Preparation method and application of conductive paste based on two-dimensional nano titanium carbide

A two-dimensional nanometer and titanium carbide technology, which is applied in the manufacture of conductive/antistatic filaments, fiber processing, textiles and papermaking, etc., can solve the problems of poor hygroscopicity of synthetic fibers, easy generation of static electricity, and easy adsorption of dust, etc., to achieve good conductivity performance, good electrical conductivity and antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

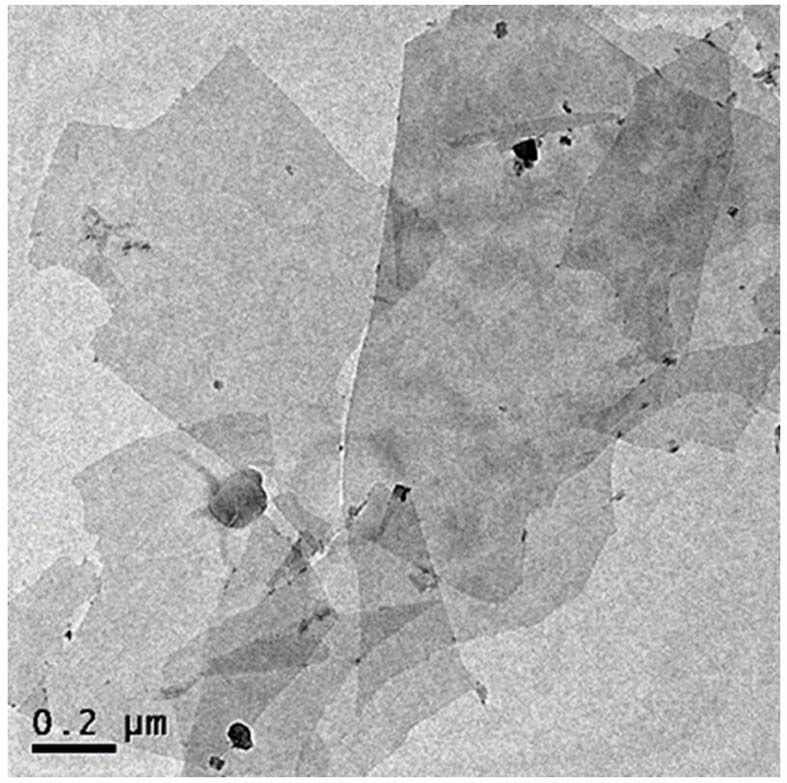

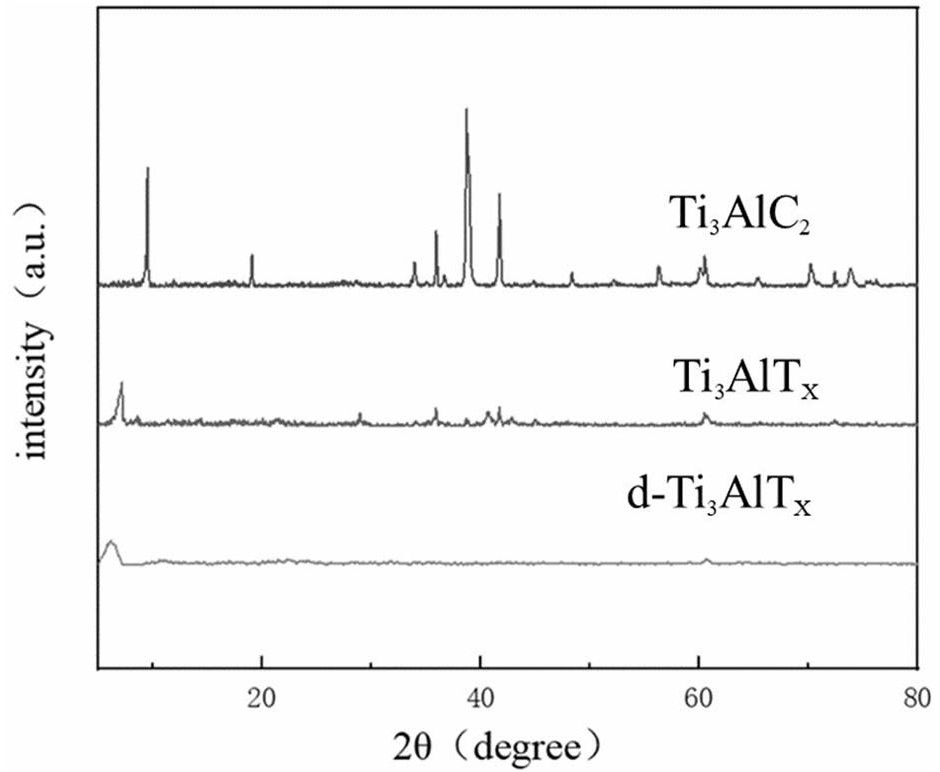

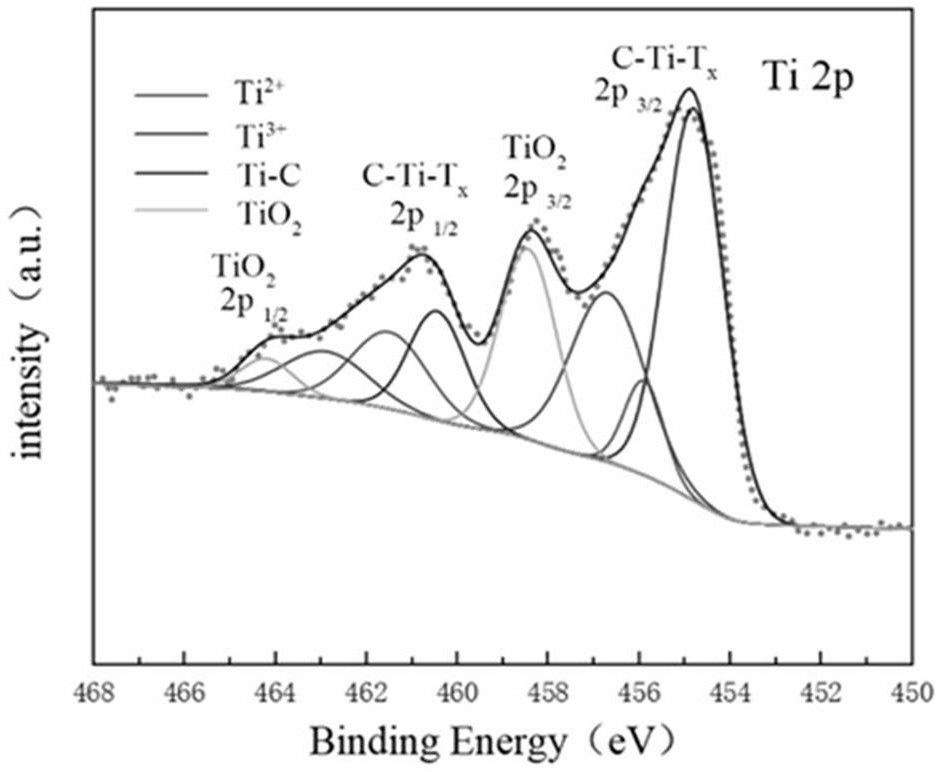

[0021] Accurately weigh 13 g of lithium fluoride and add it to a polytetrafluoroethylene beaker filled with 200 ml of hydrochloric acid (9M). After fully dissolving, slowly add 10 g of titanium aluminum carbide powder within ten minutes; seal the beaker and stir at 40 °C 18 h. The precipitate was separated by centrifugation, washed with water until pH>5, and then dispersed in 200 mL of absolute ethanol. Centrifuge after sonication for 1 h. The precipitate was dispersed in 1 L of deionized water and ultrasonicated for 30 min. After centrifugation at 3500 rpm for 5 min, the upper titanium carbide few-layer dispersion was obtained. Add 0.2 g of ammonium bicarbonate to the titanium carbide dispersion, let stand after stirring, centrifuge, collect the precipitate and wash with ethanol. Add 5 g of the precipitate to 100 mL of glycerin, then add 0.2 g of polyvinylpyrrolidone, stir for 3 h to make it well dispersed, and obtain nano-titanium carbide conductive paste.

[0022] See a...

Embodiment 2

