Patents

Literature

142 results about "Thermal explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In combustion: Thermal explosions Thermal explosion theory is based on the idea that progressive heating raises the rate at which heat is released by the reaction until it exceeds the rate of heat loss from the area. At a given composition of the mixture and a given….

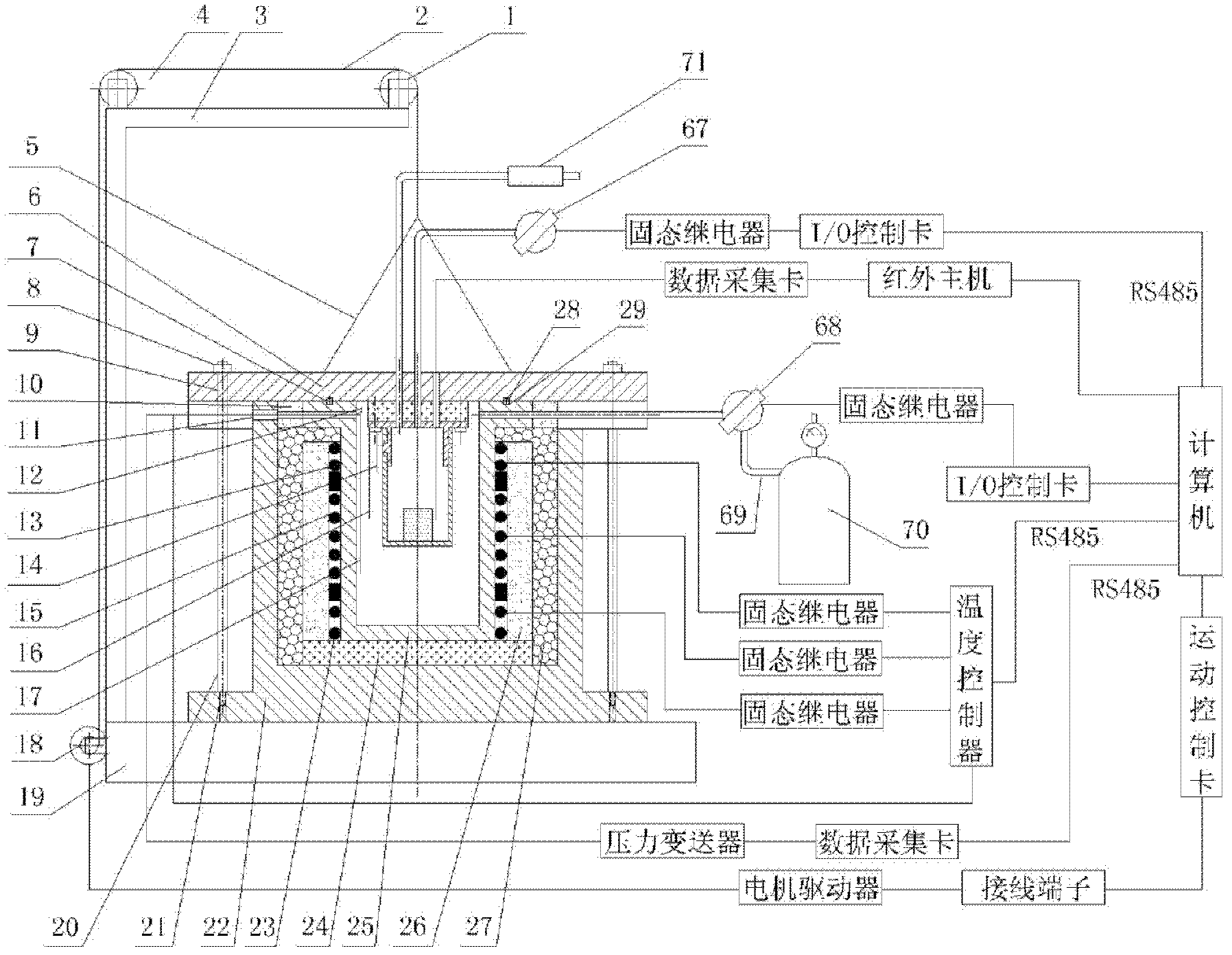

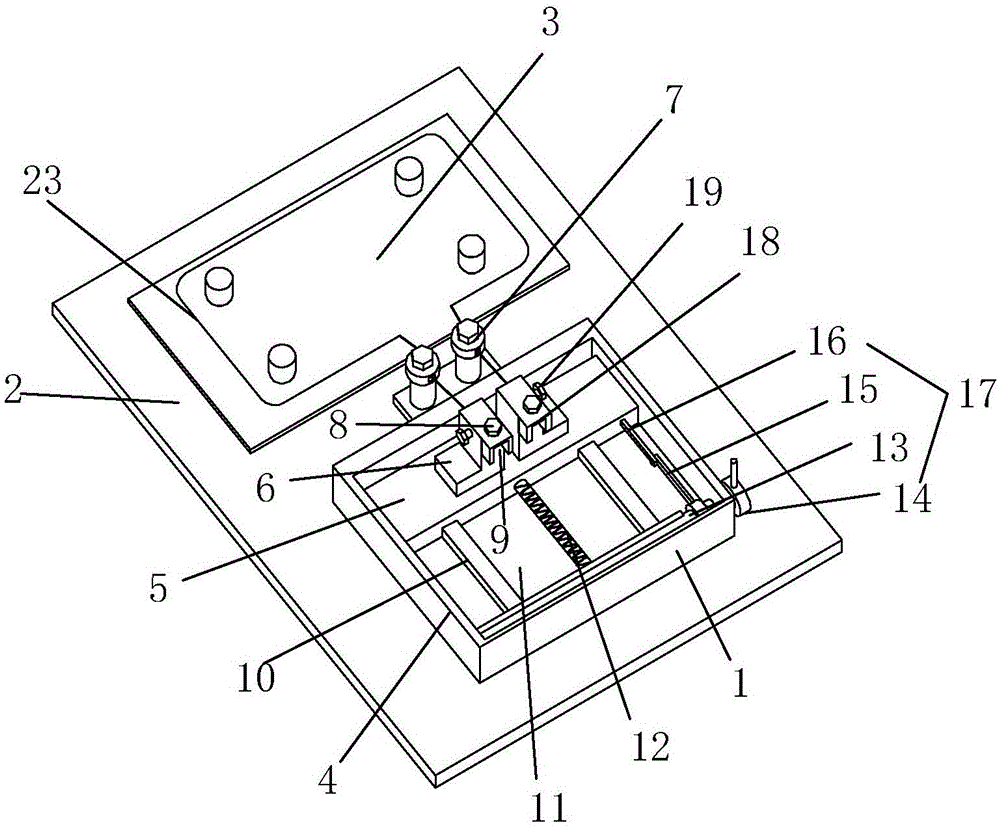

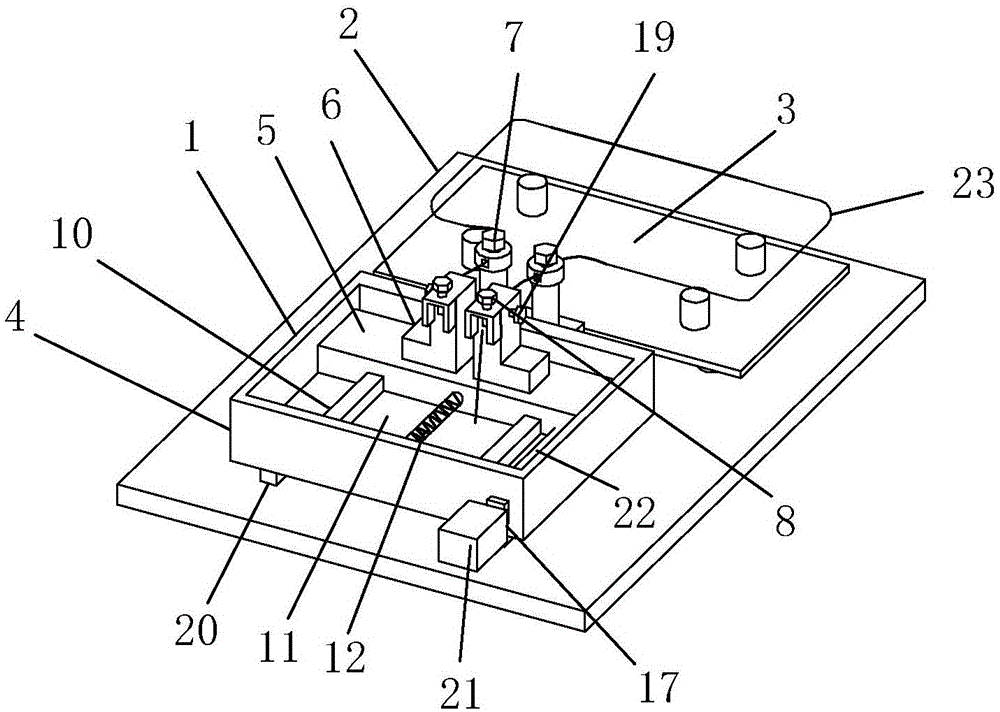

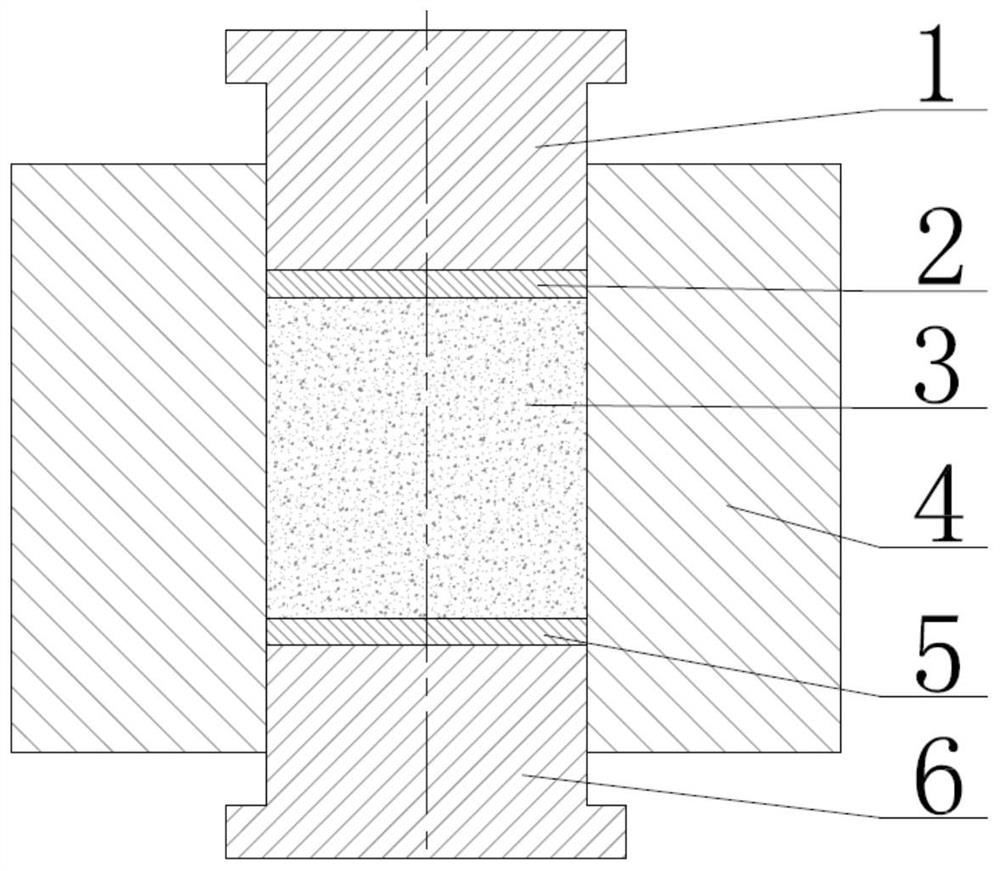

Testing system for critical pressure during thermal explosion of explosives

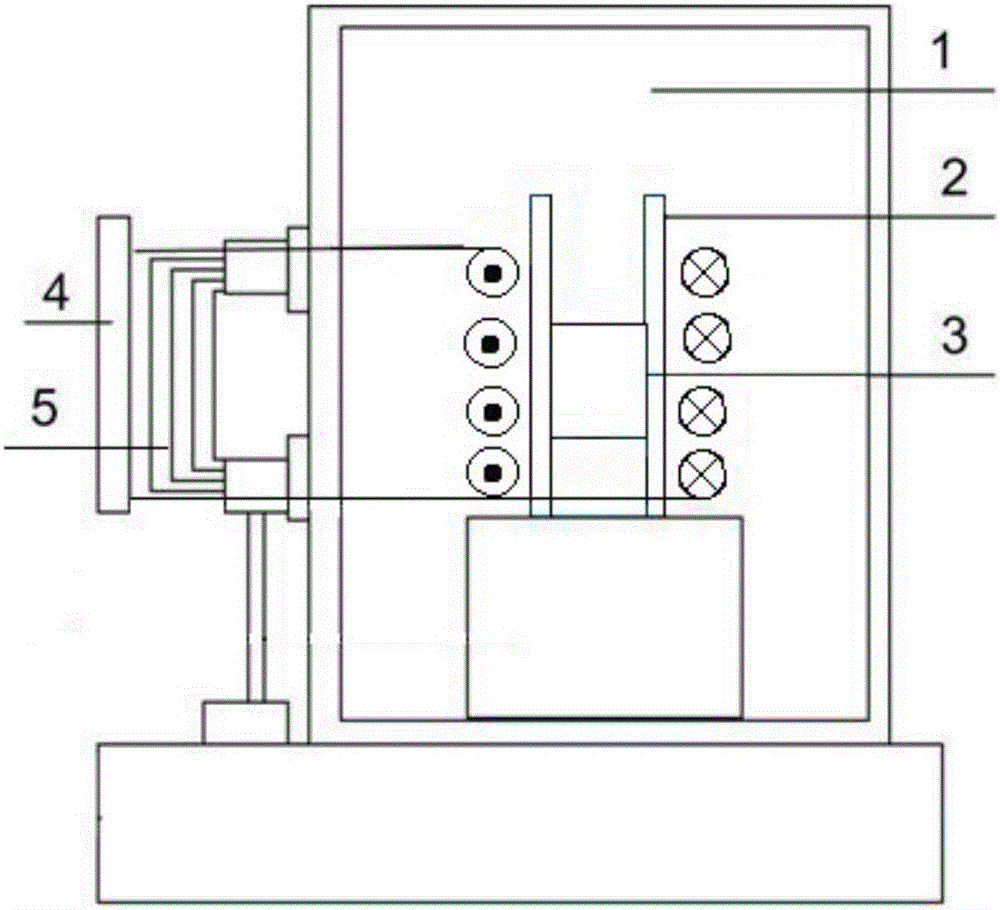

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

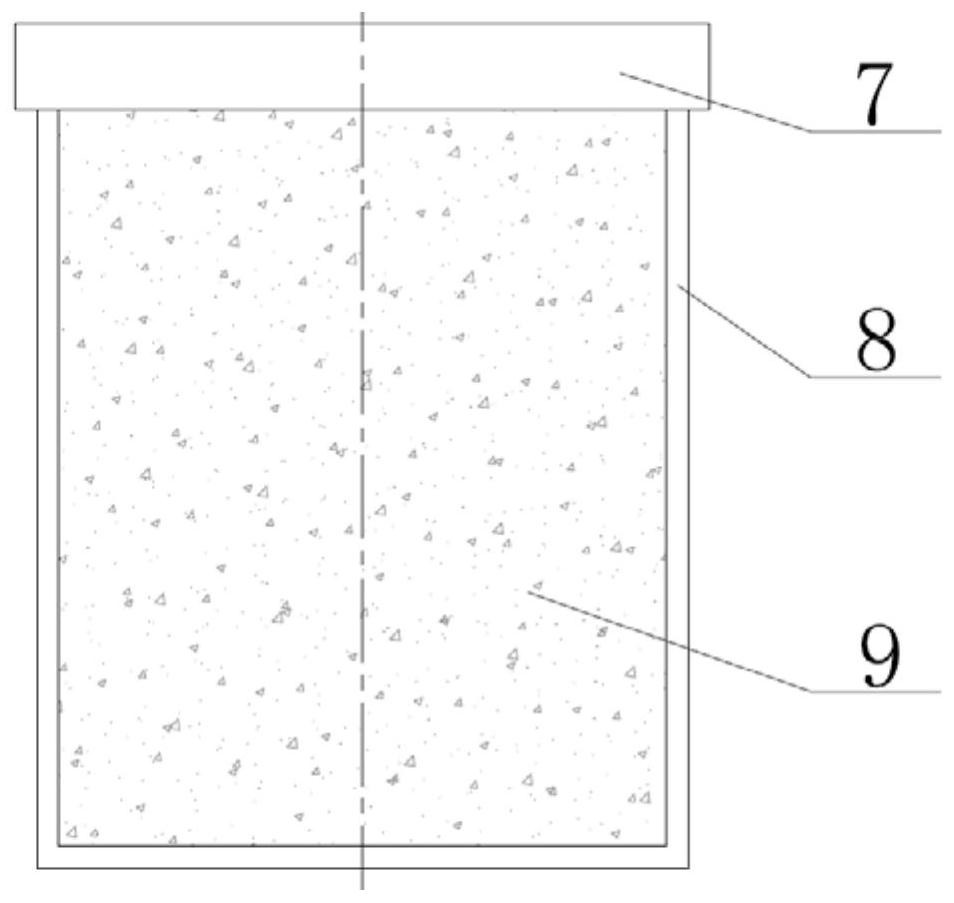

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

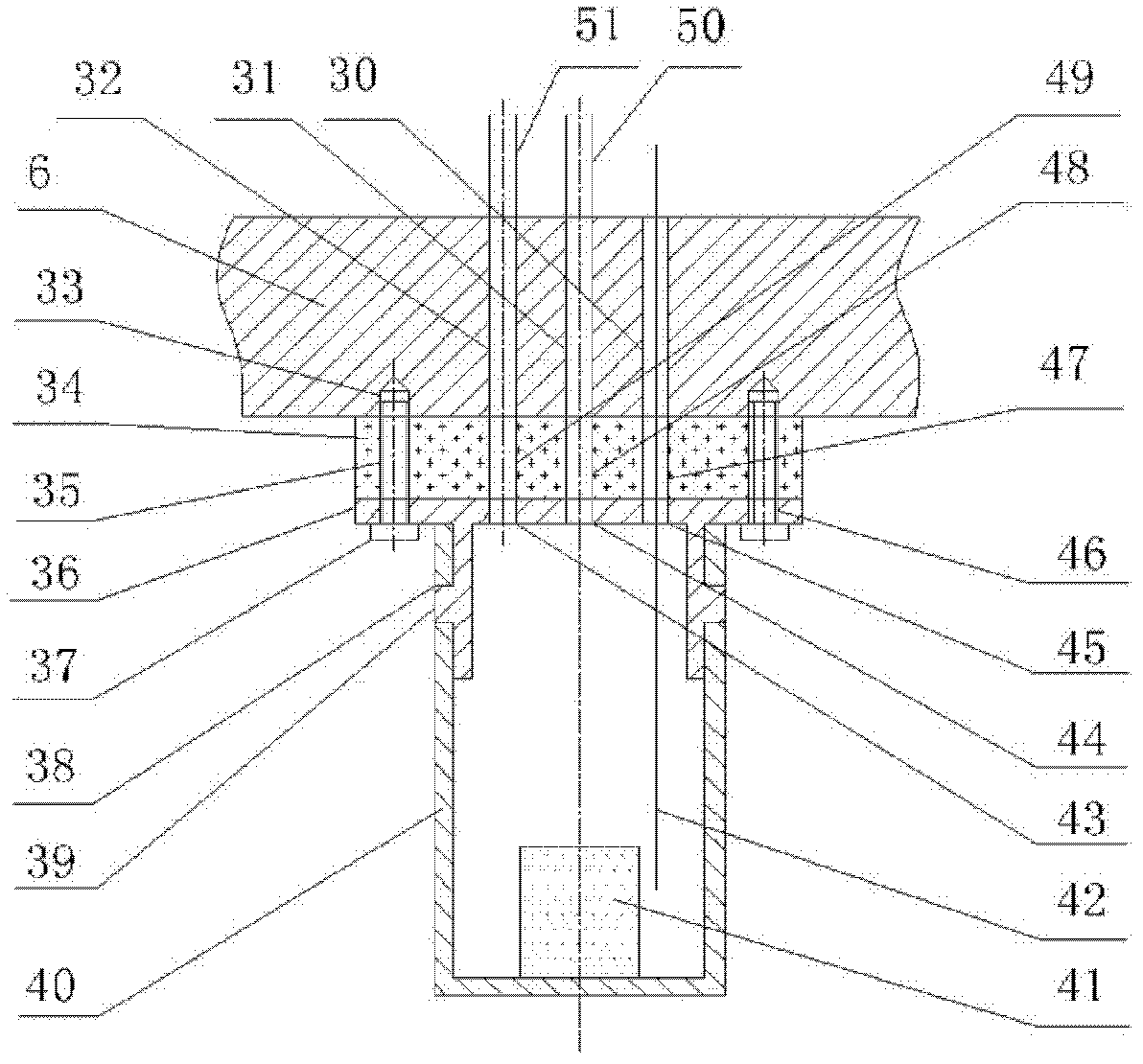

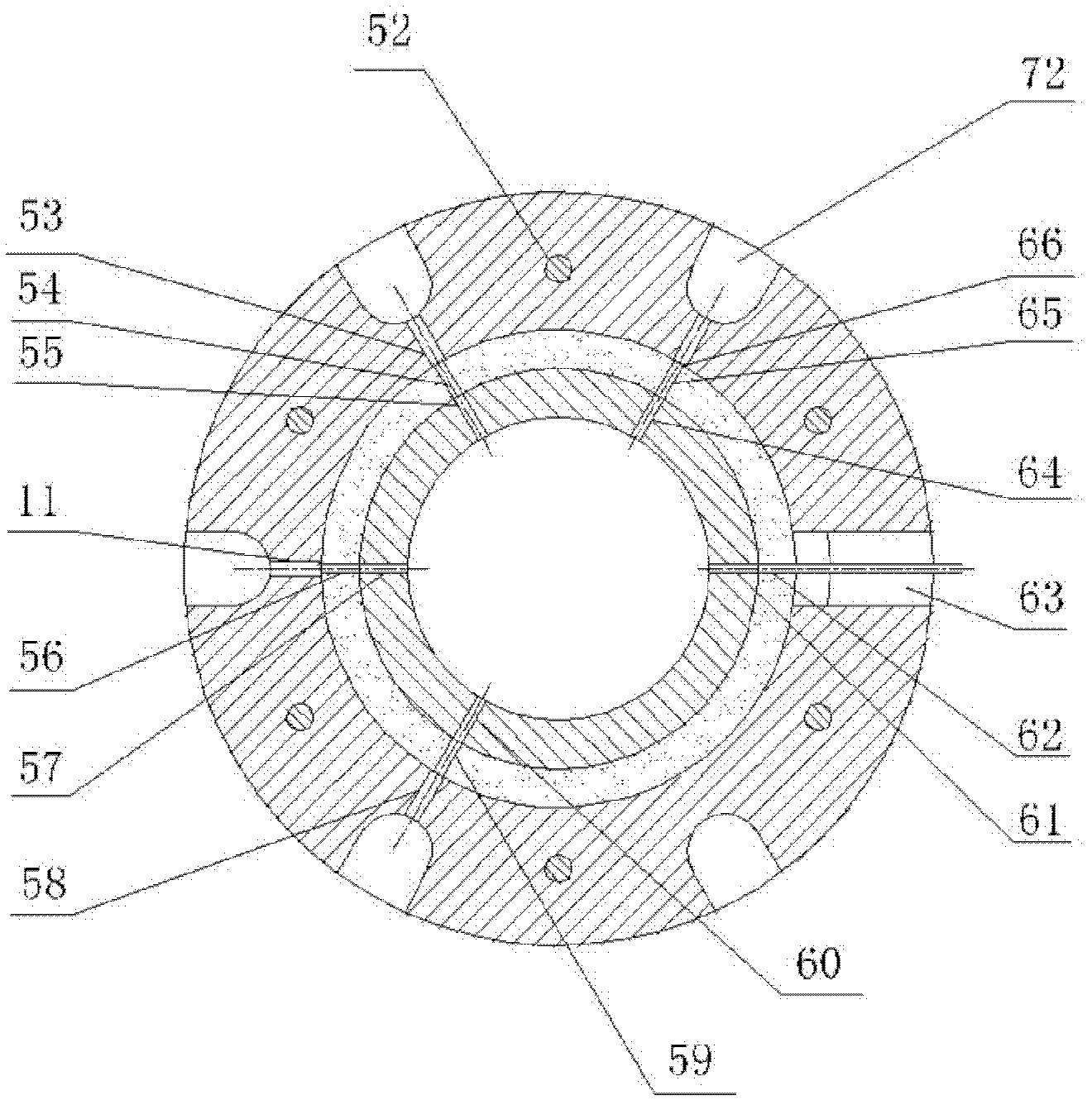

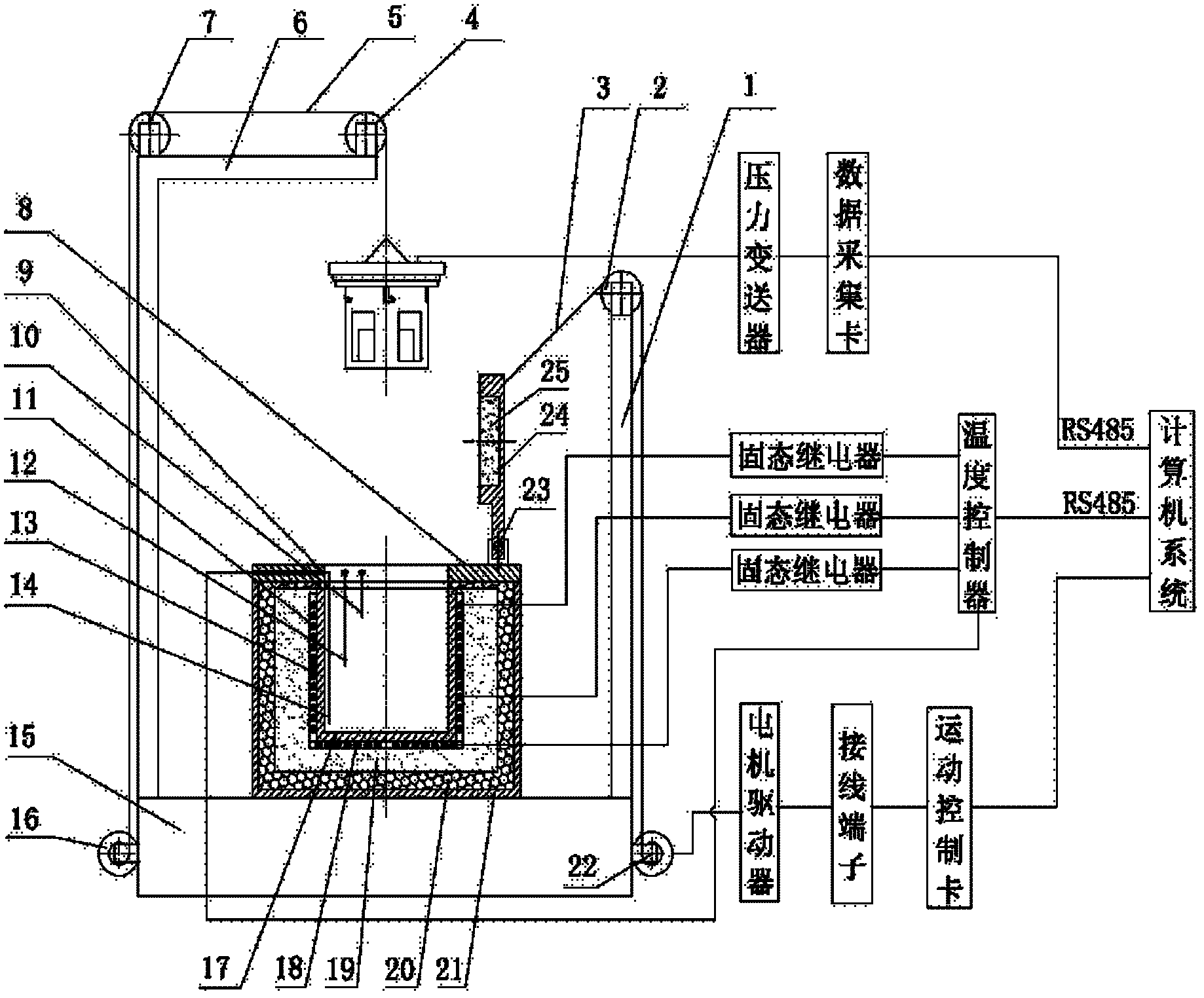

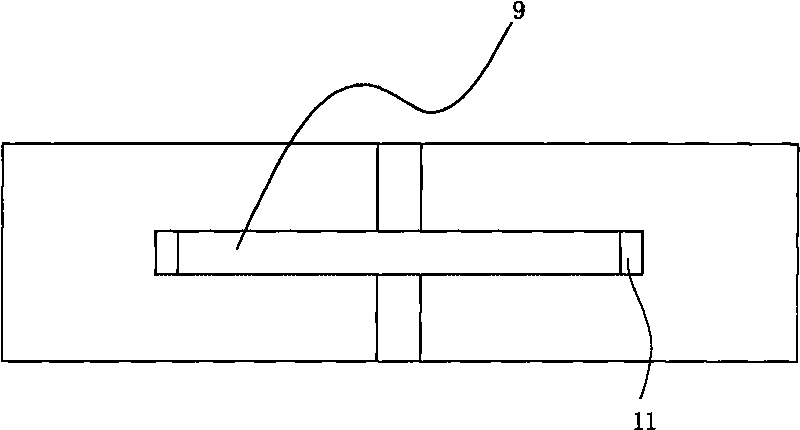

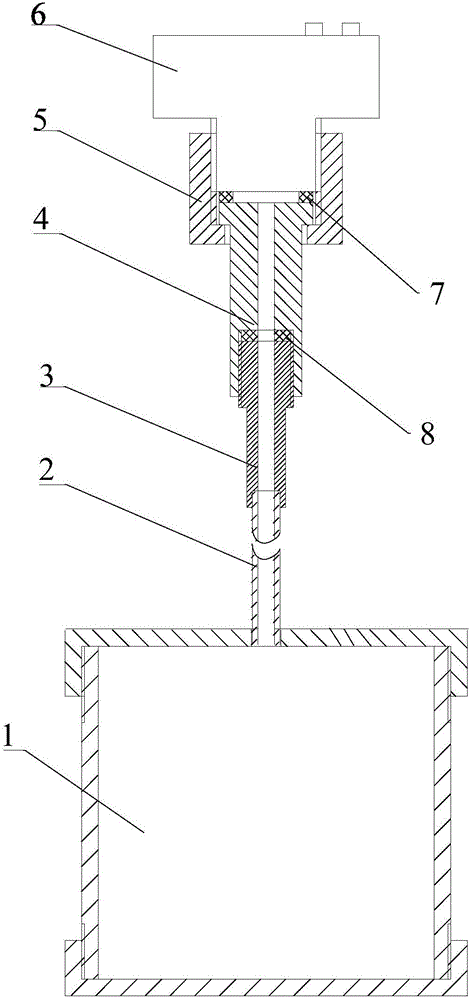

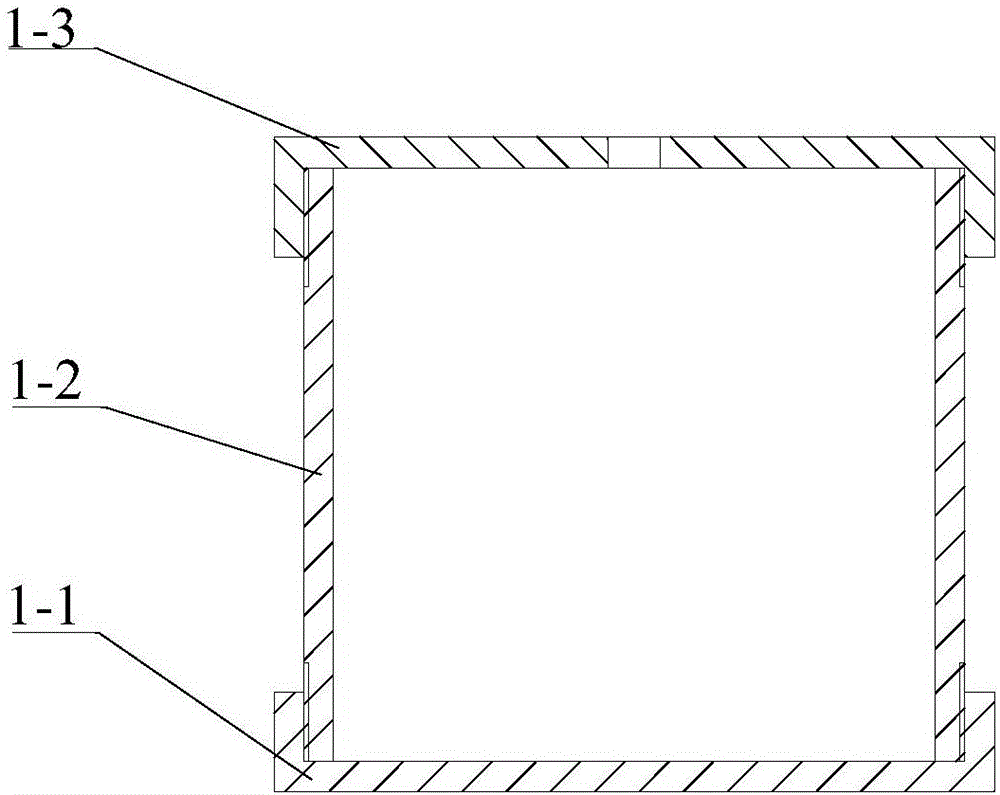

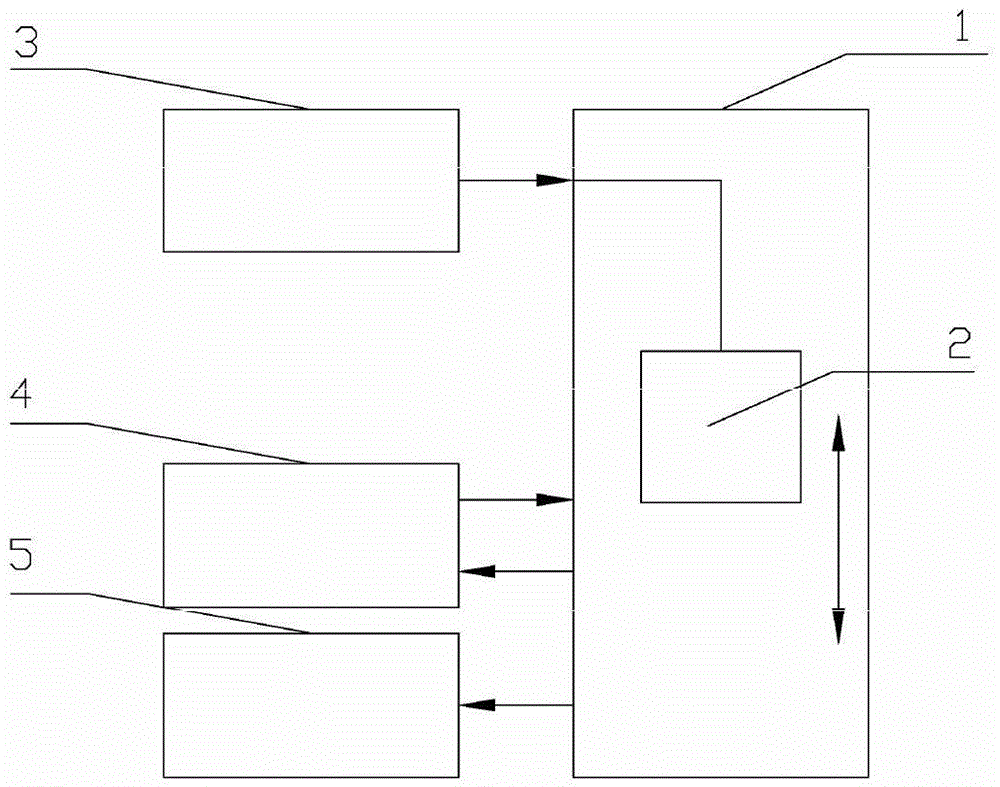

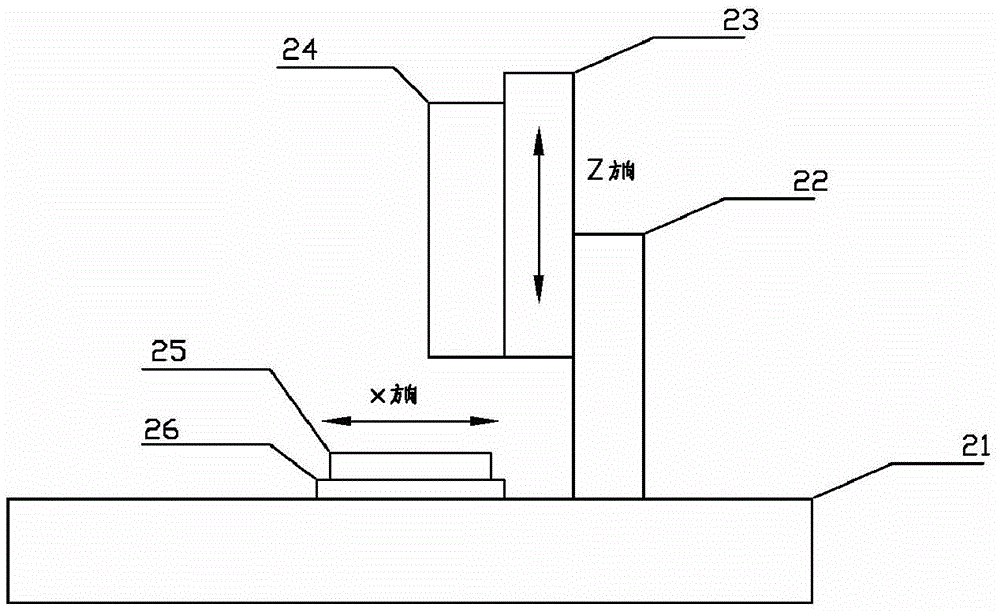

Critical temperature testing system of gunpowder and explosive thermal explosion

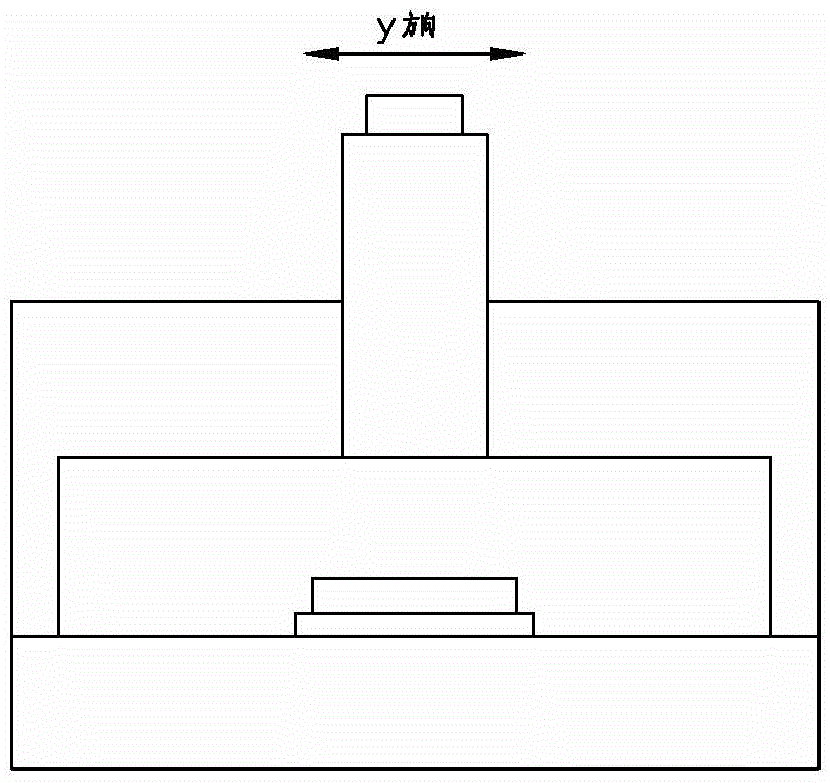

InactiveCN102608158ADifficult to collectChange the ambient temperatureMaterial heat developmentHeat conductingData acquisition

The invention discloses a critical temperature testing system of gunpowder and explosive thermal explosion, comprising a temperature-rising heating unit, a reactor unit, an automatic sample feeding unit, a pressure detection unit and a computer, wherein the temperature-rising heating unit comprises a heat-conducting layer, a heat preservation layer, and a single-cavity heating furnace body containing three groups of heating layers and ceramic heat-isolating layers; and the temperature and the temperature-rising speed of the heating furnace body are controlled by the computer. The reactor unit comprises a testing furnace cover, a lifting basket, a sample tank and a pre-heating furnace cover; the automatic sample feeding unit comprises a furnace body bracket, two stepping motors, a pulley wheel and a