Pre-warning and control method for occurrence of oil gas thermal explosion in limited space

A technology of confined space and control method, applied in the field of early warning and control of thermal explosion of oil and gas, can solve problems such as safety production, hidden dangers of life and property safety, complex mechanism, and many influencing factors, and achieve scientific analysis and control criteria. Reliable and controlled effect of oil and gas thermal explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

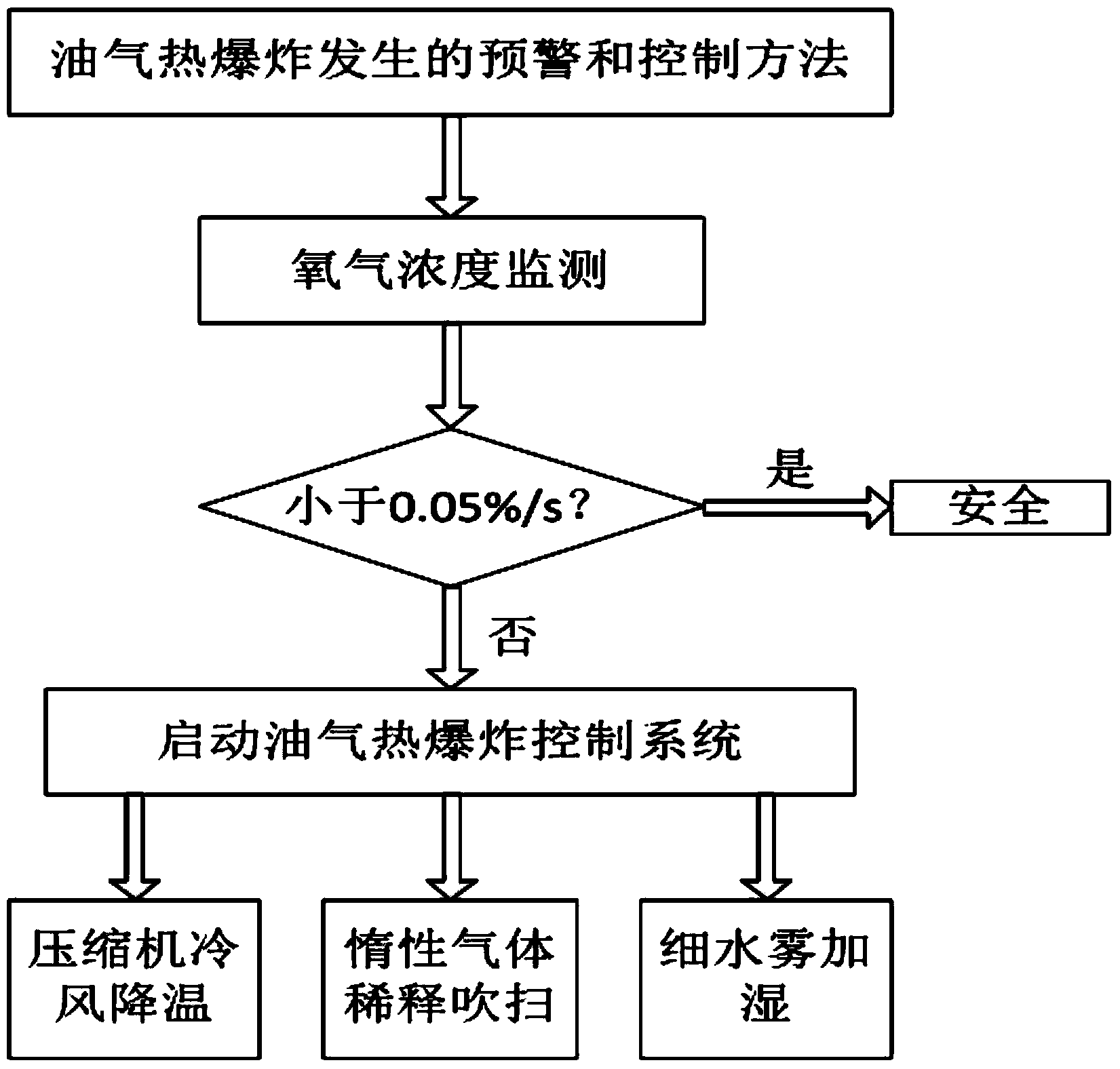

[0028] An early warning method for the occurrence of thermal explosion of oil and gas in a confined space includes the following steps:

[0029] 1) Install an oxygen concentration monitoring device in a confined space where oil is stored, and detect the oxygen concentration Y,% in the space every 1 minute from time 0;

