Method for rapidly preparing Bi2Te3-based thermoelectric material with high orientation and high power factor

A technology of high power factor and thermoelectric materials, which is applied in the field of rapidly preparing p-type or n-type Bi2Te3-based thermoelectric materials with high orientation and high power factor, which can solve the problems of increasing the internal resistance of thermoelectric devices, affecting the performance of thermoelectric devices, and decreasing the electrical conductivity. , to achieve the effect of high power factor, shortened preparation time, and shortened hot forging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

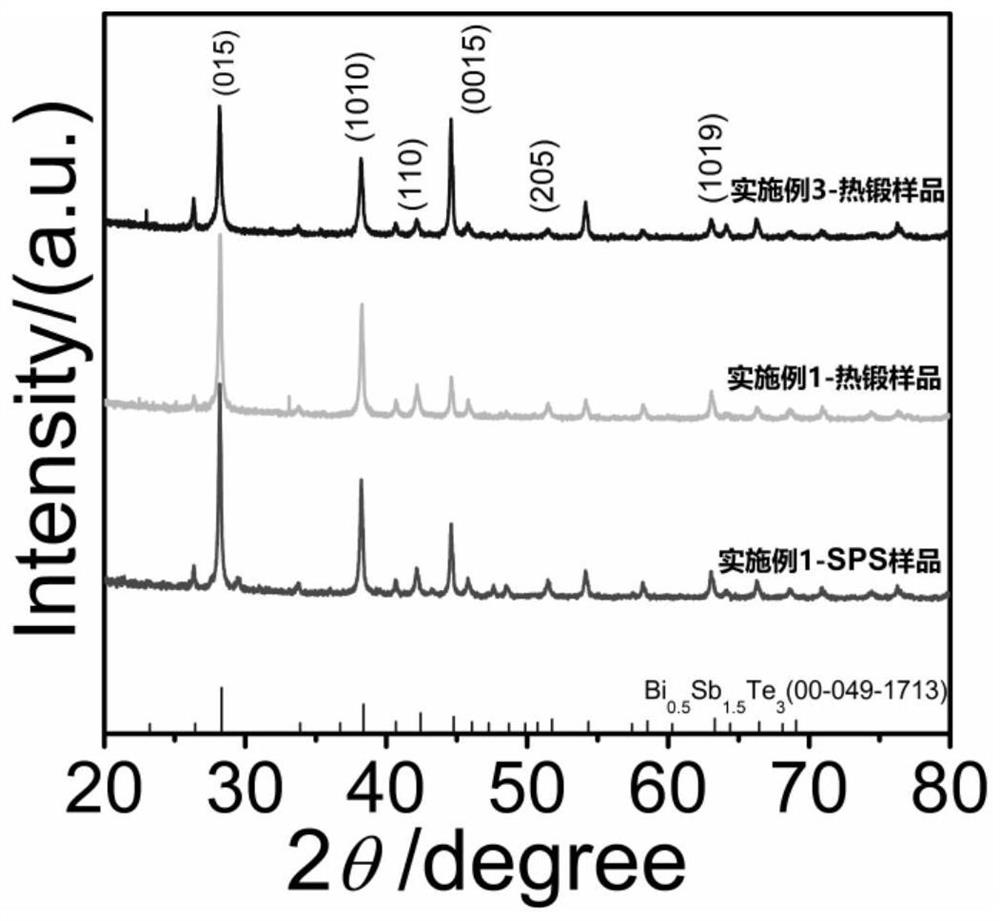

Embodiment 1

[0032] A rapid preparation of p-type Bi with high orientation and high power factor 2 Te 3 The method for base thermoelectric material, concrete steps are as follows:

[0033] (1) Using high-purity elemental Bi, Sb, and Te as initial raw materials, according to Bi 0.4 Sb 1.6 Te 3 The stoichiometric ratio of each element in the formula weighs the high-purity element, mixes it and presses it into tablets, vacuum seals it in a glass tube, and performs thermal explosion synthesis (thermal explosion temperature 550°C, time 60s) to obtain p-type Bi 2 Te 3 bulk thermoelectric material;

[0034] (2) p-type Bi obtained in step (1) 2 Te 3 The base thermoelectric material block is manually ground to obtain a powder with a smaller particle size for 10 minutes, and the powder between 200 and 400 meshes is sieved for use;

[0035] (3) Fill the powder between 200 and 400 mesh obtained in step (2) into a graphite mold with a diameter of 12.7mm, the spark plasma sintering pressure is 4...