steel wire rope; the air pressure detection unit comprises a pressure sensor; the pressure sensor is mounted in the sample tank through the testing furnace cover and is connected with the computer; and the computer is provided with a data acquisition card, an image display control piece and a data processing unit. When the critical temperature testing system is used, a gunpowder or explosive sample with the certain size is placed into a special explosion-proof furnace and the sample is heated at the equal temperature or temperature-rising condition, so as to detect the thermal explosion critical temperature when the sample is combusted or exploded.

Owner:XIAN MODERN CHEM RES INST

Grain refiner and application of grain refiner in aluminum alloy wheel hub

The invention relates to a grain refiner and an application of the grain refiner in an aluminum alloy wheel hub. The grain refiner is characterized by being prepared through the following steps: (1) preparing powdery Al, Ti and B participating in the reaction according to mass percents of 65-75%, 15-30% and 5-10%; (2) smelting an aluminum ingot containing 6.5-7.5% of silicon and 0.3-0.45% of magnesium, adding a covering agent and a refining agent, degassing and stewing to obtain a matrix alloy fused mass; and (3) putting reaction blocks in an electromagnetic induction furnace for heating and drying, pressing the reaction blocks into the fused mass according to 5-10% by mass of the matrix melt through an immersion bell in batches, keeping the temperature for 20 min to perform thermal explosion synthetic reaction on the reaction blocks in the fused mass so as to crack and disperse the reaction blocks due to strong heat release, and mechanically stirring the fused mass to completely dilute the synthetic product and disperse the synthetic product in the aluminum fused mass. The solution and diffusion periods of the TiAl3 phase of the aluminum alloy solution prepared by the method are greatly reduced, the dispersibility of the TiB2 particles is greatly improved to facilitate the refining function, and the size of the casting crystalline grain of an intermediate alloy can be effectively controlled to be lower than 40 microns.

