Method for preparing aluminum carbide from aluminum oxide

A technology of alumina and aluminum carbide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of not using mature technology, and achieve the effects of low cost, simple operation and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A. Take a total of 80g of alumina and graphite according to the mass ratio of industrial pure alumina powder and graphite as 3:1, mix them evenly, and make it under the pressure of 3Mpa 20mm×10mm block;

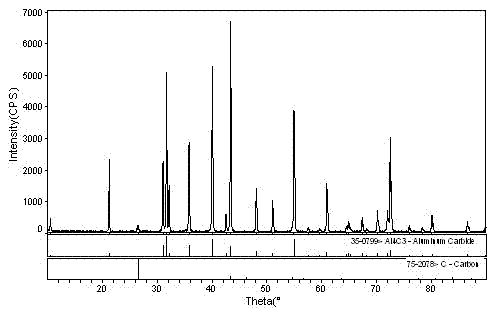

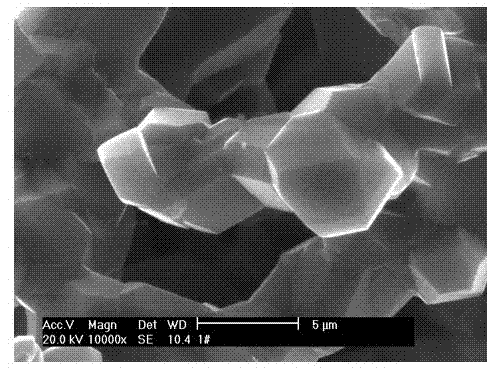

[0020] B. Put the bulk material obtained in step A under vacuum, maintain the pressure at 50Pa, heat up to 1550°C after 120min, and keep it warm for 60min. After cooling, 41.8g of aluminum carbide is obtained. The purity of aluminum carbide is over 90% according to SEM and EDS analysis .

Embodiment 2

[0022] A. According to the mass ratio of industrial pure alumina powder and graphite as 5:1, take 60g of alumina and graphite, mix them evenly, and make them under the pressure of 8Mpa 20mm×10mm block;

[0023] B. Put the bulk material obtained in step A under vacuum, maintain the pressure at 200Pa, heat up to 1600°C after 60 minutes, and keep it warm for 120 minutes. After cooling, 34.6g of aluminum carbide is obtained, and the purity of aluminum carbide reaches more than 94.57%.

Embodiment 3

[0025] A. Take a total of 80g of alumina and graphite according to the mass ratio of industrial pure alumina powder and graphite as 4:1, mix them evenly, and make them under a pressure of 10Mpa 20mm×10mm block;

[0026] B. Put the bulk material obtained in step A under vacuum, maintain the pressure at 1Pa, heat up to 1450°C after 80 minutes, and keep it warm for 30 minutes. After cooling, 42.6g of aluminum carbide is obtained, and the purity of aluminum carbide reaches more than 92.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com