Water-soluble sulfonated/quaternized chitosan and preparation method thereof

A technology of quaternized chitosan and sulfonated chitosan, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of increased energy consumption, complicated process, Problems such as single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

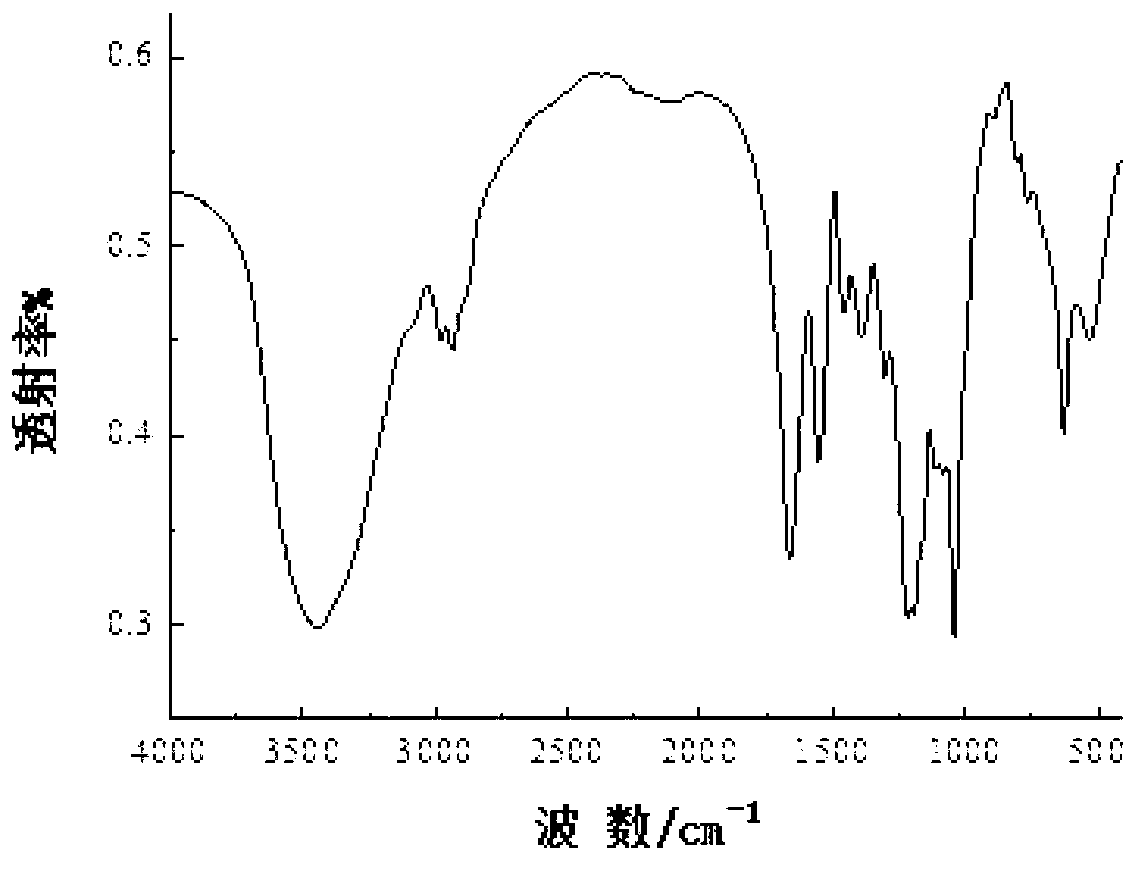

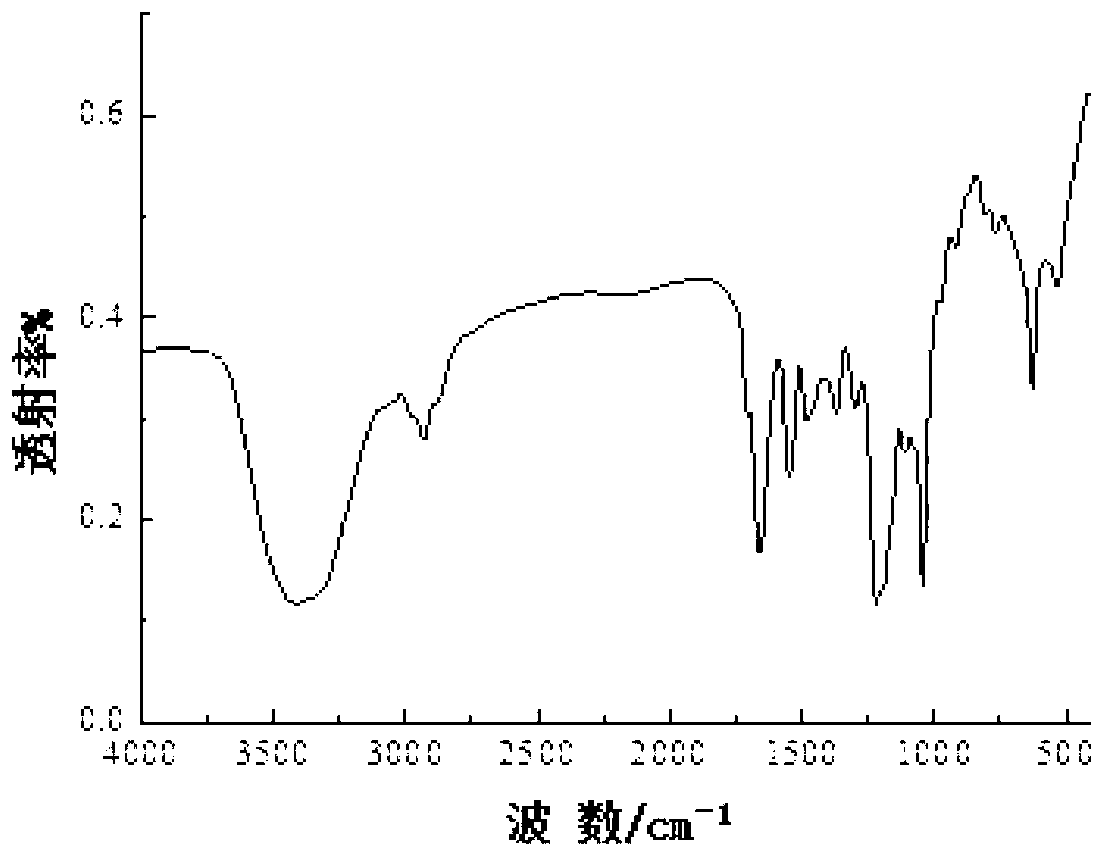

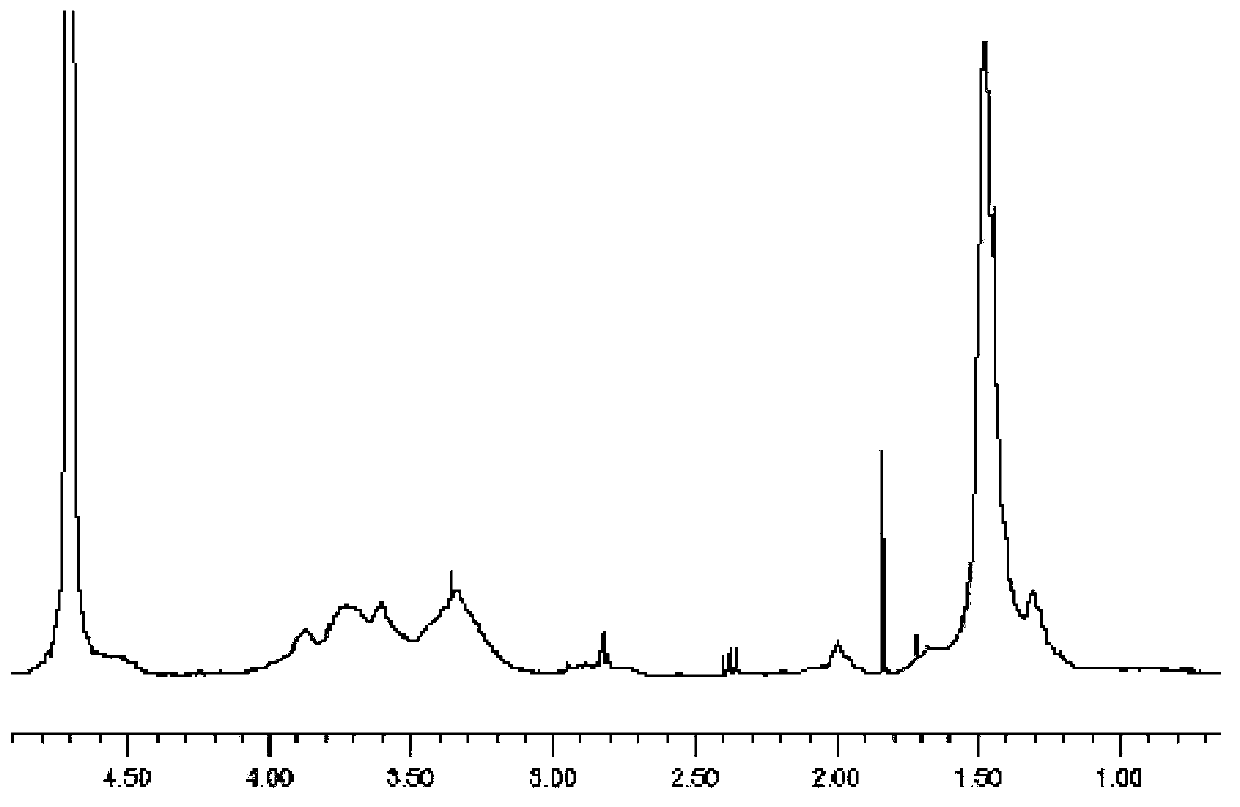

Image

Examples

Embodiment 1

[0042] Weigh 0.40 g of chitosan with a degree of polymerization n of 30 in the reactor, stir and dissolve with 20 mL of 1% (w / w) acetic acid solution; add 0.03 g of ammonium persulfate under nitrogen protection, and continue stirring until the ammonium persulfate is completely dissolved ,; Dissolve 2.05g of AMPS in 20mL of water, transfer the solution into a constant pressure dropping funnel and assemble it on a reactor that has been placed in a constant temperature water bath at 60°C, and add the AMPS solution dropwise to the reactor under nitrogen protection, Continue to stir for 4 hours after all the drops are completed; the reactant is cooled to room temperature, the solution is adjusted to neutrality with 5% sodium hydroxide, precipitated with a mixed solvent (acetone:ethanol=1:1, v / v), and vacuum-dried to obtain Sulfonated chitosan was obtained. Scale inhibition evaluation shows that when n is 30, the scale inhibition rate of sulfonated chitosan is 89%.

[0043] The res...

Embodiment 2

[0048] The steps are the same as in Example 1, except that the chitosan whose degree of polymerization n is 60 is taken by weighing 0.40g, ammonium persulfate is 0.02g, the amount of AMPS is 1.02g, the temperature of the water bath is 40°C, and the reaction time is controlled to be 3h, thereby preparing Sulfonated chitosan was obtained. Scale inhibition evaluation shows that when n is 60, the scale inhibition rate of sulfonated chitosan is 73%.

Embodiment 3

[0050] The steps are the same as in Example 2, except that 0.40 g of chitosan whose degree of polymerization n is 180 is weighed, and the reaction conditions are controlled to prepare sulfonated chitosan. The scale inhibition evaluation shows that when n is 180, the scale inhibition rate of sulfonated chitosan is 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com