Embodiment 2

[0046] The difference between this example and Example 1 lies in that: step (4) the hot forging pressure is 30 MPa, the heat preservation is 8 minutes, and the extrusion ratio is 1:4.

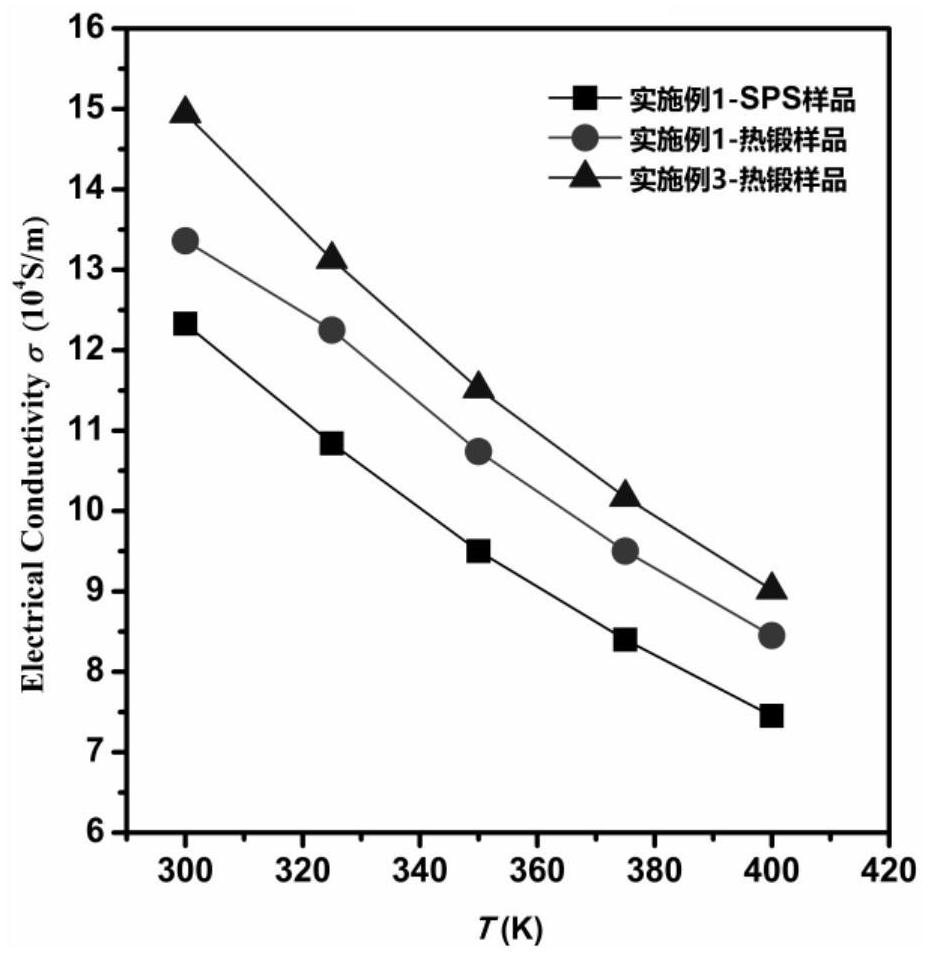

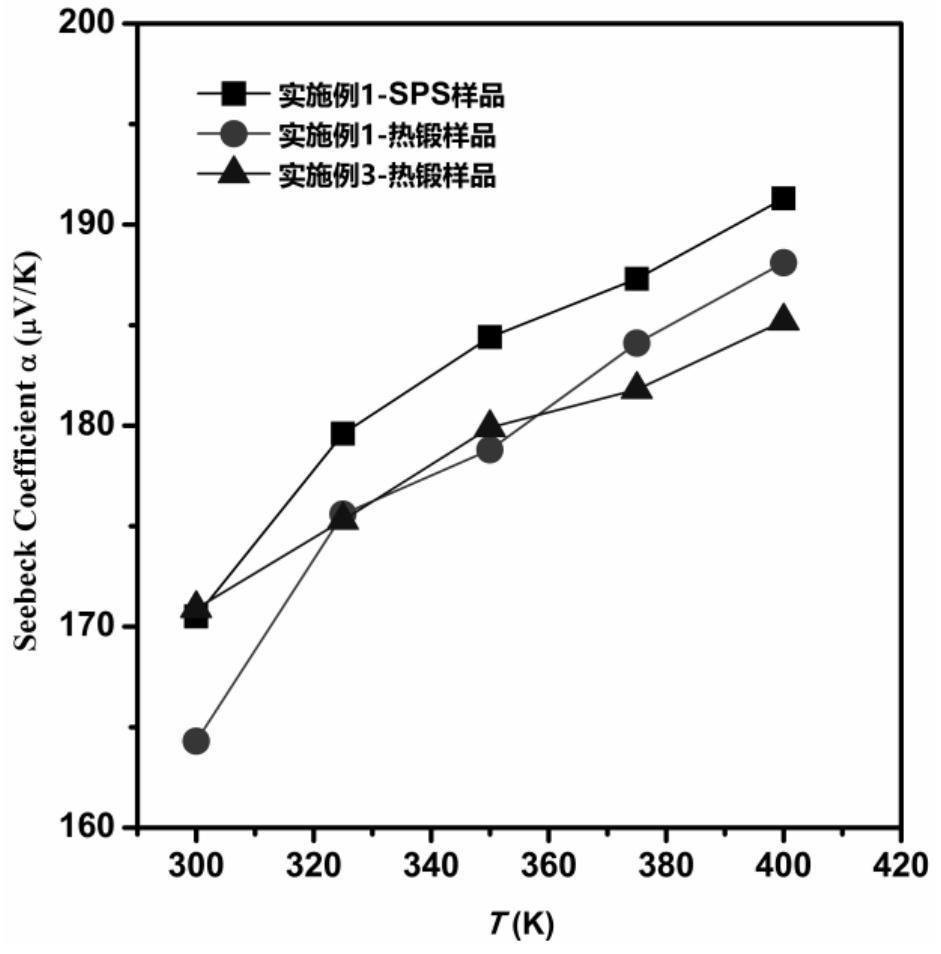

[0047] The comparison of thermoelectric properties between the SPS sample and the hot forged sample in Example 2 is given below. Table 4 shows the conductivity data of the samples at different temperatures, Table 5 shows the Seebeck data at different temperatures of the samples, and Table 6 shows the power factor data of the samples at different temperatures. It can be seen from Table 4-6 that a larger extrusion ratio and a larger hot forging pressure can make the hot forging effect more obvious, the material orientation is stronger, and a higher electrical conductivity and power factor can be obtained.

[0048] Table 4 - Conductivity (10 4 S / m)

[0049] Example 2 300K 325K 350K 375K 400K SPS sample 12.33 10.84 9.5 8.4 7.45 Hot forged sample 14.27 12.76 11.17 ...

Embodiment 3

[0055] The difference between this example and Example 1 is that in step (4), the hot forging temperature is 450°C, the hot forging pressure is 30MPa, the heat preservation is 8min, and the extrusion ratio is 1:4; The outer ring part of the sample obtained by hot forging was cut off to obtain a cylindrical sample with a diameter of 12.7mm. The second hot forging was carried out. Specifically, the extrusion ratio was 1:4, the sintering temperature was 450°C, and the heating rate was 100°C / min. , the hot forging pressure was 30MPa, and the heat preservation time was 8min, and the hot forging samples with stronger orientation were obtained.

[0056] The following is a comparison of the thermoelectric properties of the SPS sample in Example 3 and the sample after hot forging 2 times. Table 7 shows the conductivity data of the sample at different temperatures, Table 8 shows the Seebeck data at different temperatures of the sample, and Table 9 shows the power of the sample at differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com