that the influence of organic nitrogen on wastewater treatment is basically eliminated, and up-to-standard discharge of ammoximation wastewater can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

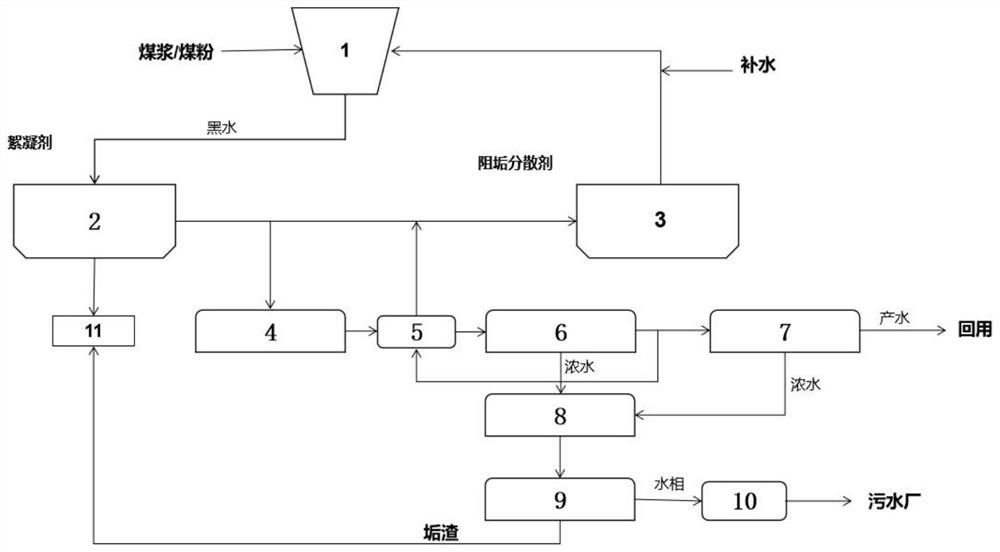

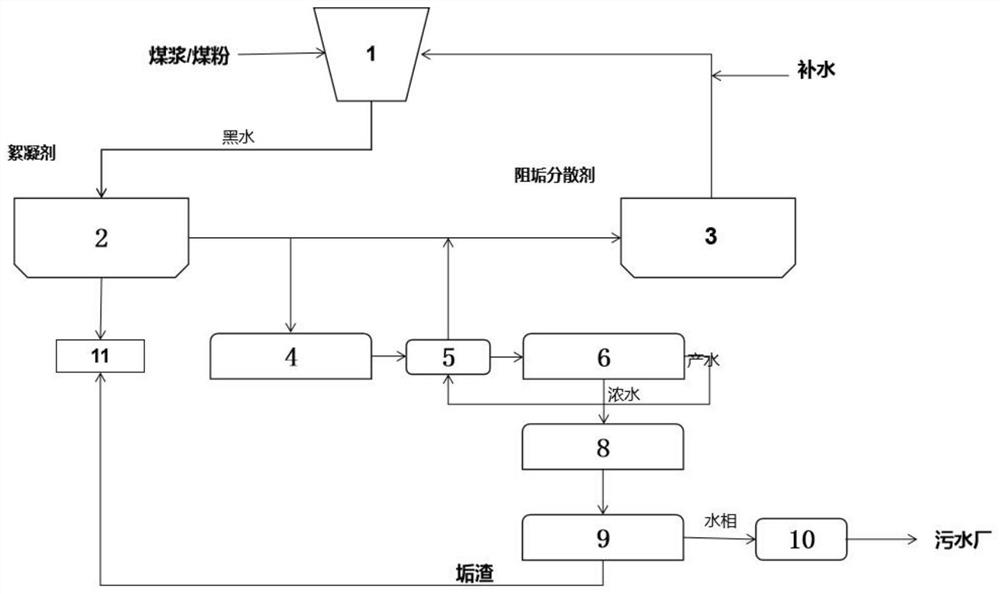

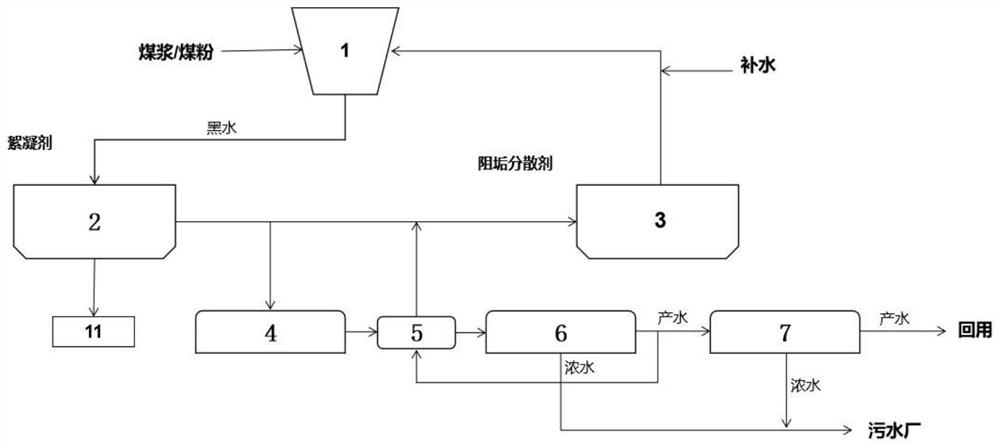

Softening method of high-hardness water

PendingCN114835313AAvoid badReduce removalGeneral water supply conservationWater/sewage treatment by electrochemical methodsProduced waterGreywater

The invention discloses a softening treatment method for high-hardness water, which comprises a pretreatment unit and a salt separation unit, and comprises the following steps: 1) introducing the high-hardness water into the pretreatment unit, and removing turbidity and silicon in the high-hardness water in the pretreatment unit to ensure that the turbidity of the effluent is less than or equal to 20NTU and the silicon (based on SiO2) is less than or equal to 20mg / L; (2) cooling the pretreated effluent, feeding the cooled effluent into a salt separation unit for salt separation, mainly retaining calcium and magnesium ions on a concentrated water side, and mainly feeding ammonia nitrogen into a produced water side; concentrated water enters a sewage treatment plant or is further softened, and produced water is conveyed to a backwater system. The method preferably comprises a recycling unit, so that resource utilization is realized. According to the method, the removal effect that the total hardness of high-hardness water with the hardness larger than 500 mg / L is reduced by 50-98% can be achieved; and especially when being used for coal gasification ash water softening treatment, the softening agent has beneficial hardness removal effect, simultaneously removes silicate scales, effectively solves the problem of scaling of a gasification furnace system, and prolongs the stable operation period.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Method for manufacturing organic esterified starch

This invention is about production method of organic esterified starch, characterized with esterization after pre-cross bonding of starch slurry, then washing and desiccation drying.the cross linker consists of chloroacetic acid and gluconolactone in the weight proportion of 3:7. compared with the previous denaturized starch method, the invention we reported here is simple-manipulated, low-priced, lower temperature in starch esterization by 10deg C (in the range of 48deg C-52deg C now), Brinell viscosity is up to 5000-7000BU from2400-3300BU. We are leading in both of the two main index, gelatinization temperature and viscosity domesticly and in the world. This invention also has a large application scale and prominent economic profit.

Owner:李国桐 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com