Aluminium tungsten carbide hard alloy sintered body

A tungsten carbide-aluminum and cemented carbide technology is applied in the field of tungsten carbide-aluminum cemented carbide sintered bodies, which can solve the problems of difficult to achieve high-density sintering, and achieve the effects of excellent oxidation resistance, high hardness and short sintering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: with 30 grams of (W 0.9 Al 0.1 ) C and 3 grams of cobalt powder are mixed and put into graphite moulds, and the weight ratio of the two is 10; 1, at 10 -1 MPa~10 -2 Sintering under MPa vacuum condition, the sintering temperature is 1600°C, the pressure is 37.5MPa, the sintering time is 30 minutes, the sample is polished, and the relative density is 98%. Microhardness 2200Kg / cm 3 , Bending strength 1573MPa.

Embodiment 2

[0014] Embodiment 2: the weight is 25 grams (W 0.75 Al 0.25 ) C and a quality of 2.50 grams of cobalt powder are mixed and put into graphite moulds. -1 MPa~10 -2 Sintering under MPa vacuum condition, the sintering temperature is 1500°C, the pressure is 35.5MPa, and the sintering time is 25 minutes. The samples were polished and had a relative density of 97%. Microhardness 2035Kg / cm 3 , Bending strength 1421MPa.

Embodiment 3

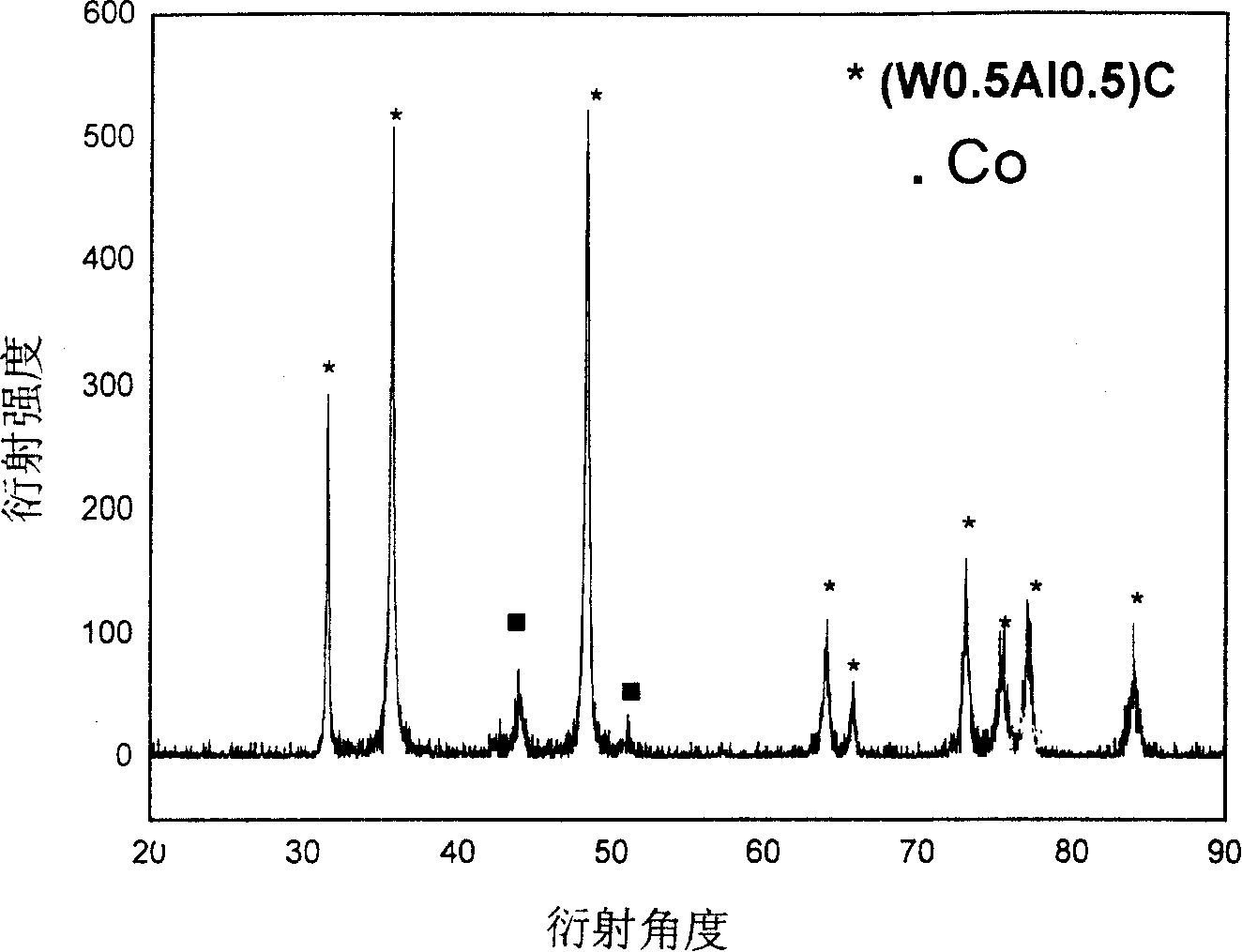

[0015] Embodiment 3: the weight is 20 grams (W 0.5 Al 0.5 ) C and a quality of 2.00 grams of cobalt powder are mixed and put into graphite moulds. The proportioning ratio of the two weights is 10. -1 MPa~10 -2 Sintering under MPa vacuum condition, the sintering temperature is 1450°C, the pressure is 35.5MPa, and the sintering time is 30 minutes. The samples were polished and had a relative density of 98%. Microhardness 1650Kg / cm 3 , Bending strength 1337MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com