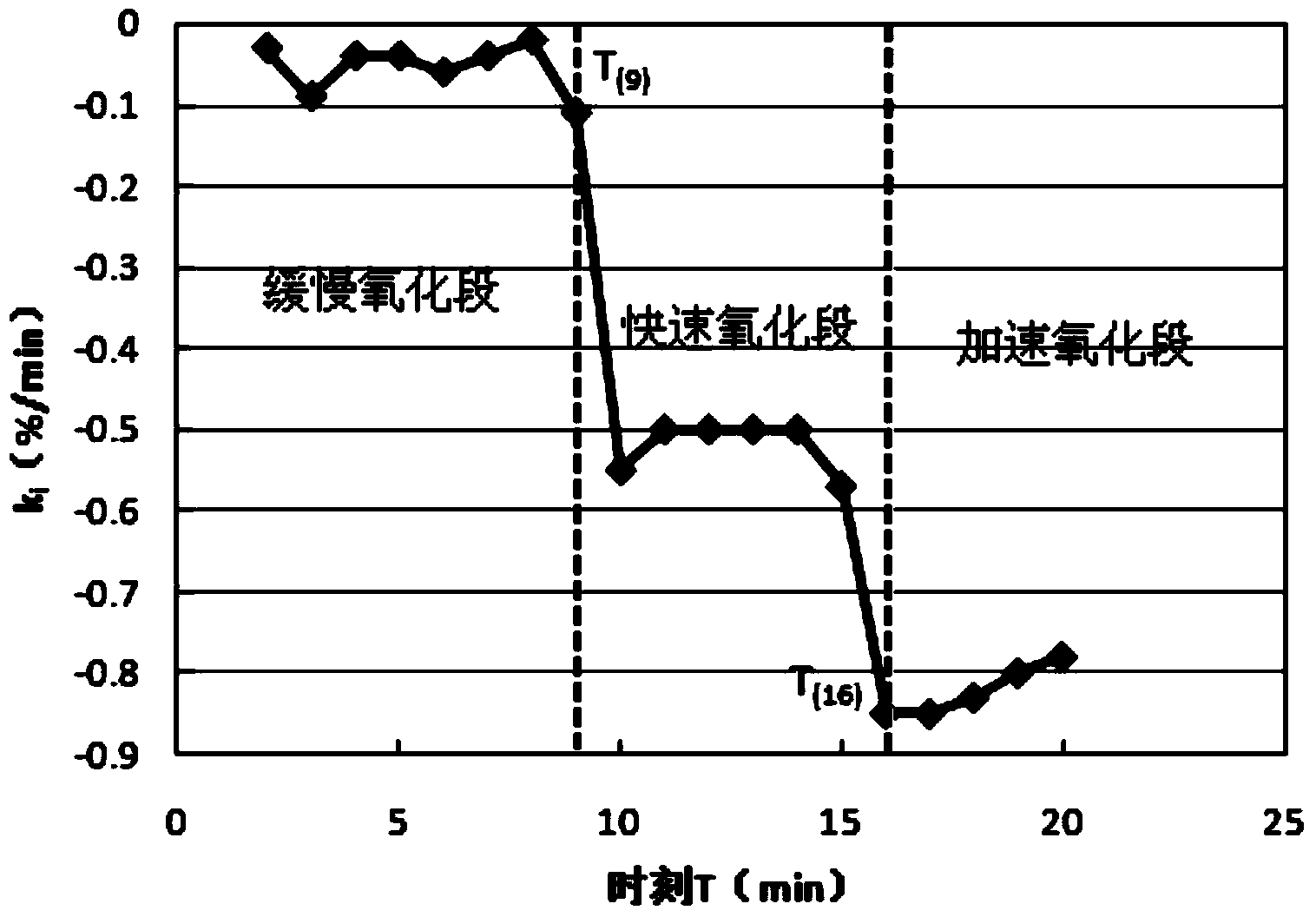

[0030] 2) 20 Y values are collected, and corresponding to 20 time T, so there are 20 sets of data, namely (Y (1) , T (1) ), (Y (2) , T (2) )...(Y (n) , T (n) ) Is: (19.78, 1), (19.75, 2), (19.66, 3), (19.62, 4), (19.58, 5), (19.52, 6), (19.48, 7), (19.46, 8) , (18.35, 9), (18.80, 10), (18.30, 11), (17.80, 12), (17.30, 13), (16.80, 14), (16.23, 15), (15.38, 16) (14.53 , 17), (13.70, 18), (12.90, 19), (12.12, 20). For these 20 sets of data "(Y (1) , T (1) ), (Y (2) , T (2) )...(Y (20) , T (20) )” to process, that is, from (Y (2) , T (2) ) Start the forward difference to get 19 difference values -0.03, -0.09, -0.04, -0.04, -0.06, -0.04, -0.02, -0.11, -0.55, -0.5, -...

