Patents

Literature

109 results about "Aluminium carbide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum carbide, chemical formula Al₄C₃, is a carbide of aluminum. It has the appearance of pale yellow to brown crystals. It is stable up to 1400 °C. It decomposes in water with the production of methane.

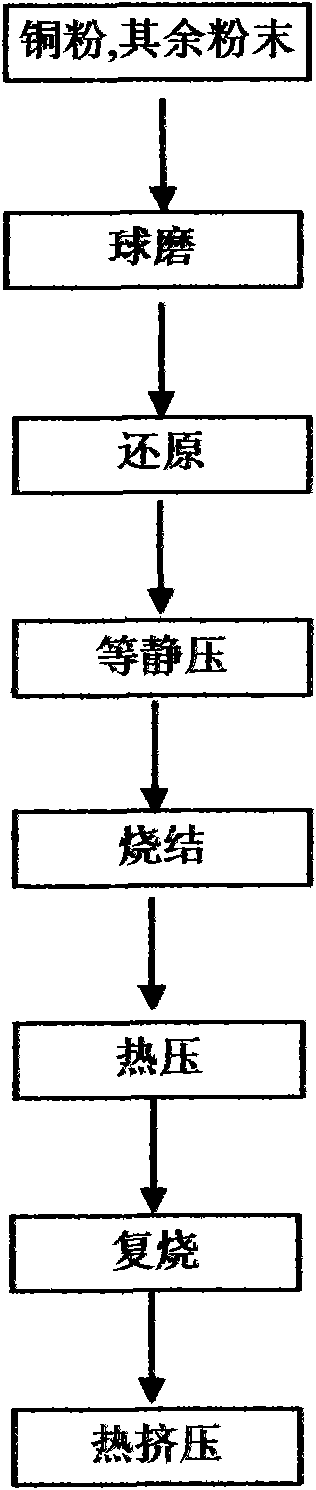

Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

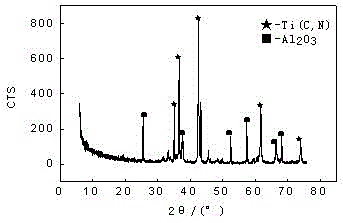

InactiveCN101613816APromote generationImprove organizational structureTitanium carbideSelf generation

The invention discloses a multiple dispersion strengthening copper-base composite material produced in situ and a preparation method thereof; the reinforced phase comprises at least three of the following substances: titanium carbide, zirconium carbide, alumina, titanium boride, aluminum carbide, chromium oxide, zirconia, graphite and copper; wherein, the contents of titanium carbide, zirconium carbide, alumina, titanium boride, chromium oxide and zirconia are not less than 0.3% and not more than 5%, the content of aluminum carbide is not less than 0.1% and not more than 5%, the content of graphite is not less than 0.1% and not more than 1% and the balance is copper. The particle size of the reinforced phase is between 10nm to 10mu m. The preparation method adopts ball milling; pressing, sintering and squeezing processes and the technological parameters are optimized and controlled properly to obtain the multiple dispersion strengthening copper-base composite material. Because the in situ self-generation technology is adopted and various reinforced phase methods are combined, the material of the invention has higher high-temperature strength and better electroconductibility and anti-creep property compared with the traditional ceramic particle strengthening copper-base composite material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method has high temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

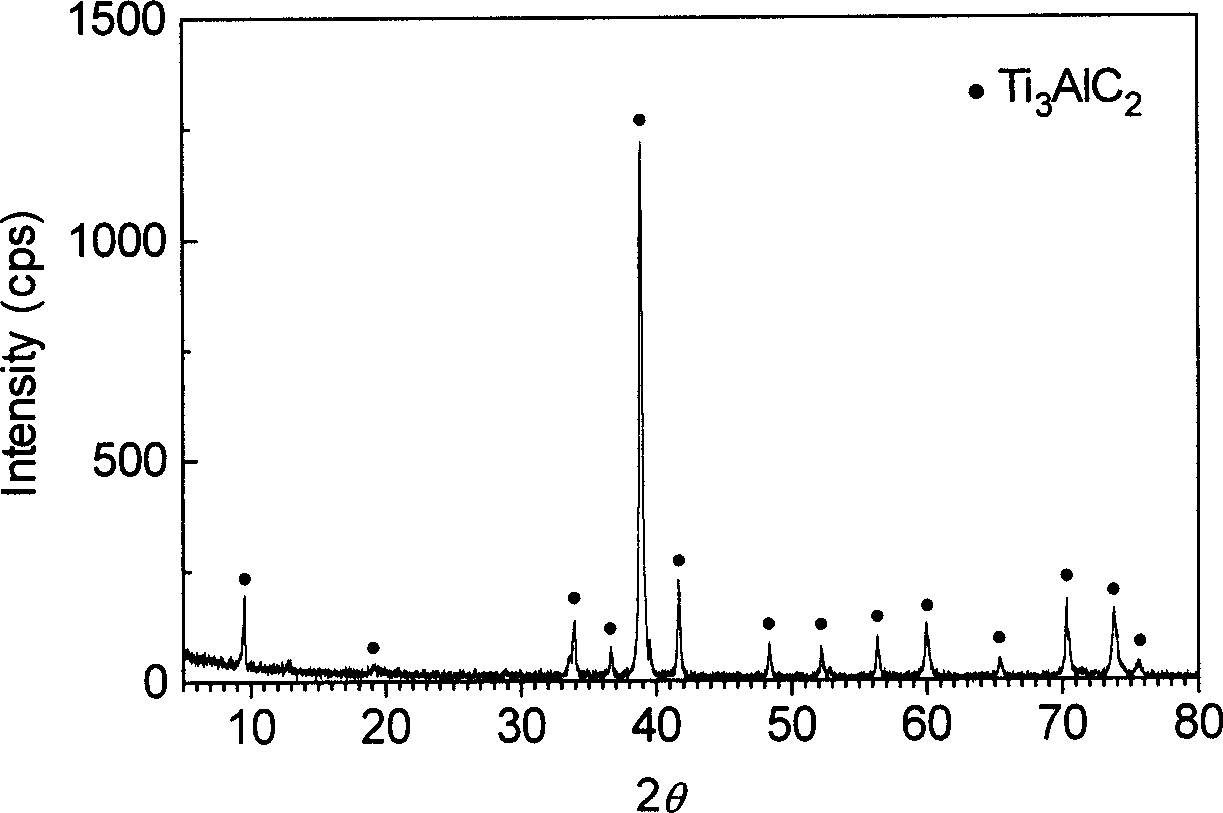

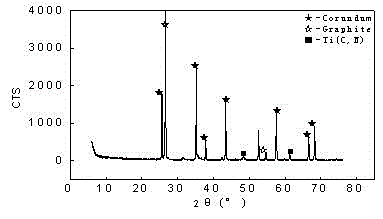

Titanium aluminium carbide powder and synthesis method using tin as reactive adjuvant therefor

InactiveCN1699159ARelaxation of technical requirementsRelaxed temperature control requirementsAluminium carbideSynthesis methods

The invention discloses a titanium aluminium carbide powder and synthesis method using tin as reactive adjuvant characterized in that, using titanium (Ti), aluminium (Al) and graphite (C) as raw material, using stannum (Sn) as reaction adjuvant, proportioning by the mol ratio of Ti : Al : C : Sn = 3.0 : 1.0 : (1.8-2.0) : (0.1-0.2), mixing 2-6 hours through ball grinding, drying at 60-70 deg. C in baking oven, briquetting the dried mixture under 10-20MPa, loading into high temperature furnace, argon shielding, elevating the temperature to 1300-1550 deg. C. at the speed of 20-40 deg. C per minutes, heat preserving for 5-10 minutes, cooling with the speed of 10-15 deg. C / min.

Owner:北京竞和科技有限公司

Cubic Boron Nitride Compact

InactiveUS20080302023A1Poor EDM-cuttabilityImprove conductivityPigmenting treatmentOther chemical processesBorideAluminium carbide

A polycrystalline cubic boron nitride compact which comprises greater than 75 volume % and not greater than 90 volume % cubic boron nitride particles, the cubic boron nitride particles comprising particles of at least two average particle sizes, and a binder phase constituting the balance of the compact and comprising at least one titanium compound selected from titanium boride, titanium nitride, titanium carbide and titanium carbonitride and at least one aluminium compound selected from aluminium oxide, aluminium boride, aluminium nitride, aluminium carbide and aluminium carbonitride.

Owner:GOUDEMOND IAIN PATRICK +2

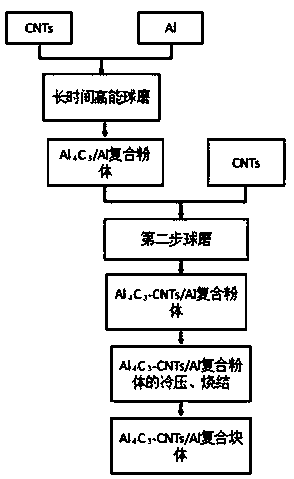

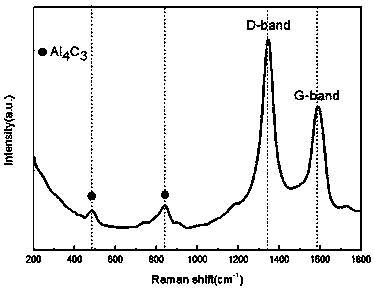

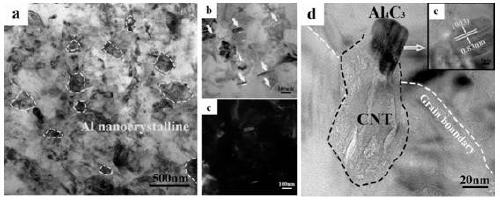

Preparation method of carbon nanotube composite materials

ActiveCN109338167AHigh strengthSolve a single, suboptimal performance problemAluminium carbideRoom temperature

Owner:KUNMING UNIV OF SCI & TECH

Cable sheath material containing modified PVC resins and preparation method thereof

ActiveCN103289261AImprove mechanical propertiesHigh mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesPolymer scienceThiourea

The invention discloses a cable sheath material containing modified PVC resins and preparation method thereof, and the cable sheath material is composed of following raw materials: modified PVC resins, polyacrylate, nanometer potter clay, sodium silicate, aluminium carbide, vulcanizing agent VA-7, antioxidant TPPD, phenyl triethoxysilane, dibenzyl thiourea, anti-oxidant DLTP, di(2-Ethylhexyl)-4,5-epoxycyclohexane-1,2-dicarboxylate and triphenylphosphine oxide; The invention employs modified PVC resin as main material, and the PVC resin is modified, and the invention has the advantages of greatly improved mechanical property, better mechanical properties, low smoke, halogen free, flame retardation, high mechanical strength and high insulation resistor, and nanometer potter clay in the raw material is used as strengthening agent, and sodium silicate and aluminium carbide are used as filling material.

Owner:中山市锐来电子有限公司

Composite hard alloy material and preparation method thereof

The invention discloses a composite hard alloy material and a preparation method thereof. The composite hard alloy material is prepared from the following components in parts by weight: 35-40 parts of nano titanium carbide, 5-15 parts of nano titanium nitride, 7-9 parts of tungsten carbide, 5-8 parts of niobium carbide, 3-7 parts of silicon carbide, 3-5 parts of cobalt powder, 1-3 parts of yttrium oxide, 1-3 parts of aluminium carbide and 1-5 parts of titanium powder. The composite hard alloy material has high strength, good toughness and good wear resistance and thermal shock resistance.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

Anti-corrosion heat-dissipation coating and preparation method thereof

InactiveCN103333565AImprove adhesionImprove cooling effectAnti-corrosive paintsCalcium silicateAcrylic resin

The invention discloses an anti-corrosion heat-dissipation coating and a preparation method thereof. The coating comprises following raw materials: acrylic resin, calcium silicate powder, acetic ether, modified aluminium carbide, iron oxide, polyethylene wax powder, triethylene tetramine, anti-oxidant 264, water-soluble nano-level silica sol, dimethyl adipate, dispersant NNO, and acetone. The method adopts acrylic resin as the main material, which has the advantages of aging resistance, good adhesivity, good heat-dissipation effect, and long-term use at the temperature between 150 and 200 DEG C. Calcium silicate powder strengthens the anti-corrosion performance of the product, and alum and modified aluminium carbide strengthen the combination between the raw materials. The coating has the advantages of durability, waterproofness, damp-resistance, corrosion-resistance and very good adhesive performance.

