Patents

Literature

73results about How to "Reduce cooling air volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

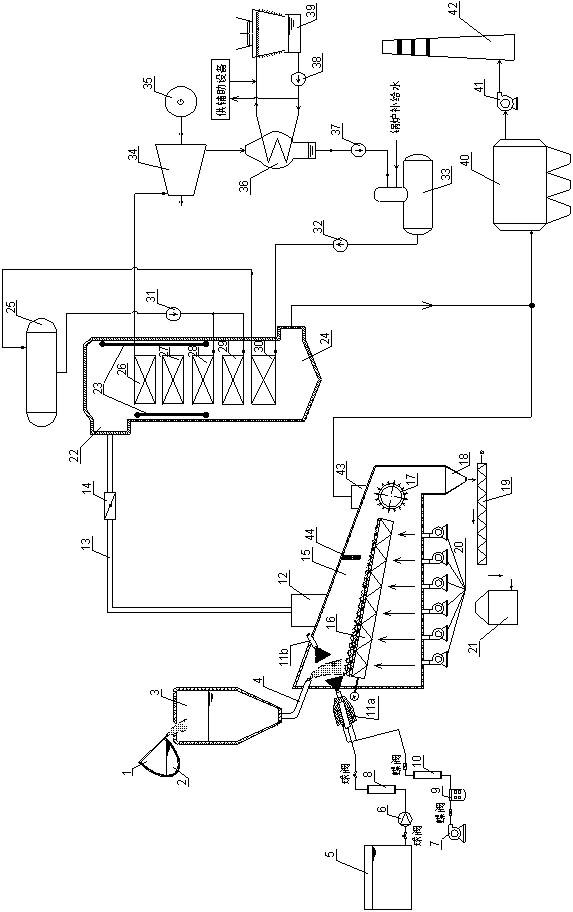

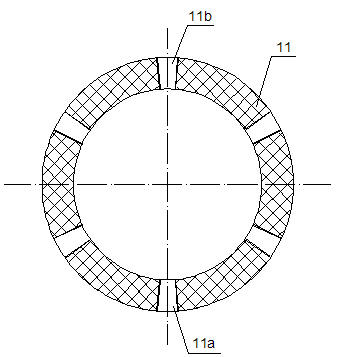

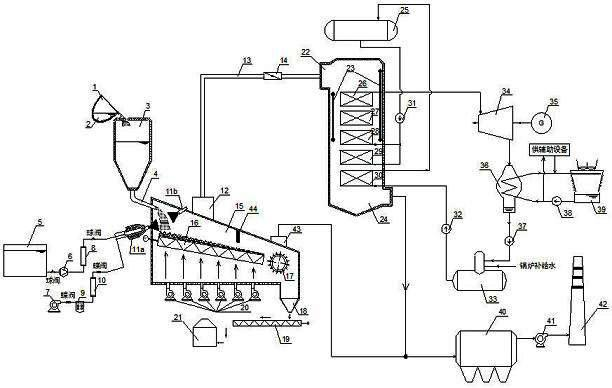

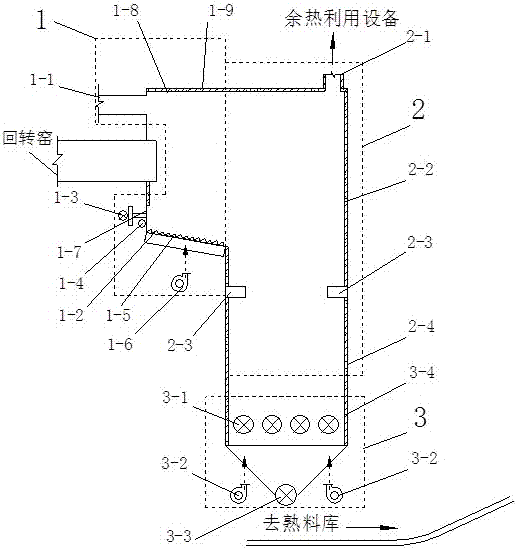

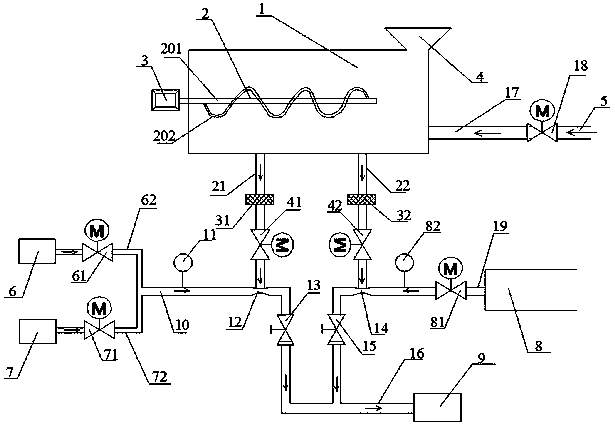

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

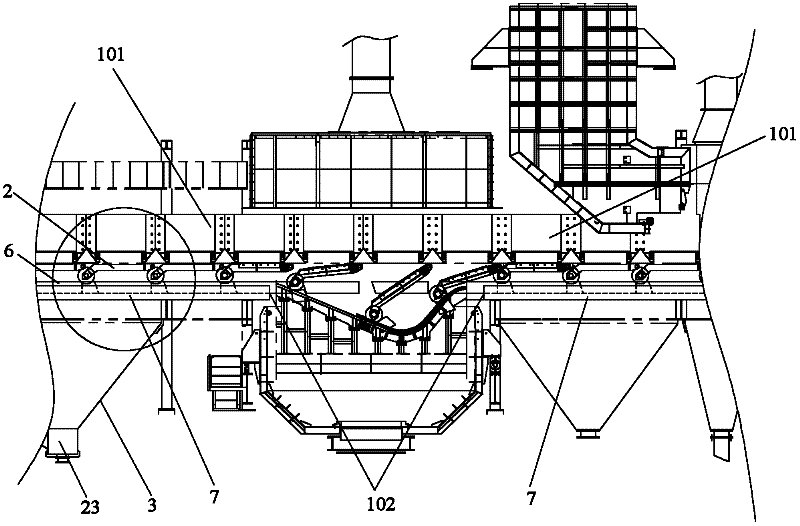

