Light tough bicycle frame material and preparation method thereof

A bicycle and frame technology, which is applied in the field of light and tough bicycle frame materials and its preparation, can solve the problems of high brittleness and poor toughness, and achieve the effects of high toughness, long service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

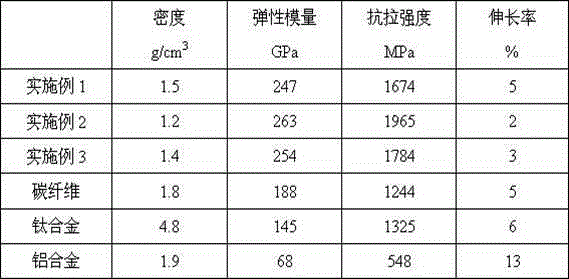

Examples

Embodiment 1

[0025] A light and tough bicycle frame material, which is mainly made of the following materials in proportion by weight: 12 parts of nano-aluminum carbide, 12 parts of carbon fiber, 8 parts of nano-silica, 9 parts of polycarbonate, and 7 parts of polyamide 8 parts, boron fiber 8 parts, carbide steel fiber 18 parts, polystyrene 6 parts, methyl diisocyanate 6 parts, polyether ether ketone fiber 7 parts.

[0026] A preparation method for a light and tough bicycle frame material, comprising the following steps:

[0027] (1) Put polystyrene, methyl diisocyanate and polyetheretherketone fibers in a reaction kettle at a reaction temperature of 330°C, stir and mix them and extrude them in a twin-screw extruder to obtain mixed fibers 1;

[0028] (2) The mixed fiber 1 obtained in step (1) is used as the warp yarn, and the carbon fiber is used as the weft yarn, and the fiber mat is woven into a fiber mat in a textile machine, and laid flat in a mold, and the mold is preheated to 270°C, ...

Embodiment 2

[0034] A lightweight and tough bicycle frame material, which is mainly made of the following materials in proportion by weight: 19 parts of nano-aluminum carbide, 21 parts of carbon fiber, 18 parts of nano-silica, 13 parts of polycarbonate, and 11 parts of polyamide 16 parts of boron fiber, 34 parts of carbonized steel fiber, 15 parts of polystyrene, 9 parts of methyl diisocyanate, 11 parts of polyetheretherketone fiber.

[0035] A preparation method for a light and tough bicycle frame material, comprising the following steps:

[0036] (1) Put polystyrene, methyl diisocyanate and polyether ether ketone fibers in a reaction kettle at a reaction temperature of 430°C, stir and mix them and extrude them in a twin-screw extruder to obtain mixed fibers 1;

[0037] (2) The mixed fiber 1 obtained in step (1) is used as the warp yarn, and the carbon fiber is used as the weft yarn, and the fiber mat is woven into a fiber mat in a textile machine, and laid flat in a mold, and the mold is...

Embodiment 3

[0043] A light and tough bicycle frame material, which is mainly made of the following materials in proportion by weight: 26 parts of nano-aluminum carbide, 28 parts of carbon fiber, 25 parts of nano-silica, 18 parts of polycarbonate, and 16 parts of polyamide 20 parts, boron fiber 20 parts, carbide steel fiber 40 parts, polystyrene 19 parts, methyl diisocyanate 14 parts, polyetheretherketone fiber 14 parts.

[0044] A preparation method for a light and tough bicycle frame material, comprising the following steps:

[0045] (1) Put polystyrene, methyl diisocyanate and polyether ether ketone fibers in a reaction kettle at a reaction temperature of 440°C, stir and mix them and extrude them in a twin-screw extruder to obtain mixed fibers 1;

[0046](2) The mixed fiber 1 obtained in step (1) is used as the warp yarn, and the carbon fiber is used as the weft yarn, and the fiber mat is woven into a fiber mat in a textile machine, and laid flat in a mold, and the mold is preheated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com