Owner:中山嘉应斯化工有限公司

Tungsten carbide coated composite hard alloy material and preparation method thereof

The invention discloses a tungsten carbide coated composite hard alloy material and a preparation method thereof. The alloy material comprises a matrix and a tungsten carbide coated layer, wherein the matrix is prepared from the following components in parts by weight: 35-40 parts of nano titanium carbide, 5-15 parts of nano titanium nitride, 5-8 parts of niobium carbide, 3-7 parts of silicon carbide, 3-5 parts of cobalt powder, 1-3 parts of yttrium oxide, 1-3 parts of aluminium carbide and 1-5 parts of titanium powder. The composite hard alloy material has high strength, good toughness and good wear resistance and thermal shock resistance.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

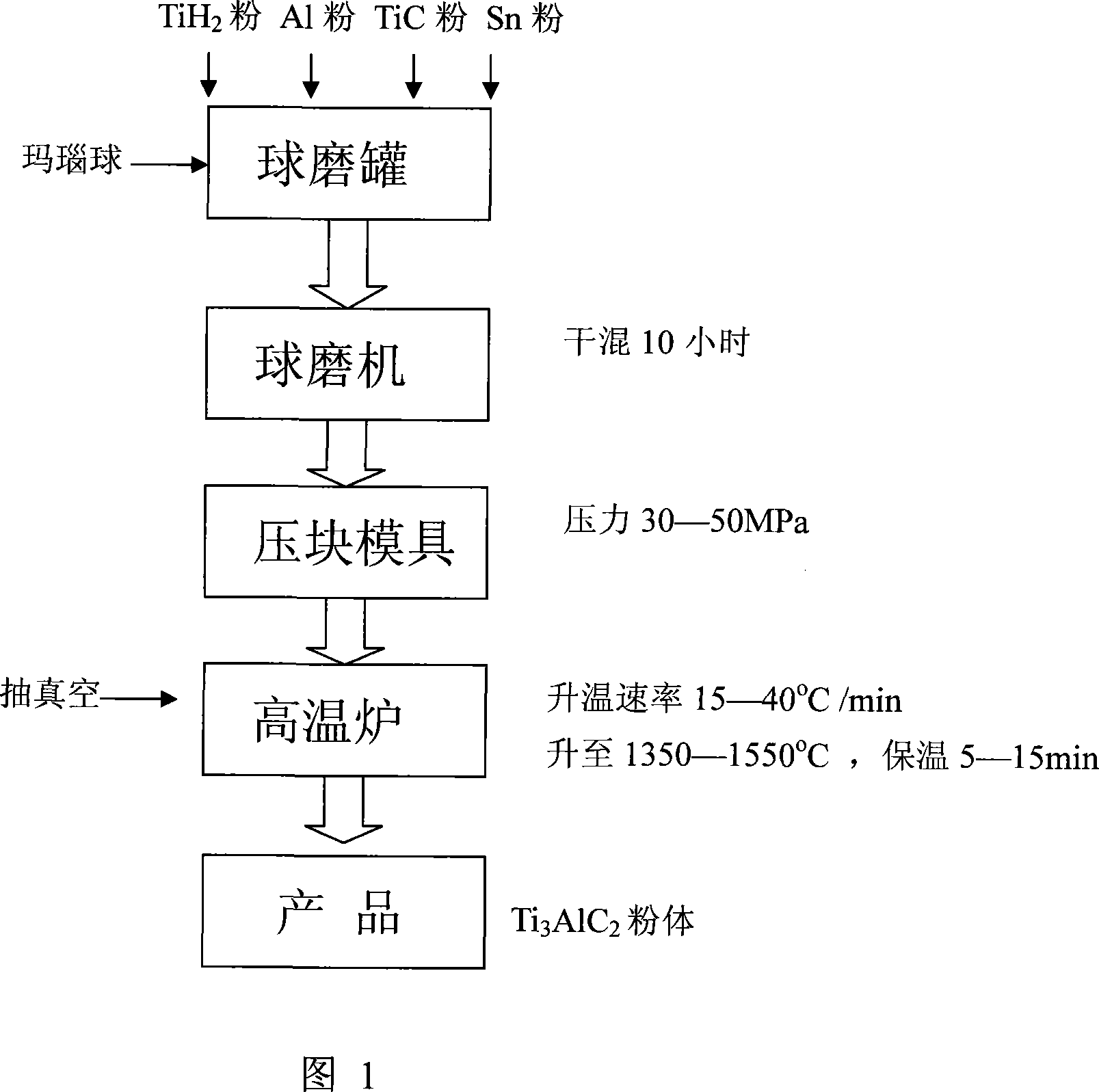

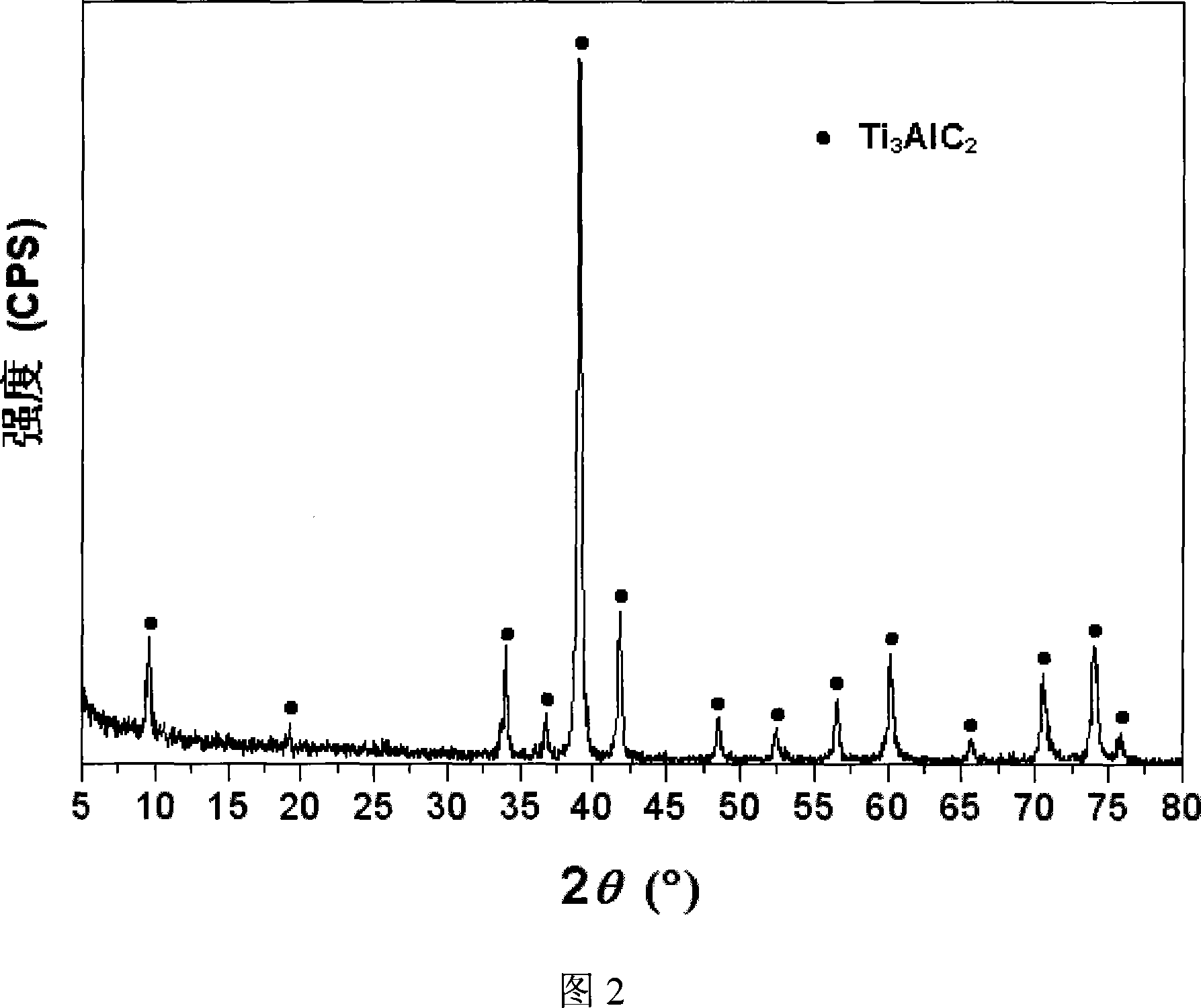

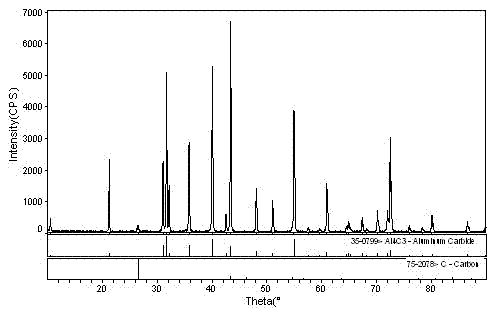

Method for synthesizing aluminium-titanium carbonate ceramic powder

This invention relates to a synthetic method of aluminium carbide titanium ceramic powder. The invention takes TiH2 powder, Al powder and TiC powder as raw material, add Sn as accessory ingredient, dyr mix the raw materials acoording to mol ratio of TiH2:TiC:Al:Sn=1:1:1:0.1 for 10 hours, execute piece under 30 to 50 pressure, then put at high temperature furnace, under vacuum atmosphere rise the furnace temperature to 1350 to 1550 deg by rate of 15 to 40 deg per minute, holding time for 5 to 15min, execute low cost high-purity Ti3AlC2 powder.