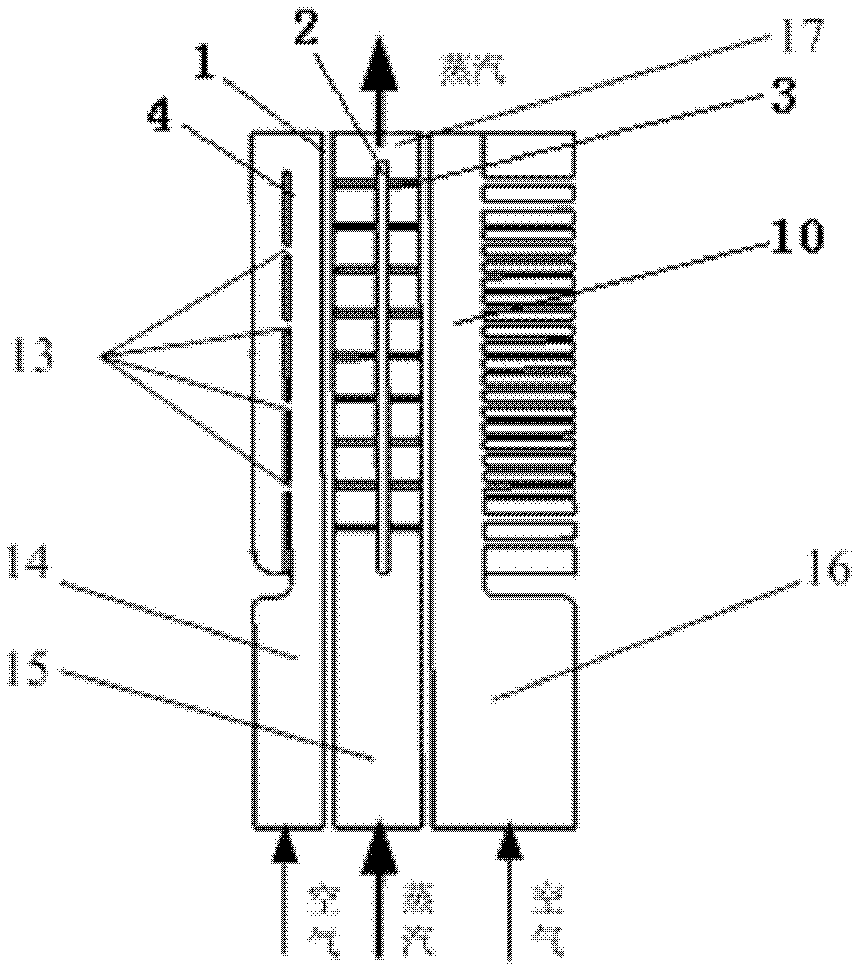

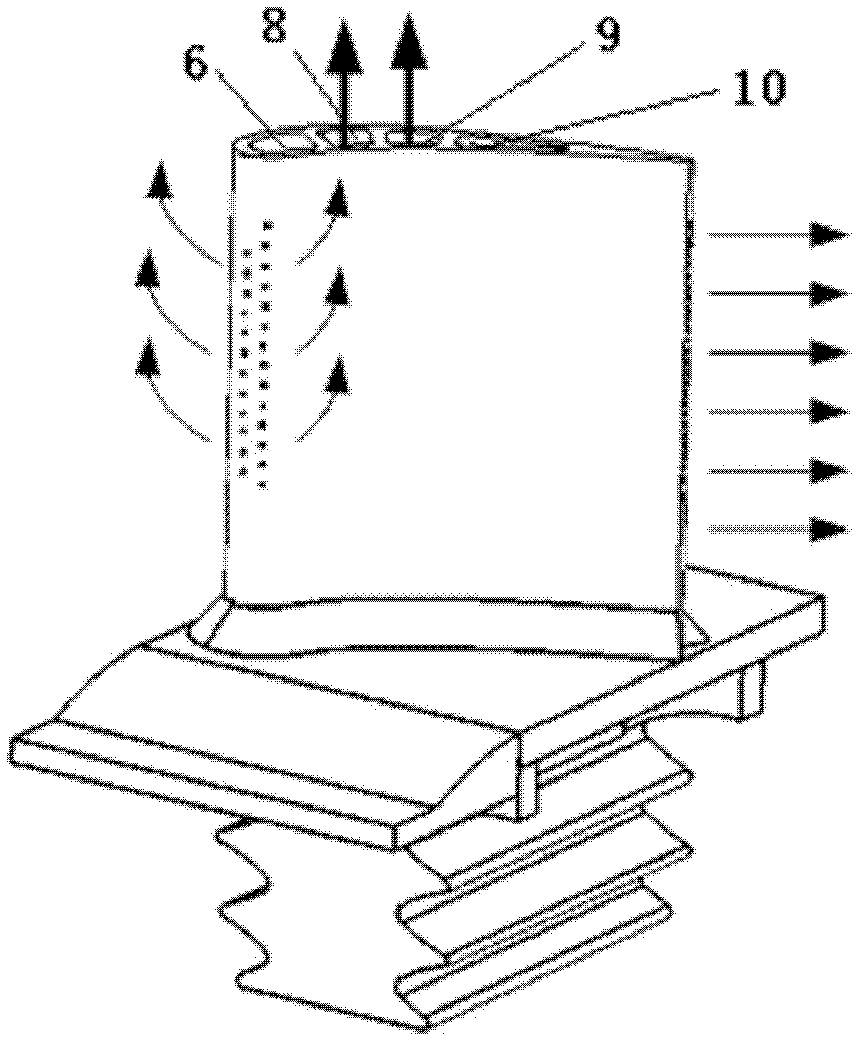

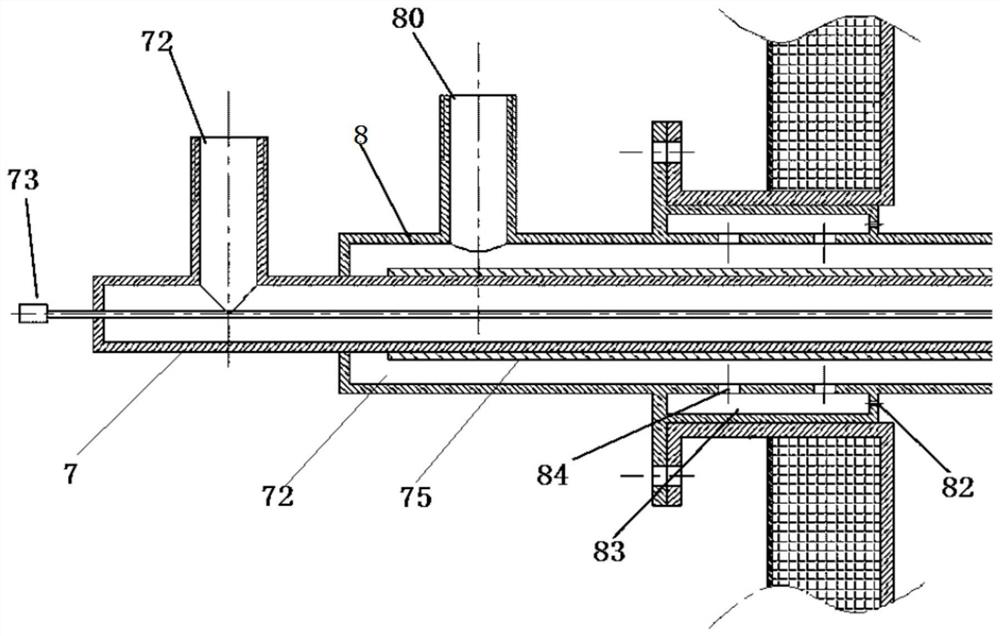

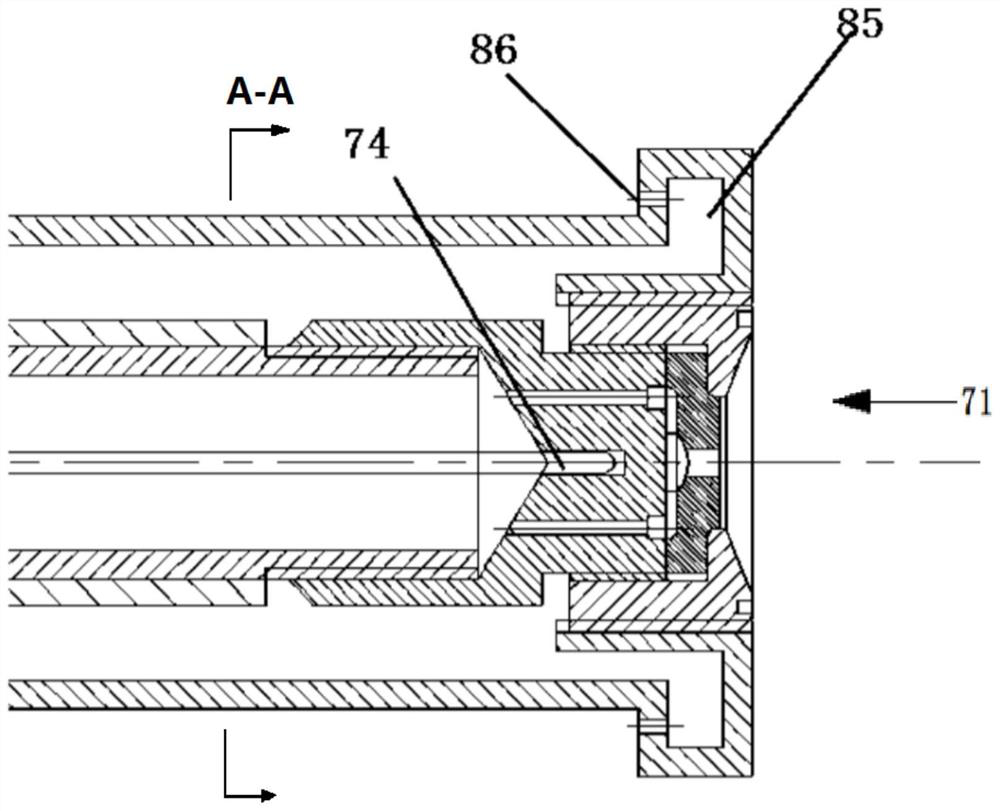

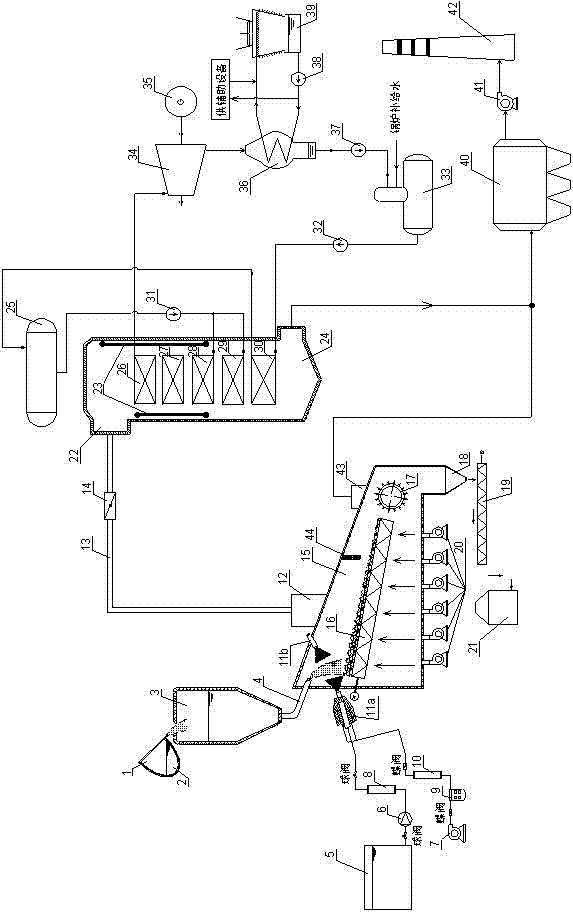

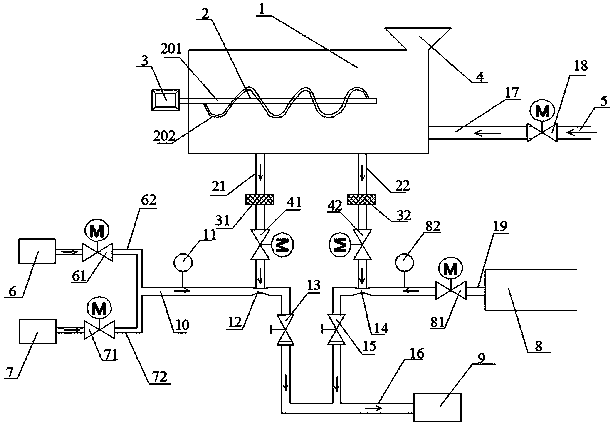

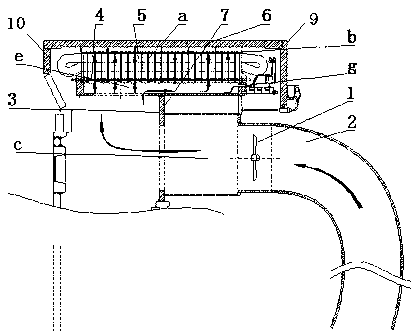

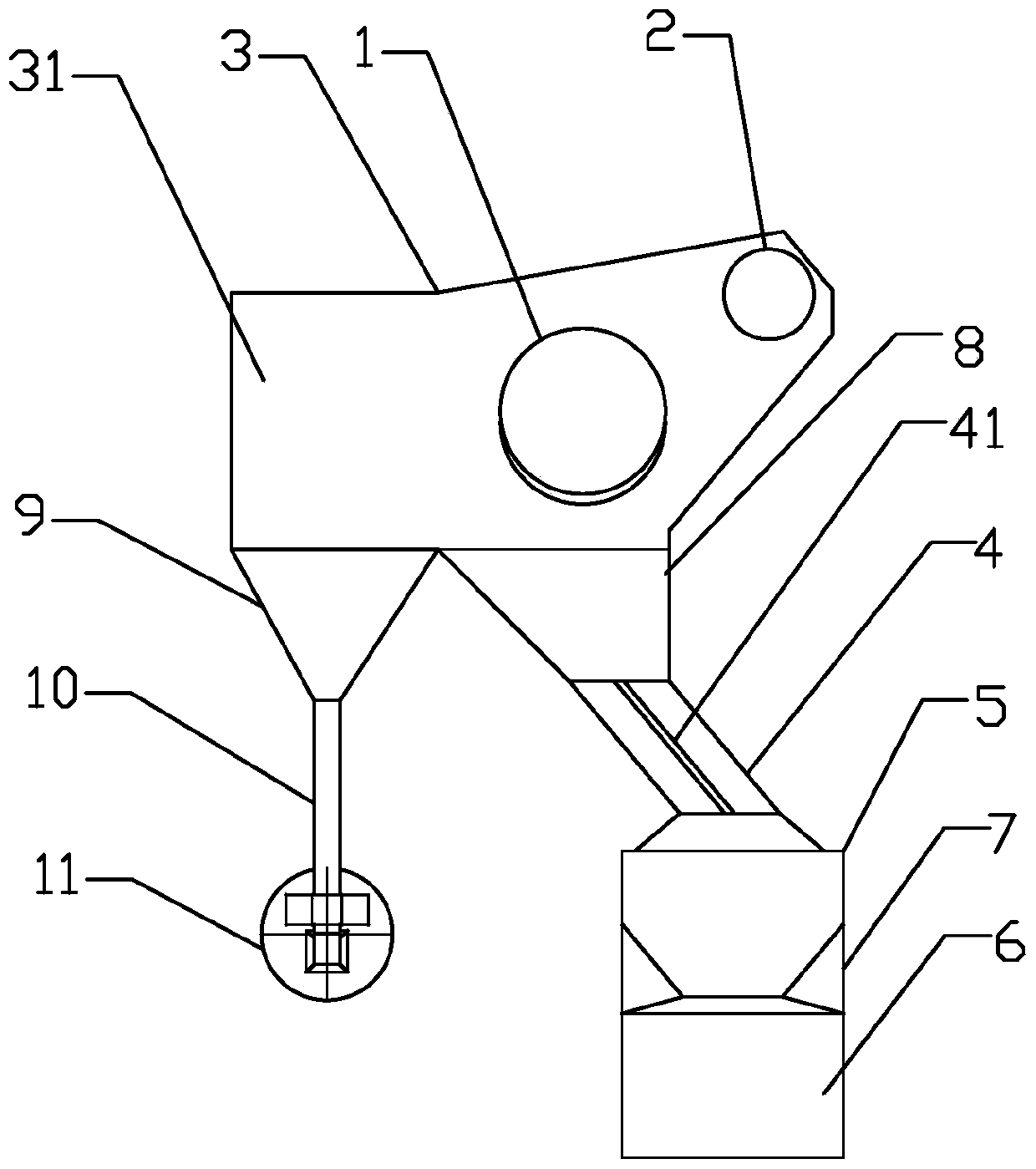

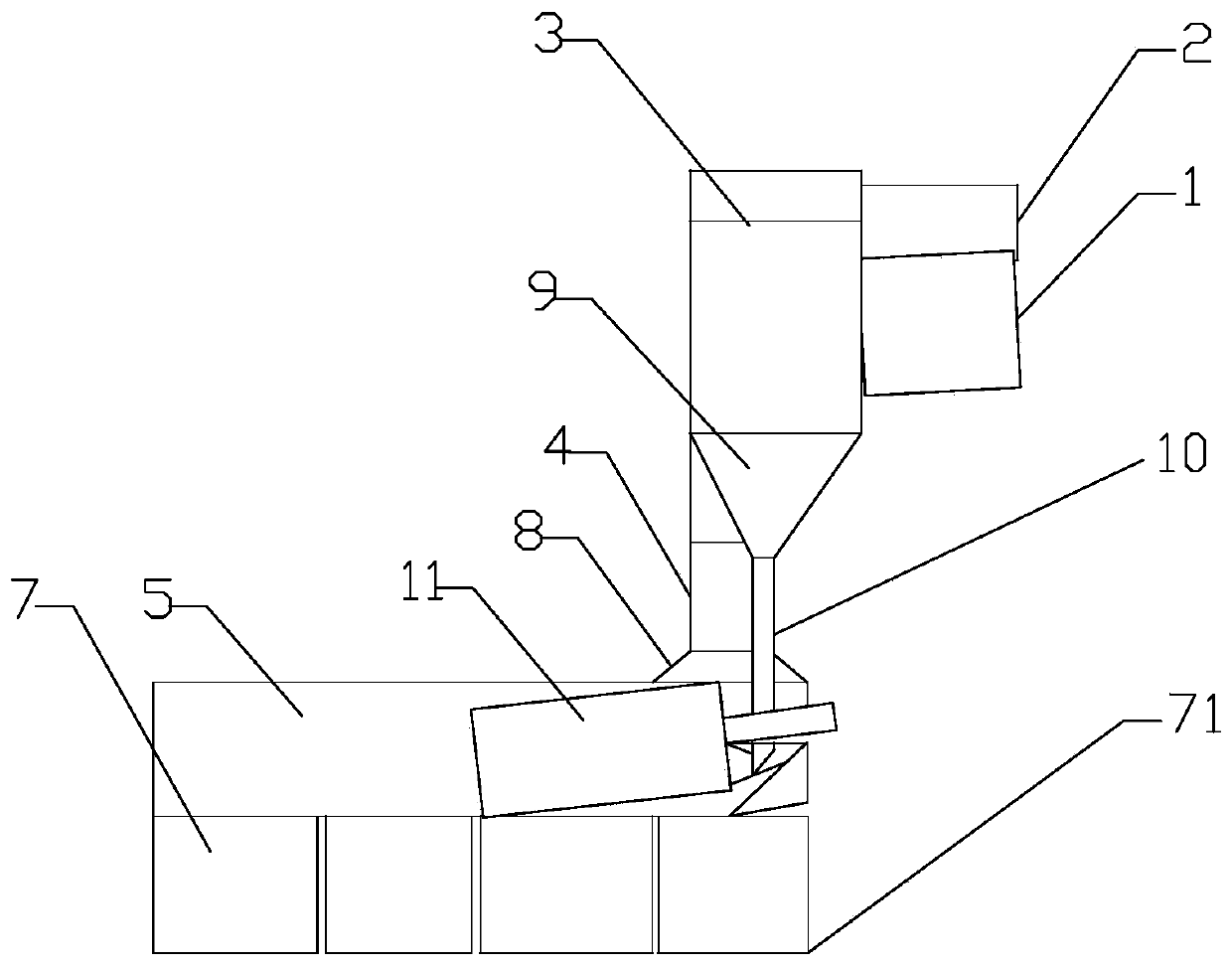

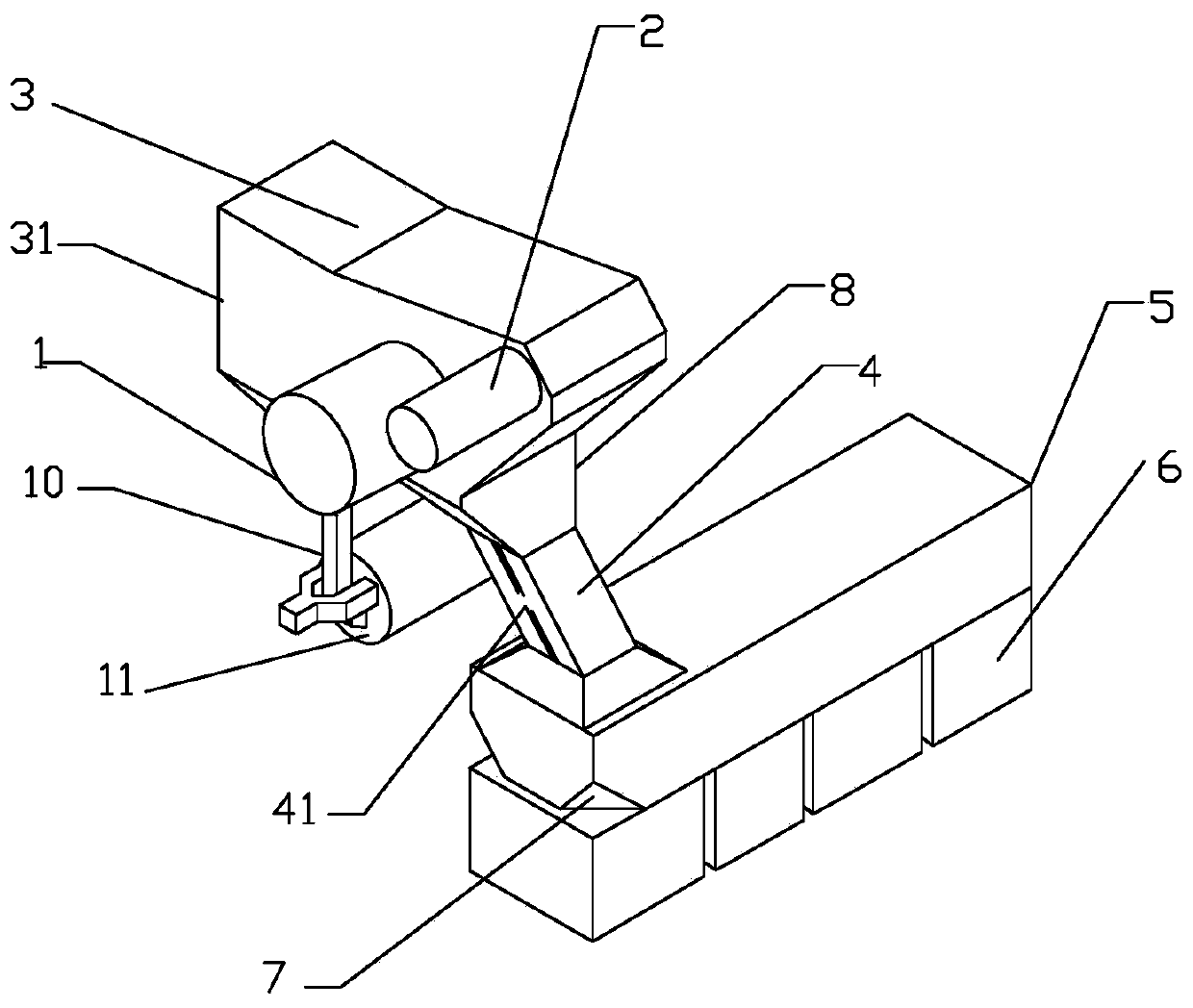