Owner:金刚

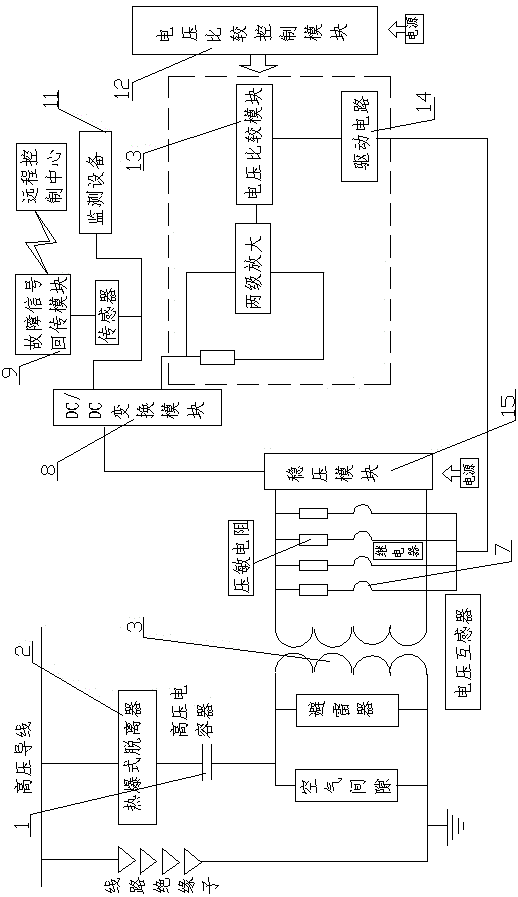

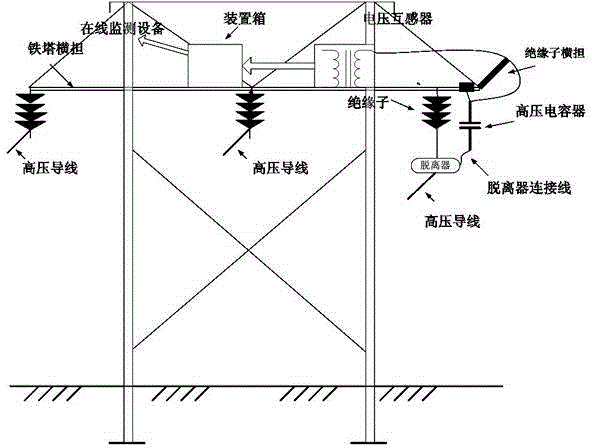

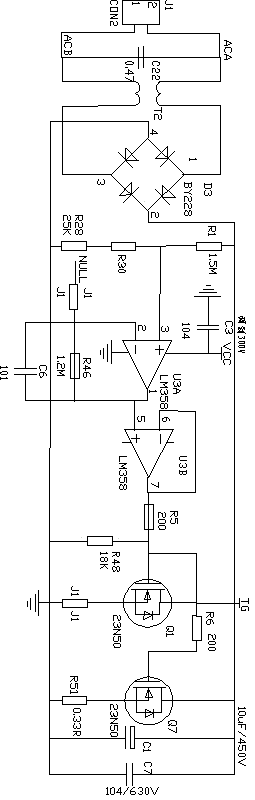

Monitoring equipment power supply system for high voltage capacitor step-down electricity taking of tower pole line

InactiveCN104377739AGuaranteed disengagementGuaranteed uptimeElectrical apparatusCapacitanceHigh voltage capacitors

The invention discloses a monitoring equipment power supply system for high voltage capacitor step-down electricity taking of a tower pole line. The power supply system comprises an electricity taking module, a voltage-stabilizing module, a DC / DC conversion module and a voltage comparison control module. The electricity taking module comprises a high-voltage wire, a high-voltage capacitor, a voltage transformer and an insulator. The high-voltage capacitor is connected with the insulator in parallel. A thermal explosion type disconnector is arranged between the high-voltage capacitor and the high-voltage wire. The high-voltage capacitor is connected with the voltage transformer in series and outputs 220 v voltage on the secondary side of the voltage transformer, the voltage is converted into a small current after being transmitted to the DC / DC conversion module through the voltage-stabilizing module, and then the current is transmitted to monitoring equipment. The output end of the DC / DC conversion module is connected with a fault signal return module and the voltage comparison control module. Compared with a traditional wind-solar power storage scheme, the design cost of the power part of a tower monitoring system is greatly reduced; besides, the power supply system can monitor running for a long time, is economical and practical and thoroughly solves the problem that the electricity taking of the tower is difficult.

Owner:STATE GRID CORP OF CHINA +2

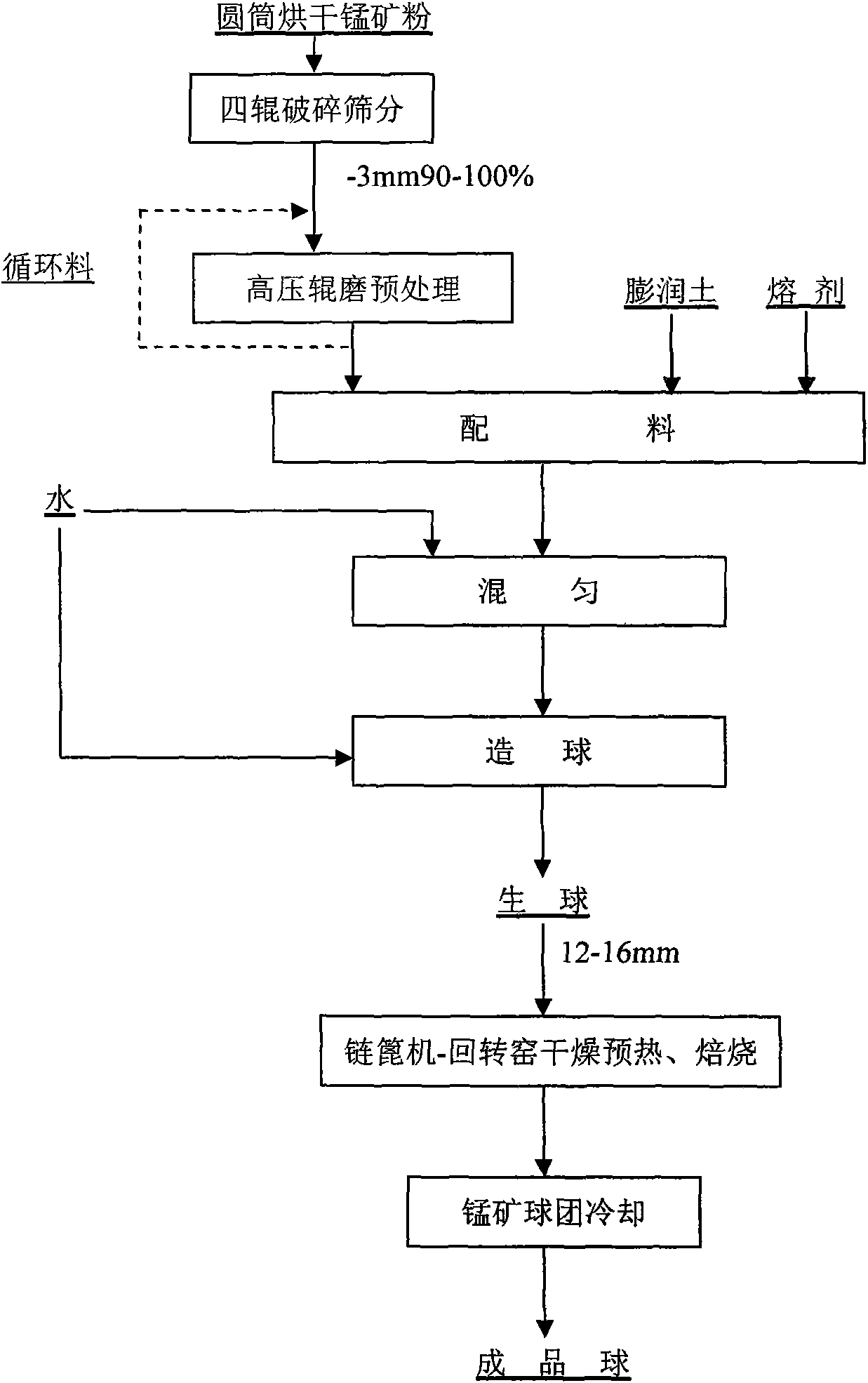

Complex manganese ore powder pelletization process

The invention relates to a complex manganese ore powder pelletization process. High-crystal-water manganese powder ore is treated by a cylindrical drier for drying, a four-roll crusher for coarse crushing and a high-pressure roller mill for fine milling pretreatment, bentonite and flux are added in finely milled manganese ore concentrate obtained after pretreatment for pelletization, green pelletsare dried and preheated on a chain-grate machine, preheated pellets enter a rotary kiln for high-temperature roasting and then is cooled to obtain a pellet product. Compared with ball milling process, the invention can reduce the energy consumption in pretreatment flow, improve the ballability index of finely milled material, eliminate thermal explosion of pellets and solve the technical problemsthat narrow manganese ore softening temperature area affects pellet roasting. The adoption of two-segment preheating effectively prevents cracks on the preheated pellets and improves the performancesof the preheated pellets; the addition of limestone or dolomite as flux changes the alkalinity and the slagging property of raw material and enhances the pellet roasting and next melting; and the produced manganese ore pellet has high strength, large output and high manganese grade.

Owner:CENT SOUTH UNIV

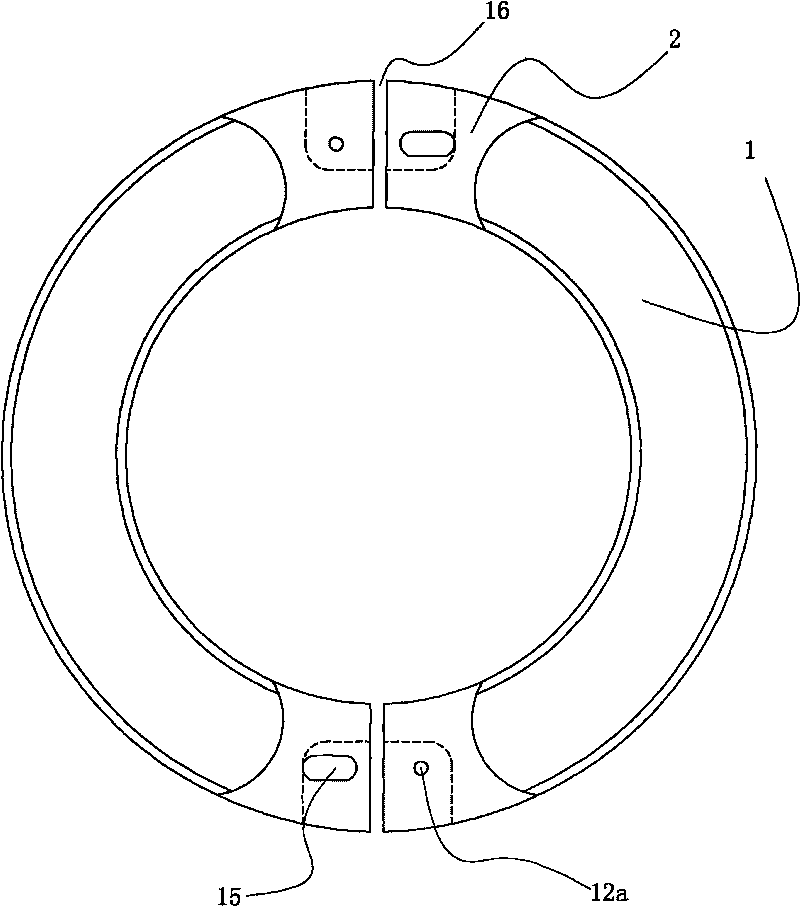

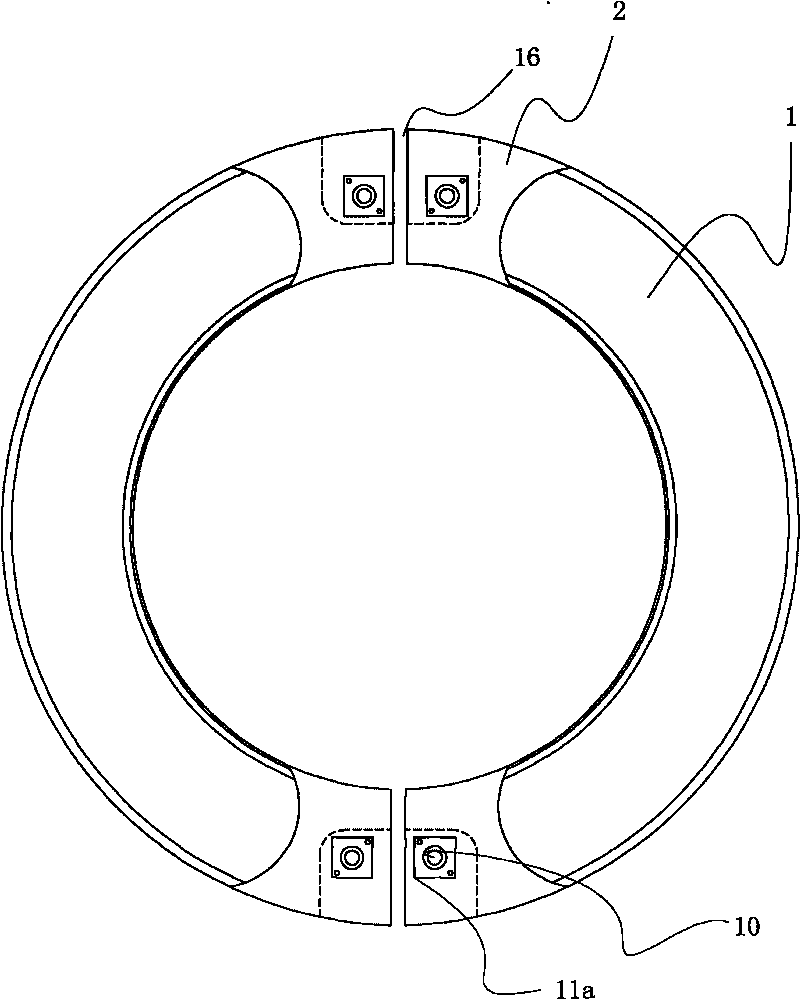

Inner supporting body for run-flat tire

The invention discloses an inner supporting body for a run-flat tire, which is characterized in that: the inner supporting body is made of a magnesium alloy serving as a raw material, and adopts a two-block split structure; the split parts comprise a main body and a joint respectively; and the joints between the split parts are connected by a connection piece. The inner supporting body has the advantages of high rigidity, good heat stability and light weight, and the inner supporting body adopts the magnesium alloy to improve the radiating condition fundamentally, prevent rubber and engineering plastics from softening due to quick and massive deformation, eliminate the ,thermal explosion, phenomenon in the process of using the inner supporting body, improve the safe driving distance after a vehicle has a flat tire, and prolong the service life.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

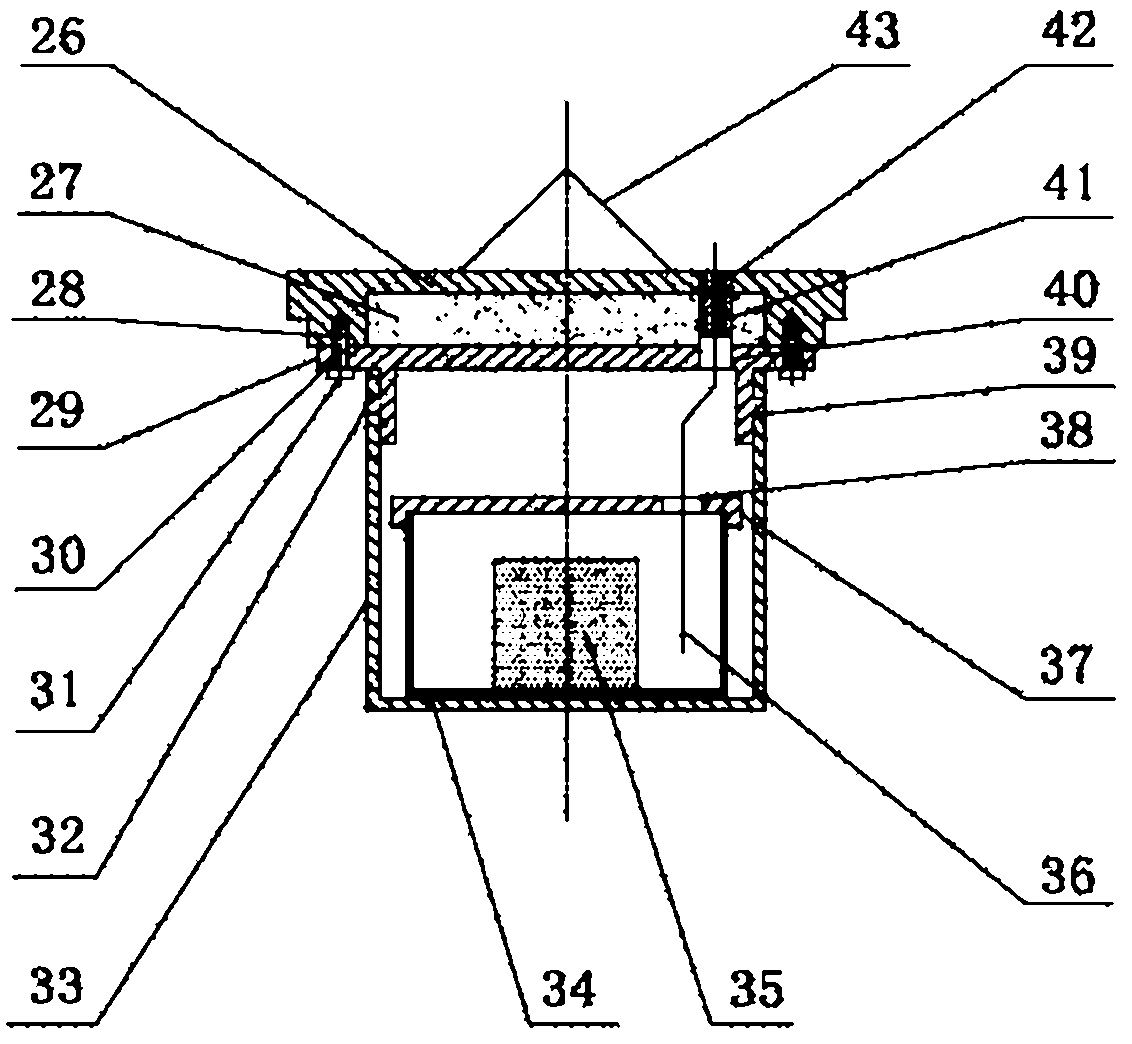

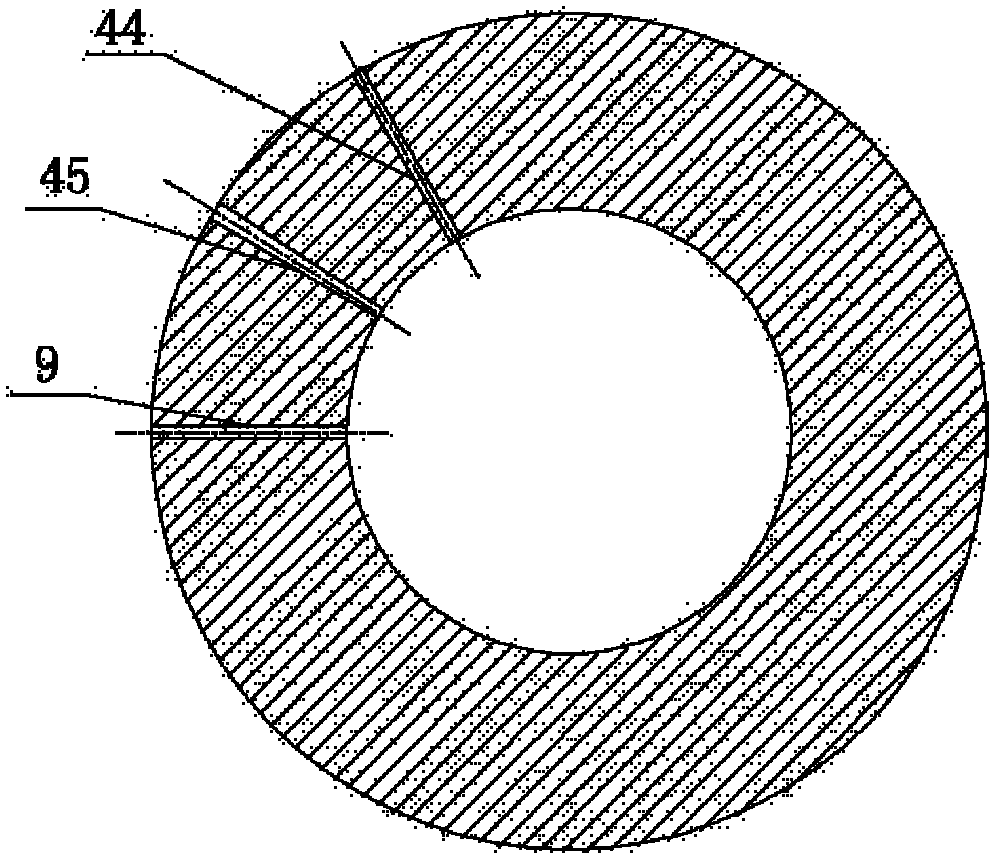

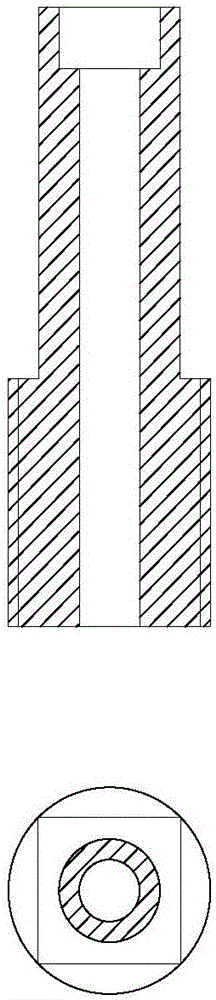

Explosive grain thermal explosion critical pressure measurement apparatus

InactiveCN105043623ASolving High Temperature Pressure Measurement ProblemsAvoid damageMaterial exposibilityApparatus for force/torque/work measurementMeasurement deviceEngineering

The invention discloses an explosive grain thermal explosion critical pressure measurement apparatus, for solving the problem of high-temperature pressure measurement of explosive grains under a thermal stimulus effect and providing a means for critical pressure measurement when the explosive grains explore under the thermal stimulus effect. The apparatus is mainly composed of a simulated cook-off bomb, a guide tube, an air tap, an adapter, a nut, a pressure sensor and sealing rings. The measurement apparatus measures the thermal explosion critical pressure of the explosive grains through the general pressure sensor by use of a guide tube gradient cooling method and can be applied to research on safety of the explosive grains under the thermal stimulus effect.

