Electron emission device, manufacturing method thereof and display

一种电子发射装置、电子发射的技术,应用在电极系统制造、放电管/灯的制造、图像/图形显示管等方向,能够解决电子发射率低、平均动能高等问题,达到提高电子出射率、提高出射率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The electron emission source, electron emission device and display according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

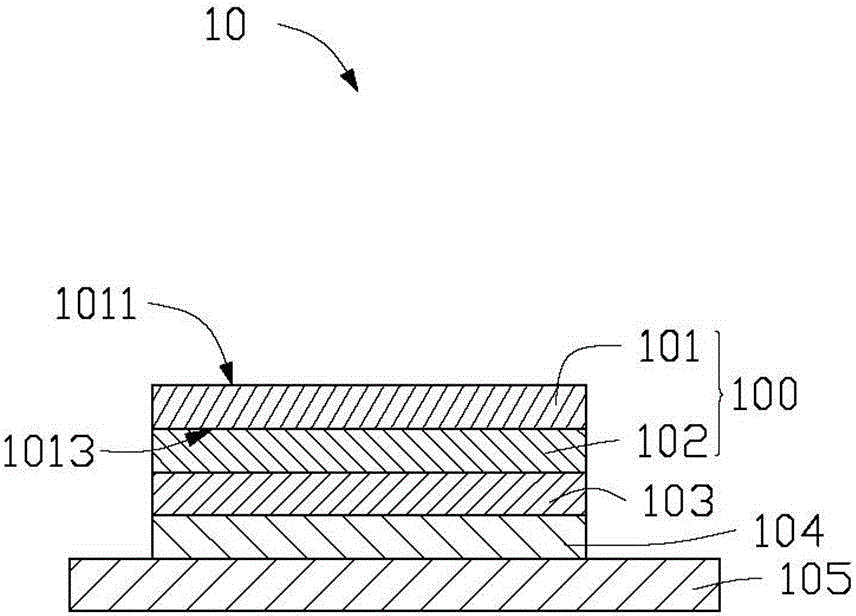

[0030] see figure 1 , The first embodiment of the present invention provides an electron emission source 10 , which includes: a first electrode 100 , an insulating layer 103 , and a second electrode 104 . The insulating layer 103 is stacked between the first electrode 100 and the second electrode 104 . The first electrode 100 is an electron emission end of the electron emission source 10 .

[0031] Further, the electron emission source 10 can be disposed on the surface of a substrate 105 , and the second electrode 104 is disposed on the surface of the substrate 105 . The substrate 105 is used to support the electron emission source 10 . The material of the substrate 105 can be selected from hard materials such as glass, quartz, ceramics, diamond, silicon wafers, or fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com