Owner:BEIJING JIAOTONG UNIV

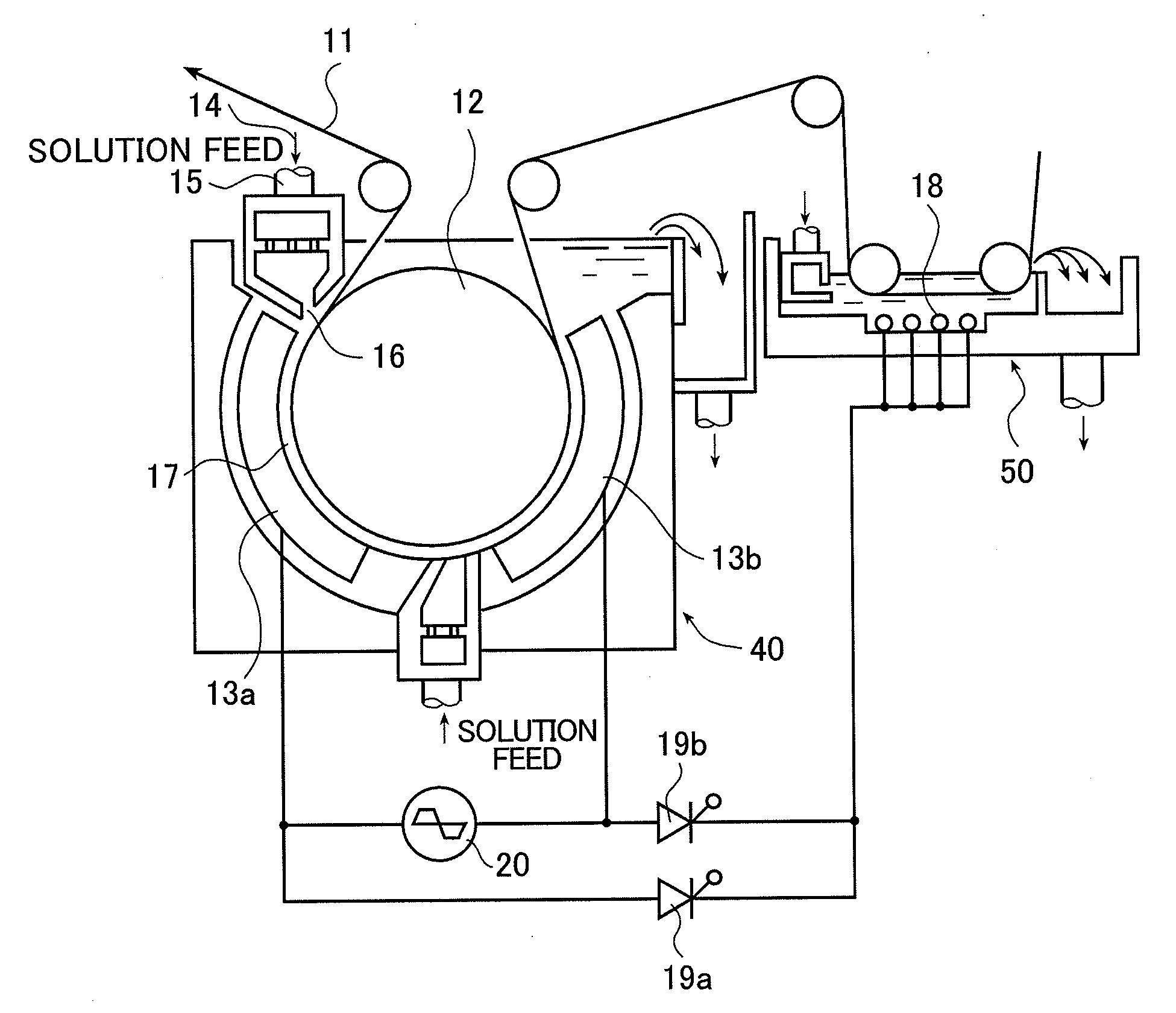

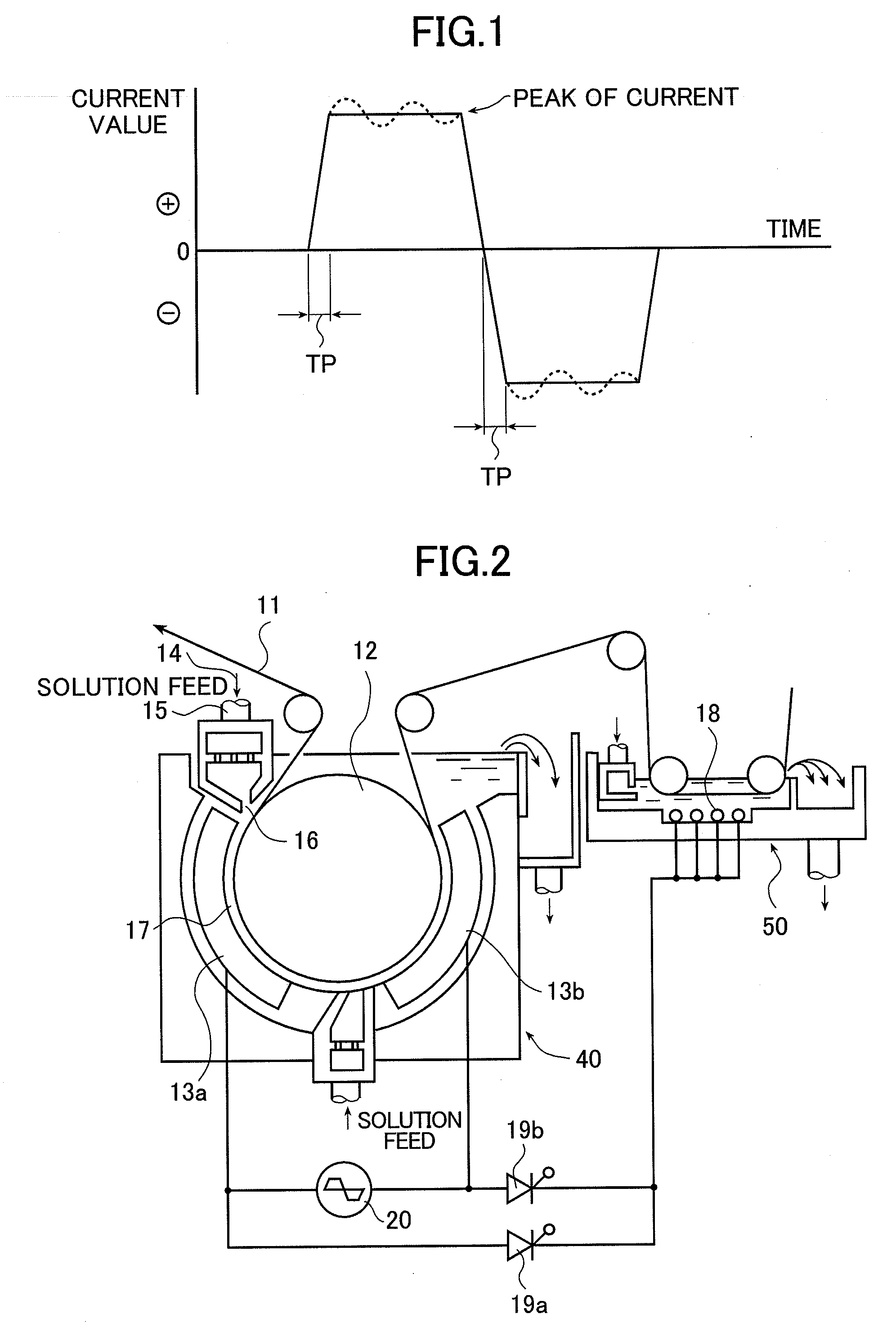

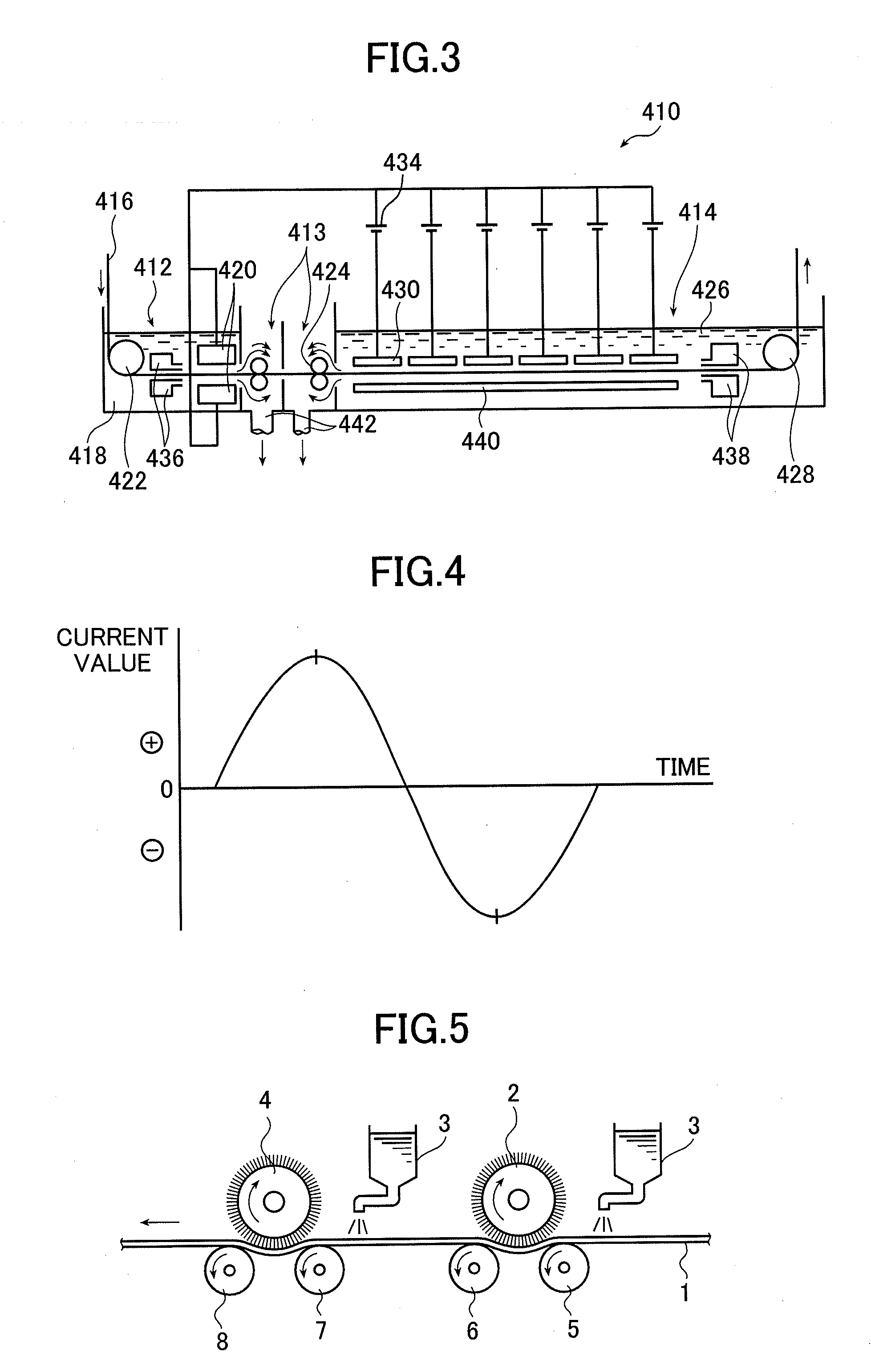

Lithographic printing original plate

ActiveUS20120189959A1Excellent scumming resistanceExtended press lifePhotosensitive materialsSemiconductor/solid-state device manufacturingCarbideAlloy

A presensitized plate having a long press life and excellent resistance to scum and corrosive micro-stains and capable of on-press development is provided. The presensitized plate includes a photosensitive layer containing (A) a sensitizing dye, (B) a polymerization initiator, (C) a polymerizable compound, and (D) a binder polymer; and a protective layer which are formed on a support in this order. The support is prepared from an aluminum alloy plate containing intermetallic compound particles with a circle equivalent diameter of 0.2 μm or more at a surface density of 35,000 pcs / mm2 or more and aluminum carbide particles with a maximum length of 1 μm or more in an amount of up to 30,000 pcs / g.

Owner:FUJIFILM CORP

Cable sheath material containing modified high density polyethylane and preparation method thereof

ActiveCN103289280AHigh mechanical strengthHigh insulation resistanceInsulated cablesInsulated conductorsLow-density polyethyleneChlorinated paraffins

The invention discloses a cable sheath material containing modified high density polyethylane and preparation method thereof, and the cable sheath material comprises the following raw materials: modified high density polyethylene, methyl vinyl silicone rubber, nanometer attapulgite, nanometer level titanium dioxide, aluminium carbide, isocyanate, anti-scorching agent CTP, titanate coupling agent TMC-TTS, isooctyl mercaptoacetate, 2.6-di t butyl-4-methyl phenol, chlorinated paraffin and polyurethane TPU; the invention employs modified high density polyethylane as main material, and the terpolymer EP rubber is modified, thereby the product has the characteristics of low-smoke, halogen free, flame retardation, high mechanical strength, high insulation resistor and high mechanical property, simultaneously the nanometer attapulgite in the raw material is used as strengthening agent, and nanometer level titanium dioxide and aluminium carbide are used as filling materials.

Owner:九江伟梦新型建材有限公司

Nanometer aluminum carbide particle reinforced aluminum matrix composite material and manufacturing method thereof

ActiveCN109680188ASolve the problem of hydrolysisFix stability issuesArgon atmosphereMetallic materials

The invention belongs to the field of metal materials, and particularly relates to an aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material and a manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material. The aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material is characterized in that according to the mass percentage of various chemical components, the mass percentage of aluminum ranges from 65% to 99.5%, the mass percentage of carbon ranges from 0.5% to 15.0%, and the balance is at least one of the magnesium element, the copper element, the silicon element, the zinc element, the ferrum element, the manganese element, the chromium element and the titanium element. Aluminum oxide cladding type nanometer aluminum carbide particles which are formed in an in-situ synthesis modeare distributed on an aluminum or aluminum alloy matrix. The manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material comprises the steps that raw materials are prepared in proportion, and graphite powder and activated carbon are subjected to vacuum drying, and then are mixed and reserved; and commercial purityaluminum and at least one of magnesium, copper, silicon, zinc, ferrum, manganese, chromium and titanium are molten in a smelting furnace, after the temperature is stabilized, the mixed powder of thegraphite powder and the activated carbon are uniformly blown to the molten body in the argon atmosphere by a rotary blowing device, then the temperature is rapidly reduced until solidification is achieved, the materials are transferred to a resistance furnace to conduct a liquid-solid reaction, and therefore the nanometer aluminum carbide particle reinforced aluminum matrix composite material is obtained. The manufacturing method is low in cost, is green and environmentally friendly, and has the good industrial production prospect.