Owner:XIAN MODERN CHEM RES INST

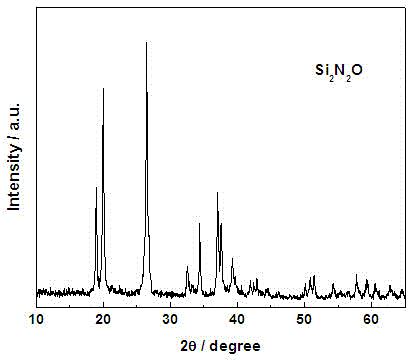

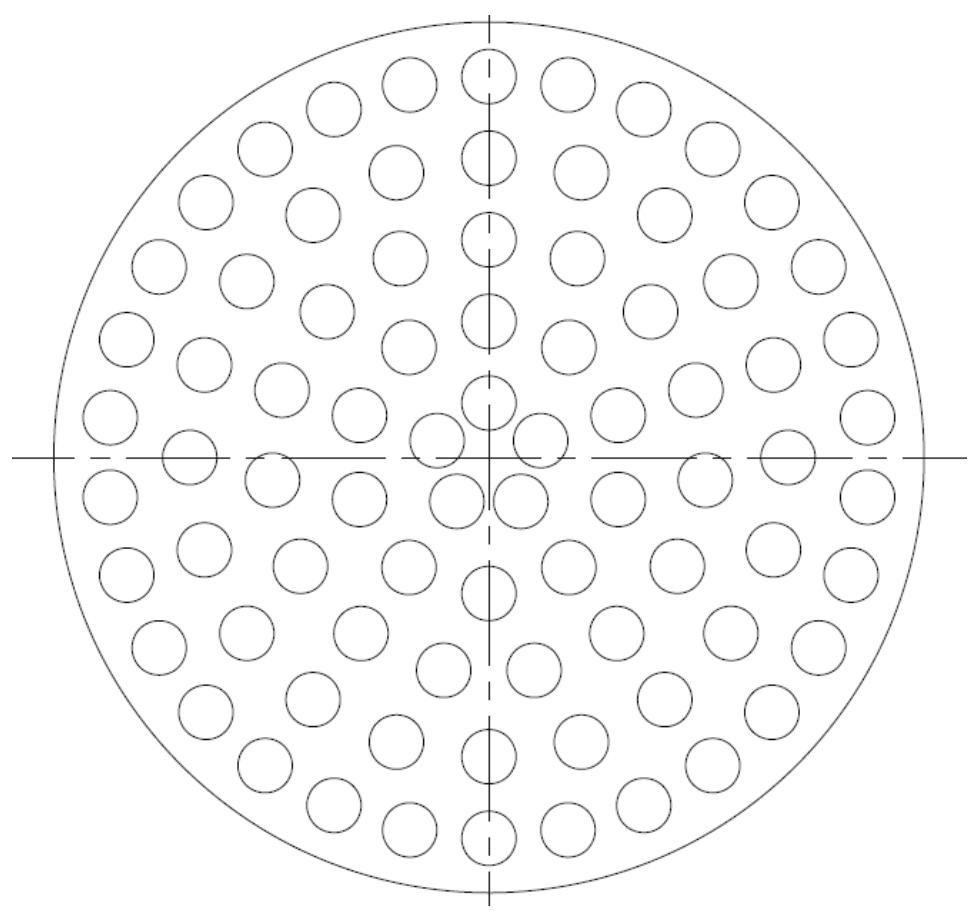

Normal pressure thermal explosion method for preparation of high purity silicon oxynitride ceramic powder

InactiveCN104891459AReduce energy consumptionReduce manufacturing costNitrogen and non-metal compoundsDiluentGravity separation

The present invention belongs to the technical field of preparation of high purity silicon oxynitride ceramic powder, and relates to a normal pressure thermal explosion method for synthesis of a silicon oxynitride ceramic powder. The method is characterized by including the stages of raw ingredient preparation, mixing, thermal explosion synthesis, and acquisition of a finished product. The steps are as below: fully mixing a Si powder and a SiO2 powder by weight ratio of 40-45:55-60; conducting thermal explosion synthesis at 1380-500 DEG C for 3-15 minutes; conducting gravity separation on the thermal explosion products in a solution medium for 2-5 min; and filtering and drying the suspension to obtain a silicon oxynitride finished product. The obtained product has high purity, no impurity phase and high powder sintering activity. The invention is characterized in that the production process does not need any diluent or catalyst, and is simple, low in cost, and easy to realize large-scale continuous production.

Owner:NANCHANG UNIV

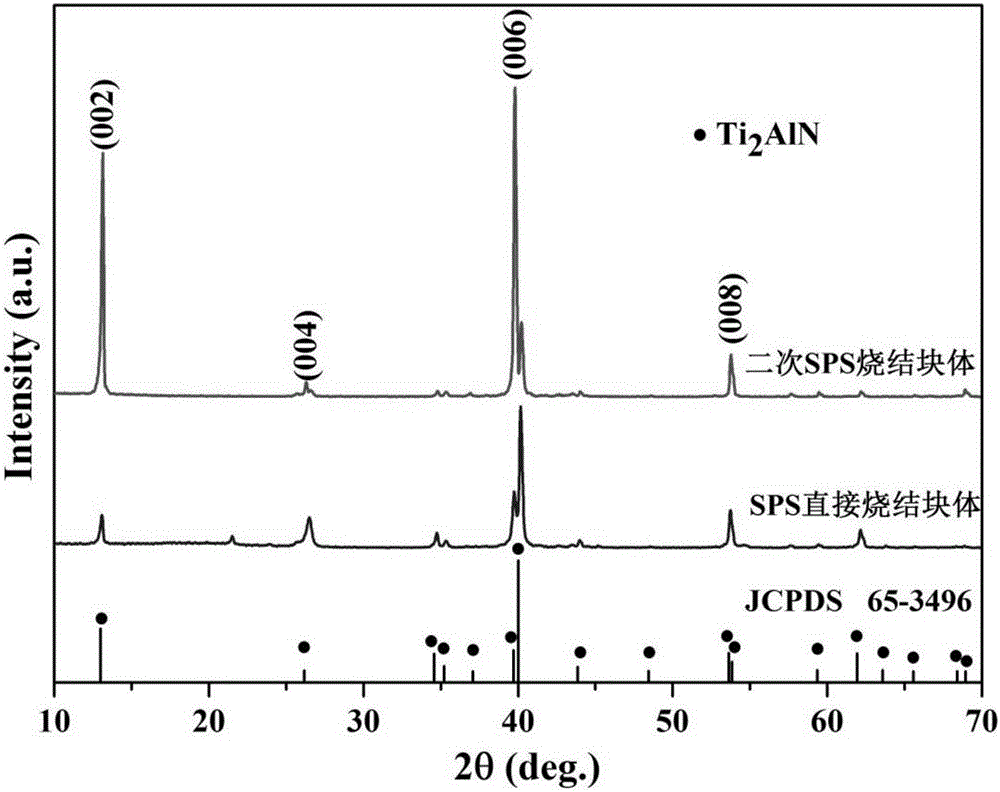

Preparation method of highly-textured Ti2AlN ceramics

Owner:SHAANXI UNIV OF SCI & TECH

Method of manufacturing thermoelectric material powder and device in superfast way

ActiveCN106384778AAvoid cumbersome intermediate linksOvercoming YieldThermoelectric device manufacture/treatmentThermoelectric materialsManufacturing technology

The invention discloses a method of manufacturing a thermoelectric material powder and a device in a superfast way. The method comprises the following steps of (1) weighing and mixing thermoelectric material composition element simple substance powders according to a stoichiometric ratio, then tabletting, and then through a self-propagating combustion reaction or a thermal explosion reaction, acquiring a thermoelectric material powder in the superfast way; (2) manufacturing a thermoelectric device in the superfast way: taking an insulation substrate, an electrode powder and the thermoelectric material powder acquired from the step (1) as starting raw materials of a selective laser fusion technology, and through three dimensional printing, manufacturing the thermoelectric device. In the invention, from a simple substance raw material of the thermoelectric material, through combining self-propagating combustion synthesis, inkjet printing and a 3D printing technology of selective laser fusion and through a material increase manufacturing technology, the thermoelectric device is printed, tedious intermediate links during a traditional thermoelectric device manufacturing technology process are avoided, simultaneously, a miniature device can be directly printed and problems that a yield and a raw material utilization rate are low in a traditional welding and assembling technology are overcome.

Owner:武汉新赛尔科技有限公司

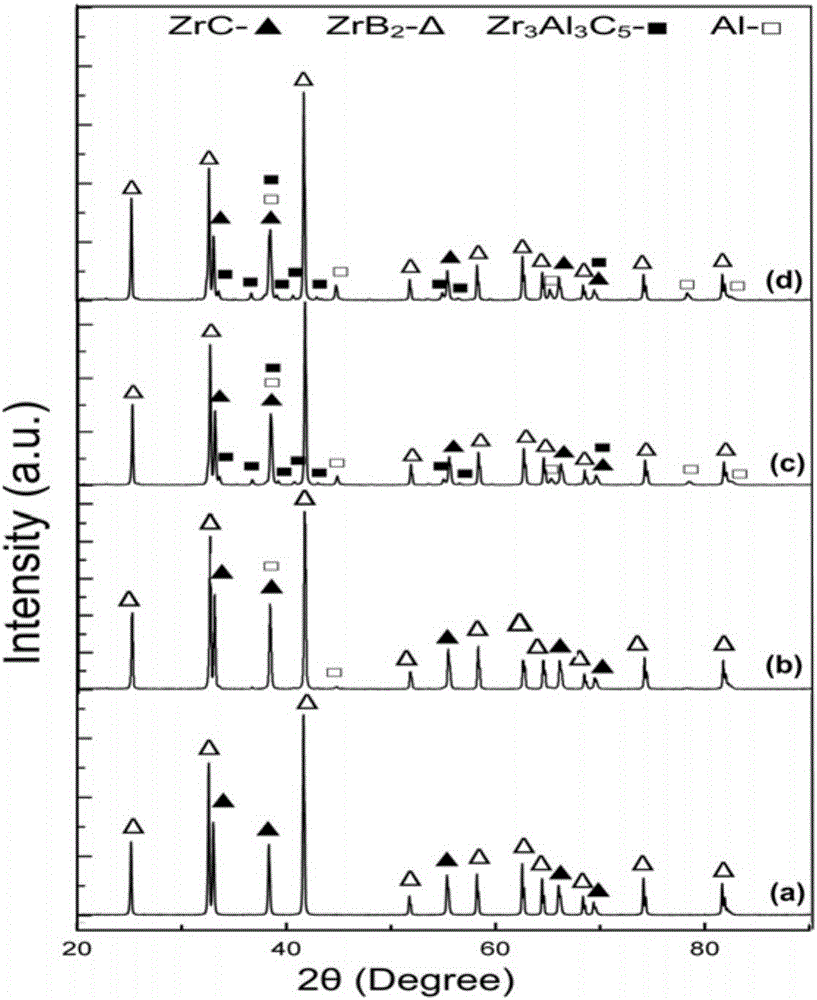

Zirconium carbide-zirconium diboride complex-phase ceramic powder synthesized through thermal explosion and preparation method thereof

The invention relates to zirconium carbide-zirconium diboride complex-phase ceramic powder synthesized through thermal explosion and a preparation method thereof. The ceramic powder is prepared from, by mass, 0%-30% of Al powder and 70%-100% of Zr powder and B4C powder, wherein the molar ratio of Zr to B4C is 3:1, and the sum of the mass percent of the components is 100%. The preparation method comprises the steps that the Al powder, the Zr powder and the B4C powder which are dried are fully mixed and then pressed into green blank blocks, a thermal explosion chemical reaction is conducted in an induction furnace which is vacuumized and then is full of Ar gas, and the ceramic powder is obtained. The ceramic powder and the preparation method thereof have the advantages that reacting is rapid, energy saving and cleanliness are achieved, and the product compounding degree is high; the product is a ceramic compound mainly containing ZrC powder and ZrB2 powder and can be directly applied as a zirconium carbide-zirconium diboride complex-phase ceramic powder material, the zirconium carbide-zirconium diboride complex-phase ceramic powder can be separated after other impurities in the compound are washed off through extraction, and then the single pure zirconium carbide or pure zirconium diboride ceramic powder can be obtained for application.

Owner:TONGREN UNIV

Method for preparing laminated conductive titanium-aluminum-carbon honeycomb ceramic by using element powder in situ and application

InactiveCN104291824AWith through-hole structureReduce manufacturing costCatalyst carriersTitaniumGraphite

The invention relates to the field of conductive honeycomb ceramic, and in particular relates to a method for preparing laminated conductive titanium-aluminum-carbon honeycomb ceramic by using element powder in situ and application. The method comprises the following steps: by taking Ti powder, Al powder and graphite powder as raw materials, adding an organic binding agent, a plastic agent and a lubricant, smelting, aging, performing extrusion molding, cutting, drying and performing pressureless sintering in an atmosphere furnace. The heating can be performed in two stages, namely, the heating velocity of the first stage is 2-5 DEG C / minute, and the temperature is kept for 2-6 hours below the melting point Al (600-650 DEG C); the heating velocity of the second stage is 2-5 DEG C / minute, the sintering temperature is 1400-1500 DEG C, and the sintering time is 0.5-3 hours, thereby preparing the conductive titanium-aluminum-carbon honeycomb ceramic. By adopting the method, the defect that the production cost is high when prepared titanium-aluminum-carbon powder is taken as a raw material for preparing the titanium-aluminum-carbon honeycomb ceramic is solved, as the heating procedures are precisely designed, the thermal explosion reaction is effectively avoided, and thus the titanium-aluminum-carbon honeycomb ceramic of regular shapes can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