Embodiment 2

[0038] This embodiment is a method for controlling the occurrence of thermal explosion of oil and gas in a confined space based on the early warning method described in Embodiment 1.

[0039] When step 5) issues an early warning signal, perform one or more of the following A to C:

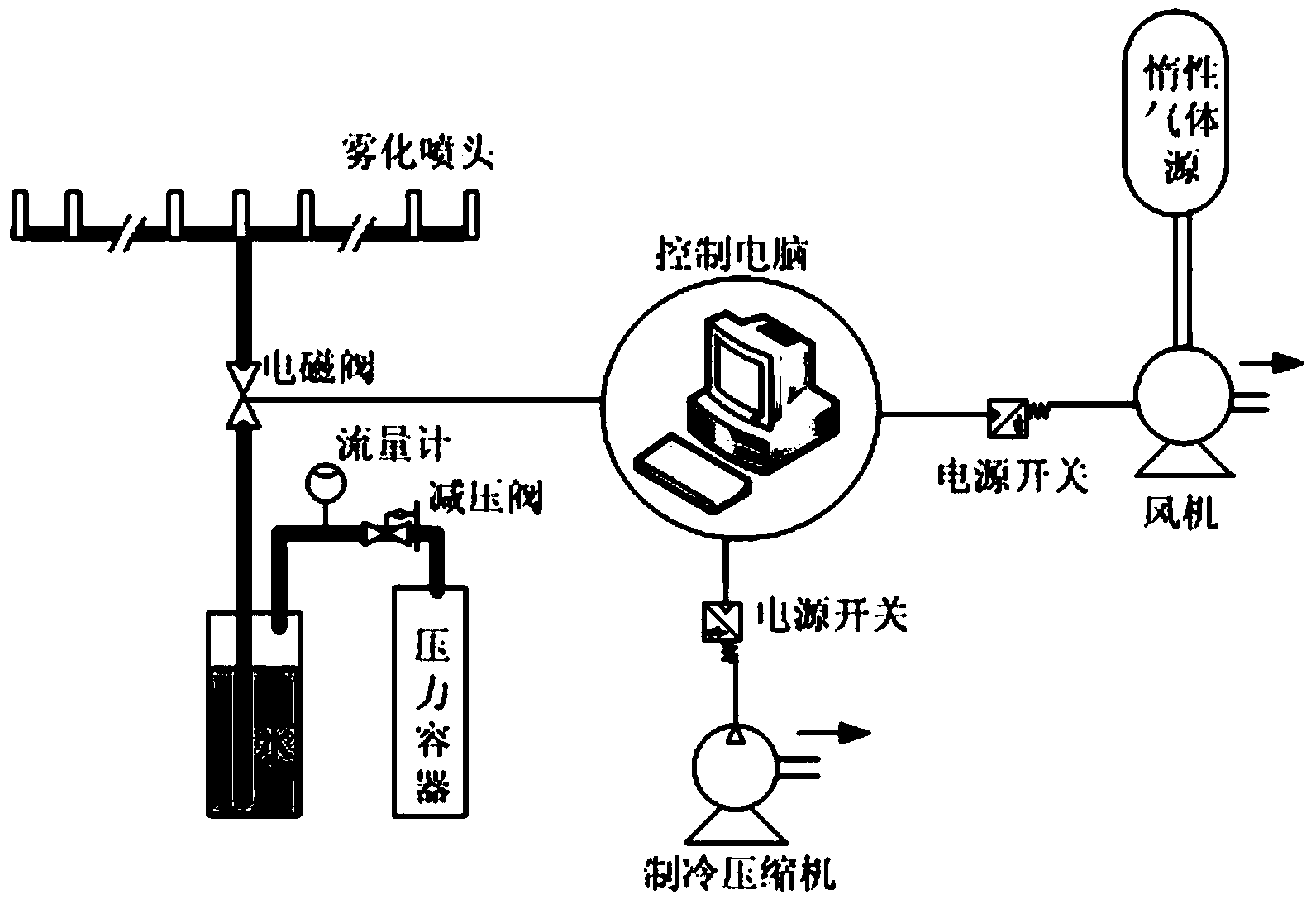

[0040] A) Turn on the power switch of the fan, and the fan will purge the inert gas from the inert gas source to the oil and gas environment;

[0041] B) Turn on the power switch of the refrigeration compressor, and the refrigeration compressor will blow the cold air into the oil and gas environment;

[0042] C) Open the solenoid valve on the atomization nozzle pipeline, and the water in the water tank will spray fine water mist into the oil and gas environment through the solenoid valve and the atomization nozzle under the action of the high-pressure air pressure in the pressure vessel.

[0043] Furthermore, this embodiment adopts a set of oil-gas thermal explosion control system. Specifically, the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com