Acrylonitrile/acrylon production comprehensive wastewater treatment technique

A technology for treatment process and production wastewater, which is applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of affecting the discharge of acrylic fiber wastewater treatment standards and not considering the removal of total nitrogen in wastewater. , low efficiency of microbial degradation of pollutants, etc., to achieve the effect of improving biodegradability, reducing operating costs, and improving treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

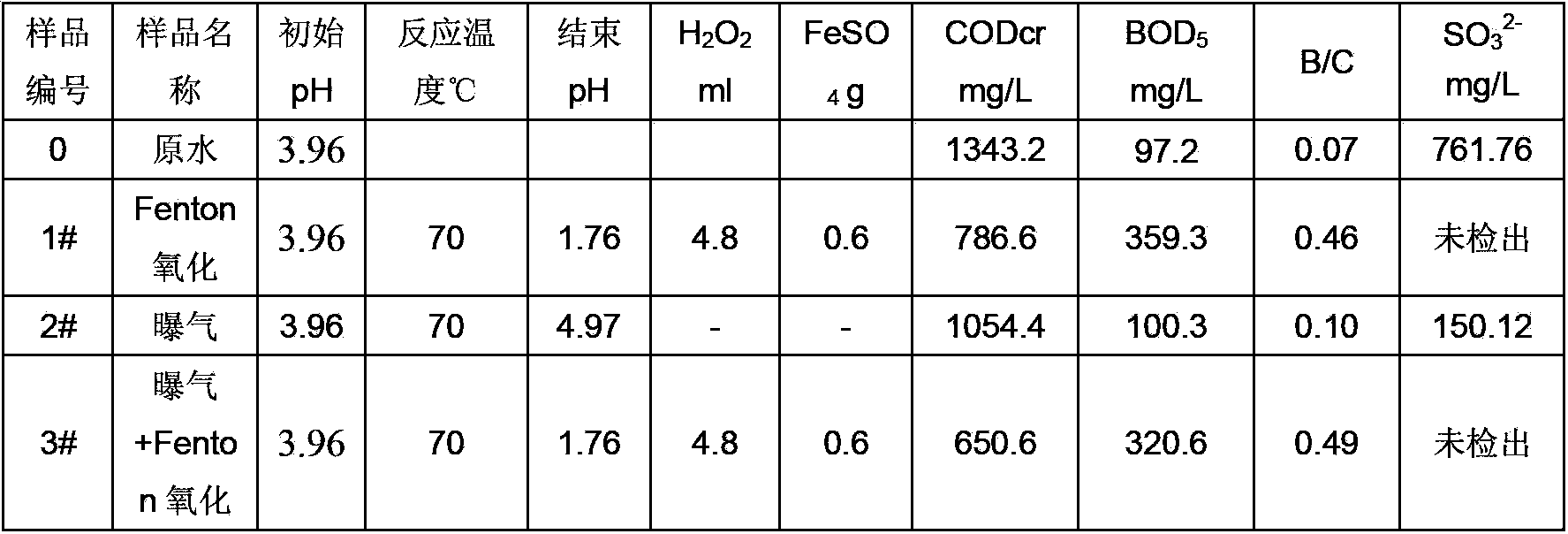

[0036] A comparative test of pretreatment was carried out for the monomer stripping tower wastewater of an acrylic fiber production unit in an acrylic fiber factory. The comparative test mainly investigates the effect of Fenton oxidation directly on monomer stripper wastewater and air aeration oxidation + Fenton oxidation on the treatment effect.