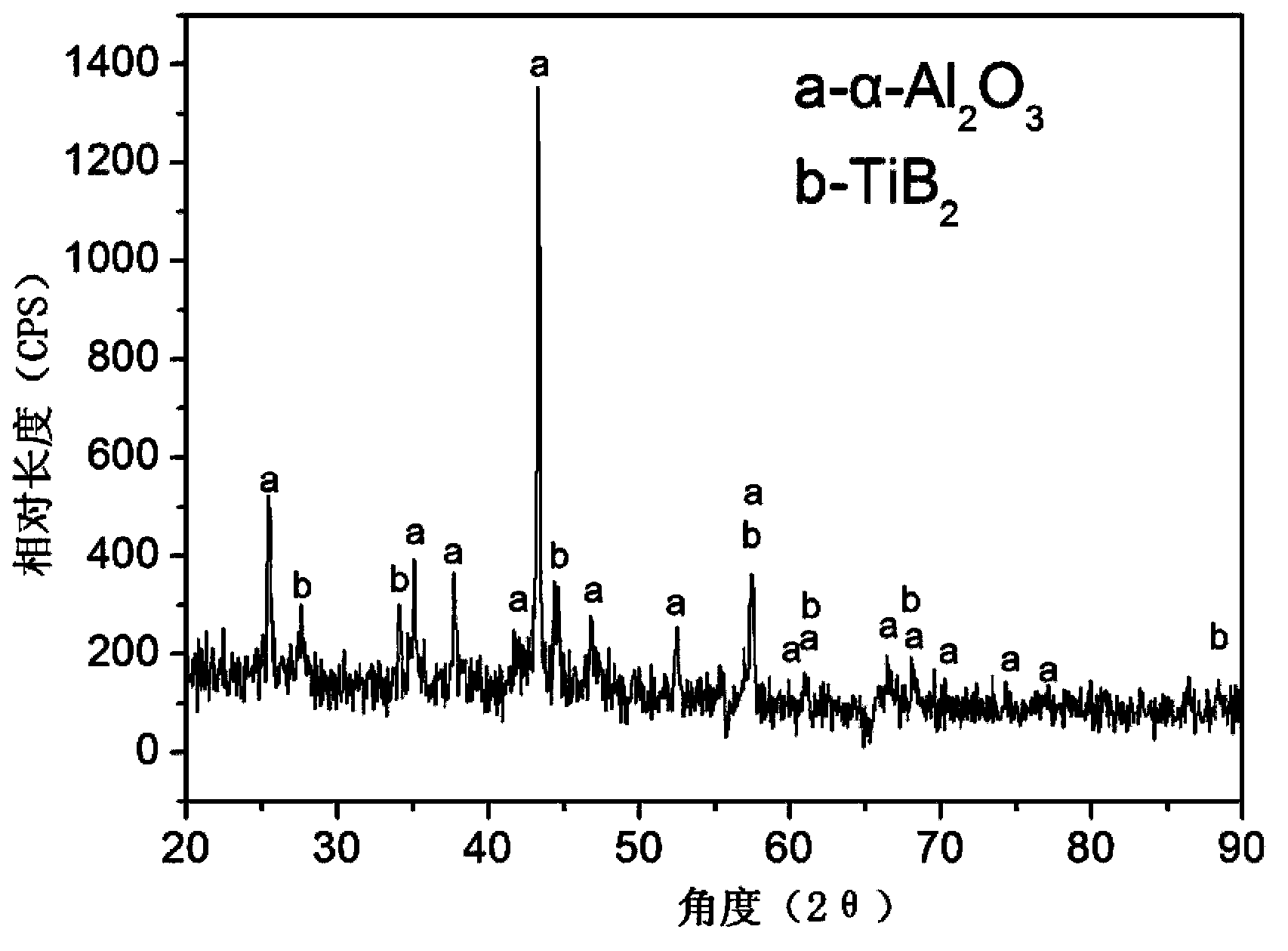

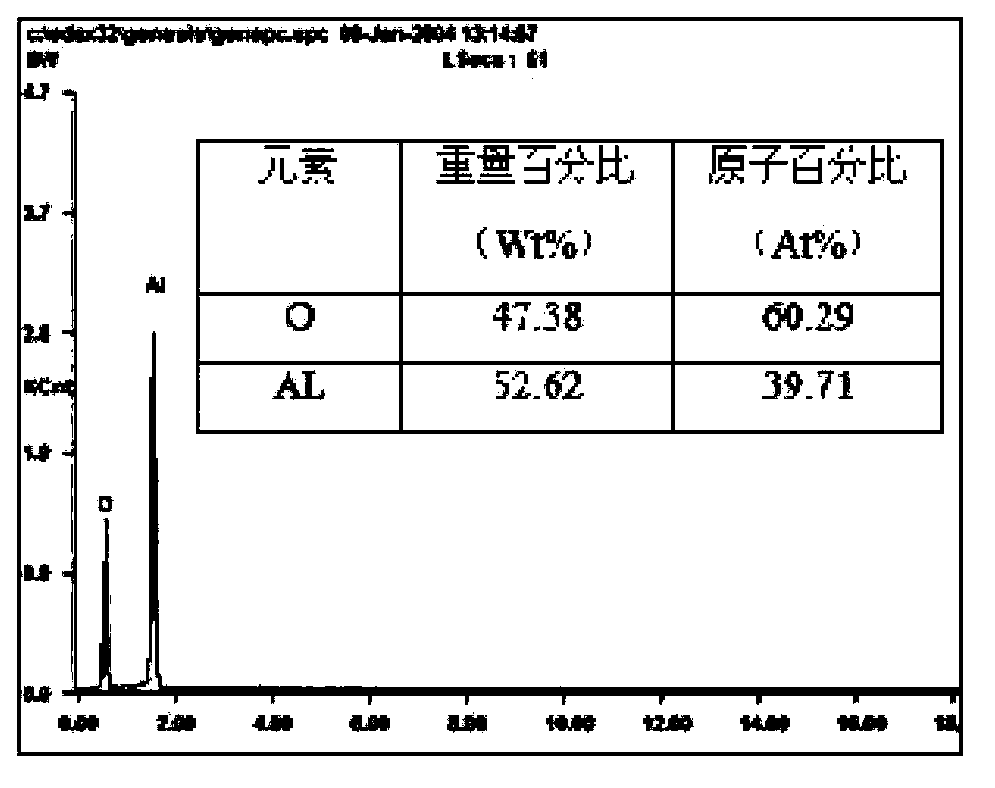

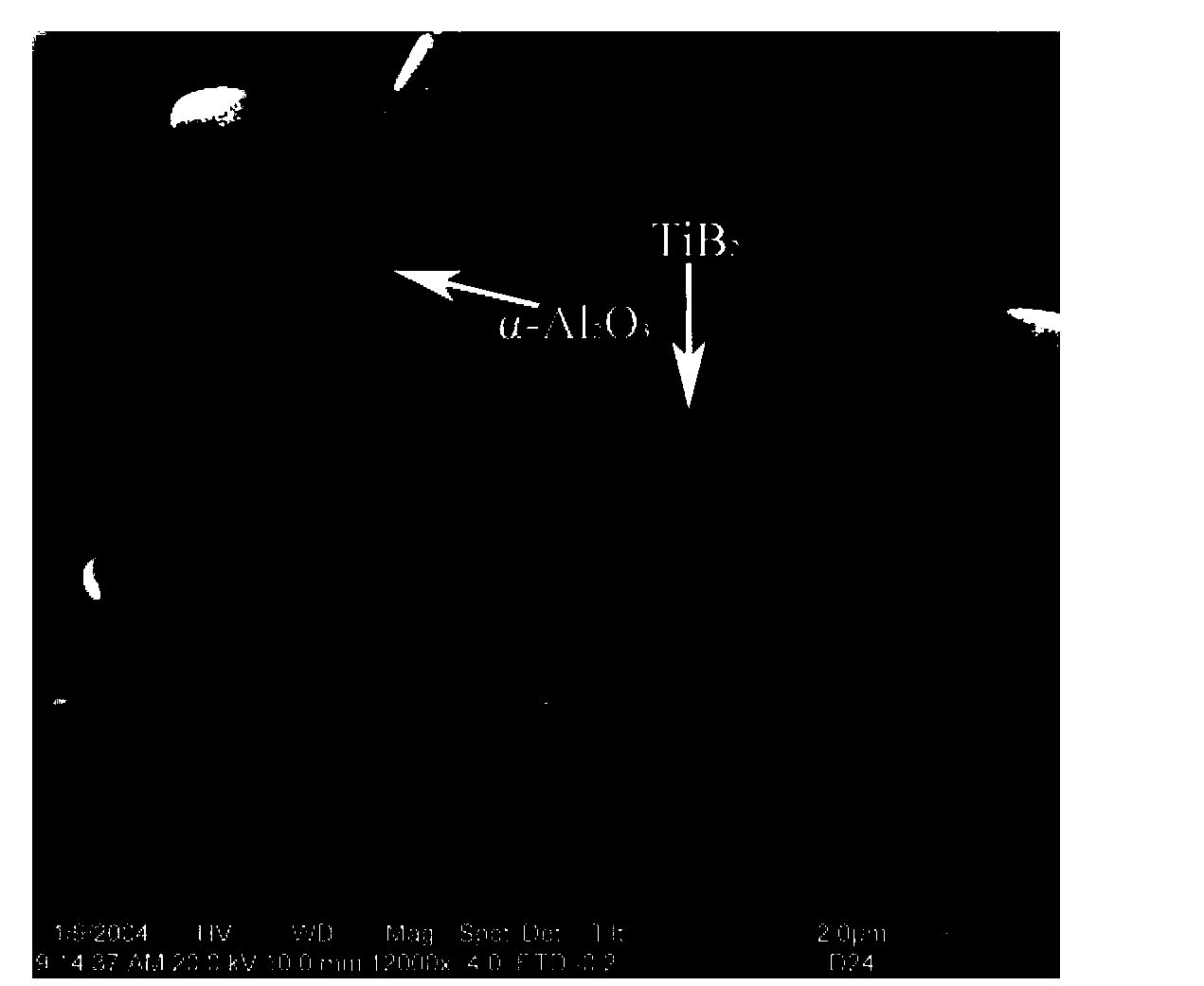

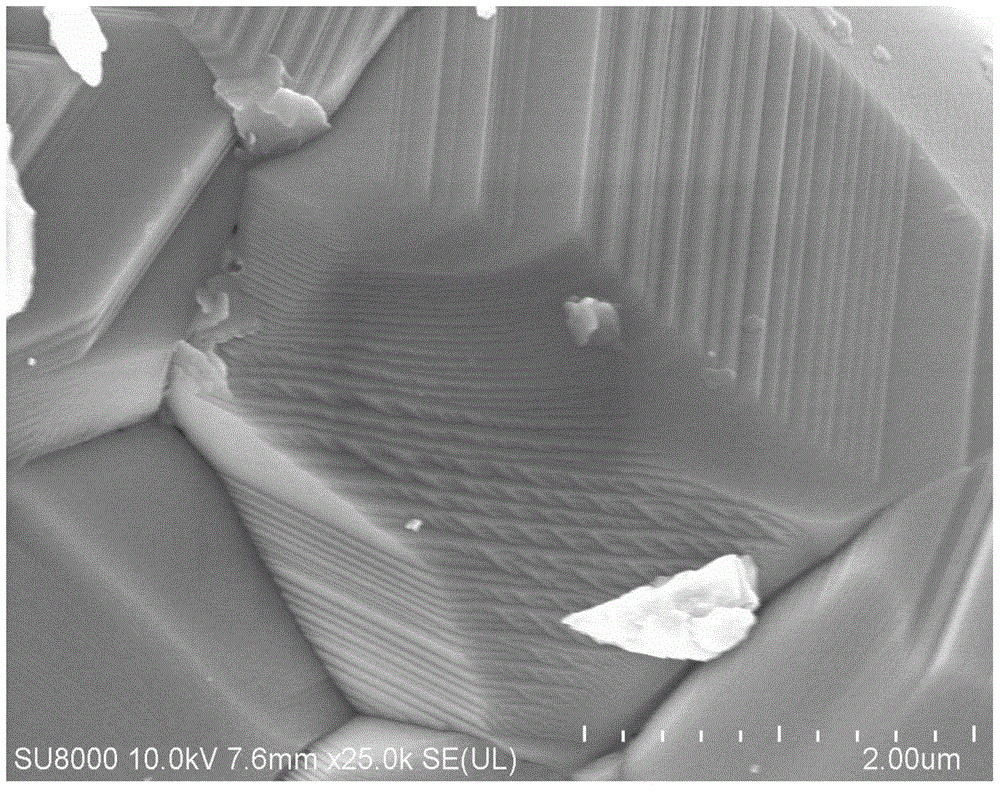

Micro-nano intragranular multiphase granule and thermal explosion reaction synthetic method thereof

The invention discloses a micro-nano intragranular multiphase granule and a thermal explosion reaction synthetic method thereof. According to the multiphase granule, micron-level alpha-Al2O3 and nanometer-level TiB2 are taken as the multiphase, and alpha-Al2O3 is grown and formed by taking nanometer-level TiB2 as a nucleus. The multiphase granule is prepared according to the following steps: mixing Al powder, TiO2 powder and B2O3 powder, and performing ball milling, wherein the molar ratio of Al, TiO2 and B2O3 is (10-17):1:1; extruding the powder subjected to ball milling into a blank sample; placing the sample in a vacuum furnace and vacuumizing; controlling the temperature raising speed at 15-20 K / min, heating to the moment that the sample is subjected to the thermal explosion reaction; after the reaction is finished, keeping the temperature for 30-60 min, shutting down the furnace to obtain intragranular multiphase granule blocks; and dissolving residual aluminium with an alkali aqueous solution, washing and filtering to obtain a wet powder, and drying to obtain the intragranular granule powder. Micro-nano granules forming the intragranular multiphase granules are all generated through the thermal explosion reaction, and the surface are clean and free of pollution; and under the exothermic effect of the reaction, the micro-nano intragranular multiphase granules are grown and formed through intracrystallization, the interfaces of the micro-nano granules are clean, the bonding strength is high, and the toughness of the intragranular multiphase granules is substantially improved.

Owner:NANJING UNIV OF SCI & TECH

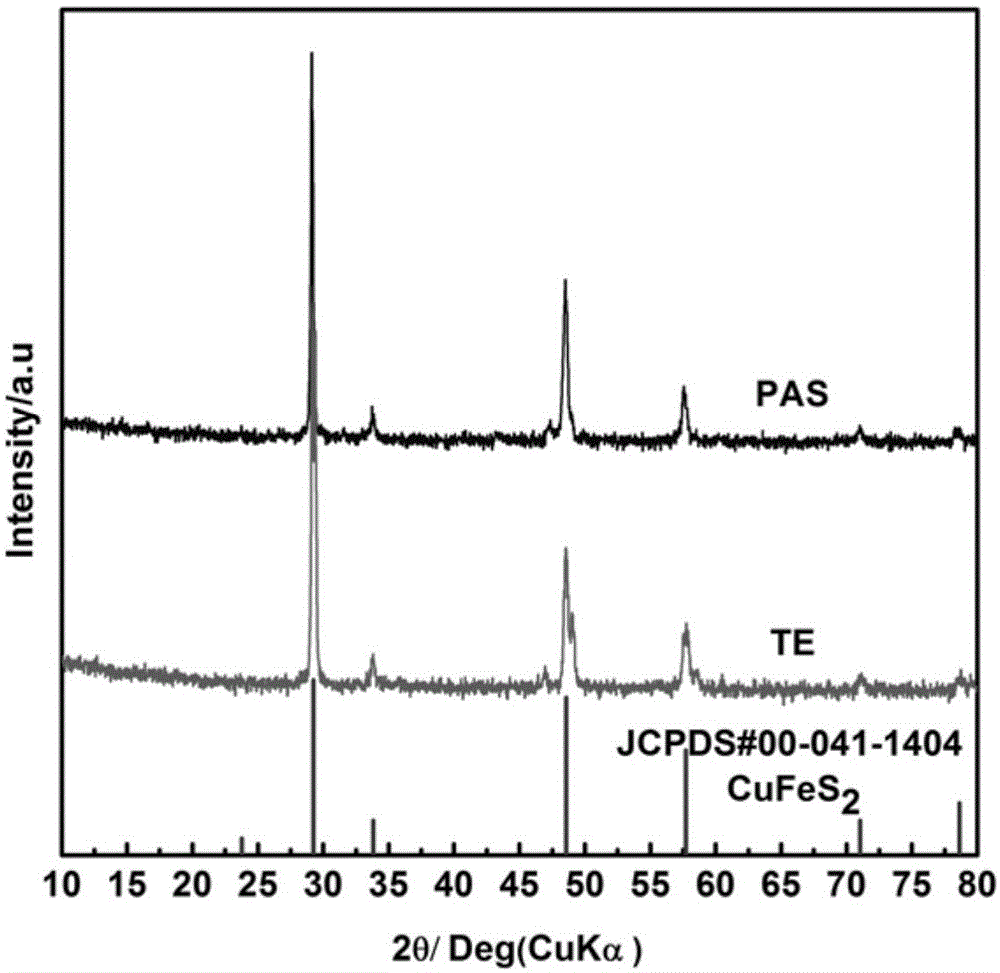

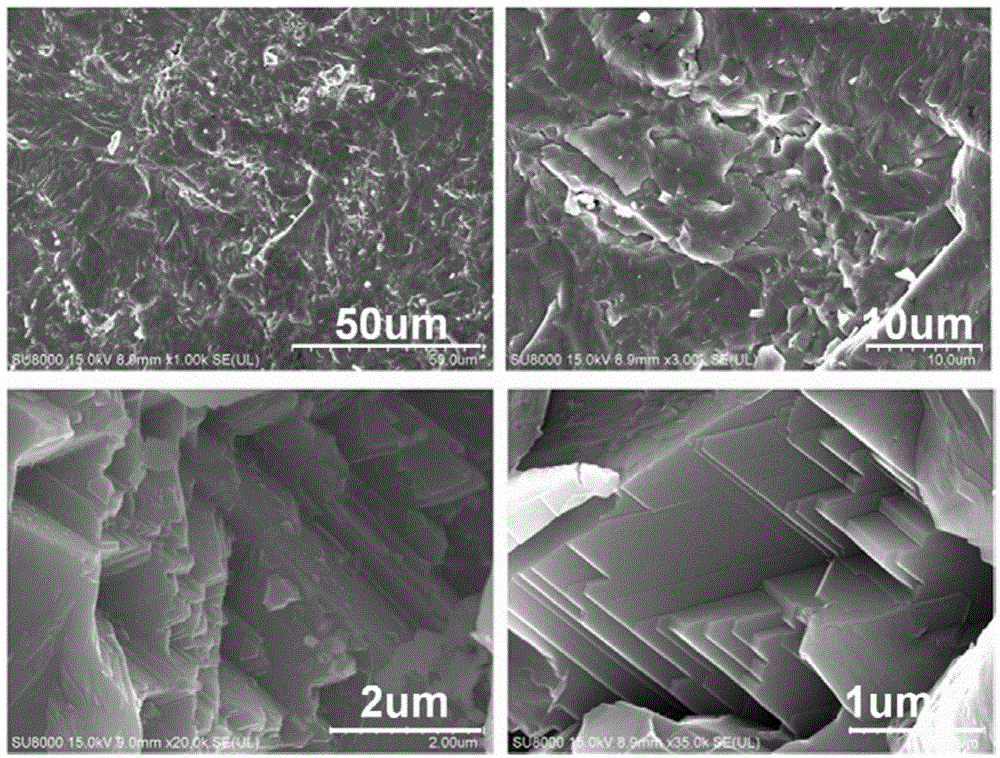

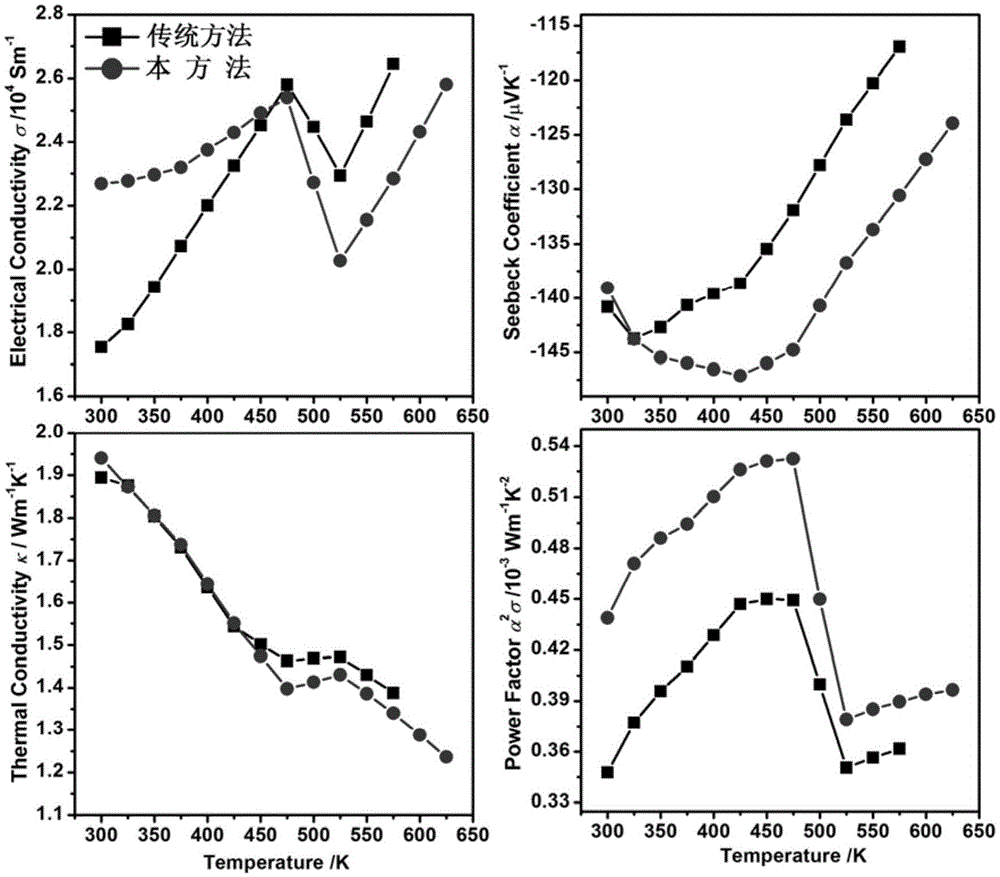

Rapid preparation method of high performance CuFeS2 thermoelectric material

The invention relates to a rapid preparation method of a high performance CuFeS2 thermoelectric material. The preparation method comprises the following steps: (1) weighing raw materials: Cu powder, Fe powder, and S powder according to the chemical stoichiometric ratio of the chemical formula CuFeS2 of (0.95-1.05):(0.95-1.05):(2-2.5), mixing and evenly grinding the powder, and then pressing the powder into block-shaped blanks; (2) triggering thermal explosion reactions in the block-shaped blanks obtained in the step (1), naturally cooling after the reactions to obtain a single-phase CuFeS2 compound; (3) grinding the product obtained in the step (2) into powder, carrying out discharge plasma activation, and sintering so as to obtain the high performance CuFeS2 thermoelectric material. The method has the advantages of fast reaction speed, simple technology, high efficiency, energy saving, and good repeatability. The whole preparation can be finished within 15 minutes, and the thermoelectric merit figure of the obtained blocks can reach 0.2 at a temperature of 350 DEG C.

