High-temperature solid phase reaction preparation of tungsten-aluminum carbide sosoloid powder

A high-temperature solid-state reaction and tungsten carbide-aluminum technology, which is applied in the field of high-temperature solid-state reaction preparation of tungsten carbide-aluminum solid solution powder, can solve the problems of complex equipment, difficult mass production, and many impurities, and achieve less impurity pollution and good crystallization , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1: the W 0.95 al 0.05 Alloy powder, purity greater than 97%, and carbon powder, particle size less than 300 mesh, purity greater than 95%, according to W 0.95 al 0.05 C weighing, C excess 6%, the total amount of raw materials is 15 grams, after ball milling and mixing, put it into a graphite crucible, then put it into a solid-phase reaction furnace, and heat it up to 1600 ° C under vacuum. After 5 hours of reaction, it was taken out and ball milled for 30 minutes. After another 5 hours of reaction, the product W can be obtained 0.95 al 0.05 c.

Embodiment 2

[0009] Example 2: the W 0.75 al 0.25 Alloy powder, the purity is the same as W 0.95 al 0.05 , same as carbon powder, particle size and purity, press W 0.75 al 0.25 C weighing, C excess 8%, the total amount of raw materials is the same as before, ball milling and mixing, put it into a graphite crucible, then put it into a solid-phase reaction furnace, under the protection of an inert gas, heat up to 1550 ° C, and take it out every 7 hours. Ball mill for 40 minutes. The total holding time reaches 14 hours to obtain the product W 0.75 al 0.25 c.

Embodiment 3

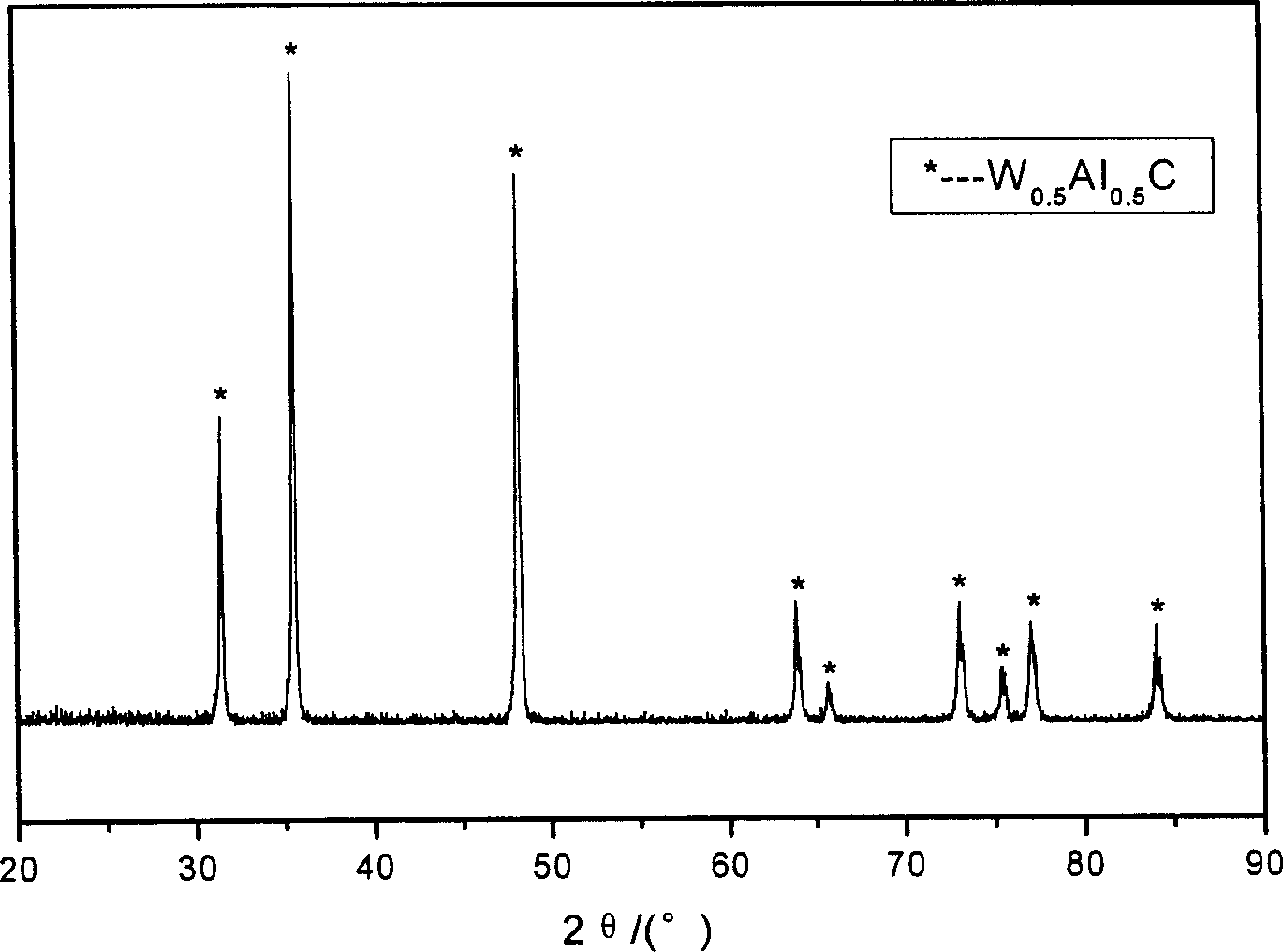

[0010] Example 3: W 0.5 al 0.5 Alloy powder, the purity is the same as W 0.95 al 0.05 , same as carbon powder, particle size and purity, press W 0.5 al 0.5 C is weighed, C is over 10%, and the total amount of raw materials is the same as before. After ball milling and mixing, put it into a graphite crucible, then put it into a solid-phase reaction furnace, and raise the temperature to 1450°C under the protection of a hydrogen reducing atmosphere. Every 10 hours of heat preservation, the ball was taken out and milled for 60 minutes, and the product W was obtained after 70 hours of reaction. 0.5 al 0.5 c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com