Owner:SHANDONG UNIV +1

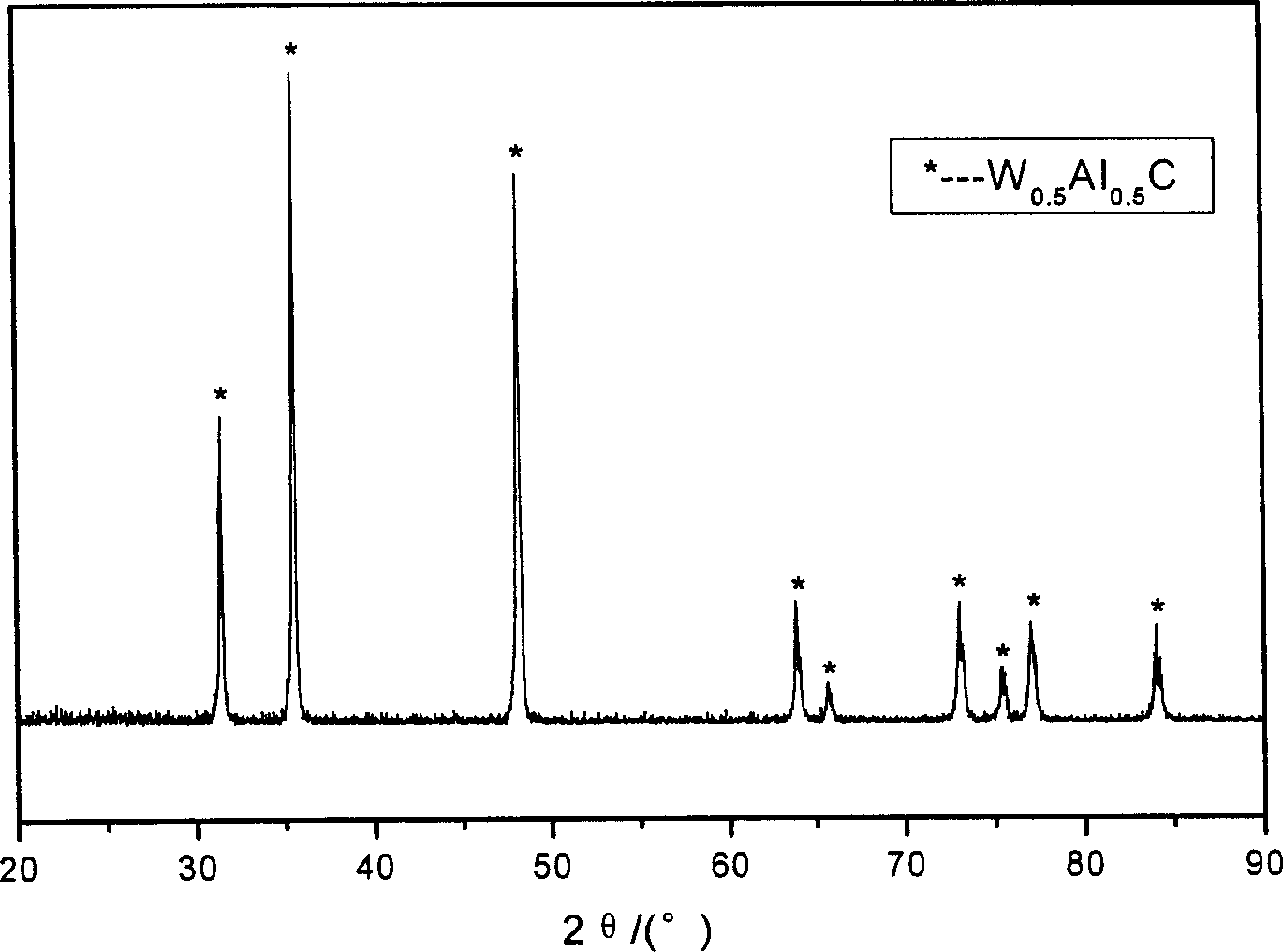

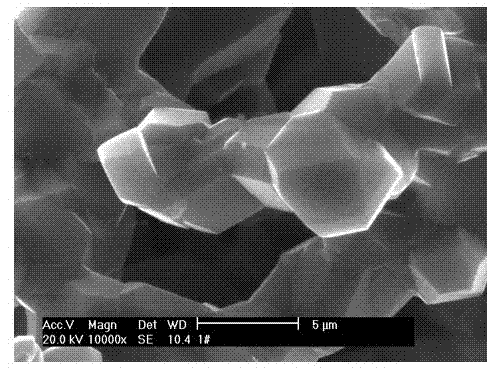

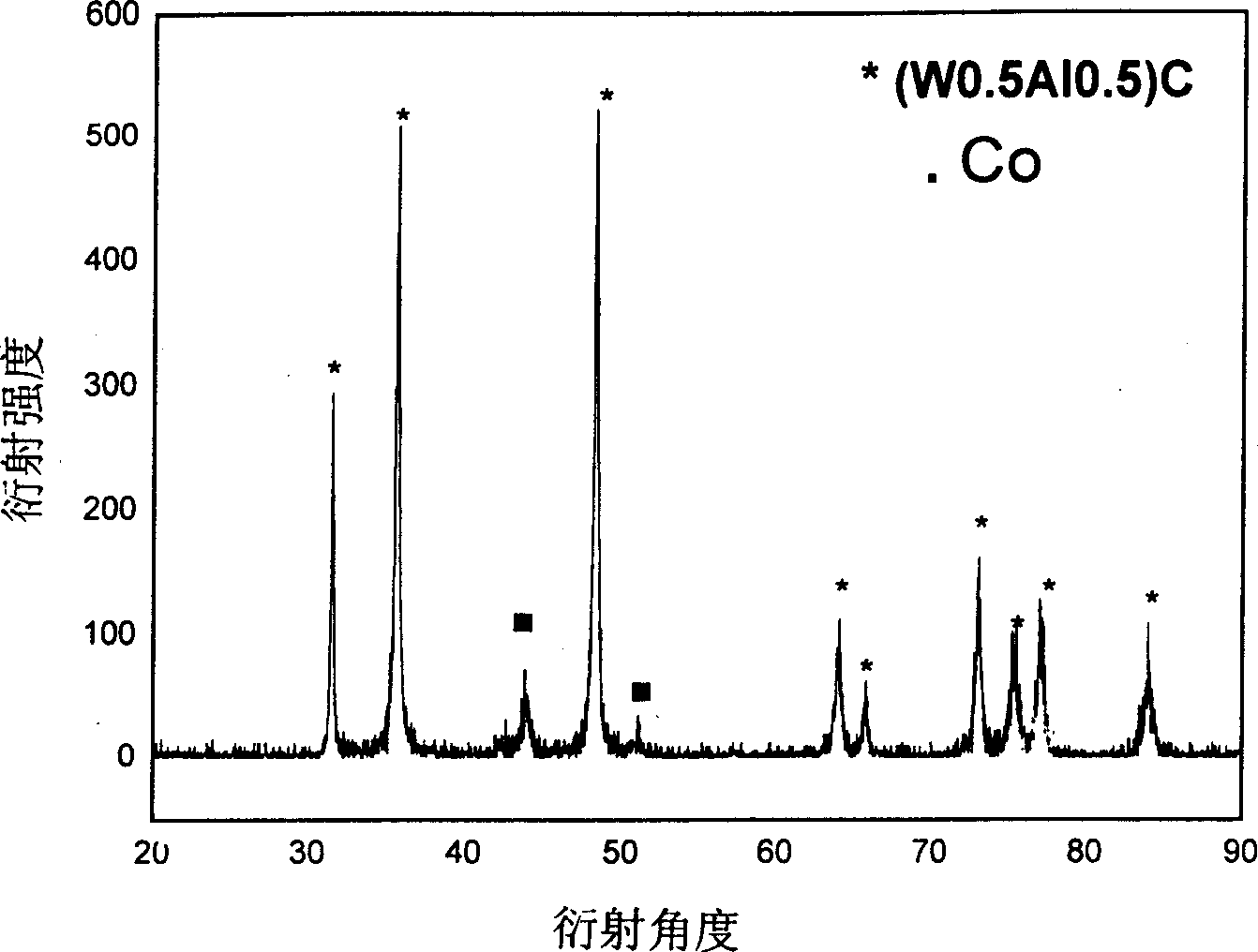

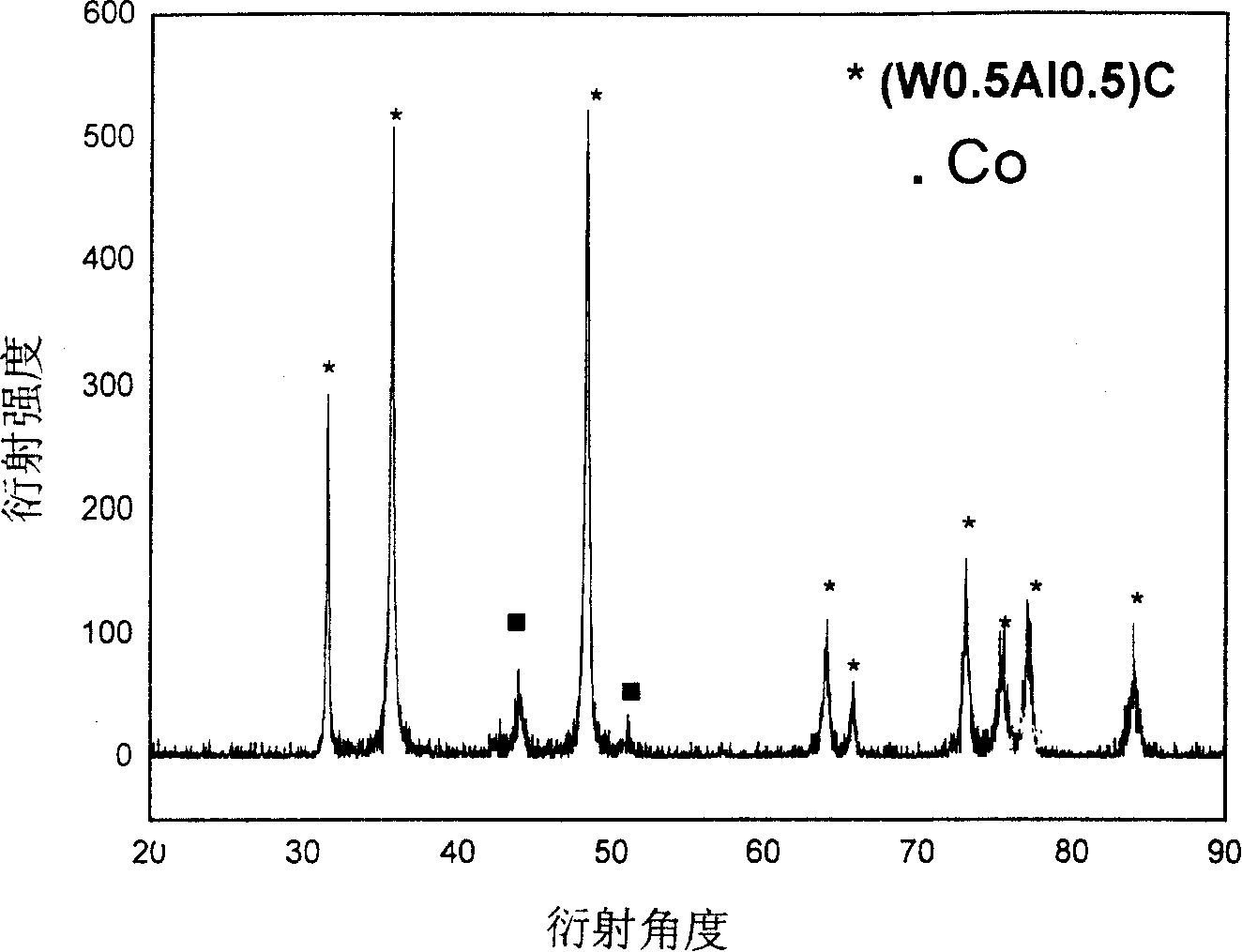

High-temperature solid phase reaction preparation of tungsten-aluminum carbide sosoloid powder

A process for preparing the sosoloid powder of tungst aluminium carbide by high-temp solid-phase reaction includes such steps as proportionally mixing W1-xAlx alloy with high-purity carbon powder, ball grinding, loading in graphite, crucible, heating to 1300-1600 deg.C in vacuum reductive atmosphere, or inertial at mosphere in solid-phase reactor, and holding the temp for 10-120 hr while ball grinding for 30-60 min at 5-10 hr of intervals. Its advantages are good crystal state, less impurity pollution, short time, and no noise.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Brake pad with good braking effect and manufacturing method thereof

InactiveCN105440567AAvoid stratificationReduce pollutionLaminationLamination apparatusMild heatHeat stability

A manufacturing method of a brake pad with a good braking effect relates to the technical field of brake pad production. The brake pad comprises a friction material and steel back. The friction material comprises the following raw materials: phenolic resin, cis-polybutadiene rubber, carbon fiber resin, talcum powder, zirconium silicide, aluminium carbide, barium sulfate, graphite, molybdenum disulfide, copper silicide, steel fibre, silicon carbide whisker, aramid fiber and molybdenum fibre. The manufacturing method comprises the following steps: burdening, mixing materials by a water method, carrying out pre-press forming and primary heat treatment to produce a friction material workblank; carrying out mild heat treatment, putting the friction material workblank into scalding hot oil to undergo scaling for 3-5 s, taking the friction material workblank out and cleaning with alcohol, and airing; carrying out steel back shot-blasting, and gluing steel back; carrying out hot press molding; and successively carrying out secondary heat-treatment, grinding, slotting chamfer, sand-blasting, and gluing silent blades. The brake pad of the invention has high strength, is oxidation resistant, and has long service life, good heat stability, high friction coefficient and good environmental protection property for production.