Owner:WUHAN UNIV OF TECH

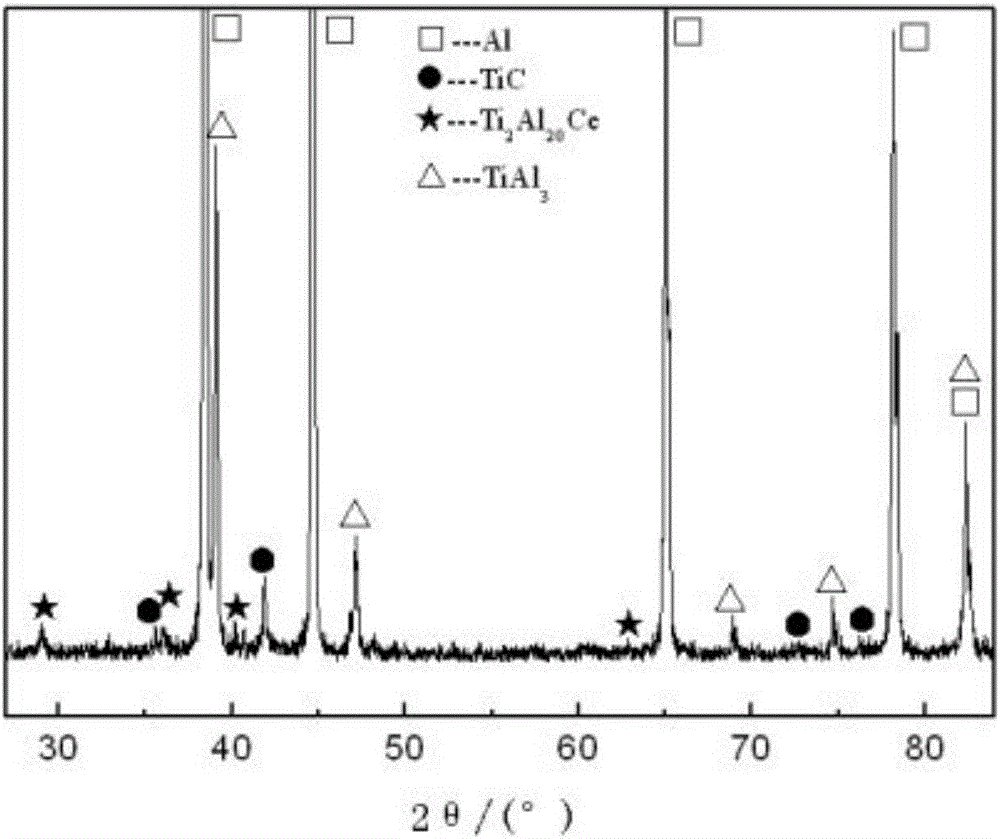

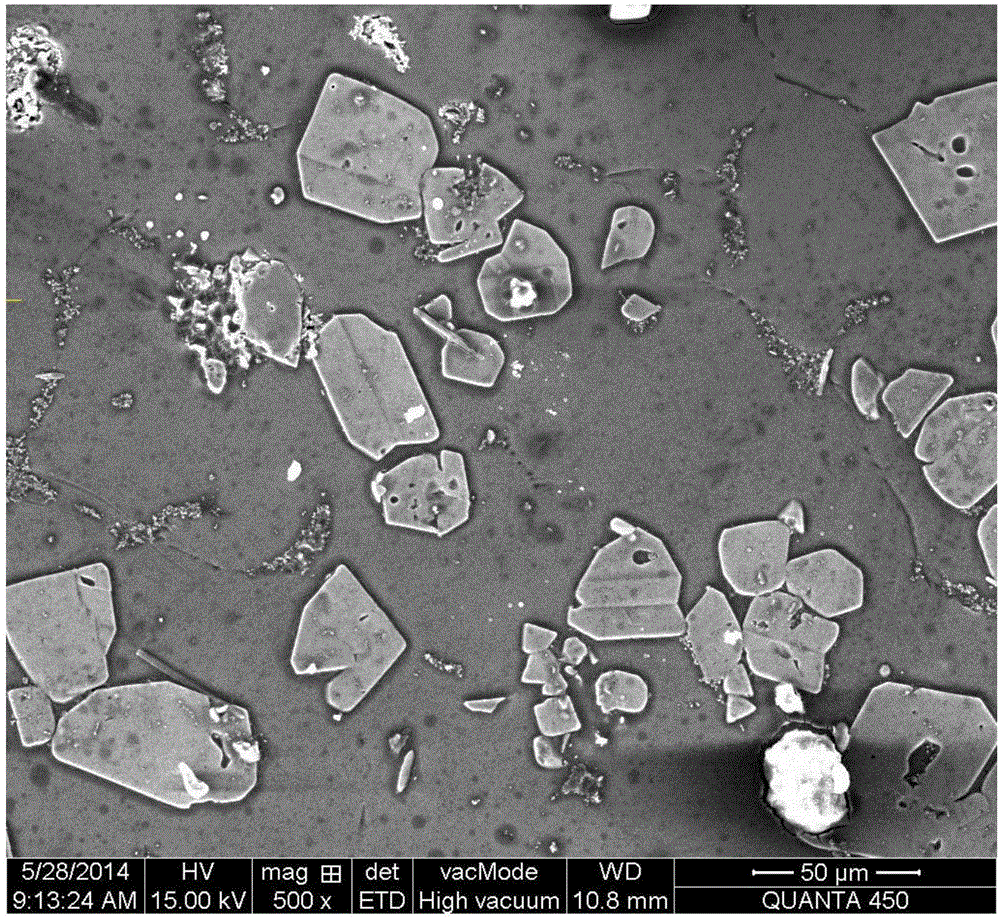

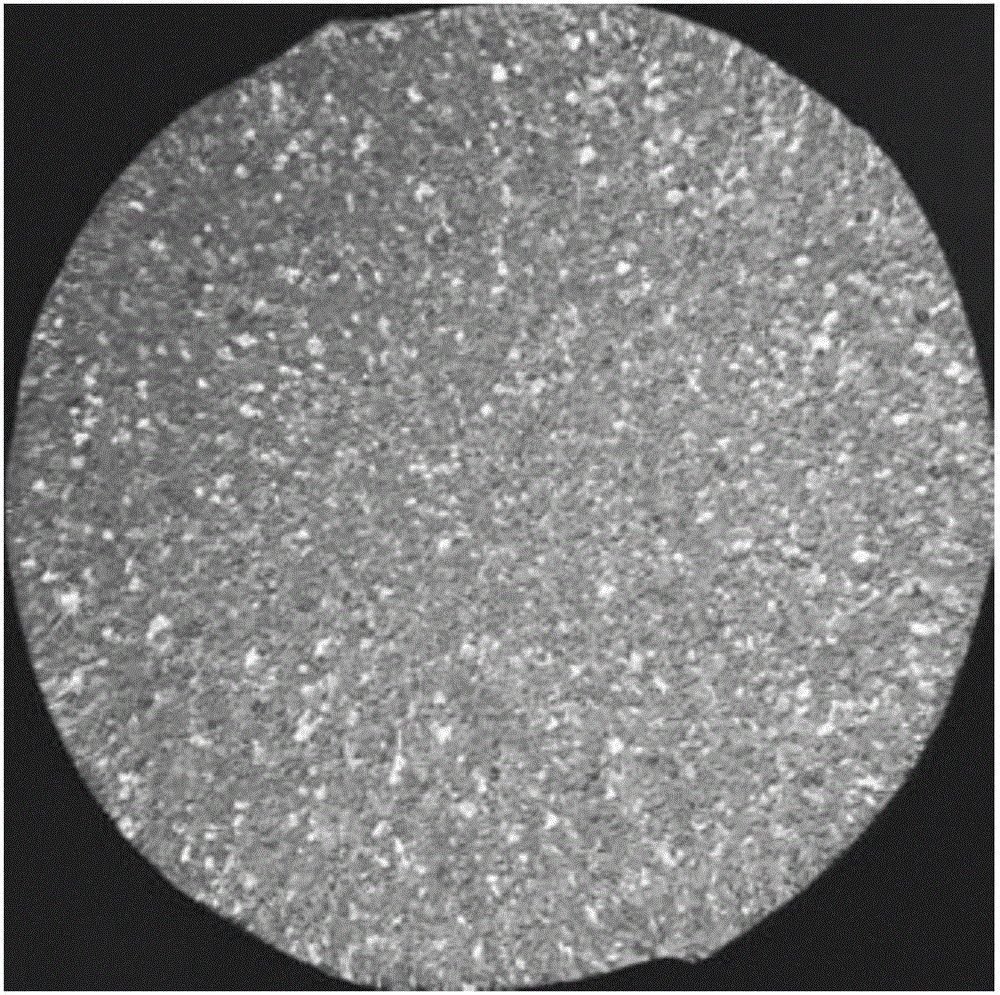

Preparation method of Al-Ti-C-Ce refiner

The invention provides a preparation method of an Al-Ti-C-Ce refiner. The preparation method of the Al-Ti-C-Ce refiner mainly comprises the following steps that aluminum powder, titanium powder, graphite powder and Ce2O3 powder are mixed and briquetted into a mixed powder block; an aluminum ingot is heated till the aluminum ingot is completely melted, and thus aluminum melt is obtained; the mixed powder block is pressed into the aluminum melt for a thermal explosion reaction, and thus alloy melt is obtained; the alloy melt is filtered and purified, then the purified alloy melt is poured into a steel mold, and thus the Al-Ti-C-Ce refiner is obtained. According to the preparation method of the Al-Ti-C-Ce refiner, sufficient reaction of elements is guaranteed, the reaction time is short, energy saving and high efficiency are achieved, and environmental pollution is avoided.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Disassembling method for waste television and equipment or disassembling equipment

InactiveCN105107816ARealize resource reuseTo achieve the purpose of harmless dismantlingSolid waste disposalElectronic waste recyclingEnvironmental resistanceSemi automatic

The invention discloses a disassembling method for a waste television and disassembling equipment or the disassembling method. The method comprises the procedures of feeding, disassembling and separating, conveying all parts to respective specified places, and finally machining the parts into raw materials. In the process, manual disassembling and semi-automatic mechanical treatment are combined, the optimized layout of complete television-part disassembling and centralized logistics transportation is achieved, logistics efficiency is greatly improved, and labor intensity is lowered. Meanwhile, the aim of conducting harmless disassembling treatment on electronic products of various types and specifications is achieved, and high safety is achieved. Recycling comprehensive reutilization on various materials of the waste kinescope television is further achieved. The disassembling equipment comprises an electric heating wire thermal explosion separator and a workbench, and is high in separation speed and free of noise. The beneficial effects of being easy to operate, high in separation efficiency, economical, environmentally friendly and the like are achieved.

Owner:ZHEJIANG SHENGTANG ENVIRONMENTAL PROTECTION TECH

Method for preparing pure black fungus or pure kelp broth product based on thermal explosion pretreatment

ActiveCN105077465AChanges in processing intakeLess investmentFood preparationAdditive ingredientFiltration

The invention discloses a method for preparing pure black fungus or pure kelp broth product based on thermal explosion pretreatment. The method is characterized in that black fungus or kelp is used as a raw material, other ingredients are avoided, and according to less water content of the raw material, through screw heating extruder normal pressure thermal explosion pretreatment, chopping, starter propagation, fermentation, leaching, filtration and disinfection, the pure black fungus or pure dry kelp broth raw stock rich in a plurality of biologically-active substances is obtained. The pure black fungus or pure dry kelp broth raw stock retains nutrients of the raw material, and can be directly mixed with local flavor nutrients of vegetables and fruits so that a series of drinks and flavorings are obtained. Through further spray drying, powder easy to be stored can be formed and the powder is used for development of a solid local flavor nutritious food and a health product.

Owner:大连圣迈生物技术有限公司

Preparation method for corrosion-resistant coating of nickel-aluminum based intermetallic compound

InactiveCN102925890AHigh economic valueHigh bonding strengthMetallic material coating processesHigh-temperature corrosionBond strength

The invention belongs to the technical field of material science, and relates to a preparation method for a corrosion-resistant coating of a compact nickel-aluminum (Ni-Al) based intermetallic compound which is synthesized by the in-situ heat explosion on the surface of carbon steel. The preparation method comprises the following steps of: firstly, preparing Ni powder and Al power according to the mole percentage that the Ni powder is 50-75%, and the Al powder is 25-50%, and evenly mixing with absolute ethyl alcohol; and drying on the basis of wet-process even mixing, stimulating the in-situ thermal explosion reaction in a heating furnace with the temperature being 550-600DEG C so as to generate a Ni-Al base intermetallic compound coating on the carbon steel base body. The coating prepared by the method is compact in interior structure and free from pores, and is higher in bonding strength when being metallurgically boned with the carbon steel base body. The preparation method is a coating preparation technology which is high in economic value, and can be widely applicable to the preparation of a protective coating resisting high temperature corrosion.

Owner:SHANDONG UNIV

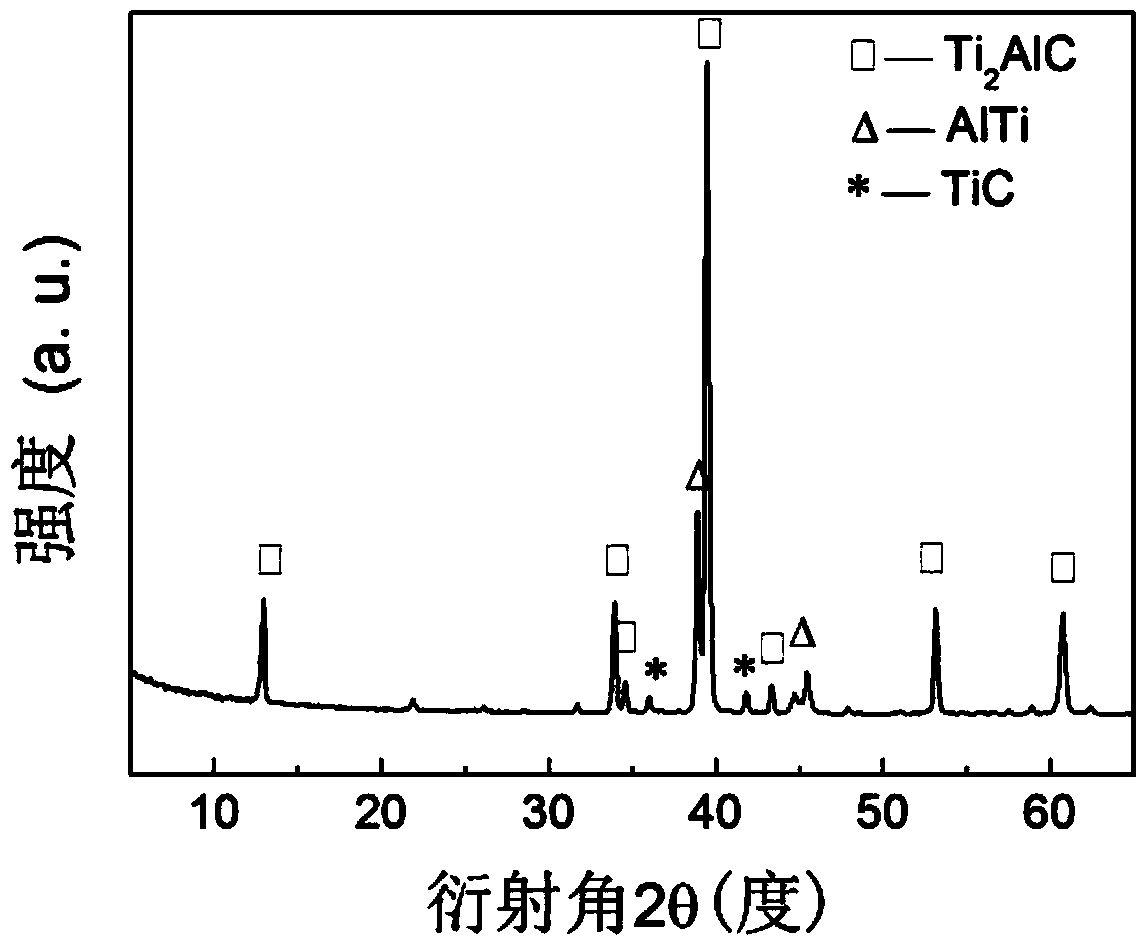

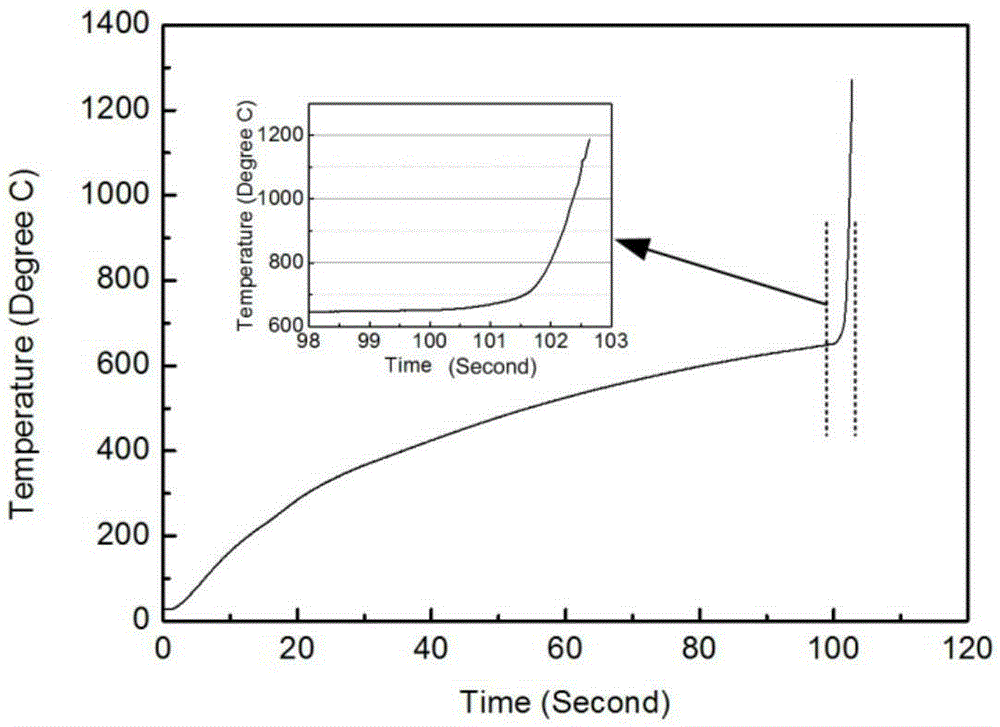

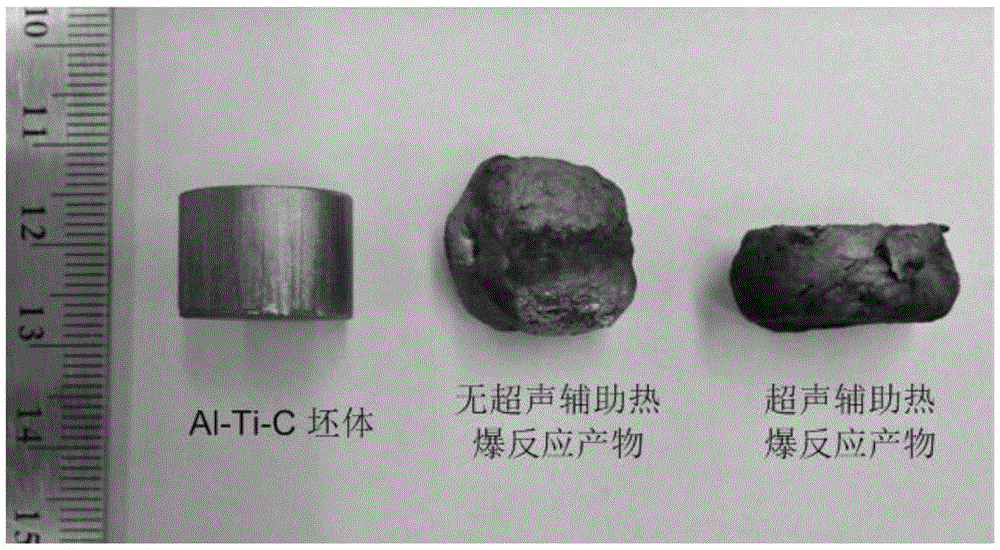

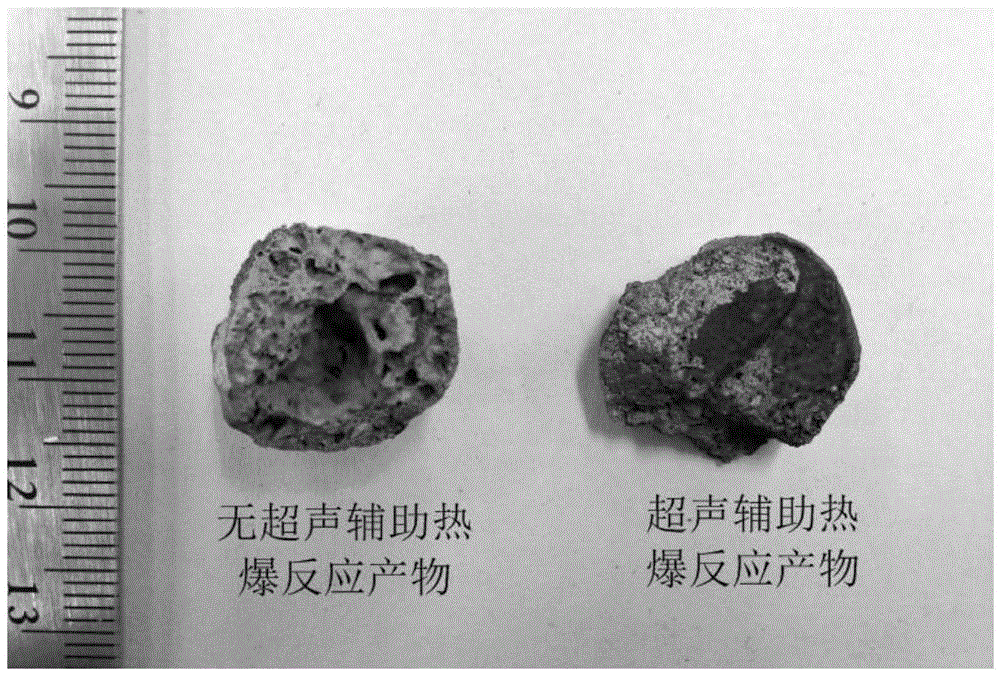

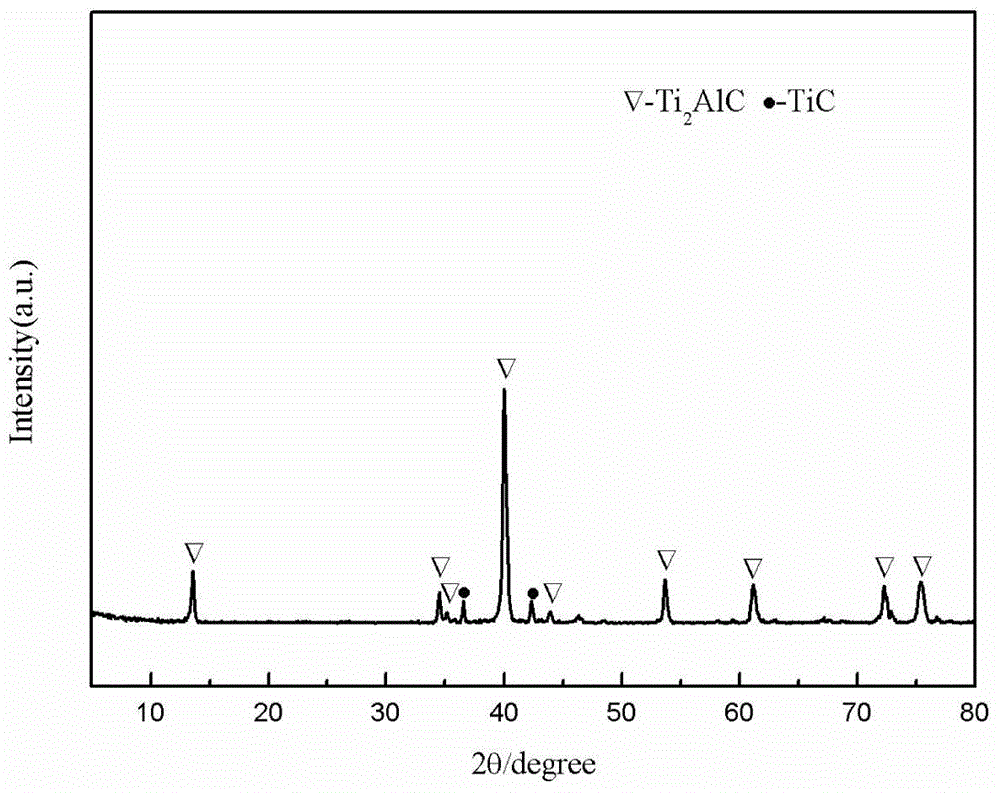

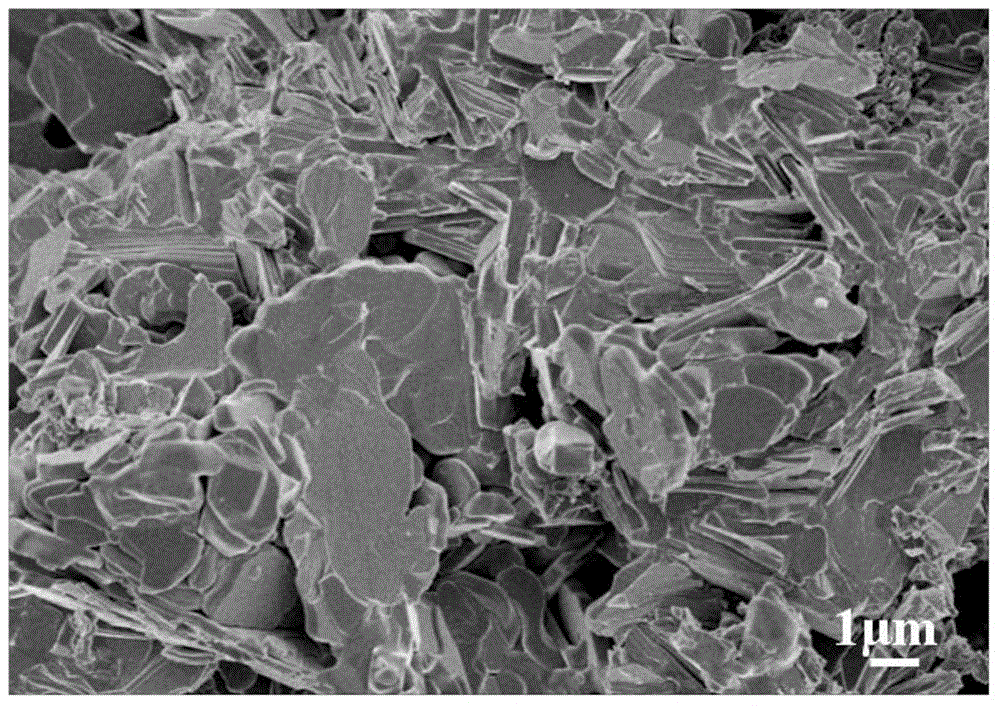

Method for preparing Ti2AlC on basis of ultrasonic wave assistance thermal explosion reaction

The invention discloses a method for preparing Ti2AlC on the basis of ultrasonic wave assistance thermal explosion reaction. The method comprises the following steps of 1, mixing Ti powder, Al powder and graphite powder according to a mol ratio being 2:1:1, and then performing grinding to obtain mixed powder; 2, putting the mixed powder into a mold for cold pressing to obtain green bodies; 3, in the insert atmosphere, directly heating the green bodies at 700 to 800 DEG C; when the heating is performed for 90 to 110s, exerting ultrasound with the power being 1.0 to 1.5kW onto the bodies of the green bodies until the thermal explosion reaction is completed, so that a reaction product with the main phase being ternary Ti2AlC is obtained. The method has the advantages that the ultrasound is used for assisting the thermal explosion reaction, and the pure Ti2AlC can be fast prepared under the low-temperature condition.

