Preparation method of carbon nanotube composite materials

A carbon nanotube and composite material technology, which is applied in the field of carbon nanotube composite material preparation, can solve the problems of carbon nanotube damage, weakened carbon nanotube load transfer effect, etc., and achieves the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

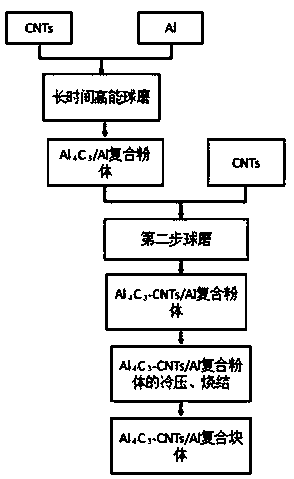

[0023] The present invention provides a novel CNTs-Al 4 C 3 / Al composite material and preparation method thereof, comprising the following steps;

[0024] (1) Preparation of Al 4 C 3 / Al composite powder: put carbon nanotubes (purity 95%, 10 μm) and pure aluminum powder (purity 99.5%, average particle size 25 μm) together with a certain number of grinding balls in a ball mill jar under an inert gas protective atmosphere. The quality of the carbon nanotube powder is 1wt.% of the total mass of the mixed powder, and a small amount of stearic acid is added as a process control agent; the ball-to-material ratio is 10:1, and the speed of the ball mill is 250 r / min; The temperature rise of the ball mill, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes, so that the cycle is carried out, and the cumulative high-energy ball milling takes 24 hours to make carbon nanotubes and pure aluminum powder react to form nano-Al in situ...

Embodiment 2

[0029] (1) Preparation of Al 4 C3 / Al composite powder: carbon nanotubes (purity 95%, 20 μm) and pure aluminum powder (purity 99.5%, average particle size 30 μm) together with a certain number of balls are placed in a ball mill jar under an inert gas protective atmosphere, among which The quality of the carbon nanotube powder is 1.5wt.% of the total mass of the mixed powder, and a small amount of stearic acid is added as a process control agent; the ball-to-material ratio is 10:1, and the ball mill speed is 250 r / min; For the temperature rise of the body, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes. This cycle is carried out. The cumulative high-energy ball milling takes 24 hours to make carbon nanotubes and pure aluminum powder react to form nano-Al in situ. 4 C 3 particles. In order to obtain nano-Al 4 C 3 Composite powder of particles;

[0030] (2) Preparation of CNTs-Al 4 C 3 / Al composite powder: combin...

Embodiment 3

[0035] (1) Preparation of Al 4 C 3 / Al composite powder: carbon nanotubes (purity 95%, 30 μm) and pure aluminum powder (purity 99.5%, average particle size 20 μm) together with a certain number of balls are placed in a ball mill jar under an inert gas protective atmosphere, among which The quality of the carbon nanotube powder is 2wt.% of the total mass of the mixed powder, and a small amount of stearic acid is added as a process control agent; the ball-to-material ratio is 10:1, and the ball mill speed is 250 r / min; The temperature rise of the ball mill, the ball mill rotates forward for 30 minutes, then pauses for 30 minutes, and then reverses for 30 minutes, so that the cycle is carried out, and the cumulative high-energy ball milling takes 24 hours to make carbon nanotubes and pure aluminum powder react to form nano-Al in situ 4 C 3 Particles; thereby obtaining nano-Al 4 C 3 Composite powder of particles;

[0036] (2) Preparation of CNTs-Al 4 C 3 / Al composite powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com