Preparation method of Al-Ti-C-Ce refiner

A refining agent, al-ti-c-ce technology, applied in the field of Al-Ti-C-Ce refining agent and its preparation, can solve insufficient reaction, serious burning loss, fluorine salt inclusions affecting refinement Agent metallurgical quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

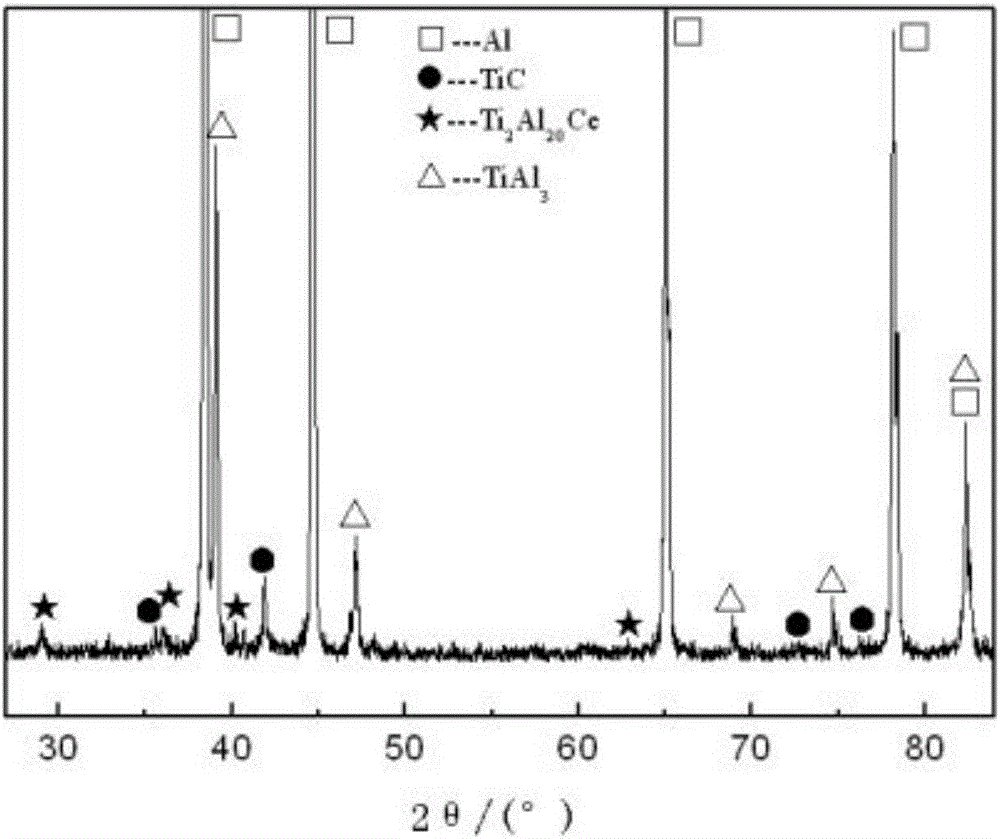

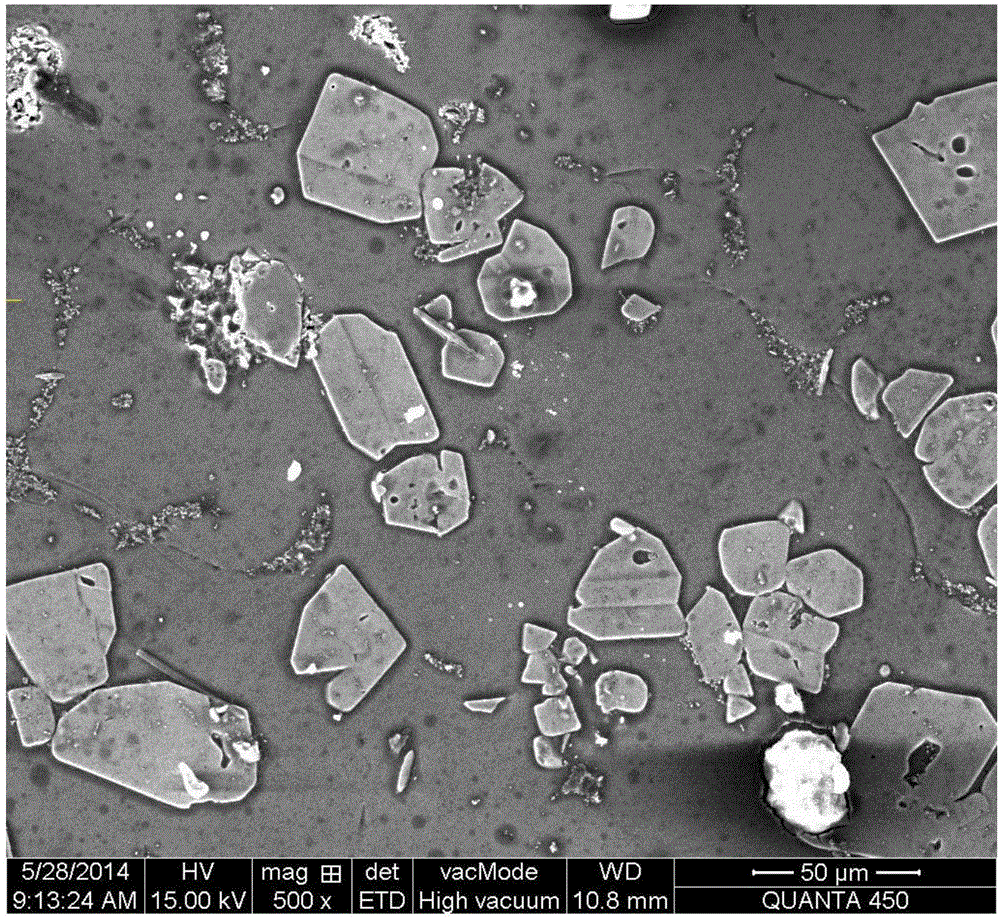

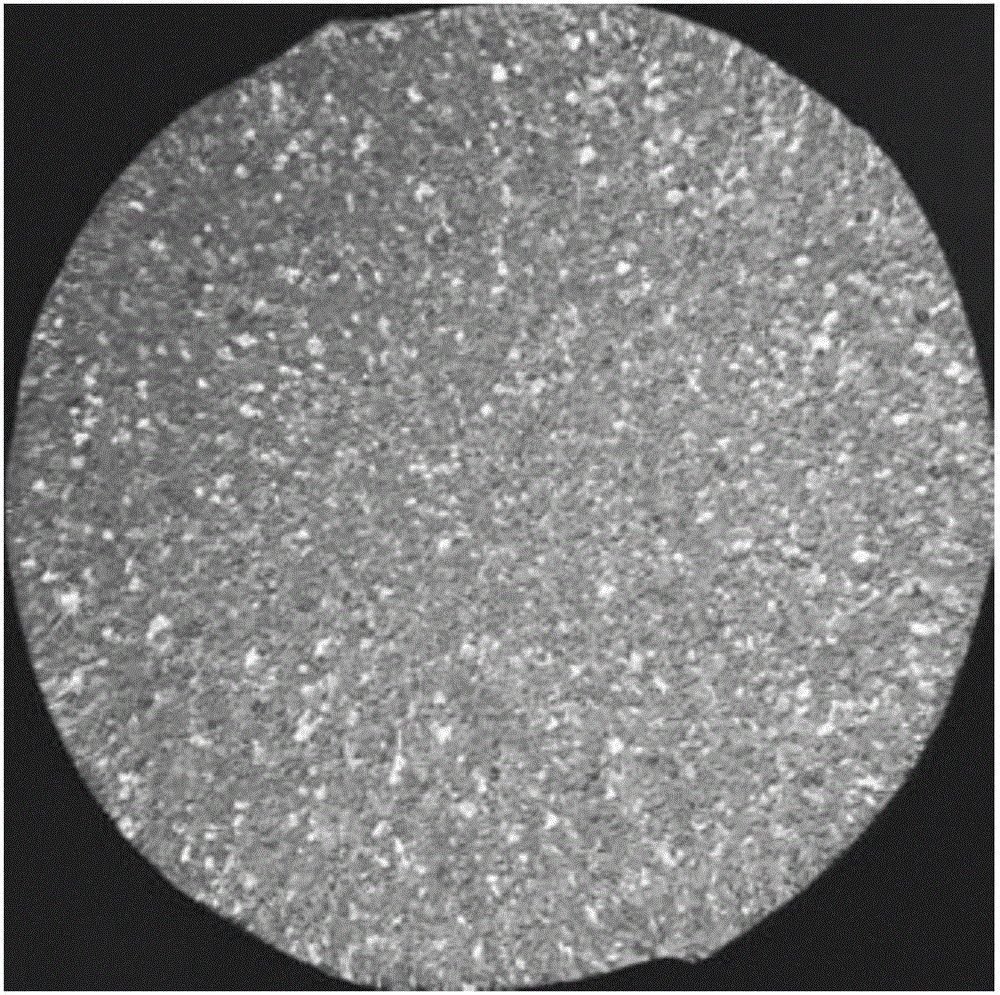

Image

Examples

preparation example Construction

[0026] The present invention provides a kind of preparation method of Al-Ti-C-Ce refining agent, comprises the following steps:

[0027] Aluminum powder, titanium powder, graphite powder and Ce 2 o 3 Powder mixed, pressed into a mixed powder block;

[0028] Heat the aluminum ingot until it is completely melted to obtain an aluminum melt;

[0029] Pressing the mixed powder block into the aluminum melt for a thermal explosion reaction to obtain an alloy melt;

[0030] Purifying the alloy melt;

[0031] The purified alloy melt is poured to obtain the Al-Ti-C-Ce refiner.