Owner:安徽创新电磁离合器有限公司

Modified terpolymer EP rubber containing cable sheath material and preparation method thereof

The invention discloses a modified terpolymer EP rubber containing cable sheath material and preparation method thereof, and the product comprises the following raw materials: modified terpolymer EP rubber, hydrogenated butadiene-acrylonitrile rubber, blast furnace slag, zeolite molecular sieve, aluminium carbide, promoter 808, promoter CZ, N-(beta-aminoethyl)-gamma-aminopropyl trimethoxysilane (triethoxysilane), barium ricinoleic acid, anti-oxidant 1010, diisobutyl phthalate and phosphate ester; the invention employs modified terpolymer EP rubber as main material, and the terpolymer EP rubber is modified, thereby the product has the characteristics of low-smoke, halogen free, flame retardation, high mechanical strength and high insulation resistor, moreover, the product has good elasticity and flexibility, simultaneously the nanometer attapulgite in the raw material is used as strengthening agent, and nanometer level titanium dioxide and aluminium carbide are used as filling materials.

Owner:东莞桥梓周氏电业有限公司

Method for preparing aluminum carbide from aluminum oxide

The invention relates to a method for preparing aluminum carbide from aluminum oxide, which comprises the steps of: mixing industrial pure aluminum oxide as a raw material with graphite as a reducing agent; then putting the mixture at a pressure of 1-200 Pa; heating the mixture to 1450-1600 DEG C for 60-120 min; then keeping the heat for 30-120 min; and cooling the mixture to obtain the aluminum carbide, wherein purity of the aluminum carbide is more than 90% and up to 96.38%. The method disclosed by the invention is finished in a vacuum environment; the obtained aluminum carbide is pure and free from impurities; and gas generated from reaction is controlled easily. As the aluminum oxide and the graphite carbon are adopted as reactive materials, the reactive materials are obtained easily and low in cost. The method for preparing aluminum carbide from aluminum oxide disclosed by the invention is short in aluminum carbide preparation technological process, clean, free from pollution, as well as simple and convenient in operation.

Owner:KUNMING UNIV OF SCI & TECH

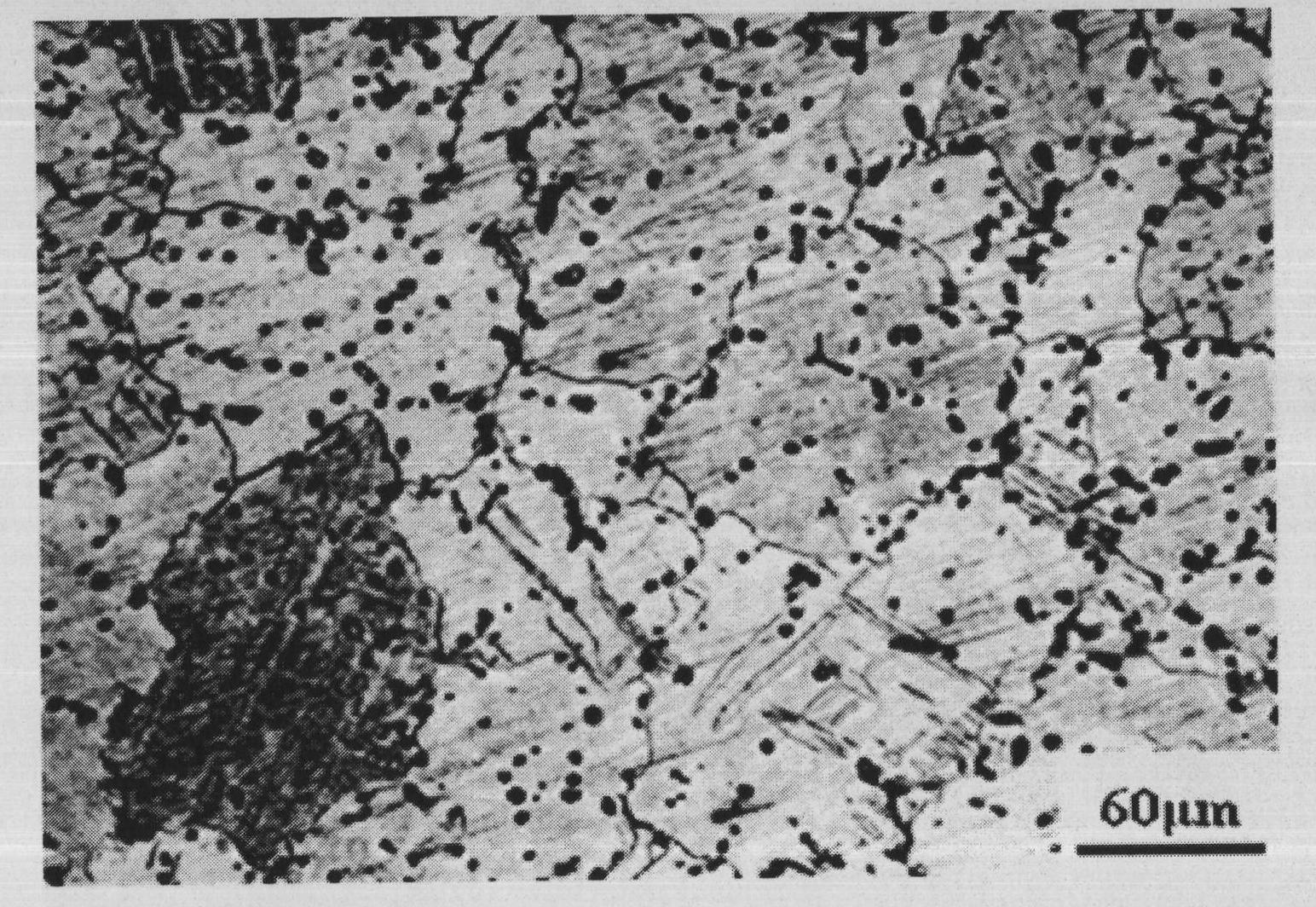

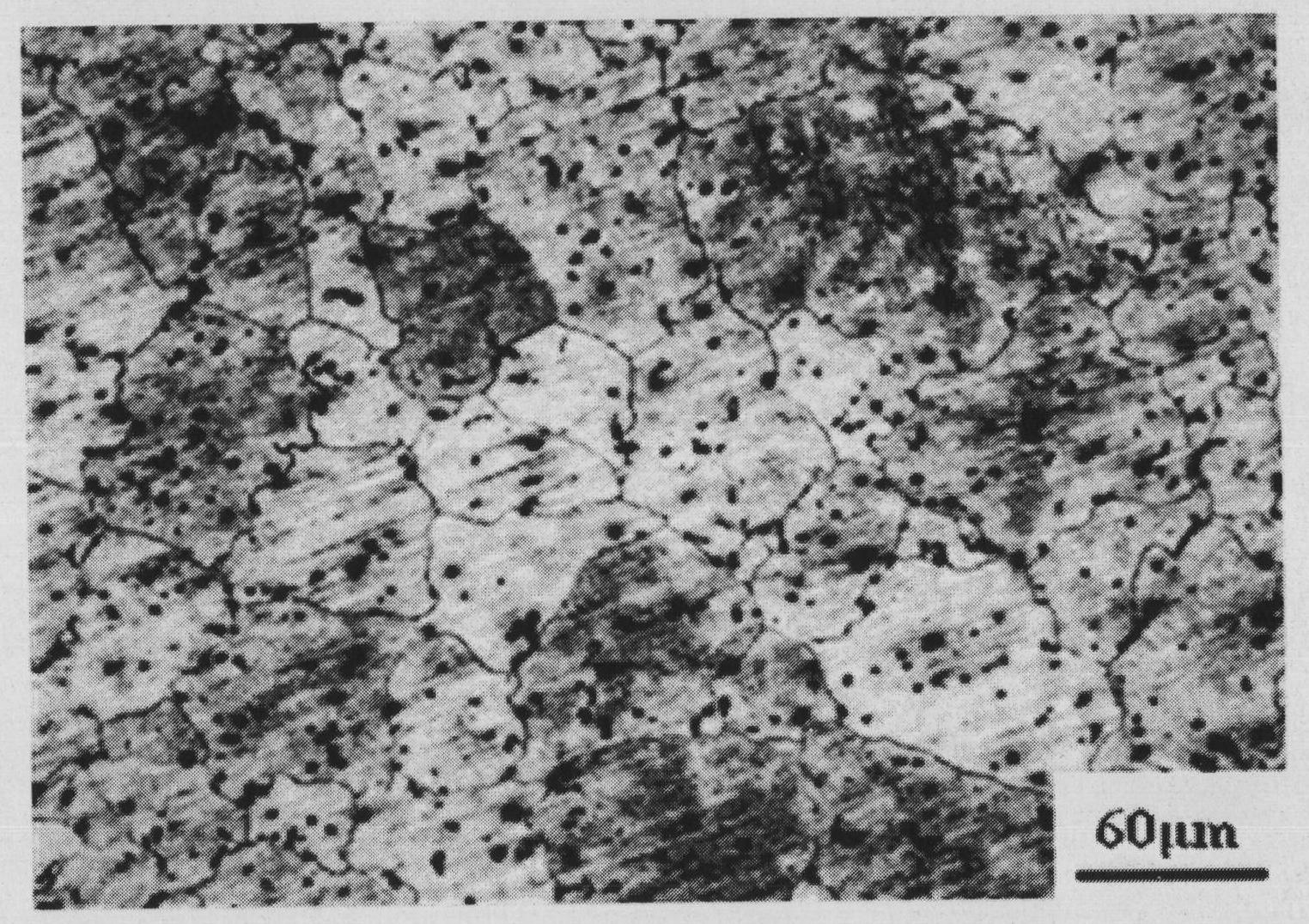

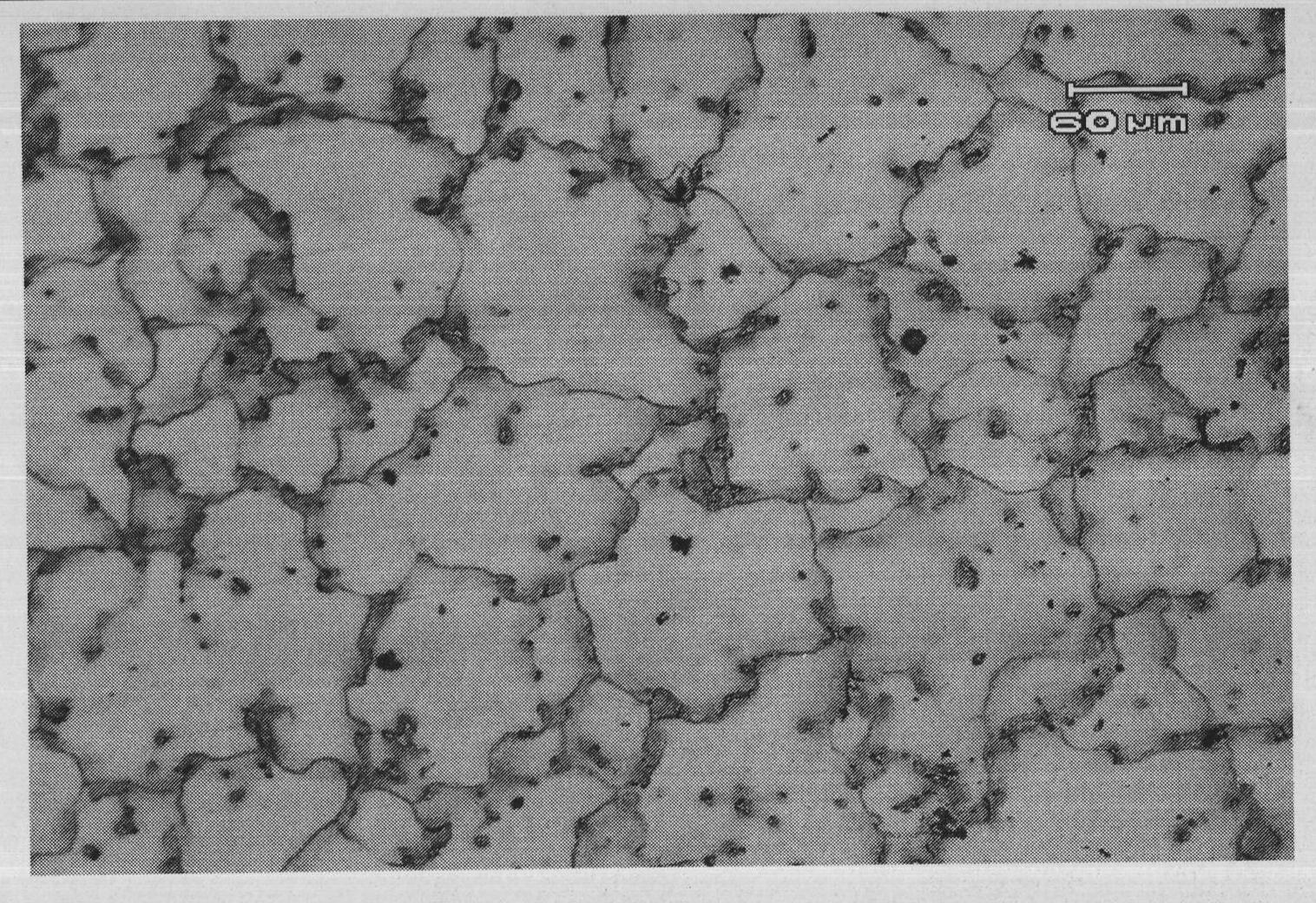

Aluminium tungsten carbide hard alloy sintered body

The invention relates to a tungsten-cemented aluminium carbide sintered body, and the expression is(W1-xAlx)C-Co, in which x=0.1-0.86, which is alloy block-shaped material with good crystalline shape and fine texture. Proved by X-ray powder diffraction analysis and scanning electron microscope analysis, the tungsten-cemented aluminium carbide sintered body is of stable structure, improved crystallinity and higher degree of compactness. The tungsten-cemented aluminium carbide sintered body of this invention not only has glass hard and high-wearing feature of tungsten carbide, but also has lightweight, oxidation resistance and fine ductility of aluminium, which makes the alloy have high hardness, high bending strength and lower density and develop into new carbide alloy with high hardness, high strength, good workability and high oxidation-resistance temperature. The said material is hoped to be used in mechanical tool, glass-cutting, bolt die, broaching die, bowl, well drill, mine drill, cutting drill and electrical contact material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Medical metal ceramic material and preparation method thereof