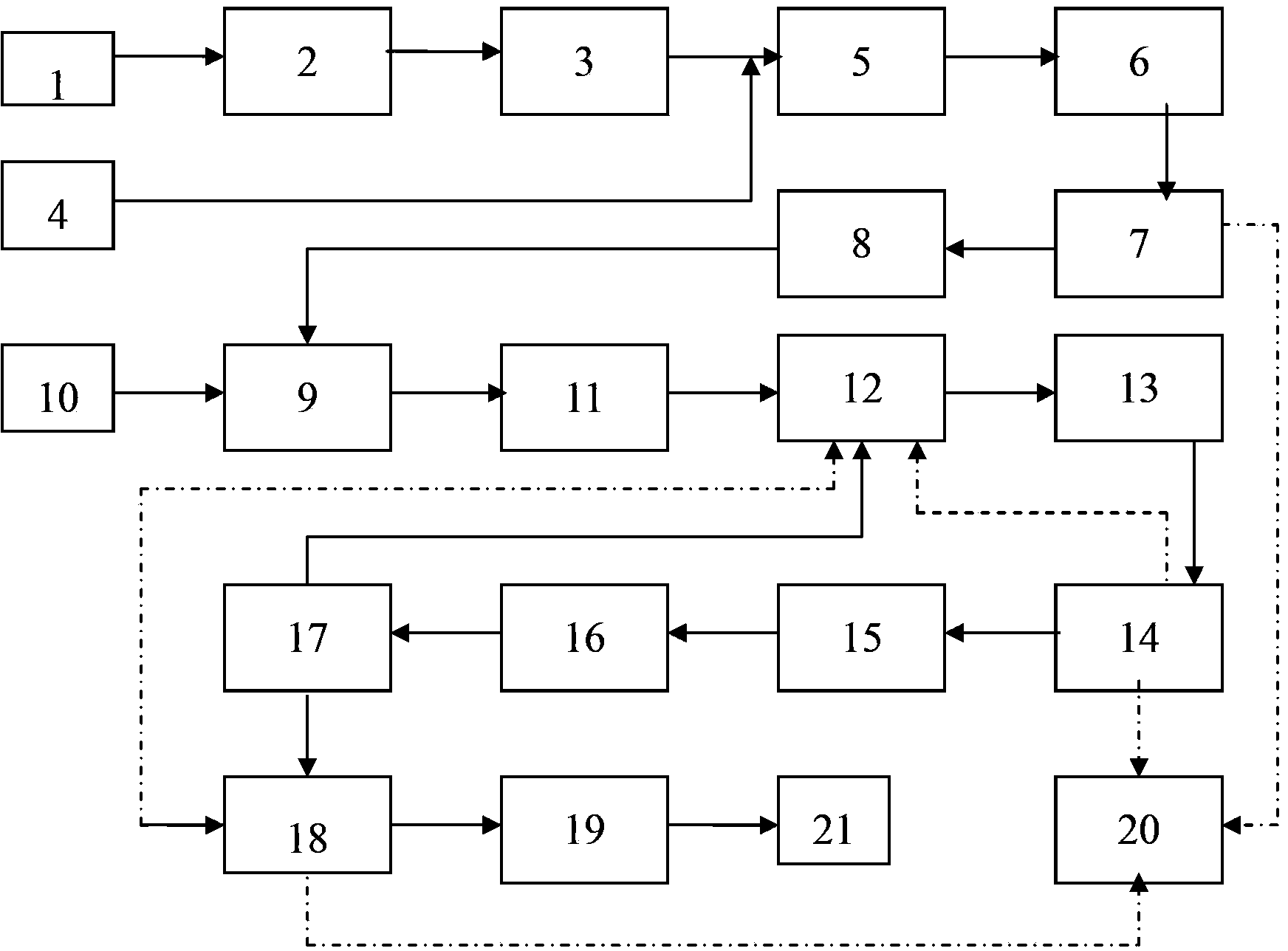

[0037] 1. Test 1: If figure 1 As shown, the monomer stripping tower wastewater 1 of the acrylic fiber production unit was directly subjected to the Fenton oxidation process test. Take 800ml monomer stripper waste water 1, heat the temperature to 70°C, then place it on a constant temperature stirrer, add 4.8ml H 2 o 2 (27.5%, v%), 0.6g FeSO 4 , reacted for 120min; after the reaction, adjust the pH value of the effluent to about 7.0, add 3.2ml of polyaluminum chloride (10%, w%), and react for 1min at a stirring speed of 120r / min, and at a stirring speed of 60r / min The reaction was carried out for 10 minutes, and the supernatant wa...

Embodiment 2

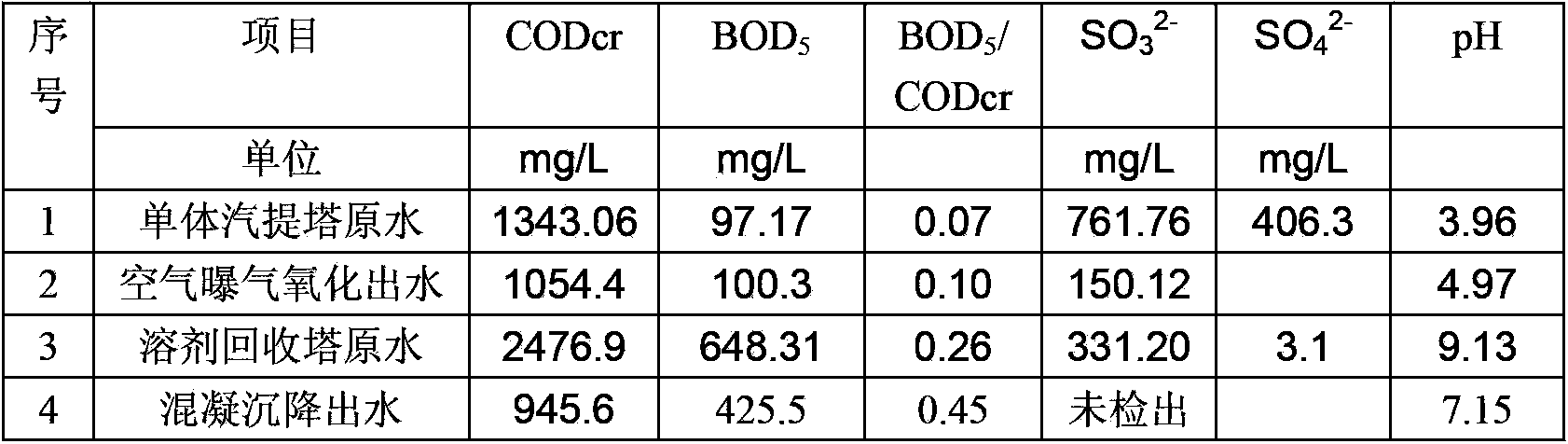

[0045] An acrylic fiber factory includes two sets of acrylonitrile and acrylic fiber production units. First, the acrylic fiber wastewater is pretreated, and then mixed with acrylonitrile production wastewater, domestic sewage in the factory area, and drainage from auxiliary facilities for biochemical treatment.

[0046] 1. Acrylic wastewater pretreatment system

[0047] Such as figure 1 As shown, the waste water 1 discharged from the monomer stripping tower of the acrylic fiber production unit is aerated and oxidized by air in the aeration tower 2 at a temperature of 70-90°C at a gas-water volume ratio of 1:30-100, and the reaction time is 2 hours. Oxidize sulfite in wastewater to sulfate. FeSO is then added in the Fenton oxidation process 3 4 and H 2 o 2 Perform Fenton oxidation to remove and decompose oligomers and refractory organic matter in wastewater, and increase the B / C value of wastewater while reducing CODcr of wastewater. FeSO 4 Adding amount is 0.75Kg / m 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com