Method for manufacturing organic esterified starch

A technology of acetate esterified starch and production method, which is applied in the field of food processing, can solve problems such as difficult control, complex operation of esterified starch process, and limited application range, and achieve the effects of simple control, significant economic benefits, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

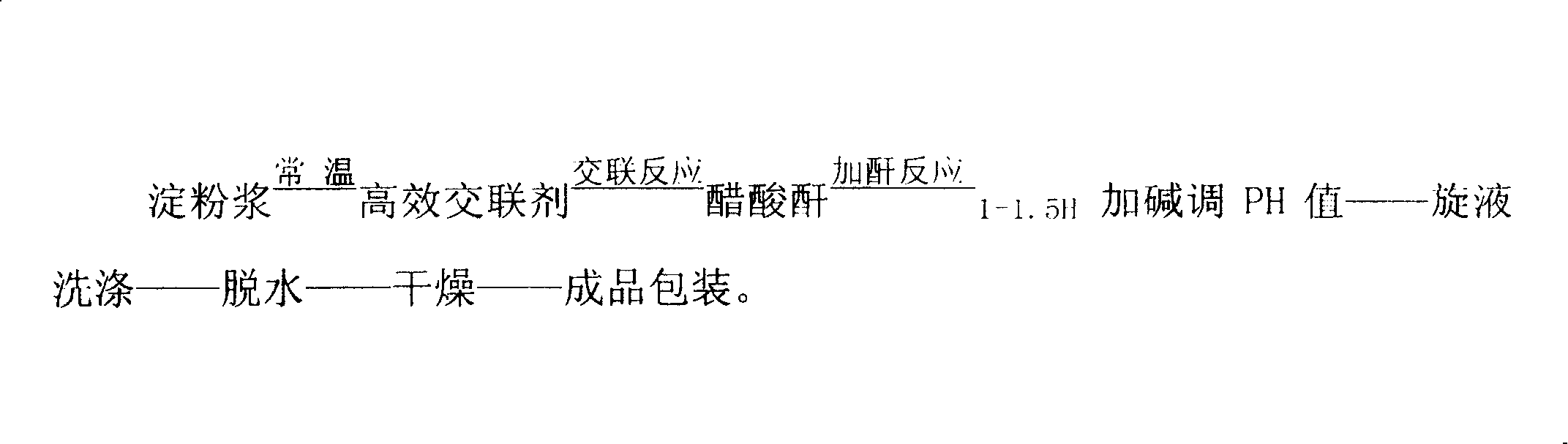

Image

Examples

Embodiment 1

[0020] Raw materials: potato starch 1000Kg,

[0021] Cross-linking agent: glucose β-lactone 0.6Kg, monochloroacetic acid 1.4Kg, (total addition is calculated as 0.2%)

[0022] Esterifying agent: acetic anhydride 80Kg,

[0023] Potassium hydroxide: 60Kg, made into lye.

[0024] Add water to the commercially available potato starch to a specific gravity of 18 degrees Baume, add a cross-linking agent under stirring at room temperature, and after about 1 hour, the starch slurry becomes uniform and viscous, add acetic anhydride to esterify, stir for about 1 hour, and pump it into the preparation. Adjust the pH of the lye to neutral, spin and wash, remove the salt in the starch solution, dehydrate and dry, and pack the finished product.

Embodiment 2

[0026] Raw materials: corn starch 1000Kg,

[0027] Cross-linking agent: 1.5Kg of gluconate σ-lactone, 3.5Kg of monochloroacetic acid, (total addition is calculated as 0.5%)

[0028] Esterifying agent: acetic anhydride 80Kg,

[0029] Sodium hydroxide 60Kg, made into lye.

[0030] Add water to the commercially available corn starch until the specific gravity is 18 degrees Baume, add a cross-linking agent under stirring at room temperature, add acetic anhydride for esterification after about 1.5 hours, and pump in the prepared lye to adjust the pH to Neutral, spin washing, remove the salt in the starch solution, dehydration and drying, finished product packaging.

experiment example

[0032] Compare the gelatinization temperature and viscosity of the above-mentioned starch before and after esterification (Brabender Viscometer)

[0033] Sample No.

[0034] Characteristics of the inventive method

[0035]

[0036] Compared with the traditional process, the gelatinization temperature has dropped by about 10°C and can reach 48°C-52°C. Brookfield viscosity is 2400-3300BU in the traditional process, but the new process can be as high as 5000-7000BU, which has created a miracle, which can make the application range wider and the economic benefits more significant. The two most important indicators of gelatinization temperature and viscosity achieved by the new technology rank first in China and reach the international advanced level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com