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

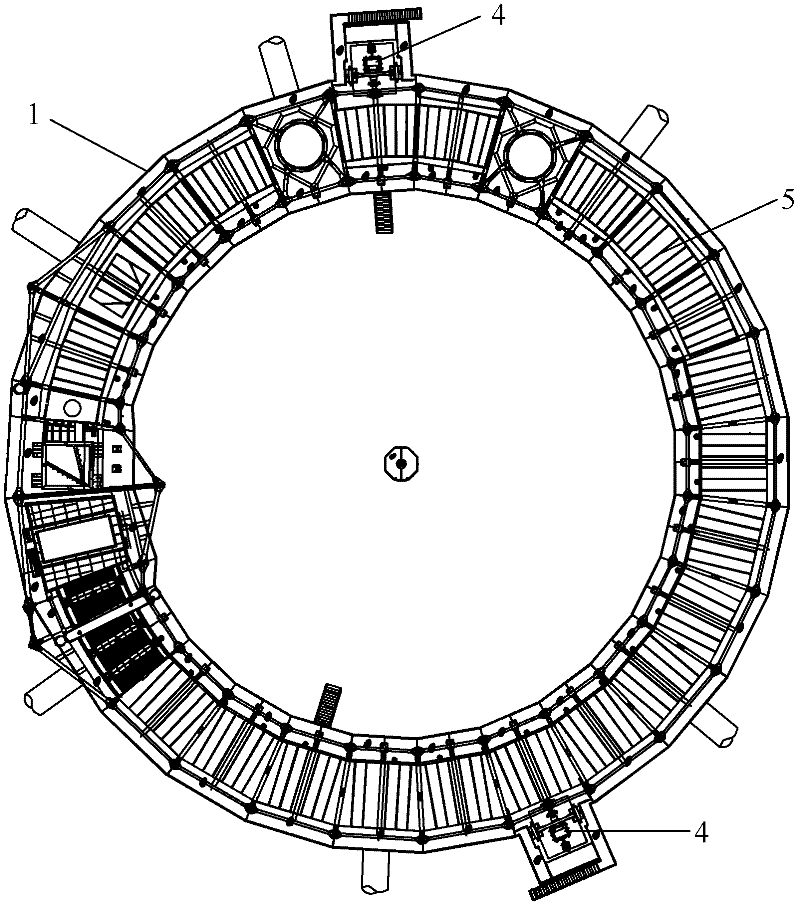

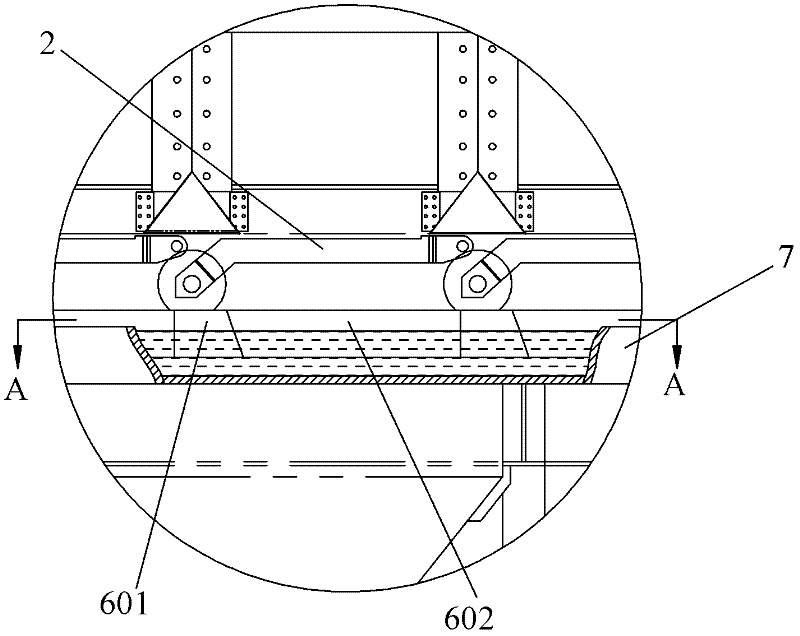

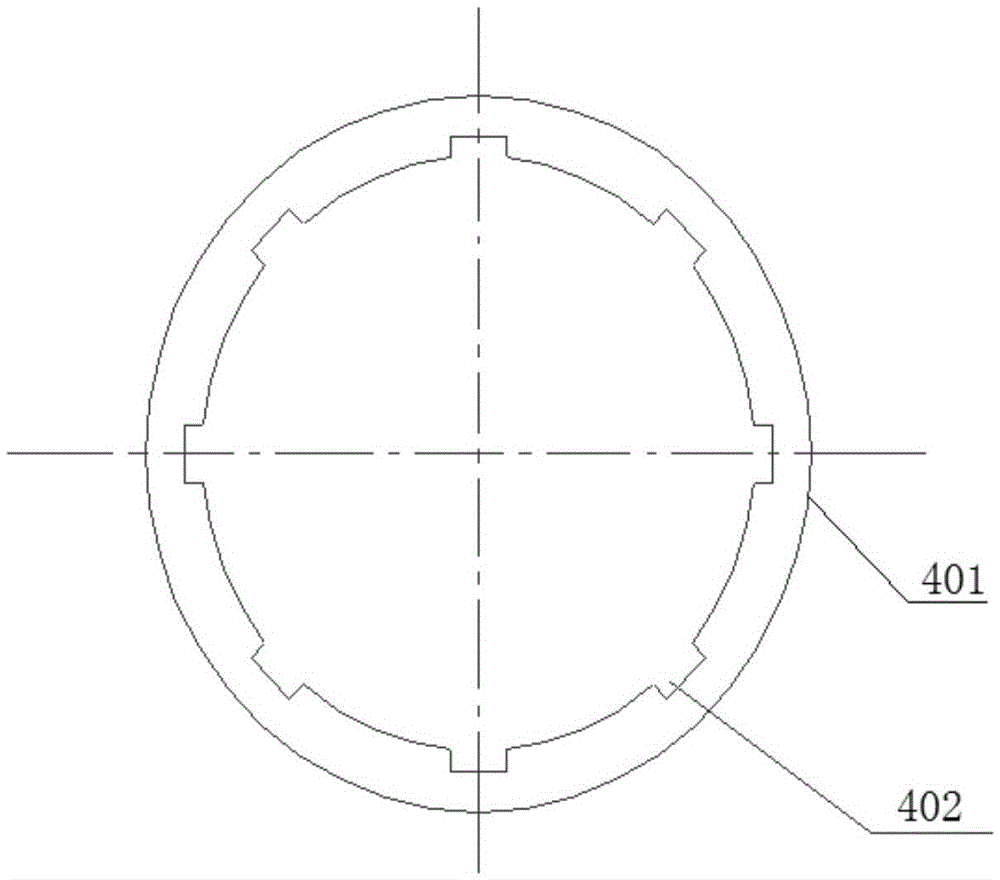

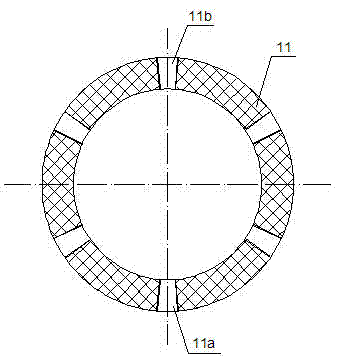

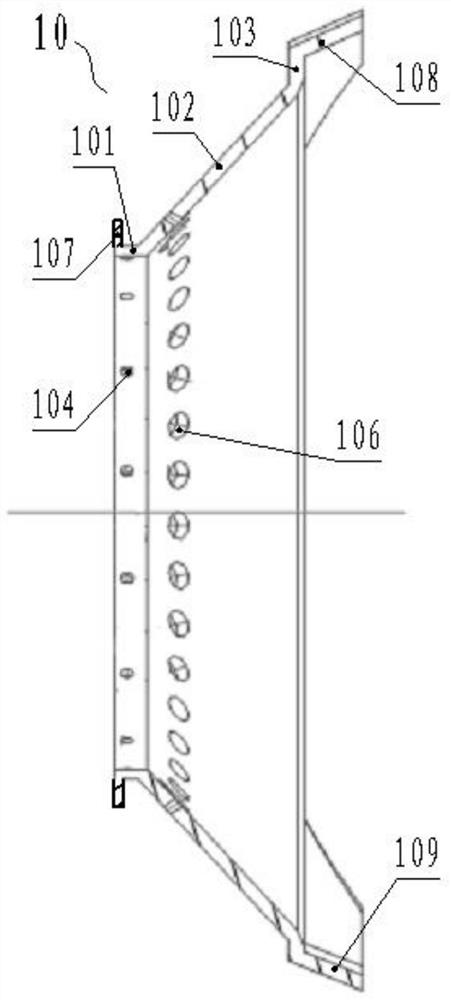

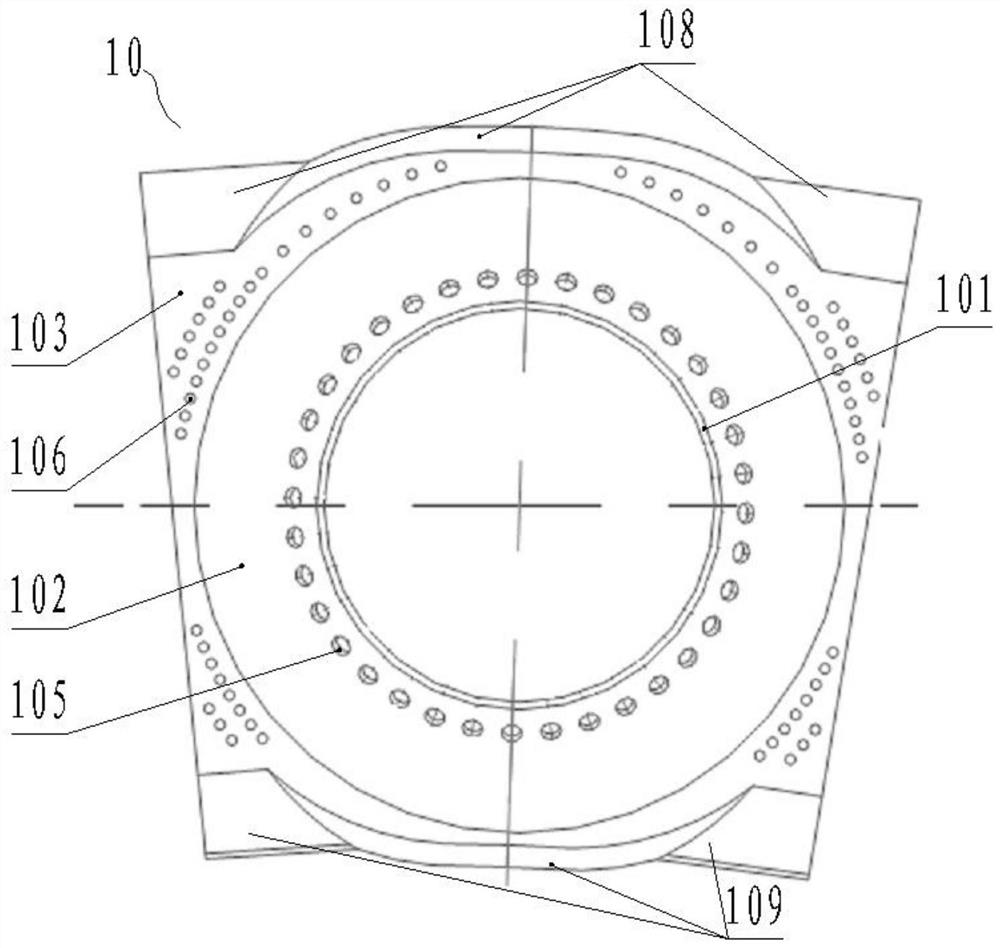

Water-sealed ring cooler

The invention discloses a water-sealed circular cooler which mainly aims at solving the problem of poor sealing effect of the existing circular cooler. The water-sealed circular cooler comprises a cooler body, a rotation system, a trolley, a blower system and water-sealed device, wherein the rotation system is arranged on the cooler body, and comprises a rotation power drive device and a rotationframework driven to rotate by the rotation power drive device; the trolley is arranged on the rotation framework; the blower system is arranged below the rotation framework, and comprises a blower and an air box arranged between the air outlet of the blower and the rotation framework; the water-sealed device is composed of two sets of water-sealed parts having the same structure, and the two setsof water-sealed parts are respectively arranged at the outer ring side and the inner ring side of the annular rotation track of the trolley and / or rotation framework and are positioned between the air box and the trolley and / or rotation framework; each water-sealed part comprises a water tank and a sealing plate; and the water tank is fixed on the cooler body, one end of the sealing plate is inserted in the water tank, and the other end is fixed below the trolley and / or the rotation framework.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