The invention belongs to the field of medical materials and discloses a medical metal ceramic material and a preparation method thereof. The medical metal ceramic material comprises 11-15 parts of zirconium oxide, 13-17 parts of titanium dioxide, 2-4 parts of nickel, 6-11 parts of magnesium silicate, 3-7 parts of cobalt, 2-4 parts of magnesium, 3-6 parts of tungsten silicide,2-4 parts of aluminum carbonate and 4-8 parts of calcium metasilicate. The preparation method comprises the following steps: (1) respectively ball-milling the metals and a ceramic material; (2) pouring into a high-speed mixture and mixing at a high speed; and (3) sintering in vacuum at a high temperature, firstly heating the inside of a high-temperature sintering furnace to the temperature of 725-755 DEG C, heating the inside of the high-temperature sintering furnace again to the temperature of 980-1220 DEG C, sintering for 2.5-3.5 hours, and cooling the metal ceramic material inside the high-temperature sintering furnace to room temperature to obtain the medical metal ceramic material.

Owner:LONGJU CEMENTED CARBIDE SUZHOU CO LTD

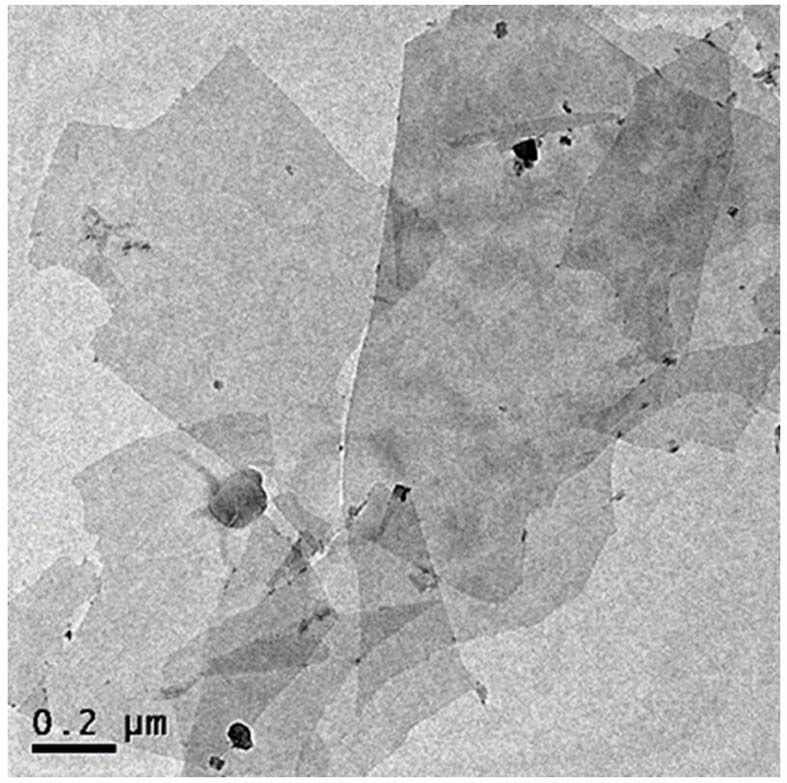

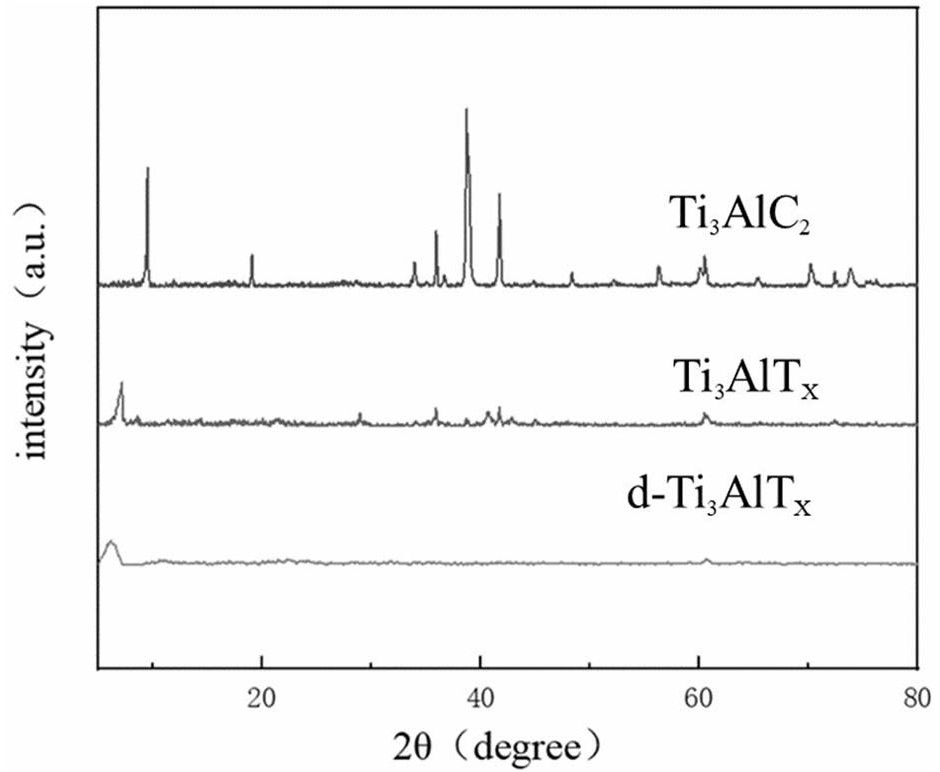

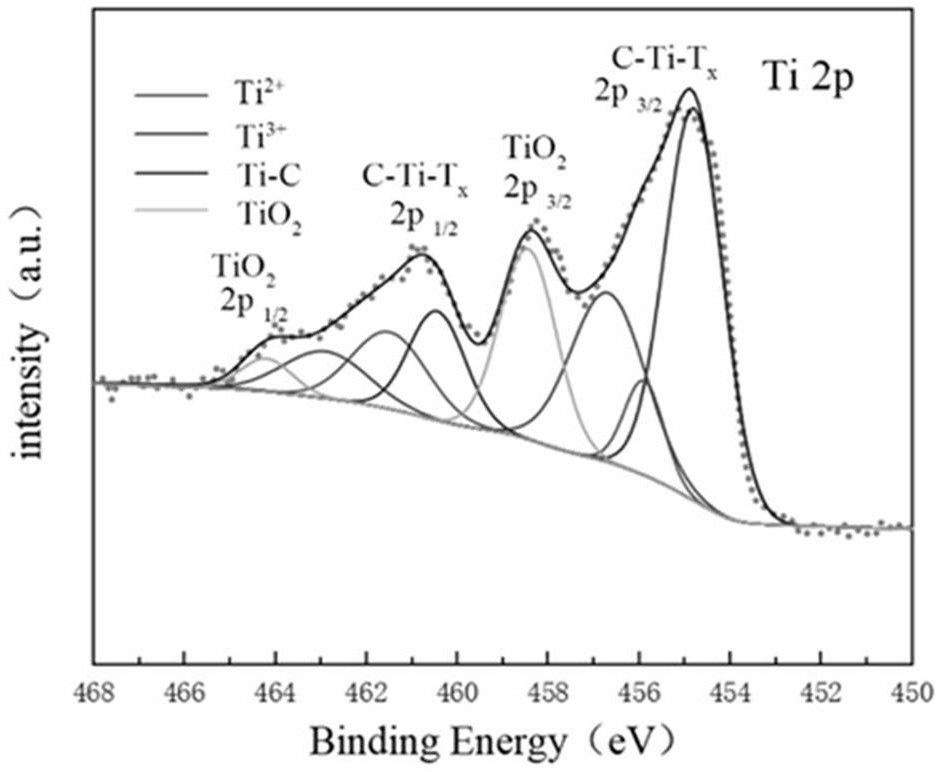

Preparation method and application of conductive paste based on two-dimensional nano titanium carbide

PendingCN112626630AImprove conductivityGood dispersionElectroconductive/antistatic filament manufactureFibre treatmentConductive pasteAluminium carbide

The invention relates to a preparation method and application of conductive paste based on two-dimensional nano titanium carbide. The preparation method comprises the steps of dissolving lithium fluoride in hydrochloric acid, adding titanium aluminum carbide, dispersing the obtained precipitate phase in absolute ethyl alcohol, performing ultrasonic treatment, dispersing in deionized water, performing ultrasonic treatment to obtain a dispersion liquid, performing centrifugal treatment to obtain an upper titanium carbide dispersion liquid, adding a settling agent, standing to obtain a precipitate product, dispersing in a base material solvent, adding a dispersing aid, and obtaining the two-dimensional nanometer titanium carbide conductive paste. A two-dimensional nano titanium carbide nanosheet is prepared by adopting an etching method, the nano titanium carbide conductive paste can be efficiently prepared through settling separation, and the nano titanium carbide conductive paste has good dispersion stability, conductivity and antistatic property, can be applied to manufacturing of conductive wires and flexible circuit printing, and realizes good conductivity and antistatic property of the base material.

Owner:JIANGSU NADN SCI TECH CO LTD

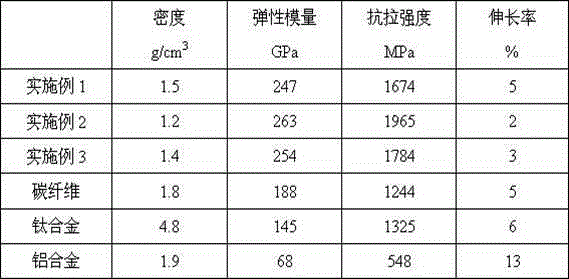

Light tough bicycle frame material and preparation method thereof

The invention discloses a light tough bicycle frame material and a preparation method thereof. The bicycle frame material is prepared from the following materials in parts by weight: 12-26 parts of nano aluminium carbide, 12-28 parts of carbon fiber, 8-25 parts of nano silica, 9-18 parts of polycarbonate, 7-16 parts of polyamide, 8-20 parts of boron fiber, 18-40 parts of carbon steel fiber, 6-19 parts of polystyrene, 6-14 parts of hexamethylene diisocyanate and 7-14 parts of polyetheretherketone fiber. Compared with the prior art, the bicycle frame material provided by the invention has the advantages that (1), the bicycle frame material is light, high in toughness and long in service life; (2), the bicycle frame material is low in production cost and inexpensive.

