Method and apparatus for reducing cyanogen content of coking wastewater

A technology for coking wastewater and ammonia water, which is used in chemical instruments and methods, oil/oily substance/float removal devices, water pollutants, etc. Ammonia wastewater contains high levels of cyanide, which can avoid secondary decomposition and biochemical sludge poisoning, save operating costs, and reduce steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

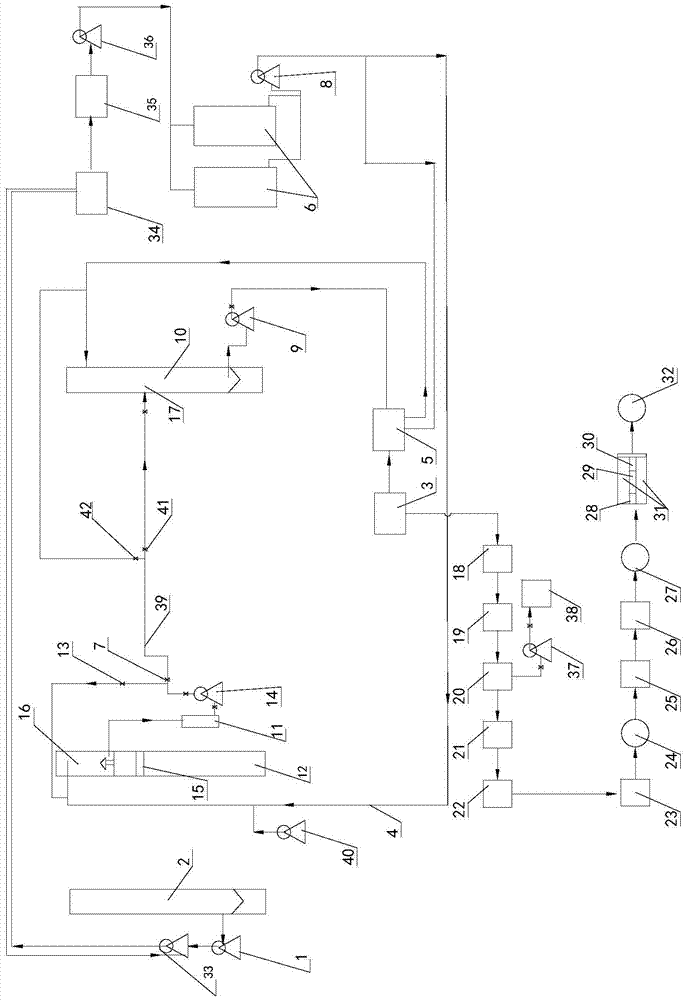

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0027] See figure 1 , a device for reducing cyanide in coking wastewater, improving the process route, changing operating conditions, adding devices, improving the efficiency of cyanide distillation, and realizing the transfer of cyanide-containing substances. The specific scheme is as follows: including desulfurization tower 12, ammonia distillation tower 10, raw materials Ammonia water tank 6, raw ammonia water pump 8, ammonia distilled wastewater pump 9, ammonia water heat exchanger 5, waste water cooler 3, environmental protection biochemical device, regeneration tower 2, circulating ammonia water pump 33, raw ammonia water pipeline 4, alkali tank 11, 42% Alkali pump 40, 2.5%-5% alkali pump 14; coke oven 34 is connected to raw material ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com