Owner:XI AN JIAOTONG UNIV

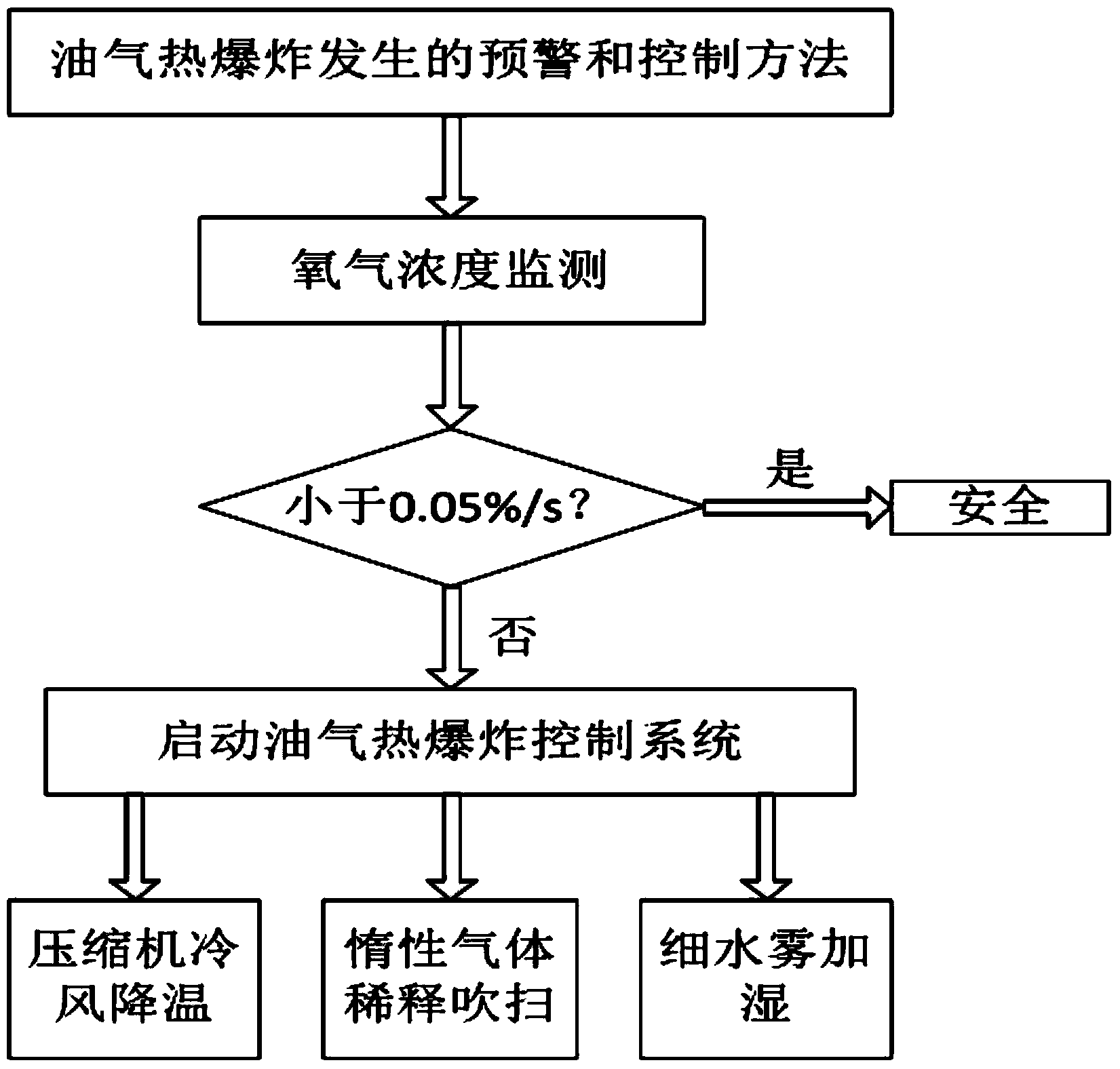

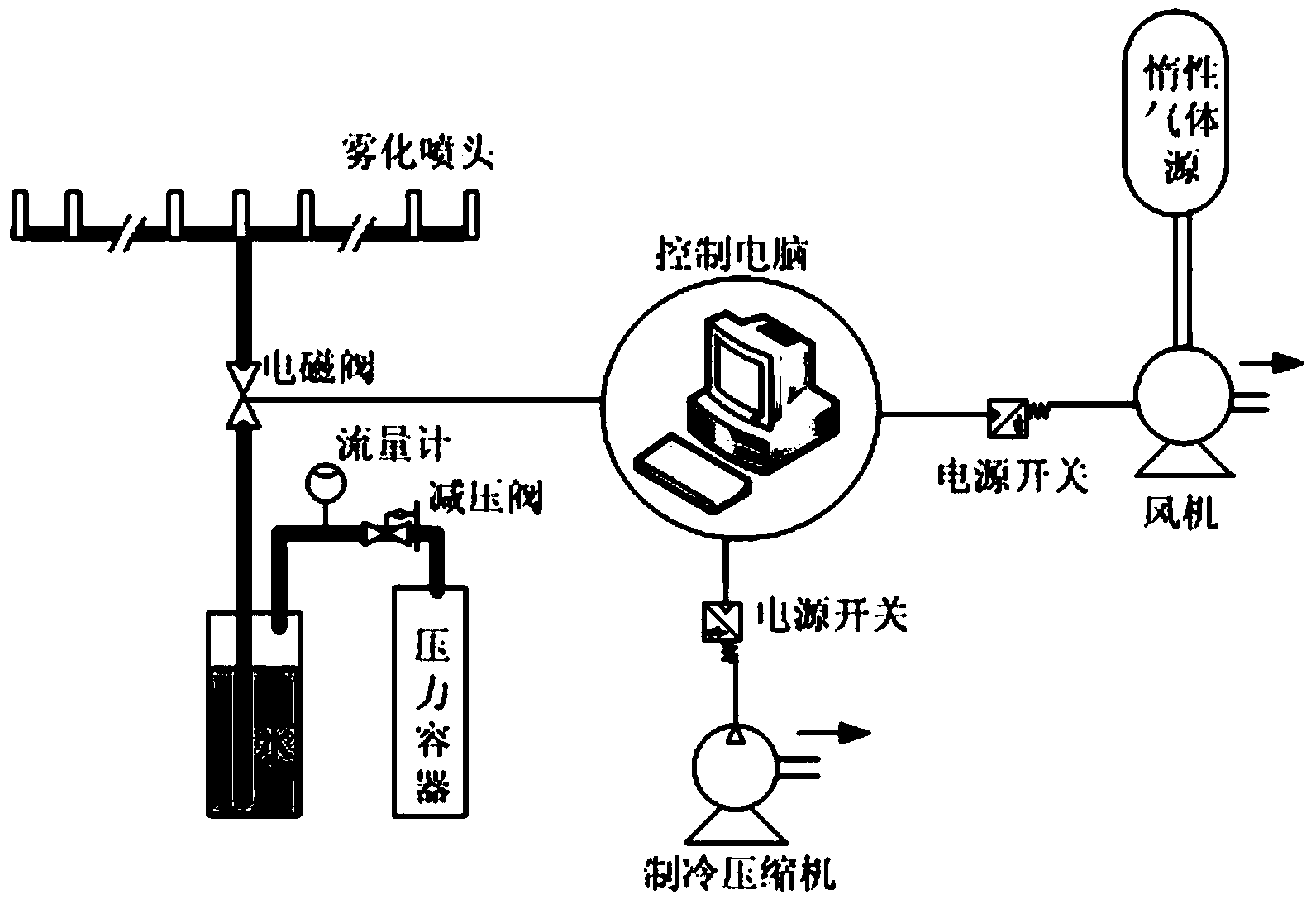

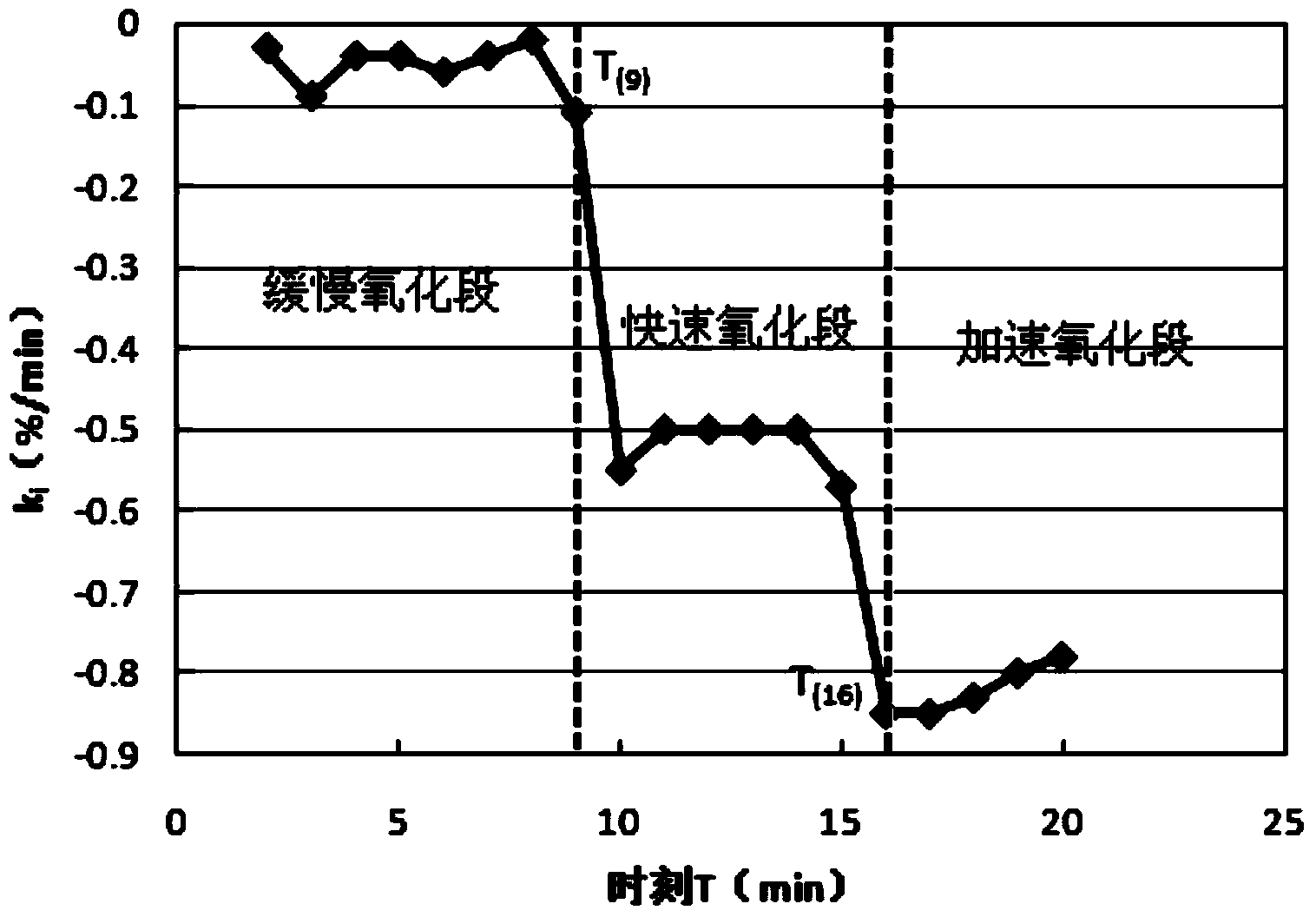

Pre-warning and control method for occurrence of oil gas thermal explosion in limited space

InactiveCN103760306AScientifically Reliable AnalysisScientific and reliable control criterionContainer filling methodsMaterial testing goodsCold airControl system

The invention discloses a pre-warning and control method for occurrence of an oil gas thermal explosion in a limited space. The fast consumption rate of oxygen when the oil gas thermal explosion occurs is taken as a pre-warning judgment criterion for the occurrence of the oil gas thermal explosion. A real-time oil gas environmental safety state can be obtained by monitoring oxygen concentration consumption rate data in an oil gas environment and performing analysis treatment on the data through a system. When the judgment shows that the risk of the oil gas thermal explosion is increased, an alarm is sent to a control system and / or field staff. After the oil gas thermal explosion control system is started, cold air cooling by a compressor, inert gas dilution purging, water mist humidification and other measures are adopted, the conditions for enabling the oil gas thermal explosion to occur are damaged, and the oil gas thermal explosion is further effectively controlled.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Titanium-aluminum-based high temperature alloy block preparing method based on thermal explosion reaction

The invention provides a titanium-aluminum-based high temperature alloy block preparing method based on a thermal explosion reaction. According to the titanium-aluminum-based high temperature alloy block preparing method based on the thermal explosion reaction, Ti / Al mixed powder is used as a raw material, an appropriate amount of titanium alloy powder is added to conduct alloying, a novel titanium-aluminum alloy material is prepared through the thermal explosion reaction and hot pressing sintering; compared with conventional gamma-TiAl, the novel titanium-aluminum alloy material remarkably improves indoor temperature ductility and has stable high temperature breaking strength and oxidation resistance at the temperature of 750 DEG C. Chinese weaponry urgently needs the high temperature titanium alloy material with the long-term working temperature capable of stably reaching 750 DEG C, such as high-pressure compressor blades, high-pressure compressor disks and high-pressure compressor casings, but the indoor temperature fragility of the existing gamma-TiAl material is too large. The novel titanium-aluminum alloy researched in the project basically keeps the heat resistance of the gamma-TiAl, but the novel titanium-aluminum alloy significantly lowers the indoor temperature fragility, greatly improves engineering practicability and embodies remarkable technology development, and then important technical support is provided for researching and manufacturing of heat-resistant components on aviation engines with thrust-weight ratio being 12-15 and high-performance aerospace thrusters.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

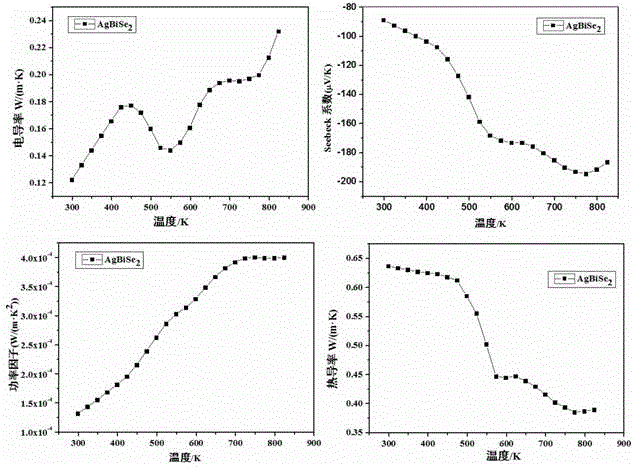

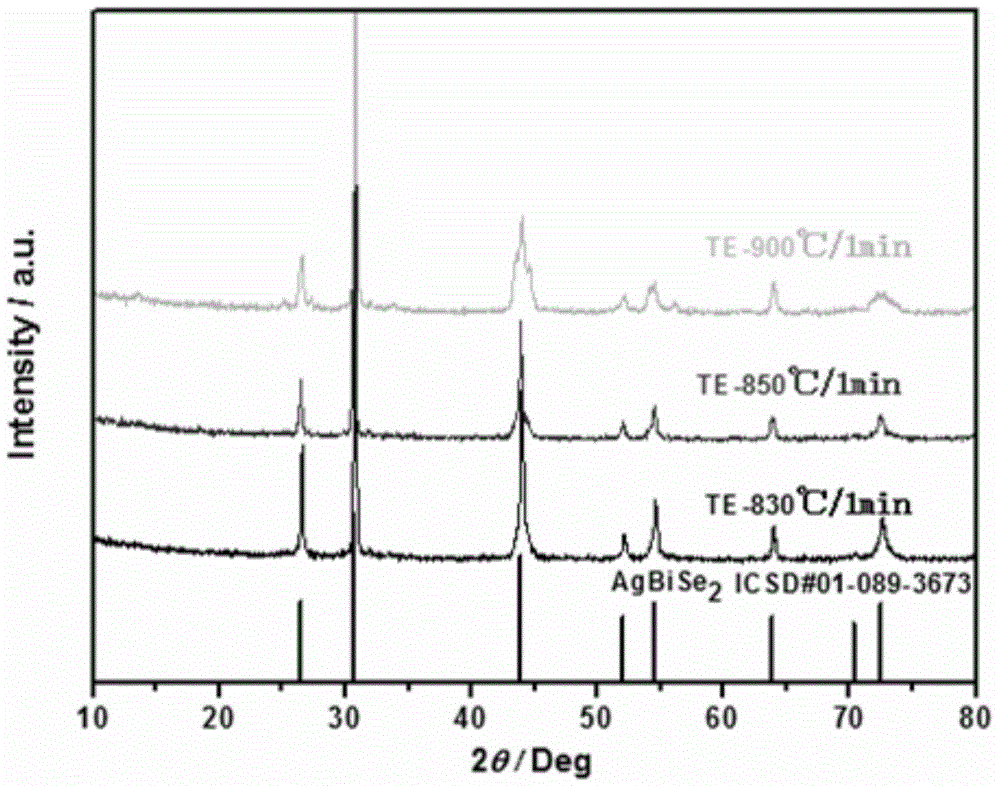

Method for rapid preparation of high performance AgBiSe2 block thermoelectric material

The invention provides a method for rapid preparation of a high performance AgBiSe2 block thermoelectric material, and the method comprises the following steps: 1) according to the stoichiometric ratio of 1:1:2, respectively weighing Ag powder, Bi powder and Se powder as raw materials, grinding the raw material powder then evenly mixing and pressing into a block; 2) performing thermal explosion reaction on the block obtained in the step 1), and after the reaction, naturally cooling to obtain single phase AgBiSe2 compound; 3) grinding the AgBiSe2 compound obtained in the step 2) into powder, performing discharge plasma activated sintering to obtain the high performance AgBiSe2 block thermoelectric material. According to the method, rapid thermal explosion reaction and discharge plasma activated sintering process are combined for preparation of the AgBiSe2 block thermoelectric material with ZT reaching 0.85 (at 550 DEG C) within 30min, and the method has the advantages of short preparation time, low energy consumption, simple process, low requirements on equipment, suitability for large-scale production, and the like.

Owner:WUHAN UNIV OF TECH

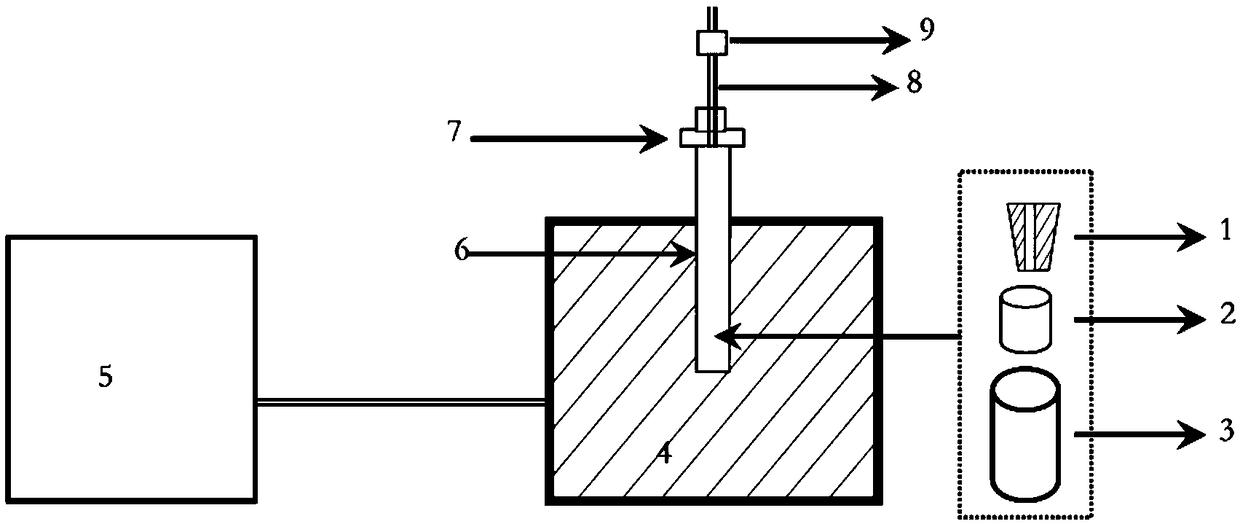

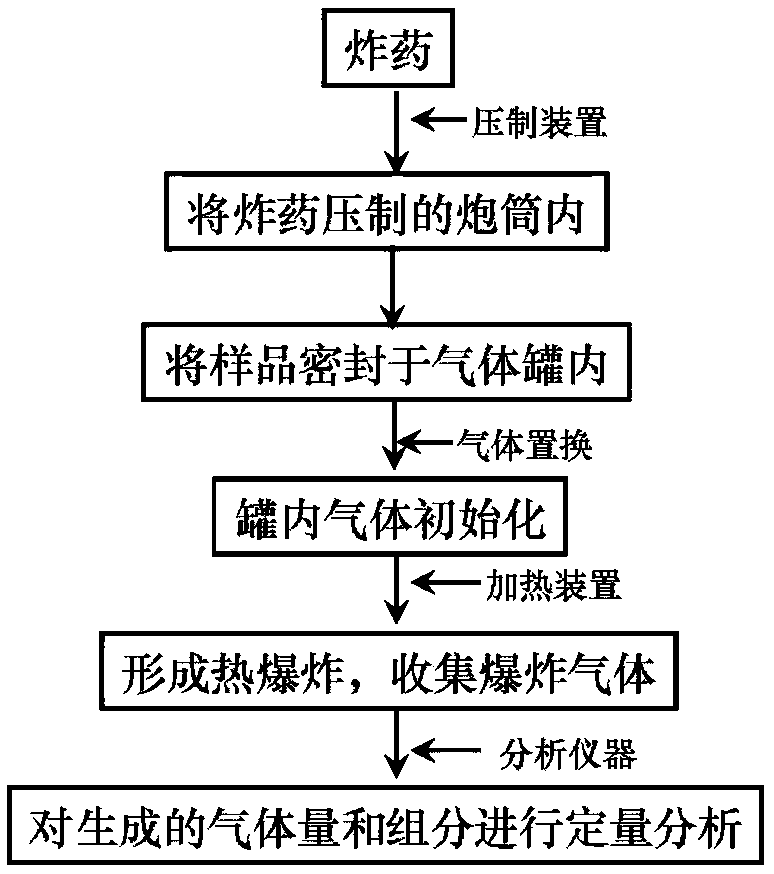

Small-charge thermal explosion gas collecting device and gas analysis method

ActiveCN109085271ARealize the collectionRealize analysisComponent separationWithdrawing sample devicesGas analysisVapor phase chromatography