Owner:苏州天健竹业科技有限公司

Ceramic brake block

InactiveCN104214249ALow densityStrong wear resistanceOther chemical processesBraking membersPolyesterCarbon fibers

The invention discloses a ceramic brake block, which consists of the following ingredients in the following parts: 20 to 30 parts of alumina silicate fiber, 30 to 50 parts of glass fiber, 40 to 50 parts of carbon fiber, 30 to 35 parts of bamboo charcoal fiber, 50 to 80 parts of ceramic fiber, 20 to 25 parts of asbestos fiber, 30 to 40 parts of polyester fiber, 40 to 45 parts of polyacrylonitrile fiber, 20 to 25 parts of polyvinyl alcohol fiber, 10 to 15 parts of polypropylene fiber, 15 to 25 parts of ultra to high molecular weight polyethylene fiber, 10 to 15 parts of sepiolite fiber, 20 to 25 parts of fibrilia, 15 to 18 parts of viscose, 5 to 10 parts of hollow particles, 4 to 6 parts of glass particles, 5 to 7 parts of silicon carbide, 5 to 8 parts of aluminium carbide, 2 to 5 parts of silicon dioxide, 2 to 5 parts of magnesium oxide, 3 to 6 parts of graphite, 10 to 12 parts of frictionpowder, 10 to 12 parts of reclaimed rubber, 8 to 10 parts of silicon carbide whiskers, 8 to 10 parts of magnesium borate whiskers and 6 to 8 parts of vanadium pentoxide. The ceramic brake block provided by the invention has the advantage that through the ingredient improvement matching and the composition, the technical problems of easy rustiness, higher noise, unstable high-temperature friction performance, easy locking or dragging friction, lower abrasion resistance performance and the like in the prior art are solved.

Owner:黄惠娟

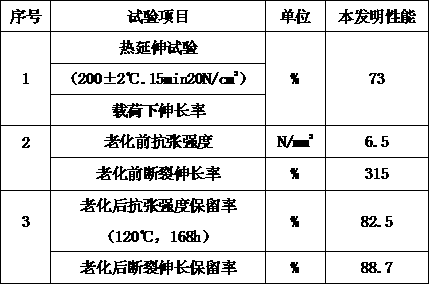

Cable sheath material containing modified chloroprene rubber CR322 and preparation method thereof

ActiveCN103289277AImprove performanceInsulated cablesInsulated conductorsDiphenyl phosphatePolymer science

The invention discloses a cable sheath material containing modified chloroprene rubber CR322 and preparation method thereof. The cable sheath material is composed of the following components: modified chloroprene rubber CR322, polyvinyl acetate, magnesium carbonate, bauxitic clay, aluminium carbide, promoter C-15E86, antioxidant OD, isopropyl tri(dioctylpyrophosphate) titanate, zinc stearate, anti-oxidant DSTP, diphenyl isophthalate and cresyl diphenyl phosphate; the invention employs modified chloroprene rubber CR322 as main material, therefore, the cable sheath has better tensile strength, fracture elongation percentage, tensile strength conservation rate after aging and fracture stretch maintenance rate, impact brittle temperature and excellent performance, and magnesium carbonate in the material is used as strengthening agent, and bauxitic clay and aluminium carbide are used as filling materials.

Owner:山东省未来人才发展有限公司

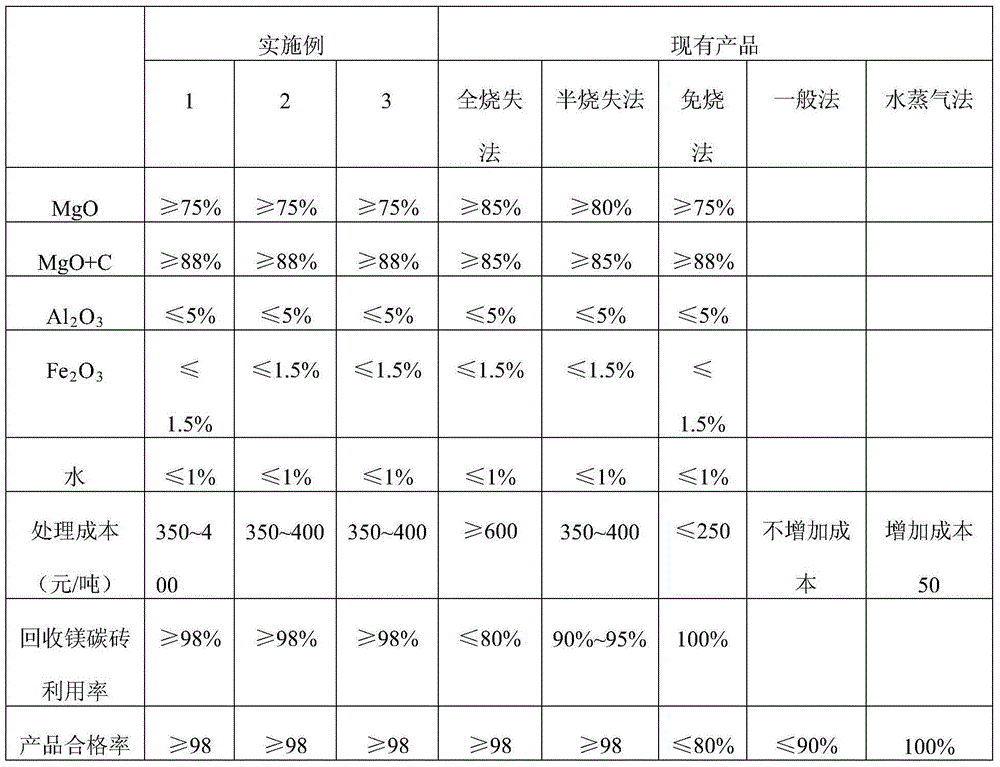

Heat treatment method after magnesia carbon brick recovery

The invention discloses a heat treatment method after magnesia carbon brick recovery. The heat treatment comprises the following steps: firstly, selecting magnesia carbon bricks and removing sundry bricks and impurities attached on the magnesia carbon bricks; secondly, performing watering treatment on the collected magnesia carbon bricks; thirdly, putting the watered magnesia carbon bricks into a semi-sealed device, heating to 500-800 DEG C from the room temperature at a rate of 5-20 DEG C per minute and then carrying out heat-retaining heat treatment, wherein the heat retaining time ranges from 6 to 24 hours; crushing the magnesia carbon bricks after the heat treatment and removing iron to obtain magnesia carbon powder. The heat treatment method is characterized in that the non-dried used recycled magnesia carbon bricks are subjected to semi-sealed type heat treatment, in a semi-sealed iron housing, water in the used recycled magnesia carbon bricks is heated to form water vapor which is not discharged immediately and formed into high-pressure water vapor, the high-pressure water vapor promotes hydration of aluminum carbide in the used recycled magnesia carbon bricks, and therefore, an independent water vapor treatment process is reduced and the treatment cost of the used recycled magnesia carbon bricks is reduced; meanwhile, in the meantime, the oxidization loss of graphite in the used recycled magnesia carbon bricks is reduced and the utilization rate of the used recycled magnesia carbon bricks is increased.

Owner:WUGANG REFRACTORY CO LTD

Aluminium nitride-based multi-element nano-composite ceramic die material and preparation method thereof

The invention discloses an aluminium nitride-based multi-element nano-composite ceramic die material and a preparation method thereof. The material comprises the following raw materials in parts by weight: 60-80 parts of aluminium nitride, 10-20 parts of aluminium carbide, 15-25 parts of silicon boride, 2-6 parts of scandium oxide, 4-8 parts of neodymium oxide, 2-4 parts of chromium, 1-3 parts of tungsten and 1-3 parts of nickel, wherein nanoscale powder of all the materials is adopted; the grain size of aluminium nitride is 10-100 nanometers; the grain sizes of aluminium carbide and silicon boride are 1-10 nanometers; the grain sizes of the other raw materials are 1-100 nanometers. The preparation method is characterized by using aluminium nitride as the matrix, adding aluminium carbide and silicon boride as reinforcing phases, scandium oxide and neodymium oxide as stabilizing agents and chromium, tungsten and nickel as sintering aids and carrying out hot pressed sintering on the materials, thus preparing the material. A die has strong ageing and defect resistance, good comprehensive mechanical properties and excellent antifriction and wear resistance properties.

Owner:辽宁跨克石油装备有限公司

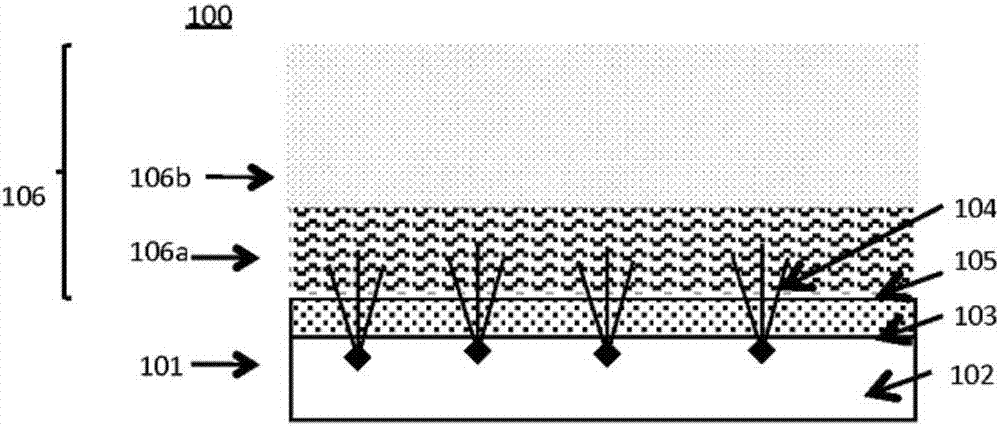

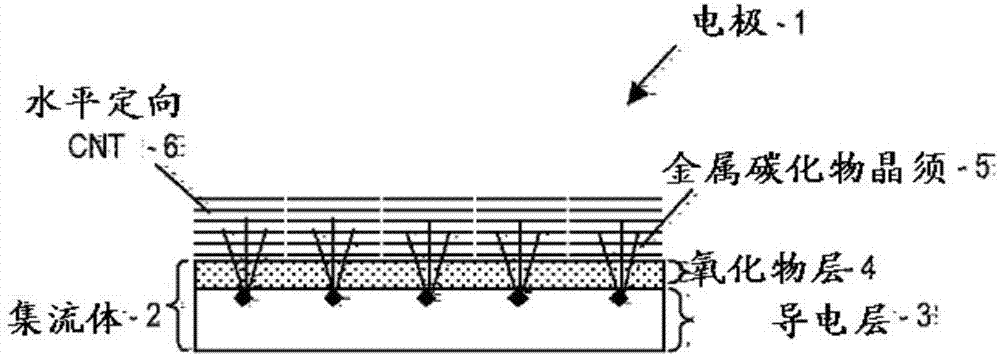

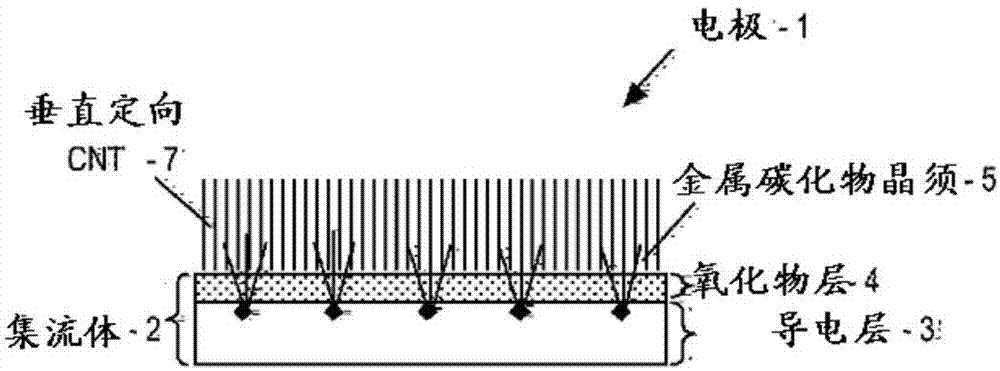

Nanostructured electrode for energy storage device

ActiveCN107533925AMaterial nanotechnologyHybrid capacitor electrodesAluminium carbideNano structuring

In one embodiment, an electrode is provided. The electrode includes a current collector comprising aluminum with an aluminum carbide layer on at least one surface, on which at least one layer of carbon nanotubes (CNTs) is disposed. The electrode may comprise vertically-aligned, horizontally-aligned, or nonaligned (e.g., tangled or clustered) CNTs. The electrode may comprise compressed CNTs. The electrode may comprise single-walled, double-walled, or multiwalled CNTs. The electrode may comprise multiple layers of CNTs.

