Method for synthesizing aluminium-titanium carbonate ceramic powder

A technology of ceramic powder and synthesis method, which is applied in the synthesis of aluminum carbide titanium ceramic powder, low-cost aluminum carbide Ti3AlC2 ceramic powder in the field of normal pressure synthesis, and can solve the problem of affecting the purity and performance of the powder and difficult control of temperature parameters , elemental Al volatilization loss and other issues, to achieve the effect of wide synthesis temperature range, stable sintering process parameters, and reduced high temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of synthetic method of aluminum carbide titanium ceramic powder, comprises the following steps;

[0027] 1) Press TiH 2 : Al: TiC: Sn=1: 1: 1: 0.1 molar ratio batching, take by weighing 16.8 grams of Ti powder, 9.1 grams of Al powder, 20.1 grams of TiC powder, 4.0 grams of Sn powder;

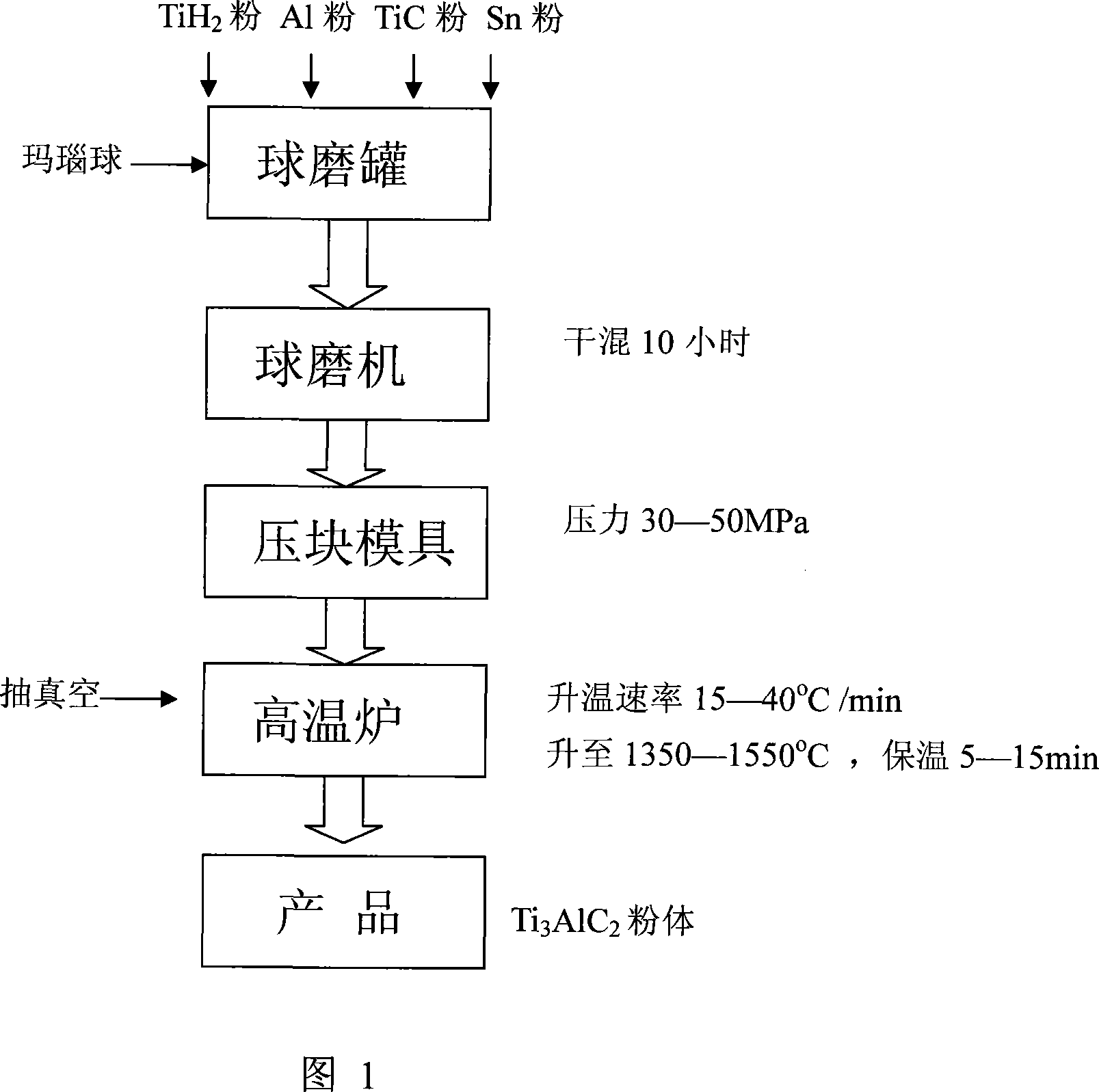

[0028] 2) As shown in Figure 1, put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0029] 3) Press the homogeneously mixed ingredients into a block under a pressure of 30 MPa.