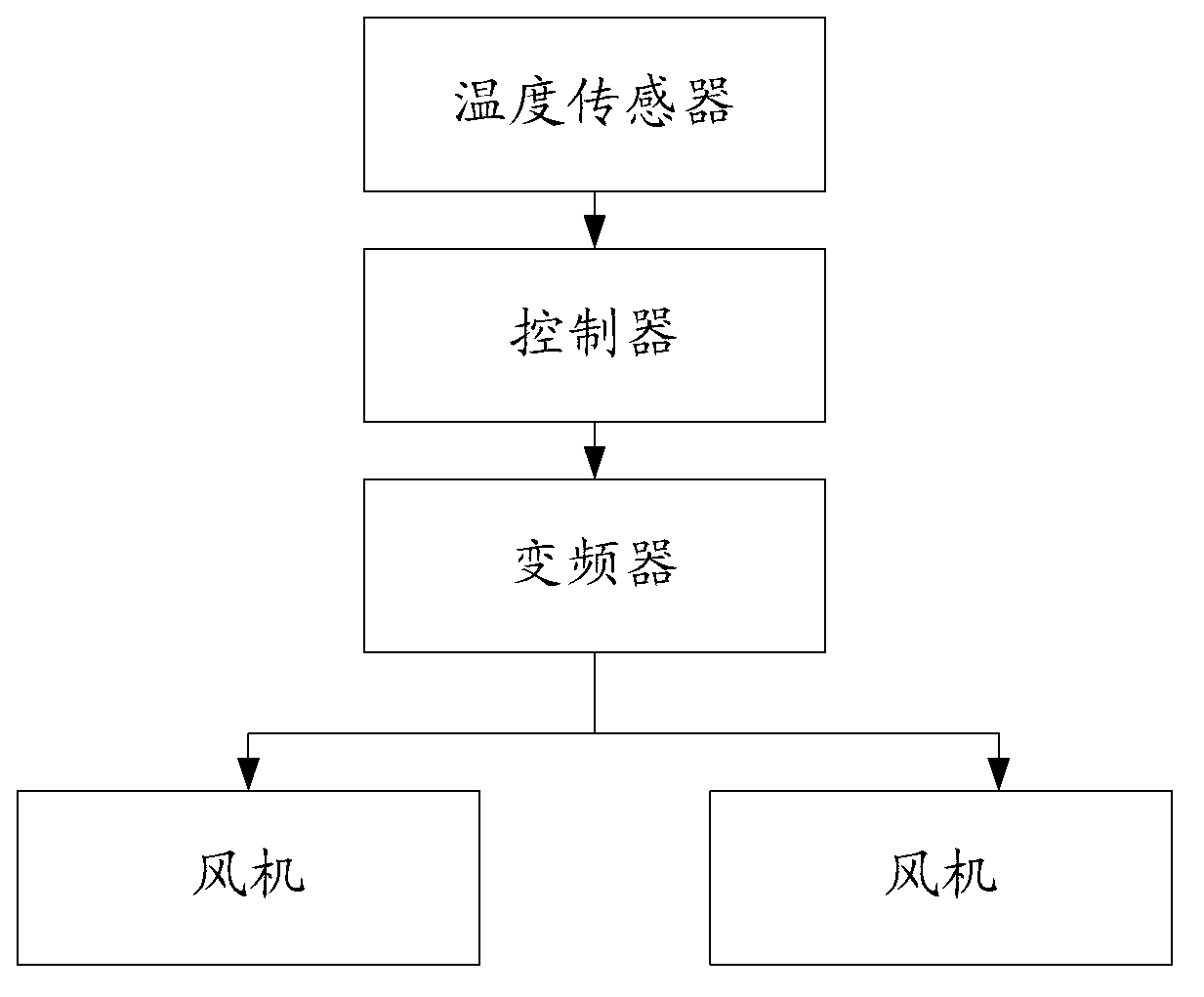

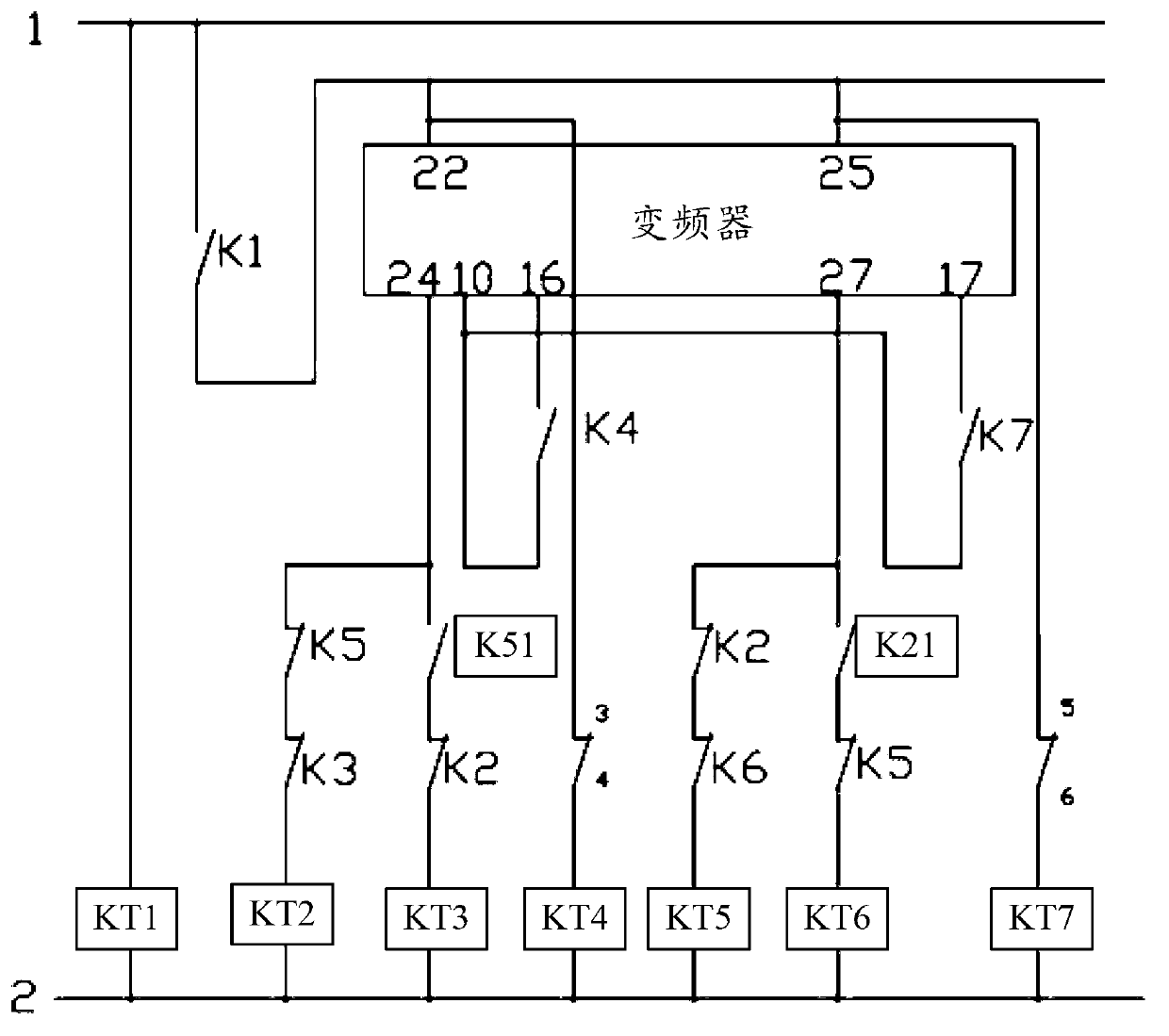

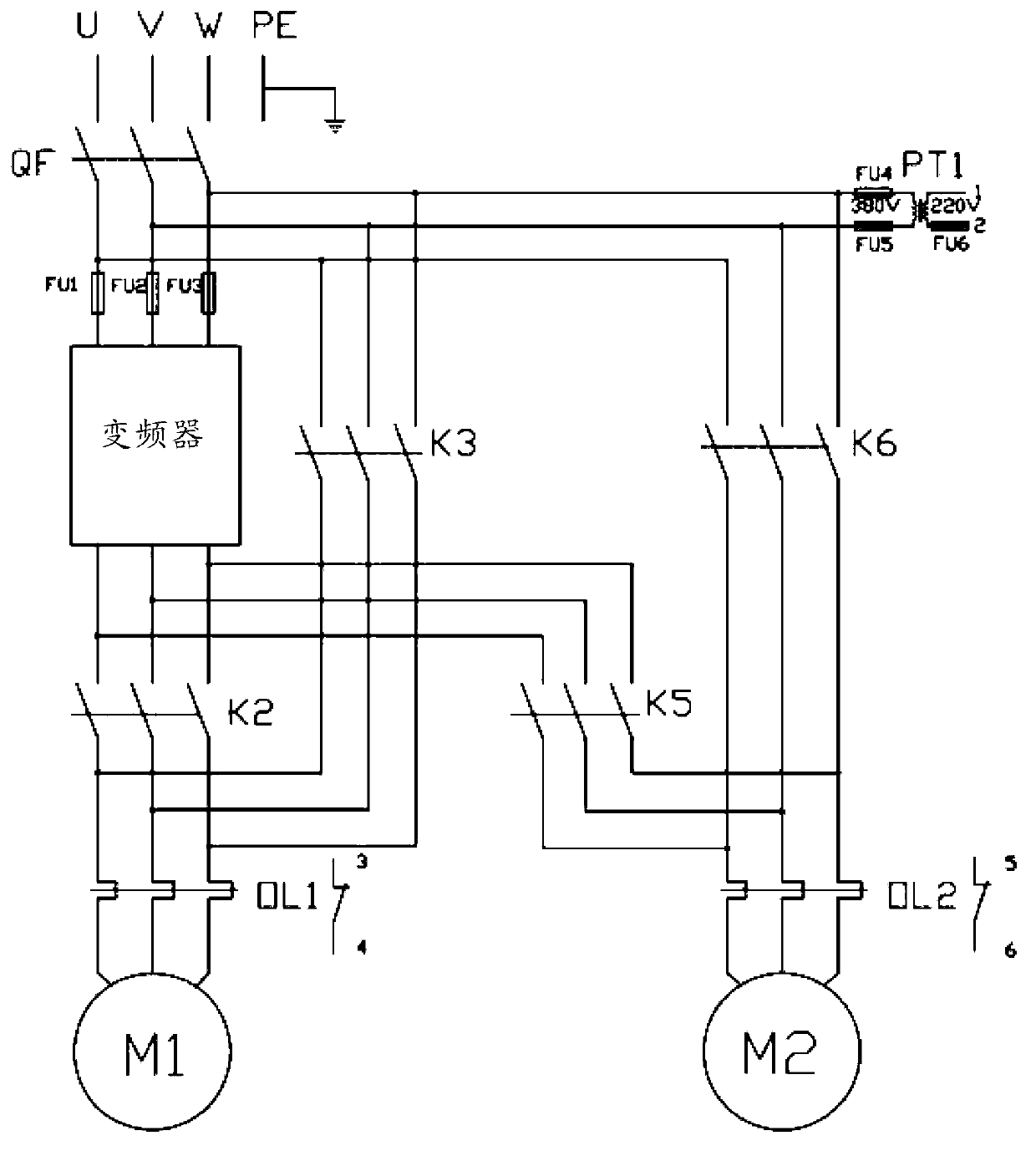

Cooling device and cooling method

ActiveCN102996481AIncrease powerRealize miniaturizationPositive displacement pump componentsPump controlFrequency changerAir volume

The invention discloses a cooling device used for cooling an air compressor. The cooling device comprises at least one fan, a temperature sensor, a controller and a frequency converter, wherein the temperature sensor is used for detecting exhaust temperature of the air compressor; the controller is connected with the temperature sensor and is used for comparing the exhaust temperature with preset exhaust temperature and outputting a signal after comparison; and the frequency converter is respectively connected with the at least one fan and the controller and is used for controlling the at least one fan to output cooling air volume corresponding to the signal after comparison according to the signal after comparison. When the cooling device is in use, a cooing temperature is firstly set, the exhaust temperature of the air compressor is detected by the temperature sensor, when the controller determines that the temperature is lower than the cooling temperature, the power supply frequency of the fan is reduced by the frequency converter, the power of the corresponding fan can be reduced, and the cooling air volume is reduced, therefore, the energy consumption is reduced, the energy sources are saved, and the service life of lubricating oil in the air compressor is effectively prolonged simultaneously. The invention also discloses a cooling method.

