Softening method of high-hardness water

A high hardness and softening treatment technology, applied in the direction of scale removal and water softening, chemical instruments and methods, separation methods, etc., can solve problems such as gray water system jamming, reduce wastewater discharge, solve scaling problems, and reduce chemicals The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment is a method for fully softening coal gasification gray water that can realize resource utilization, and is aimed at the following types of users: not only the hardness of the gray water system needs to be removed, but also the recycling of gray water sewage wastewater. The grey water sewage wastewater cannot be directly received, and it is necessary to use an ammonia distillation tower to remove most of the ammonia nitrogen before entering the sewage treatment plant. The ammonia distillation tower generally requires that the hardness of the incoming water is not higher than 100mg / L, so it is necessary to soften the incoming tower wastewater.

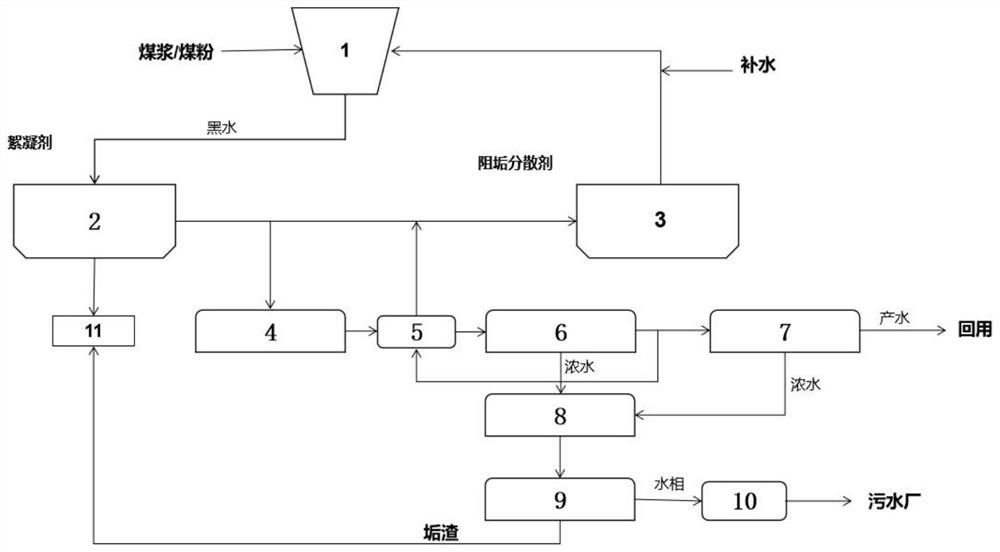

[0085] The process flow of this embodiment is as follows figure 1 Shown: water is diverted from the outlet of the settling tank 2 to the pretreatment unit 4, cooled by the heat exchanger 5 and then enters the salt separation unit 6, and a part of the produced water of the salt separation unit 6 returns to the grey ...

Embodiment 2

[0107] The technical process of this embodiment is basically the same as that of embodiment 1, except that the salt separation unit is changed from nanofiltration to frequent reverse electrodialysis (EDR), the hard removal unit is pure chemical method, and the separation unit is changed to flat ultrafiltration membrane. The concrete test operation of this embodiment is as follows:

[0108] 1) Preprocessing unit:

[0109] In the mixing tank with stirring, liquid alkali was used to adjust the pH to about 8.0, and 500 ppm of sodium metaaluminate was added at the same time. After 30 minutes of sedimentation in the sedimentation zone, the clear liquid was directly overflowed to the clear liquid storage tank, and then pumped to the exchange The heat exchanger is sent to the salt separation unit after heat exchange. Periodically discharge the settled sludge.

[0110] 2) Salt division unit:

[0111] The pretreated qualified water (3 / h) sent to the reuse unit, concentrated water (0...

Embodiment 3

[0125] This embodiment is a complete softening method of coal gasification grey water, which is designed for the following users: the water replenishment of the grey water system is desalinated water, there is no need to reuse the waste water discharged from the grey water, and at the same time, the discharged grey water needs to be dehardened and then sent to the The demand for reducing ammonia nitrogen to the ammonia distillation tower and sending it to the sewage system.

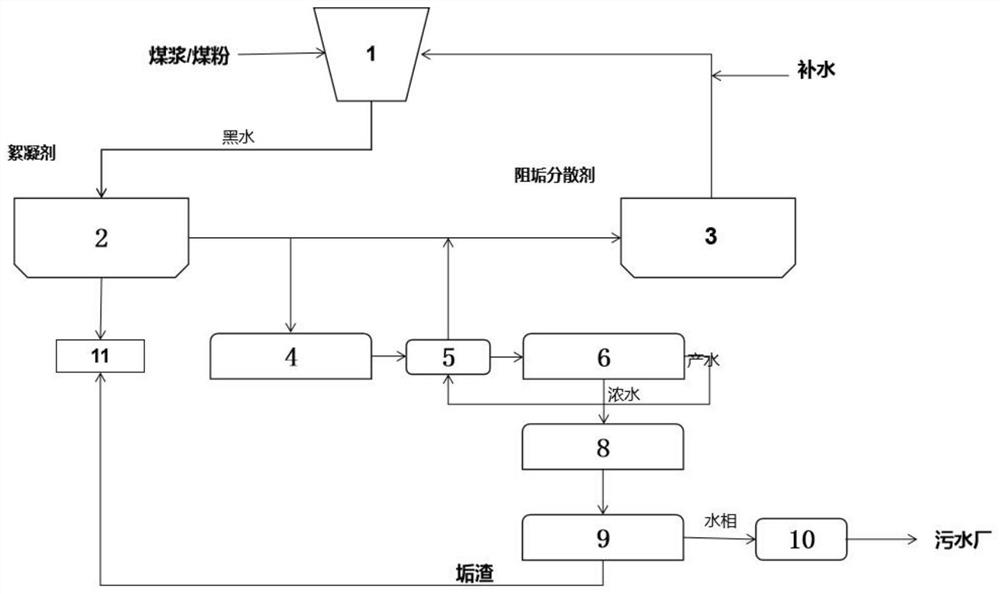

[0126] The process route of this embodiment is as follows figure 2 Shown: water is diverted from the outlet of the settling tank 2 to the pretreatment unit 4, and after cooling by the heat exchanger 5, it enters the salt separation unit 6. The concentrated water of 6 enters the hardening unit 8, the product water of the hardening unit 8 all enters the separation unit 9, and the water phase of the separation unit 9 enters the ammonia distillation tower 10 to remove ammonia nitrogen and then send it to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com