Modified terpolymer EP rubber containing cable sheath material and preparation method thereof

A technology of EPDM rubber and cable sheath material, applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problems of hindering safe evacuation and fire fighting work, loss of life and property, etc., and achieve high mechanical strength and high insulation resistance. , the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

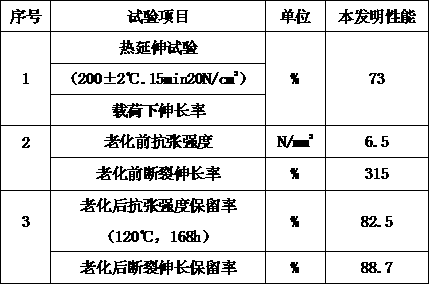

Examples

Embodiment 1

[0017] Example 1: Cable sheathing material containing modified EPDM rubber, the weight (kg) of the raw materials is: modified EPDM rubber 88, hydrogenated nitrile rubber 12, blast furnace slag 3.5, zeolite molecular sieve 22 , aluminum carbide 16, accelerator 808 1.2, accelerator CZ 1.8, N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane 4.2, barium ricinoleate 2.5, antioxidant 1010 0.4 , Diisobutyl Phthalate 3.8 and Phosphate 3.4.

[0018] The preparation method of the cable sheath material containing modified EPDM comprises the following steps:

[0019] (1) Preparation of modified EPDM rubber:

[0020] Formula (kg): EPDM rubber 28, maleic anhydride 12, xylene 38, acrylate 2.2, maleic anhydride 3.0, 2,6 di-tert-butyl p-cresol 3.8, montmorillonite powder 1.3 and cross Joint agent TAIC 0.6;

[0021] The preparation method is as follows:

[0022] a: Stir and react EPDM rubber, xylene, and maleic anhydride at 120°C for 4 hours according to the weight of the raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com