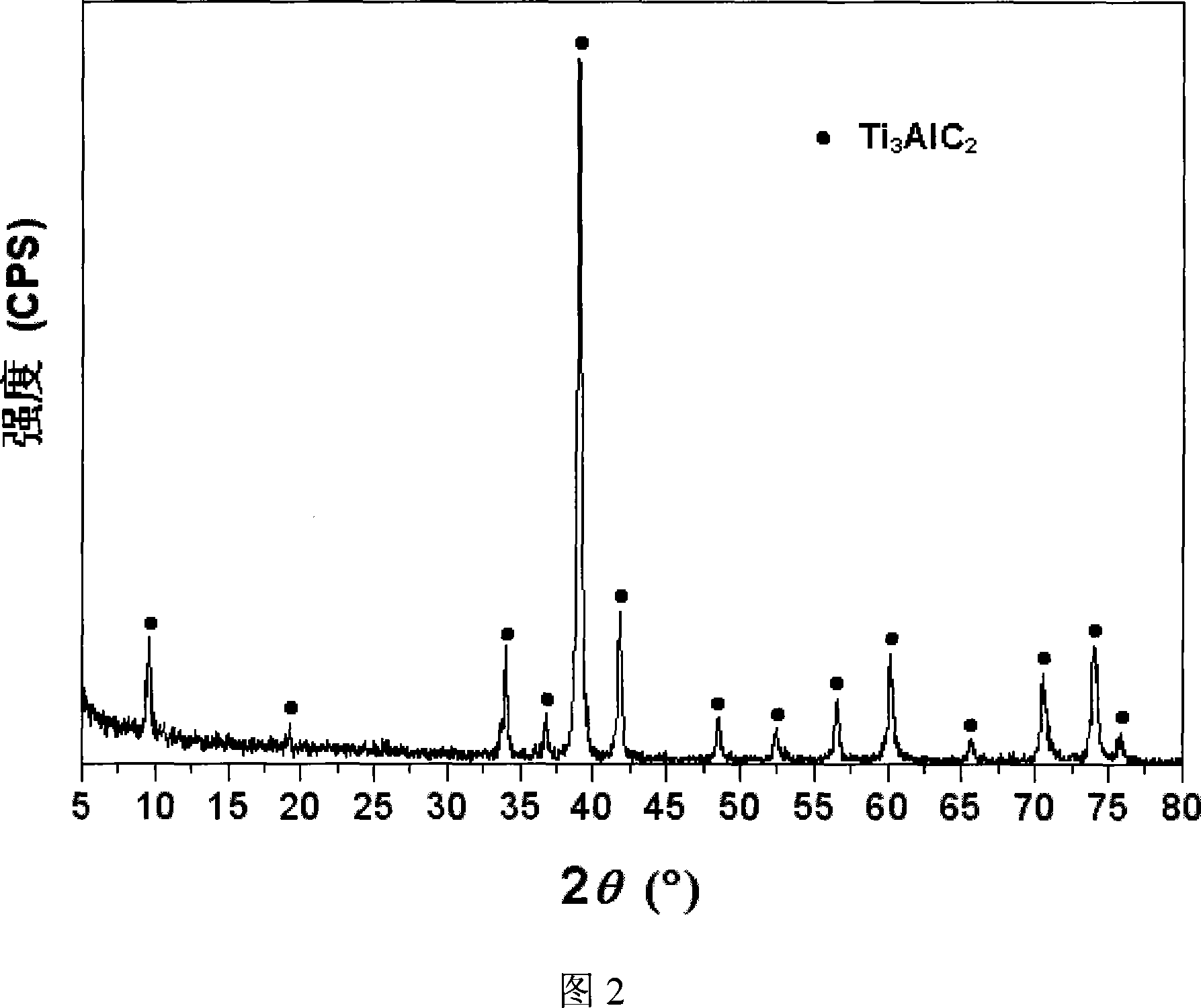

[0030] 4) Put the above briquettes into a high-temperature furnace in a vacuum atmosphere, raise the temperature of the furnace to 1350°C at a heating rate of 15°C / min, and hold the temperature for 15 minutes to obtain high-purity Ti 3 AlC 2 powder, the X-ray diffraction (XRD) spectrum of the powder is shown in Figure 2. As can be seen from Figure 2, the product is of high purity, except for Ti in the XRD pattern. 3 AlC 2 Bes...

Embodiment 2

[0031] Embodiment 2: a kind of synthetic method of aluminum carbide titanium ceramic powder: contain following steps;

[0032] 1) Press TiH 2 : Al: TiC: Sn=1: 1: 1: 0.1 molar ratio batching, take by weighing 16.8 grams of Ti powder, 9.1 grams of Al powder, 20.1 grams of TiC powder, 4.0 grams of Sn powder;

[0033] 2) Put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0034] 3) Press the homogeneously mixed ingredients into a block under a pressure of 40 MPa.

[0035] 4) Put the above briquette into a high-temperature furnace, and in a vacuum atmosphere, raise the temperature of the furnace to 1450°C at a heating rate of 30°C / min, and hold the temperature for 10 minutes to obtain high-purity Ti 3 AlC 2 Powder, its XRD result is identical with embodiment one.

Embodiment 3

[0036] Embodiment 3: a kind of synthetic method of aluminum carbide titanium ceramic powder: contain following steps;

[0037] 1) Press TiH 2 : Al: TiC: Sn=1: 1: 1: 0.1 molar ratio batching, take by weighing 16.8 grams of Ti powder, 9.1 grams of Al powder, 20.1 grams of TiC powder, 4.0 grams of Sn powder;

[0038] 2) Put the above-mentioned ingredients into the ball mill tank and place on the ball mill for mixing for 10 hours;

[0039]3) Press the uniformly mixed ingredients into a block under a pressure of 50 MPa.

[0040] 4) Put the above briquette into a high-temperature furnace, and in a vacuum atmosphere, raise the temperature of the furnace to 1500°C at a heating rate of 40°C / min, and hold the temperature for 5 minutes to obtain high-purity Ti 3 AlC 2 Powder, its XRD result is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com