[0027] Accurately weigh 16 g of lithium fluoride and add it to a polytetrafluoroethylene beaker filled with 200 ml of hydrochloric acid (9M). After fully dissolving, slowly add 10 g of titanium aluminum carbide powder within ten minutes; seal the beaker and stir at 45 °C 24 h. The precipitate was separated by centrifugation, washed with water until pH>5, and then dispersed in 200 mL of absolute ethanol. Centrifuge after sonication for 1 h. The precipitate was dispersed in 1 L of deionized water and ultrasonicated for 30 min. After centrifugation at 3500 rpm for 5 min, the upper titanium carbide few-layer dispersion was obtained. Add 0.2 g of copper acetate monohydrate into the titanium carbide dispersion, let it stand still after stirring, and centrifuge to collect the precipitate and wash it with ethanol. Add 5 g of the precipitate to 100 mL to 50 mL of polyacrylate, stir for 3 h to make it well dispersed, and the obtained nano-titanium carbide conductive paste can be appl...

Embodiment 3

[0029] Accurately weigh 10 g of lithium fluoride and add it to a polytetrafluoroethylene beaker filled with 200 ml of hydrochloric acid (9M). After fully dissolving, slowly add 10 g of titanium aluminum carbide powder within ten minutes; seal the beaker and stir at 35 °C 36 h. The precipitate was separated by centrifugation, washed with water until pH>5, and then dispersed in 200 mL of absolute ethanol. Centrifuge after sonication for 1 h. The precipitate was dispersed in 1 L of deionized water and ultrasonicated for 30 min. After centrifugation at 3500 rpm for 5 min, the upper titanium carbide few-layer dispersion was obtained. Add 1 L of absolute ethanol to the titanium carbide dispersion, let stand after stirring, and centrifuge to collect the precipitate. Add 5 g of precipitate into 50 mL of ethylene glycol, then add 0.5 g of silane coupling agent KH560, stir for 3 h to make it well dispersed, and the obtained nano-titanium carbide conductive paste can be applied to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com