Titanium aluminium carbide powder and synthesis method using tin as reactive adjuvant therefor

A synthesis method and technology of reaction aids, applied in the field of synthesis of titanium aluminum carbide powder, can solve the problems of harmful powder performance, difficulty in increasing the content of synthetic powder, unfavorable formation, etc., to achieve industrial scale production and relax Effect of technical conditions and temperature control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

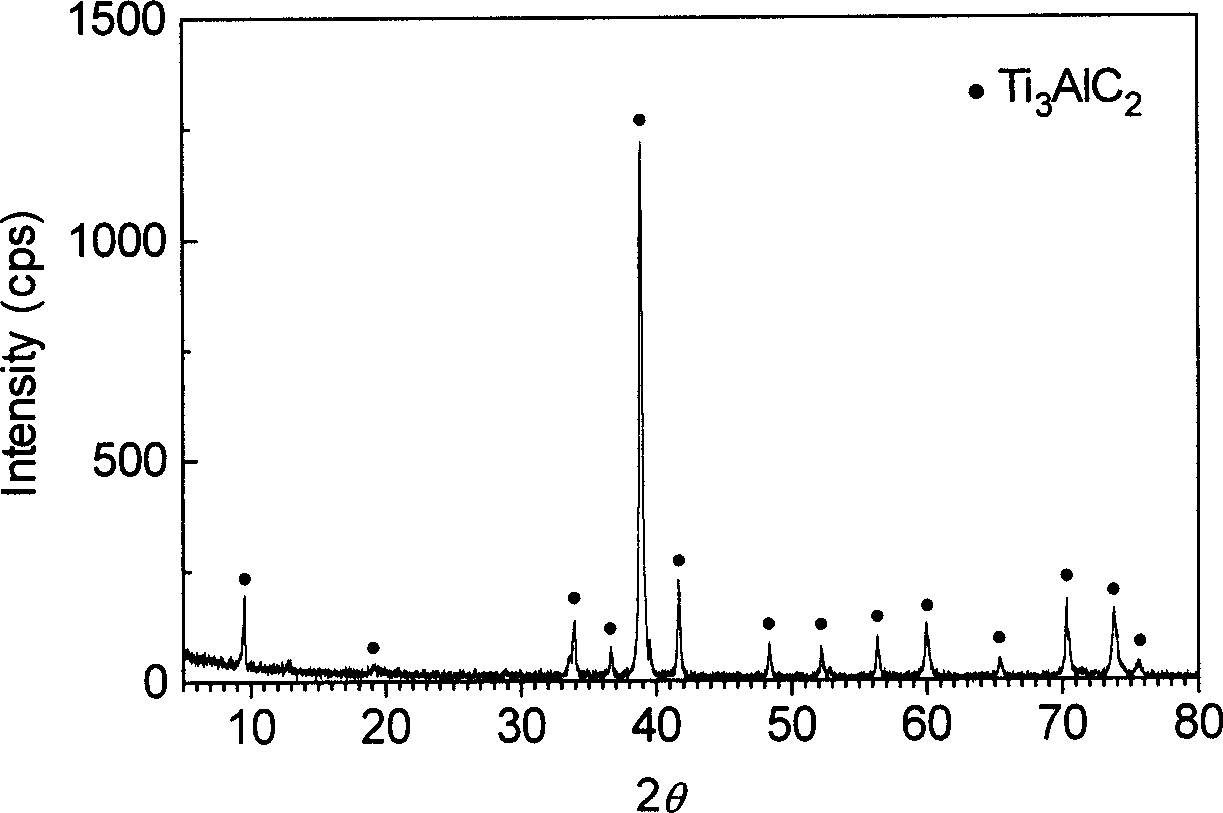

Embodiment 1

[0021] A small sample with a total weight of 9.0 grams. Weigh 5.98 grams of Ti powder, 1.12 grams of Al powder, 0.91 grams of graphite powder, and 0.99 grams of Sn powder, add 6 milliliters of absolute ethanol and 20 grams of agate balls after mixing, ball mill the mixture for 2 hours, then dry, grind, pass 100-mesh sieve, compacted under a pressure of 15MPa, put into a graphite mold in a high-temperature furnace, protected by argon, heat up to 1500°C at a rate of 38°C / min, hold for 5min, and heat at a rate of 10-15°C / min The furnace temperature is lowered to 60°C, and the loose block formed by the reaction is taken out and ground to obtain the titanium-aluminum carbide powder of the present invention; wherein the volume content of the titanium-aluminum carbide is greater than 99%. This example shows the details of the operation of synthesizing titanium aluminum carbide powder under the upper limit temperature and heating rate close to the upper limit described in the present ...

Embodiment 2

[0023] A small sample of the invention had a total weight of 44.3 grams. Weigh 30.0 grams of Ti powder, 6.0 grams of Al powder, 4.6 grams of graphite powder, and 3.7 grams of Sn powder, add 31 milliliters of absolute ethanol and 100 grams of agate balls after mixing, and mix the materials for 3 hours by ball milling, then dry, grind, pass 100-mesh sieve, compacted under a pressure of 20MPa, put it into a graphite mold in a high-temperature furnace, protect it with argon, raise the temperature to 1450°C at a rate of 30°C / min, keep it for 5min, and heat it at a rate of 10-15°C / min. The temperature of the furnace is lowered to 60°C, and the loose block formed by the reaction is taken out and ground to obtain the titanium-aluminum carbide powder of the present invention; wherein the volume content of the titanium-aluminum carbide is greater than 98.5%. This example shows the operation details of synthesizing titanium aluminum carbide powder under the conditions of optional paramet...

Embodiment 3

[0025] A larger sample with a total weight of 432.3 grams. Take by weighing 287.5 grams of Ti powder, 54.0 grams of Al powder, 43.3 grams of graphite powder, and 47.5 grams of Sn powder, add 303 milliliters of absolute ethanol and 1080 grams of agate balls after mixing, and ball mill the mixture for 6 hours, then dry, grind, pass 100-mesh sieve, compacted under a pressure of 10MPa, put into a graphite mold in a high-temperature furnace, protected by argon, heat up to 1350°C at a rate of 20°C / min, hold for 5min, and heat at a rate of 10-15°C / min The temperature of the furnace is lowered to 60° C., and the loose block formed by the reaction is taken out and ground to obtain the titanium-aluminum carbide powder of the present invention; wherein the volume content of the titanium-aluminum carbide is greater than 98.0%. This example demonstrates the operation details of synthesizing titanium aluminum carbide powder under the conditions of the lower limit temperature and the lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com