Titanium suboxide/MXene/Co3O4 composite electrode and preparation method thereof

A titanium oxide, composite electrode technology, applied in the field of electrochemistry, can solve the problems of nanoparticle agglomeration, difficult to recycle, increase cost, etc., and achieve the effect of increasing ion concentration, enhancing electrical conductivity, and increasing electron transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

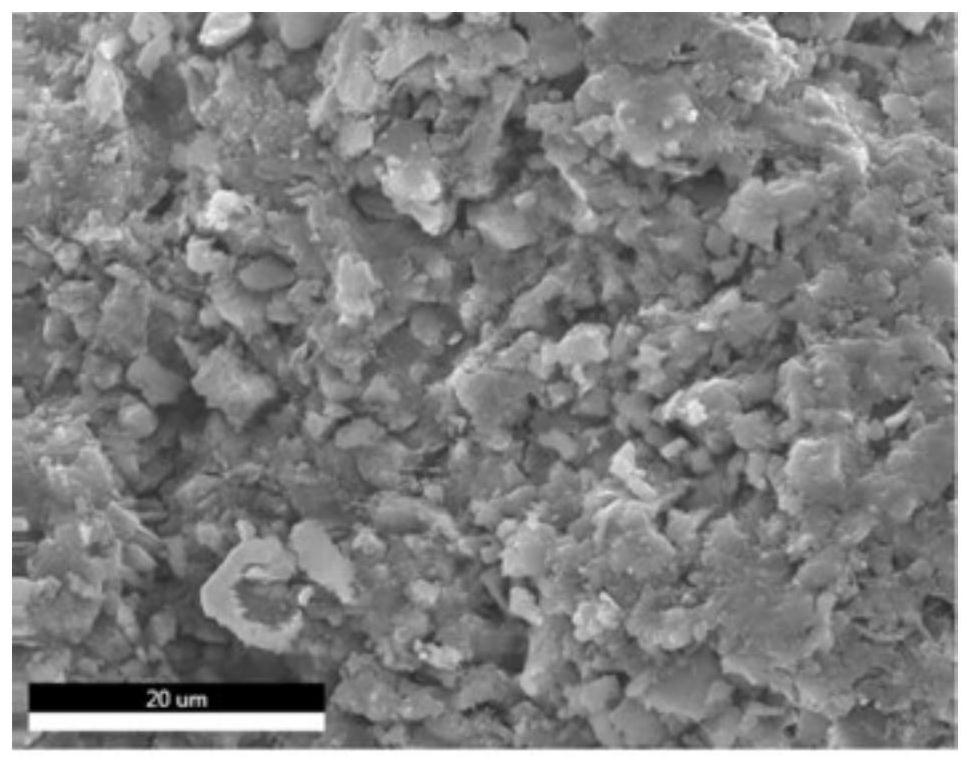

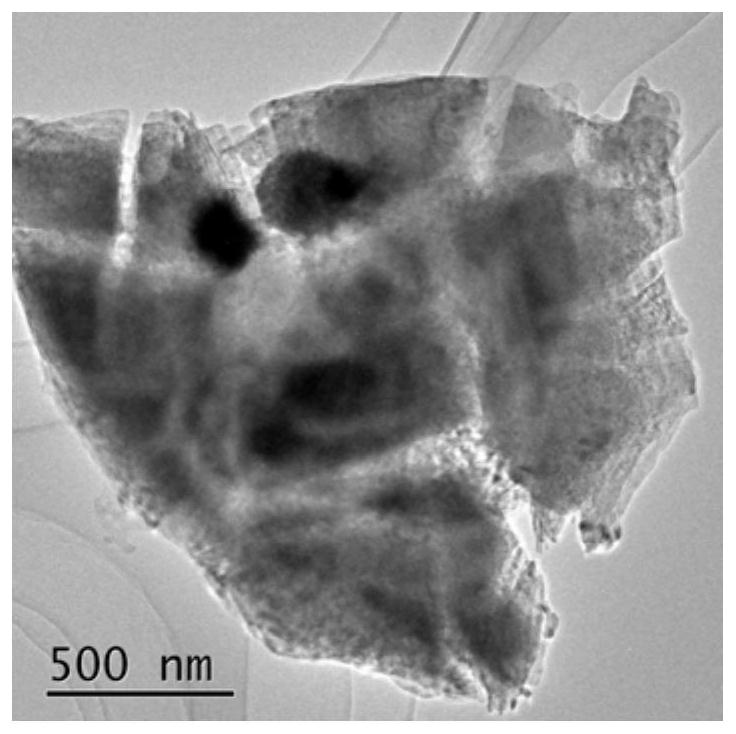

Image

Examples

Embodiment 1

[0032] Step 1: Weigh 90% TiO2, 9% MXene, 1% Co 3 o 4 , placed in a vortex shaker for 3 minutes to obtain 2 g of mixed powder.

[0033] Step 2: Put the mixed powder in a vacuum plasma sintering furnace, set the vacuum pressure to 45Pa, the sintering temperature to 500°C, the sintering pressure to 1.5MPa, and the sintering time to 12 minutes to obtain titanium dioxide / MXene / Co 3 o 4 composite electrode.

[0034] In this scheme, the titanium oxide is Ti 4 o 7 ; the Co 3 o 4 The average particle size of the MXene is 50nm; the above-mentioned MXene is purchased from Jilin Yiyi Technology Co., Ltd.; Co 3 o 4 purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

Embodiment 2

[0036] Step 1: Weigh 88% titanium dioxide, 10% MXene, 2% Co 3 o 4 , placed in a vortex shaker for 4 minutes to obtain 2 g of mixed powder.

[0037] Step 2: Put the mixed powder in a vacuum plasma sintering furnace, set the vacuum pressure to 55Pa, the sintering temperature to 600°C, the sintering pressure to 2MPa, and the sintering time to 15 minutes to obtain titanium dioxide / MXene / Co 3 o 4 composite electrode.

[0038] In this scheme, the titanium oxide is Ti 5 o 9 ; the Co 3 o 4 The average particle size of the MXene is 80nm; the above-mentioned MXene is purchased from Jilin Yiyi Technology Co., Ltd.; Co 3 o 4 purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

Embodiment 3

[0040] Step 1: Weigh 85% TiO2, 10% MXene, 5% Co 3 o 4 , placed in a vortex shaker for 2 minutes to obtain 2 g of mixed powder.

[0041] Step 2: Put the mixed powder in a vacuum plasma sintering furnace, set the vacuum pressure to 25Pa, the sintering temperature to 400°C, the sintering pressure to 1M Pa, and the sintering time to 10 minutes to obtain titanium dioxide / MXene / Co 3 o 4 composite electrode.

[0042] In this scheme, the titanium oxide is Ti 4 o 7 and Ti 5 o 9 Two mixtures; the Co 3 o 4 The average particle size of the MXene is 20nm; the above-mentioned MXene is purchased from Jilin Yiyi Technology Co., Ltd.; Co 3 o 4 purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com