Ammoximation wastewater treatment method and application thereof

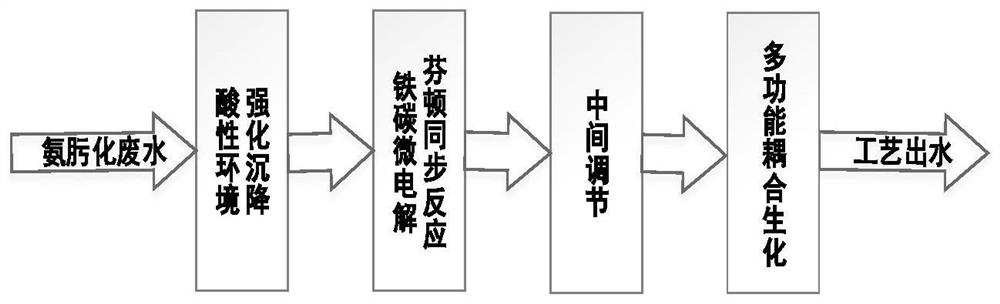

A treatment method and ammoximation technology, which can be applied in special compound water treatment, natural water treatment, multi-stage water treatment, etc., can solve the problems of high content of organic nitrogen, difficult to reach the standard of total nitrogen, difficult to handle, etc., and achieve good results. , Complementary functions, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The caprolactam production unit of a petrochemical plant discharges ammonia oximation wastewater. The characteristics of the wastewater are: COD3025mg / L, pH8.5, total nitrogen 938.8mg / L, organic nitrogen 247mg / L, BOD 5 / COD0.002. The waste water is treated as follows:

[0058] Step 1: Acidic environment strengthens coagulation settlement.

[0059] Add 80 mg / L polyaluminum chloride to the waste water, and stir for 25 minutes to react. Afterwards, the pH of the waste water was adjusted to 3.0 with sulfuric acid, and further settled. After 25 minutes, add 35 mg / L non-ionic polyacrylamide coagulant, react for 1 hour, and filter. Product water COD2625mg / L, total nitrogen 815mg / L, organic nitrogen 123mg / L, BOD 5 / COD 0.01.

[0060] Step 2: Iron-carbon micro-electrolysis-Fenton synchronous treatment.

[0061] Add hydrogen peroxide to the coagulation effluent at a rate of 3000 mg / L and mix evenly, enter the iron-carbon bed, and iron-carbon micro-electrolysis and Fenton ox...

Embodiment 2

[0067] The caprolactam production unit of a petrochemical plant discharges ammonia oximation wastewater. The characteristics of the wastewater are: COD3170mg / L, pH8.5, total nitrogen 1284mg / L, organic nitrogen 599mg / L, BOD 5 / COD0.005. The waste water is treated as follows:

[0068] Step 1: Acidic environment strengthens coagulation settlement.

[0069] Add 100 mg / L polyaluminum chloride to the waste water, and stir for 25 minutes. Afterwards, the pH of the waste water was adjusted to 3 with sulfuric acid, and further settled. After 25 minutes, add 40 mg / L non-ionic polyacrylamide coagulant, react for 1 hour, and filter. Product water COD2416mg / L, total nitrogen 950mg / L, organic nitrogen 310mg / L, BOD 5 / COD 0.01.

[0070] Step 2: Iron-carbon micro-electrolysis-Fenton synchronous treatment.

[0071] Add hydrogen peroxide to the coagulation effluent at a rate of 3500mg / L and mix evenly, enter the iron-carbon bed, and iron-carbon micro-electrolysis and Fenton oxidation reac...

Embodiment 3

[0077] The caprolactam production plant treated in Example 2 is used to discharge ammonia oximation waste water, the water quality characteristics of waste water are: 3170mg / L, pH8.5, total nitrogen 1284mg / L, organic nitrogen 599mg / L, BOD 5 / COD0.005. The waste water is subjected to conventional flocculation treatment, and the steps are as follows:

[0078] Step 1: Add 100mg / L polyaluminum chloride, stir and react for 25min;

[0079] Step 2: adjusting the pH of the wastewater to 5.0 with sulfuric acid;

[0080] Step 3: After 25 minutes, add 40 mg / L non-ionic polyacrylamide coagulant, react for 1 hour, and filter. Product water COD 2579mg / L, total nitrogen 1058mg / L, organic nitrogen 376mg / L, BOD 5 / COD 0.01.

[0081] Comparing the treatment results of Step 1 of Example 2 with that of Example 3, with the same dosage and reaction time, the effluent COD, total nitrogen, and organic nitrogen are all higher, and the treatment effect is not good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com