Ceramic fireproof fire-resistant silicon rubber wire and cable

A ceramic silicone rubber, wire and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of brittle mica tape, difficult to promote, difficult to ensure communication, safe and smooth power supply, etc., and achieve good flame retardancy.

Inactive Publication Date: 2014-01-01

江苏金枫达科技有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Magnesia mineral fire-resistant insulated cables need special production and processing equipment, and the equipment for producing magnesium oxide mineral fire-resistant insulated cables not only needs to be imported, but also very expensive, and the capital investment is too large; in addition, the outer sheath of magnesium oxide mineral fire-resistant insulated cables is full The cost of copper is relatively high, and its practical application is limited to a certain extent; coupled with the special requirements of copper-sheathed magnesium oxide mineral fire-resistant insulated cables in the process of production, processing, transportation, line laying, installation and use, such as The production and processing of magnesium oxide mineral fire-resistant insulated cables cannot be as convenient as polymer materials. It is difficult to lay and install, and the cost of raw materials is high. It is difficult to popularize and use it on a large scale, especially difficult to promote it in civil buildings, etc.

The fire-resistant cable wrapped with mica tape needs to be wound in multiple layers in the production process. Due to the limitation of process conditions, it is easy to cause defects at the lap joints. It is difficult to ensure the safety and smoothness of communication and power in case of fire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

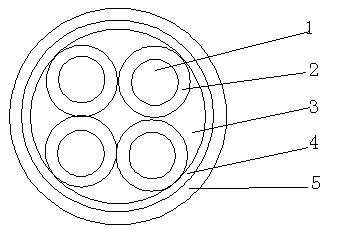

[0022] Ceramicized fireproof and refractory silicone rubber wire and cable, including multiple conductors 1, the conductors 1 are extruded with a ceramicized silicone rubber insulating layer 2 to form a core, and multiple cores are extruded with a glass fiber tape layer 4 to form a cable core. A glass fiber filling 3 is provided inside the cable core, and a vitrified silicone rubber outer sheath 5 is provided outside the cable core.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a ceramic fireproof fire-resistant silicon rubber wire and cable. The wire and cable comprise a plurality of conductors, each conductor is wrapped by a ceramic silicon rubber insulating layer in an extruding mode to form a wire core, multiple wire cores are wrapped by a wrapping tape layer to form a cable core, padding is arranged in the cable core, and a ceramic silicon rubber outer sheath is arranged outside the cable core. The ceramic fireproof fire-resistant silicon rubber wire and cable have characteristics batter than those of a common rubber cable and a flame retardant rubber cable and form a hard shell after being ablated by high-temperature flames to protect a burned article from being damaged, and the hard shell formed after ablation protects the wire and cable, so that unblocked electric power and communication are ensured, and precious time are won for personnel evacuation and rescue under the fire disaster condition.

Description

technical field [0001] The invention relates to a wire and cable, in particular to a ceramic fireproof and refractory silicon rubber wire and cable. Background technique [0002] In recent years, after fires in several large public entertainment venues, chemical industry, coal mines, and commercial buildings in China caused tragic loss of people's lives and property, people have a deeper understanding of fire protection and fire safety. With the rapid growth of urban population, the continuous increase of high-rise buildings, hotels, large supermarkets, hospitals, stations, and airports, the construction of subways and tunnel traffic, and the increase of large-scale public sports, entertainment venues, and public transportation facilities, fire prevention and fire prevention The importance of safety is highlighted. How to ensure the smooth flow of power and communication within a certain period of time in the event of a fire, maximize the precious rescue time, and reduce ca...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/02H01B7/17H01B7/29

Inventor 王跃先夏传林

Owner 江苏金枫达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com