[0032] The present invention will aluminum powder, titanium powder, graphite powder, Ce 2 o 3 The powder is mixed and pressed into a mixed powder block. In the present invention, the molar ratio of the aluminum powder, titanium powder and graphite powder is preferably 1:0.2~0.8:0.1~0.6, more preferably 1:0.4~0.6:0.2~0.3; the titanium powder and graphite powder The molar ratio of Ce is preferably 1.5 to 2...

Embodiment 1

[0045] Weigh 27g (1mol) of 200 mesh aluminum powder, 9.6g (0.2mol) of 350 mesh titanium powder, 1.2g (0.1mol) of 400 mesh graphite powder, and 400 mesh rare earth oxide Ce 2 o 3 Powder 1.89g (5% of the total mass of aluminum powder, titanium powder and graphite powder), wherein the rare earth oxide Ce 2 o 3 The powder purity requirement is 99.9%;

[0046] The weighed aluminum powder, titanium powder, graphite powder, rare earth oxide Ce 2 o 3 The powder is mixed evenly, placed in the mold, and pressed into a mixed powder block, and the pressure on the block is 50MPa;

[0047] Heat the aluminum ingot with a purity of 99.7% to 780°C. After the aluminum ingot is completely melted, use a graphite bell jar to press the mixed powder block into the aluminum melt. The block is preheated by the aluminum melt and reacts violently. The reaction time is After the reaction is completed, let it stand for 5 minutes, then use a graphite rod to stir the melt vigorously, and the stirring i...

Embodiment 2

[0052] Weigh 27g (1mol) of 200 mesh aluminum powder, 19.2g (0.4mol) of 350 mesh titanium powder, 2.4g (0.2mol) of 400 mesh graphite powder, and 400 mesh rare earth oxide Ce 2 o 3 Powder 1.46g (3% of the total mass of aluminum powder, titanium powder and graphite powder), wherein the rare earth oxide Ce 2 o 3 The powder purity requirement is 99.9%;

[0053] The weighed aluminum powder, titanium powder, graphite powder, rare earth oxide Ce 2 o 3 The powder is mixed evenly, placed in the mold, and pressed into a mixed powder block, and the pressure on the block is 60MPa;

[0054] Heat the aluminum ingot with a purity of 99.7% to 820°C. After the aluminum ingot is completely melted, use a graphite bell jar to press the mixed powder block into the aluminum melt. The block reacts violently due to the preheating of the aluminum melt. The reaction time is After the reaction is completed, let it stand for 3 minutes, then use a graphite rod to stir the melt vigorously, and the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com