The invention discloses an analysis method for testing a thermal explosion gas product of explosives, and provides a small-charge thermal explosion gas collecting device. During testing, a small amount of explosives are pressed into the cartridge, placed in a gas collection tank; the gas collection tank is placed in a high-temperature heating medium, the explosives are rapidly heated and exploding, the gas collecting tank is taken out, and a thermal explosion gas product of explosives is obtained. The total amount and composition of the thermal explosion gas product of explosives can be analyzed by directly connecting the collecting device to a gas chromatography-mass spectrometer or mass spectrometer. The method can realize collection and analysis of a small-charge thermal explosion gas product, and can be used for researching energetic materials, in particular the thermal explosion reaction mechanism of energetic materials in the exploration phase.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

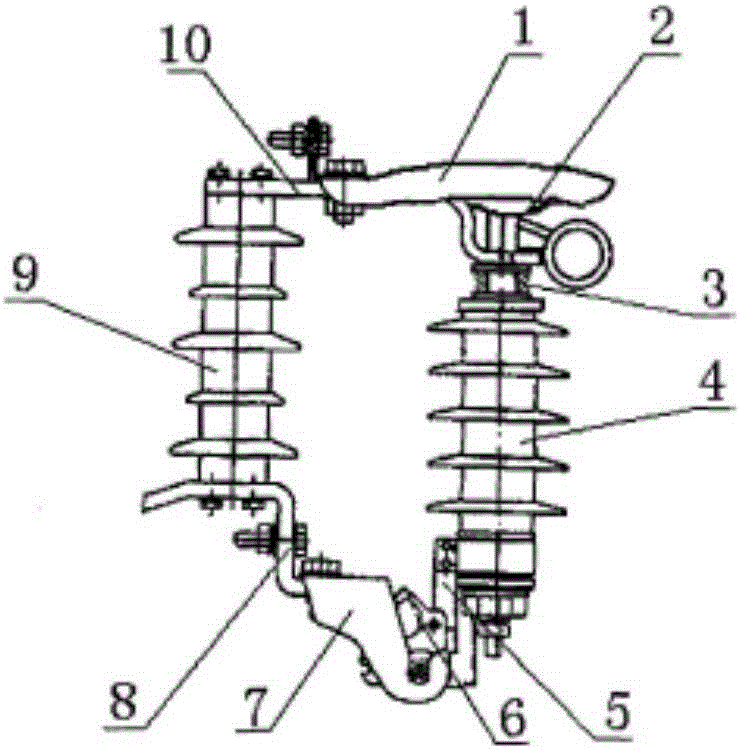

EnOcean drop type lightning arrester

ActiveCN105207191AEasy to detectEasy maintenanceInstallation of lighting conductorsEmergency protective arrangements for limiting excess voltage/currentElastic componentLocking mechanism

Disclosed in the invention is an EnOcean drop type lightning arrester comprising a silicone rubber support post, an upper wiring seat arranged at the upper end of the silicone rubber support post, a lower wiring seat arranged at the lower end of the silicone rubber support post, a lightning arrester body, a contact arranged at the upper end of the lightning arrester body, a bearing seat arranged at the lower end of the lightning arrester body, a conductive pressing plate connected with the upper wiring seat, a rotation block connected with the bearing seat, and a support seat connected with the lower wiring seat. A long slot hole locking mechanism is arranged between the rotation block and the support seat. A hot-melting or thermal-explosion disconnector is connected to the bottom of the lightning arrester body and is connected to the rotation block by a conductive and limiting element; and the conductive pressing plate has an arc structure. An elastic component is arranged between the contact and the lightning arrester body. Besides, an EnOcean block is arranged between the lightning arrester body and the bearing seat.

Owner:WUHU KAIXIN ARRESTER

3D printing mold making self-propagating thermal explosion forming porous NiTi artificial implant technique

InactiveCN106141188ASlow to avoid entitiesAvoid difficult to print and easy to oxidizeAdditive manufacturing apparatusNiti alloyBrick

The invention provides a 3D printing mold making self-propagating thermal explosion forming porous NiTi artificial implant technological method. The method comprises the following technological steps that 1, a plastic model is printed, specifically, scanning is conducted through a CT machine so that a human body CT image file can be obtained, a 3D file of the printing model is designed through part of a bone joint digital 3D file compounded and intercepted by mimics10.0 software, and a polyethylene model of an artificial joint is printed through a 3D printer; 2, duplication of a thermal explosion forming mold is conducted, specifically, the printed plastic model is used for duplicating the self-propagating thermal explosion forming mold, and cement and light refractory brick powder are used for duplicating the porous NiTi alloy thermal explosion mold; and 3, a porous NiTi alloy artificial implant is formed, specifically, Ni powder and Ti powder are mixed evenly and pressed through a press machine according to the approximate equi-atomic ratio, a green body is formed, the green body is placed into the thermal explosion mold, then the green body and the thermal explosion mold are placed into a resistance furnace together, the temperature is increased to the NiTi self-propagating reaction temperature under the argon protection, a self-propagating reaction is conducted on the whole green body simultaneously, and the thermal explosion forming porous NiTi artificial implant is formed.

Owner:陈威

Method for preparing Ti2AlC ceramic material at low temperature

A method for preparing Ti2AlC ceramic material at the low temperature comprises steps as follows: Ti powder, Al powder and TiC powder are selected as raw materials, firstly, the raw materials are subjected to ball milling and mixing in a certain mole ratio and then are pressed to form blocks, the pre-pressed blocks are put in an air furnace to be subjected to a thermal explosion reaction, the reacted block samples are taken out and cooled to the room temperature, oxidation layers on surfaces of the samples are rubbed off, the block samples without the oxidation layers are broken and subjected to ball milling, powder is obtained, and the high-purity Ti2AlC ceramic material can be obtained after acid treatment, washing and drying. The prepared Ti2AlC ceramic material has stable technological parameters, the method is suitable for large-scale production of the Ti2AlC ceramic material, and the method has the characteristics that the process is simple, the synthesis temperature is low, the preparation time is short and the purity is high.

Owner:SHAANXI UNIV OF SCI & TECH

Production method of germinated popped rice and thermal explosion rice hulls

InactiveCN101756104AExcellent nutrition and flavorReduce manufacturing costFood preparationVegetable oilChemical products

The invention provides a production method of germinated popped rice and thermal explosion rice hulls, which take fresh rice with complete and plump granules as raw materials, wherein the rice is cultured to germinate until the germination length is 0.5 to 3mm after being soaked in clear water or aqueous solution of 0.005-0.02 percent of gibberellin for 20 to 30 hours, the germinated rice is cleaned, is added with proper salt, sodium cyclamate and vegetable oil to be again soaked for 2 to 4 hours and then is drained and dried, then a grainpuffer or a microwave oven is used for heating for 2 to 5 minutes, then the popped rice is obtained, and after the popped rice is scattered and separated, the germinated popped rice and the thermal explosion rice hulls are obtained. The germinated popped rice has excellent nutrition and flavor because of germinating, containing coarse rice hulls, repeated soaking by oil, salt and sugar as well as thermal explosion. The thermal explosion rice hulls are easy to be decomposed by cellulose and other biochemical reagents under the destructive function of heat, have the similar effects of gas explosion rice straws and straws so that the production cost is lower when the thermal explosion rice hulls are used as raw materials for producing xylitol, ethanol and other chemical products, and have rather better effect compared with the unprocessed rice hulls.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

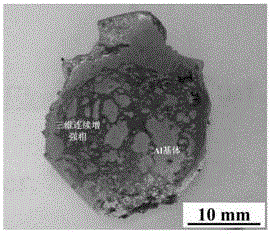

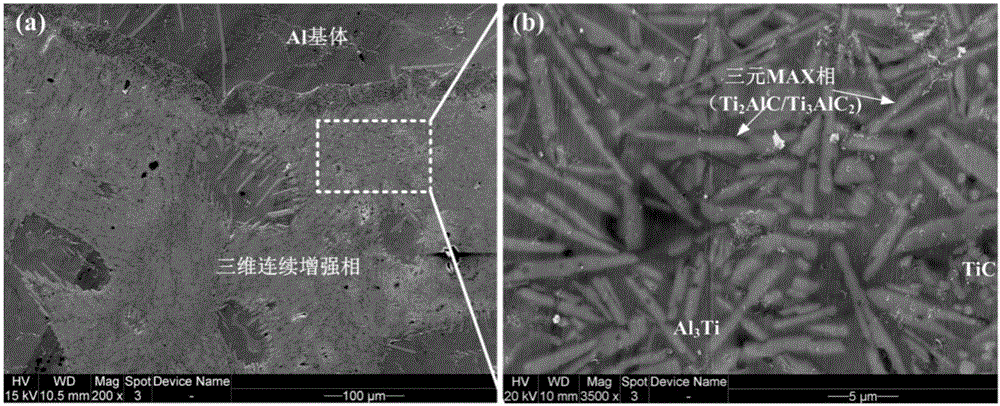

Method for preparing in-situ three-dimensional continuously-reinforced Al-base composite material

ActiveCN106086500AAchieving controllable designImprove the bonding strength of the interfaceAl powderGraphite

The invention discloses a method for preparing in-situ three-dimensional continuously-reinforced Al-base composite material. The method includes the steps of mixing Ti powder, Al powder and graphite powder according to the mole ratio of 2 to 1-1.2 to 1, grinding the powder and obtaining mixed powder; placing the mixed powder into a mold, carrying out cold-pressing and obtaining green bodies; and finally adding the preheated green bodies into molten Al with the temperature being 700-900 DEG C, taking out the green bodies from the molten Al after reaction is completed, cooling the green bodies and obtaining the in-situ three-dimensional continuously-reinforced Al-base composite material. According to the method, the in-situ three-dimensional continuously-reinforced Al-base composite material can be fast prepared through thermal explosion reaction of an Al-Ti-C system.

Owner:咸阳瞪羚谷新材料科技有限公司

Aluminum-titanium-boron-carbon-magnesium intermediate alloy and preparation process thereof

InactiveCN103184371APromote reaction synthesisIncrease the number ofIntermediate frequencySynthesis methods

The invention discloses an aluminum-titanium-boron-carbon-magnesium intermediate alloy and a preparation process of the aluminum-titanium-boron-carbon-magnesium intermediate alloy, wherein the alloy comprises the chemical components of 10%-80% of potassium fluotitanate, 5%-50% of potassium fluoborate, 1%-30% of graphite powder, 1%-30% of magnesium powder, and the balance of pure aluminum according to weight percentage. The preparation process of the alloy is as follows: pressing the graphite powder and the magnesium powder into a prefabricated block according to a proportion, drying the prefabricated block at the temperature of 400-500 DEG C for 0.5-4 hours, melting the pure aluminum according to the proportion in an intermediate frequency furnace through a thermal explosion synthesis method, raising the temperature to be 780-1200 DEG C, then melting the potassium fluotitanate and the potassium fluoborate at a proportion, standing for 20-50 minutes and then slagging off, then raising the temperature of the intermediate frequency furnace to be 1000-1600 DEG C, then adding the prefabricated block, standing after stirring, adding a refining agent to refine, and finally pouring into a wire rod. The intermediate alloy provided by the invention has the characteristics of higher strength, better toughness and more stable mechanical property.

Owner:周凡

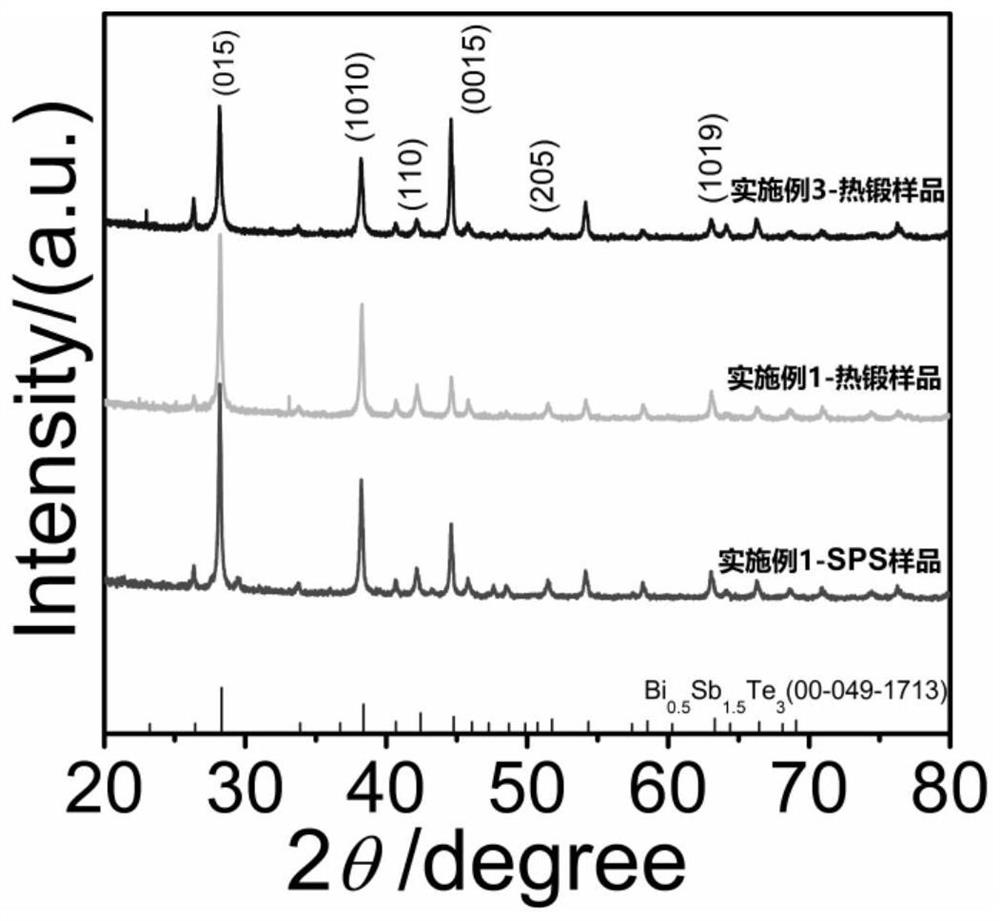

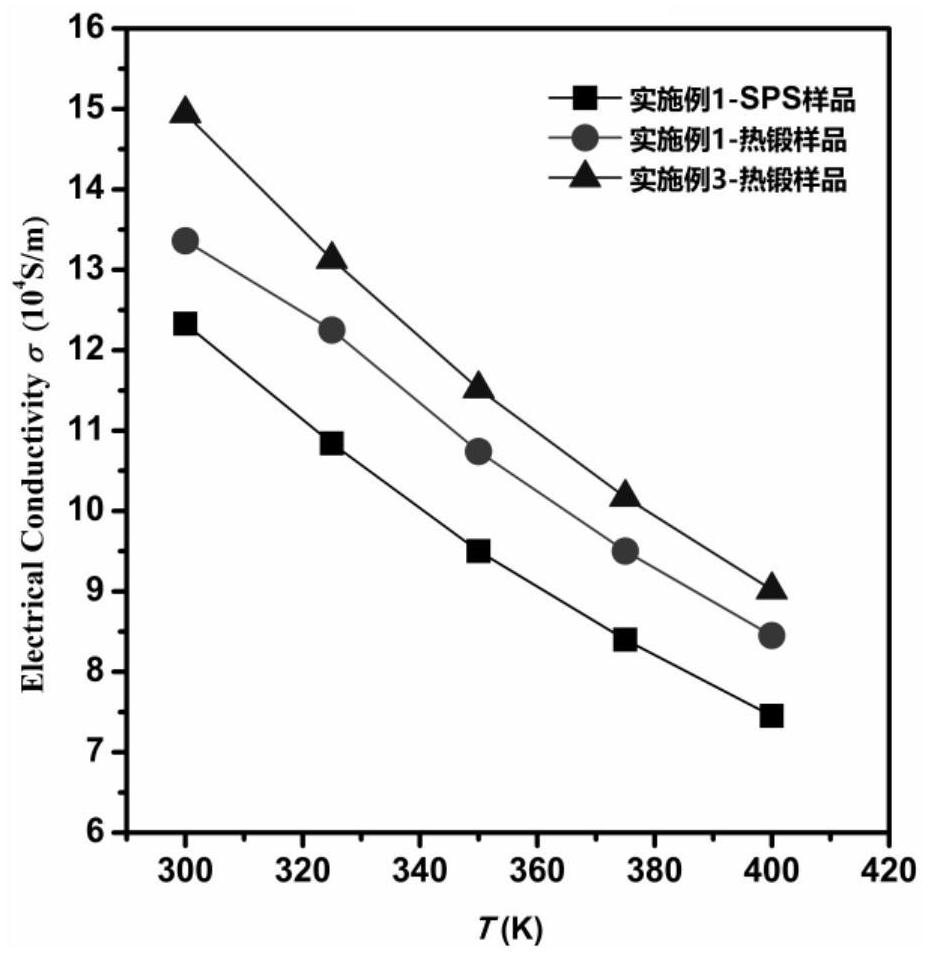

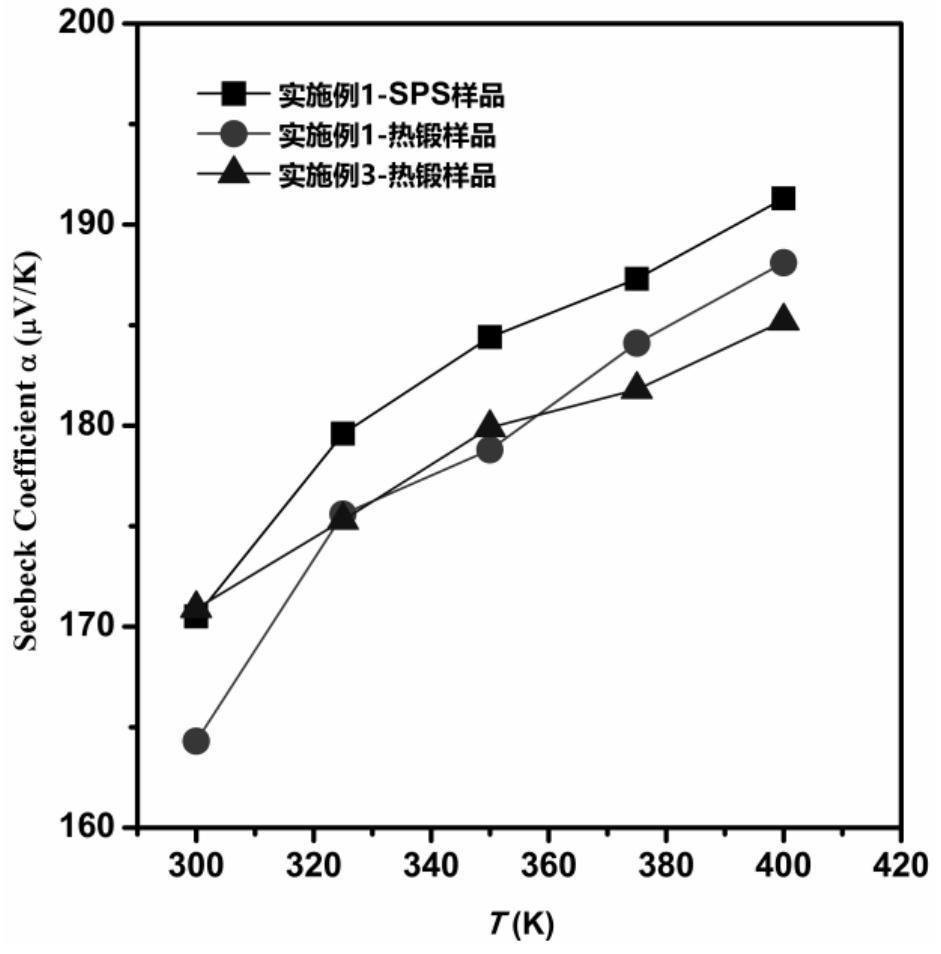

Method for rapidly preparing Bi2Te3-based thermoelectric material with high orientation and high power factor

The invention discloses a method for rapidly preparing a p-type or n-type Bi2Te3-based thermoelectric material with high orientation and high power factor, and belongs to the technical field of energymaterials. The method is divided into three parts of compound preparation, forming and hot forging, and comprises the following steps that at first, high-purity Bi, Sb, Te, Se and S are weighed according to a stoichiometric ratio, and the p-type or n-type Bi2Te3-based thermoelectric material is extremely rapidly prepared through a self-propagating synthesis or thermal explosion synthesis manner;then the p-type or n-type Bi2Te3-based thermoelectric material is ground and screened, and the material with a proper particle size is selected for spark plasma sintering to obtain a compact block material; and the compact block material is subjected to hot forging through a spark plasma sintering technology to obtain the p-type or n-type Bi2Te3-based thermoelectric material with high orientationand high power factor. According to the method, the time required for raw material preparation and the time required for conducting grinding to reach the required particle size can be greatly shortened through the thermal explosion and self-propagating combustion synthesis technology, hot forging is conducted in combination with the spark plasma sintering technology, the grain growth can be effectively controlled, the time is short, and the material has high orientation and high power factor.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com