Owner:FASTCAP SYST

A preparation method of in-situ composite aluminum-carbon refractory material containing titanium nitride

The invention belongs to the technical field of preparation of refractory materials and mainly relates to a preparation method of a titanium nitride-containing in-situ composite aluminum-carbon refractory material. The preparation method is characterized by comprising the following steps: preparing composite powder of metallic aluminum and titanium dioxide by means of a gelcasting method, wherein the composite powder is a precursor, and the precursor is mainly characterized in that metallic aluminum powder is coated with titanium dioxide; introducing the precursor which is 1-4wt% of the total weight of main raw materials aluminum oxide and graphite for preparing the aluminum-carbon refractory material into the raw materials of the aluminum-carbon refractory material and mixing together to obtain a blank; carrying out isostatic press moulding on the blank to obtain a aluminum-carbon refractory material green body; carrying out the heat treatment process in a protective gas, wherein the reaction 4Al+3TiO2+N2=2Al2O3+Ti3N4 is carried out in the heat treatment process, aluminothermic reaction is facilitated since metallic aluminum powder is coated with titanium dioxide, and meanwhile generation of aluminum carbide is greatly reduced and pulverization of powder is greatly reduced, and the reaction generates two ceramic combination phases Al2O3 and Ti3N4; and finally forming the titanium-containing nitride in-situ composite aluminum-carbon refractory material.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

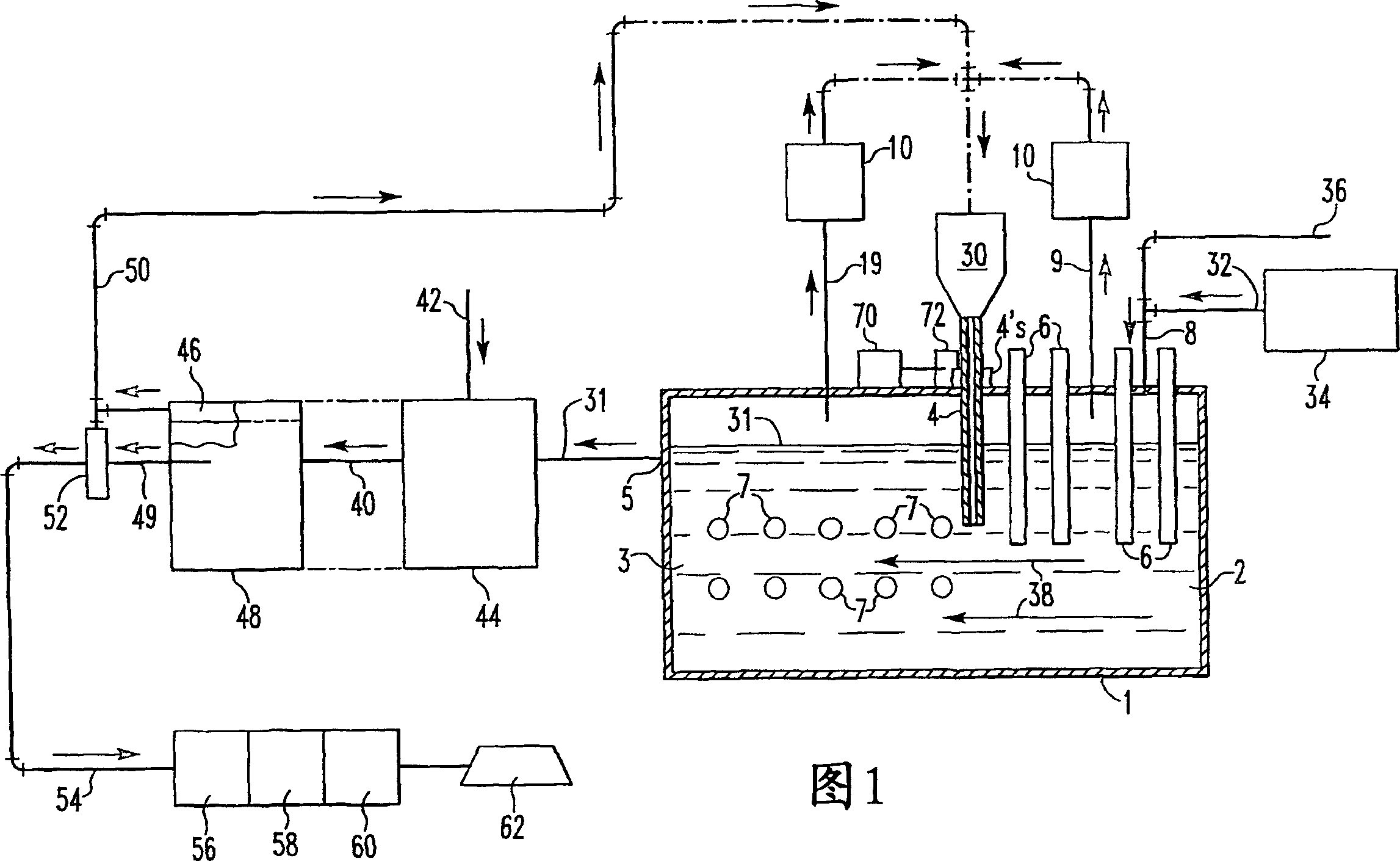

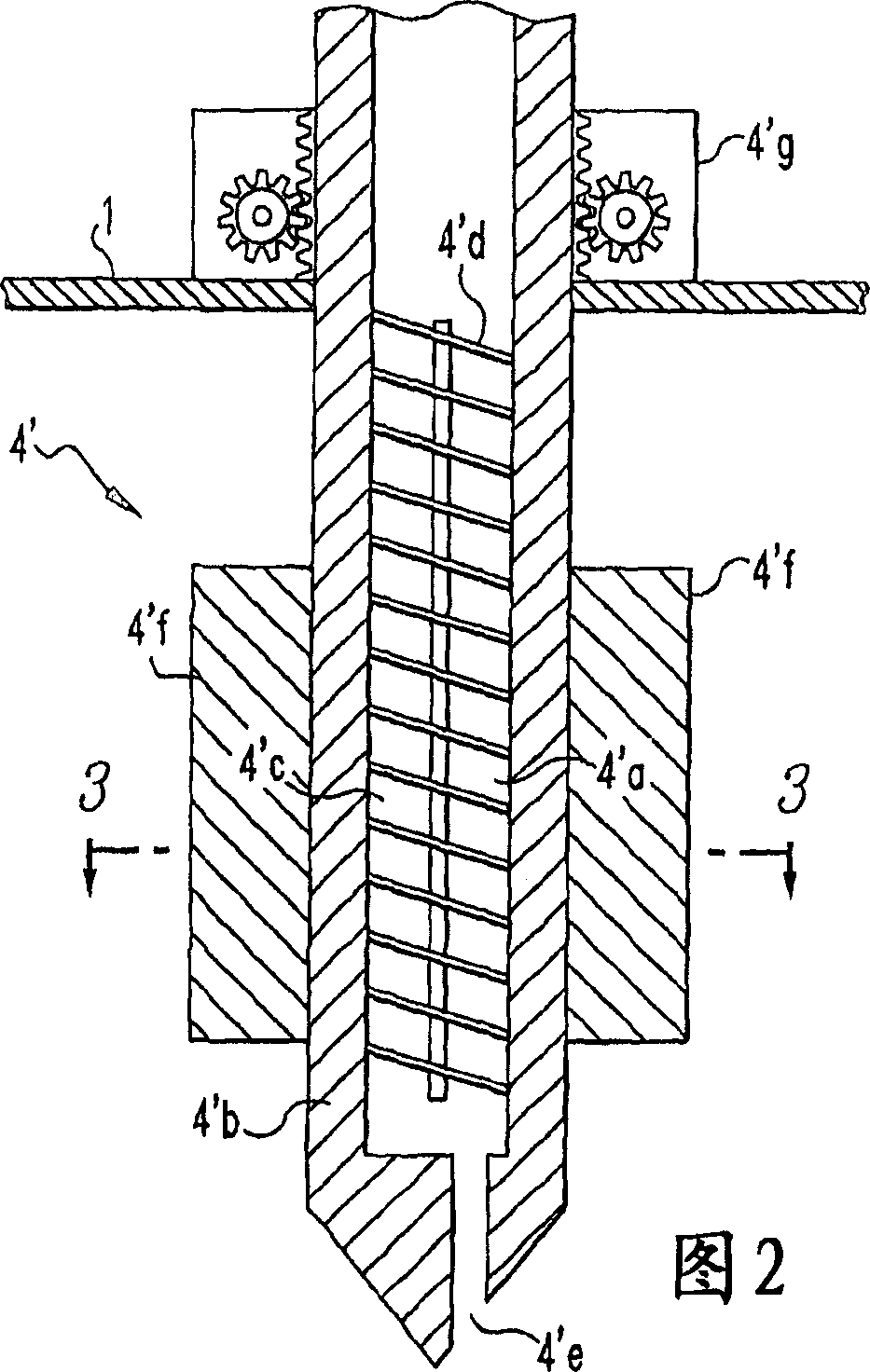

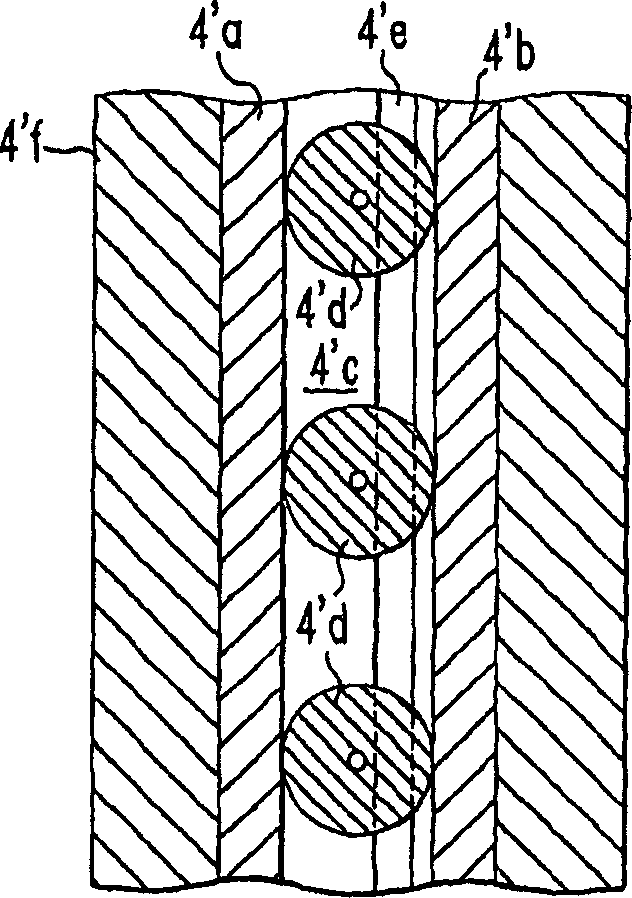

Method and reactor for production of aluminum by carbothermic reduction of alumina

A hollow partition wall (4) is employed to feed carbon material to an underflow of a carbothermic reduction furnace used to make aluminum. The partition wall (4) divides a low temperature reaction zone (2) where aluminum oxide is reacted with carbon to form aluminum carbide and a high temperature reaction zone (3) where the aluminum carbide and remaining aluminum oxide are reacted to form aluminum and carbon monoxide.

Owner:ARCONIC INC +1

Aluminium tungsten carbide hard alloy sintered body

The invention relates to a tungsten-cemented aluminium carbide sintered body, and the expression is(W1-xAlx)C-Co, in which x=0.1-0.86, which is alloy block-shaped material with good crystalline shape and fine texture. Proved by X-ray powder diffraction analysis and scanning electron microscope analysis, the tungsten-cemented aluminium carbide sintered body is of stable structure, improved crystallinity and higher degree of compactness. The tungsten-cemented aluminium carbide sintered body of this invention not only has glass hard and high-wearing feature of tungsten carbide, but also has lightweight, oxidation resistance and fine ductility of aluminium, which makes the alloy have high hardness, high bending strength and lower density and develop into new carbide alloy with high hardness, high strength, good workability and high oxidation-resistance temperature. The said material is hoped to be used in mechanical tool, glass-cutting, bolt die, broaching die, bowl, well drill, mine drill, cutting drill and electrical contact material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Metal cutting gas

InactiveCN102229826ALow temper rateWide variety of sourcesGaseous fuelsGas flame welding apparatusMetallurgyOxygen

The invention discloses a metal cutting gas, composed of fuel gas and a synergistic agent, wherein the synergistic agent is composed of aluminium carbide, ferrocene, methyl alcohol and MDPE (medium density polyethylene). The metal cutting gas disclosed by the invention has high combustion temperature and good cutting quality and can be completely combusted in the air, the combustion efficiency of the metal cutting gas in oxygen is higher, the temperature can reach about 3300 DEG C, the cutting accuracy is higher, and the grinding process is reduced, thus the product quality is improved; the environmental pollution is less, and extremely less CO or SO2 is produced, thus pollution is greatly reduced; air sources are wide, the application is safe, and the tempering rate is extremely low when the cutting gas is used, thus being very safe; the cutting gas is lighter than air and can directly enter a room to carry out welding and cutting; and the application scope is wide, the selection range of the fuel gas in the cutting gas is wide, and the requirement to the purity of each fuel gas is low.

Owner:JIYUAN JIGANG GASOLINEEUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com