Method and reactor for production of aluminum by carbothermic reduction of alumina

A technology of reactor and aluminum carbide, which is applied in the field of producing aluminum by carbothermal reduction of alumina and the reactor field, which can solve the problems of aluminum yield loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

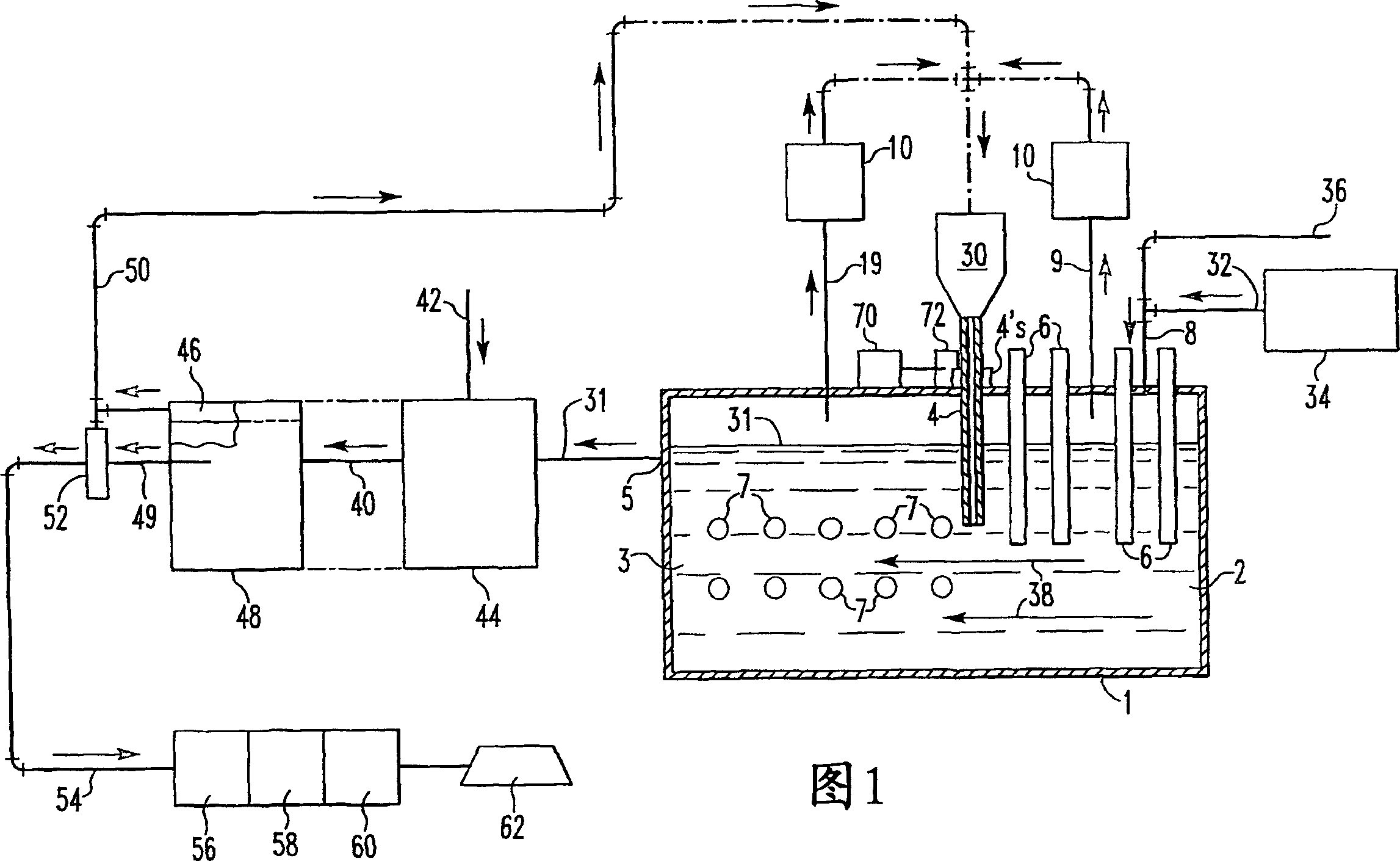

[0020] Figure 1 shows a generally rectangular, airtight reaction vessel 1 divided into a low-temperature compartment 2 and a high-temperature compartment 3 by a hollow underflow partition 4 which allows a molten bath to flow from the low-temperature compartment 2. The flow is to the high temperature compartment 3 and additional carbon material is added to the flow of the molten bath as the molten bath passes below the partition 4 . At one end of the high-temperature compartment 3 opposite to the low-temperature compartment 2 , an outlet 5 is arranged for leading out or taking out the molten aluminum layer 31 . The molten bath flows from the low temperature compartment 2 to the high temperature compartment 3 by gravity. This flow is influenced and regulated by tapping the aluminum 31 at the outlet 5 . When the aluminum is withdrawn from the high temperature compartment, a corresponding amount of molten bath flows from the low temperature compartment into the high temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com