A kind of compound chelated iron desulfurizer and preparation method thereof

A technology of chelating agent and desulfurizing agent, which is applied in the field of compound chelating iron desulfurizing agent and its preparation, which can solve the problems of low saturated sulfur capacity, narrow pH value and narrow application range of complexing iron desulfurizing agent, and achieve high desulfurization efficiency , facilitate accurate detection and control, and reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

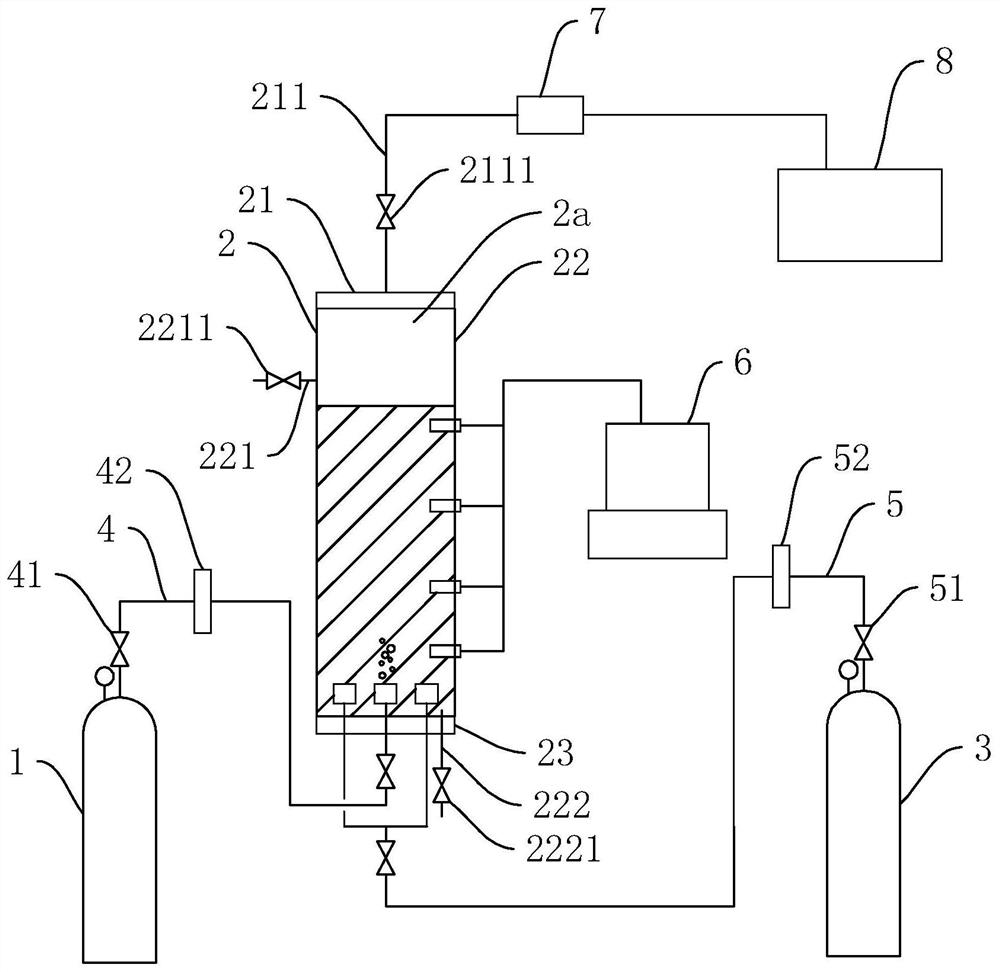

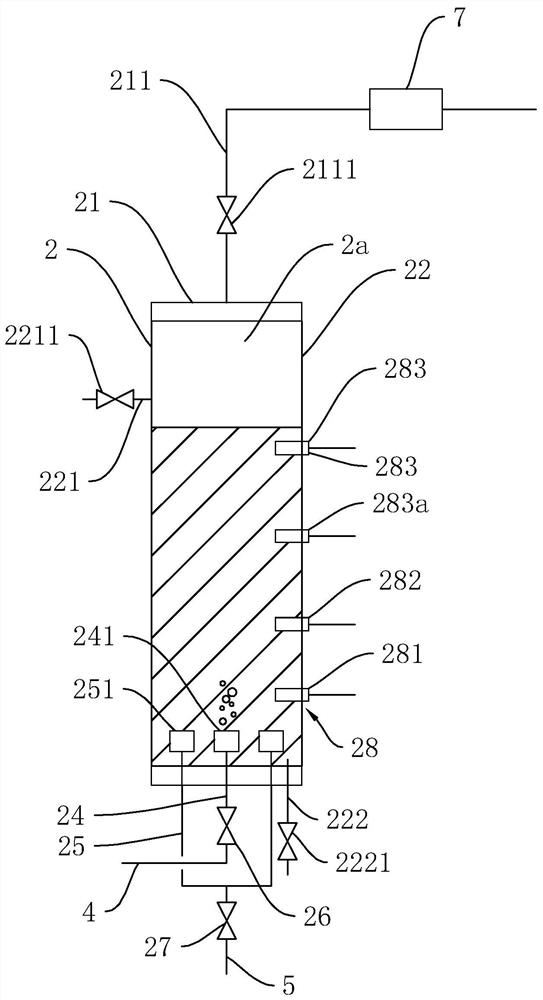

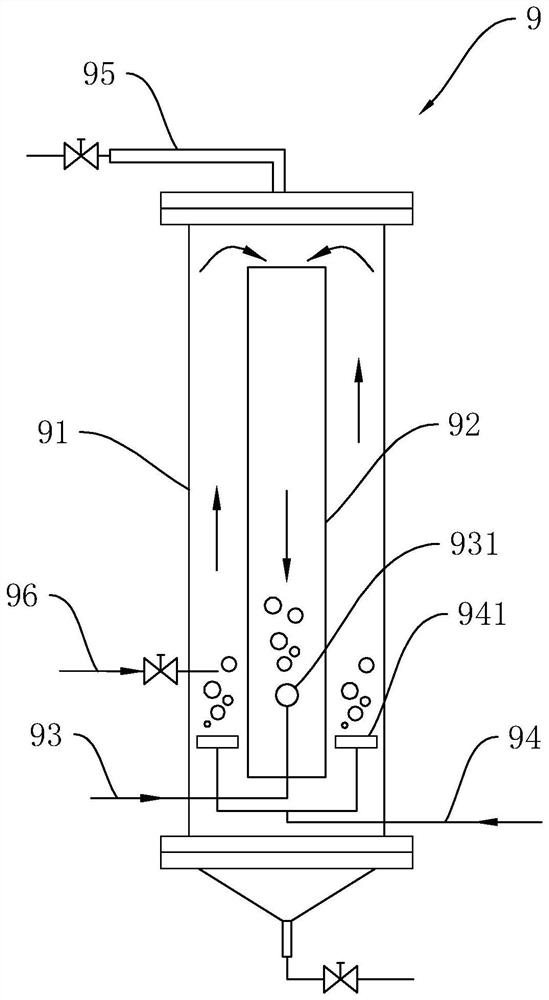

Image

Examples

Embodiment 1

[0095] A compound chelated iron desulfurizer, comprising the following raw materials: high-valent water-soluble iron salt, chelating agent, pH buffer and deionized water, and the mass fraction of Fe in the desulfurizer is 1.0-6.0 wt%.

[0096] The high-valent soluble iron salt is a trivalent soluble iron salt, and the trivalent soluble iron salt is one or more of ferric chloride, ferric acetate, ferric nitrate, ferric ammonium sulfate, and ferric sulfate. Ferric chloride, ferric acetate, ferric nitrate, ferric ammonium sulfate, and ferric sulfate are all commercially available products, of which ferric acetate is a commercially available product from Xi'an Lanzhiguang Fine Materials Co., Ltd.

[0097] The molar ratio of the chelating agent and the high-value water-soluble iron salt is 1:1-3:1, the chelating agent is a compound of the A-type chelating agent and the B-type chelating agent, and the molar ratio of the A-type chelating agent and the B-type chelating agent is 1:1-1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com