Owner:FUSHENG IND SHANGHAI

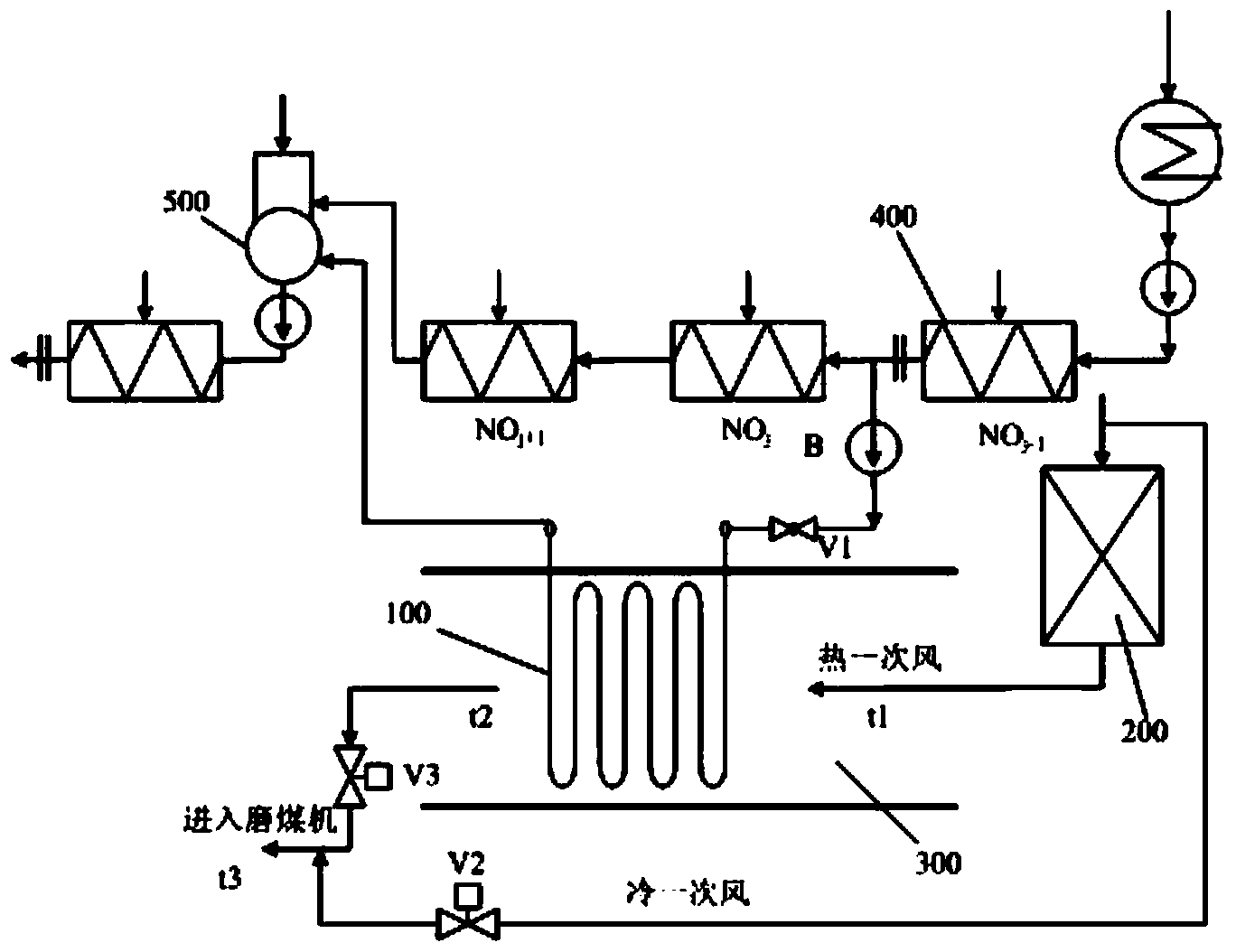

Coal-fired boiler hot primary wind heating system

InactiveCN101709882ALower exhaust gas temperatureImprove operating economyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a coal-fired boiler hot primary wind heating system. The hot primary wind pipeline in the original air supply system of a boiler is provided with a hot primary wind heater, the hot primary wind heater is communicated with a cooling medium inlet pipeline and a cooling medium outlet pipeline, the heat source for heating is the hot primary wind, and the cooling medium flow of the hot primary wind heater can be changed to control the temperature of the hot primary wind on the back of the heater so that the temperature of the hot primary wind is reduced to the temperature required by a coal pulverizing system, the quantity of the cool primary wind introduced in the coal pulverizing system is reduced to less than 5%, even 0, thus the cool primary wind which was introduced in the coal pulverizing system in the past is now introduced to an air preheater and converted to the hot primary wind so as to increase the heat exchange effect of the air preheater and reach the aim of reducing the smoke temperature of the boiler.

Owner:XIAN THERMAL POWER RES INST CO LTD

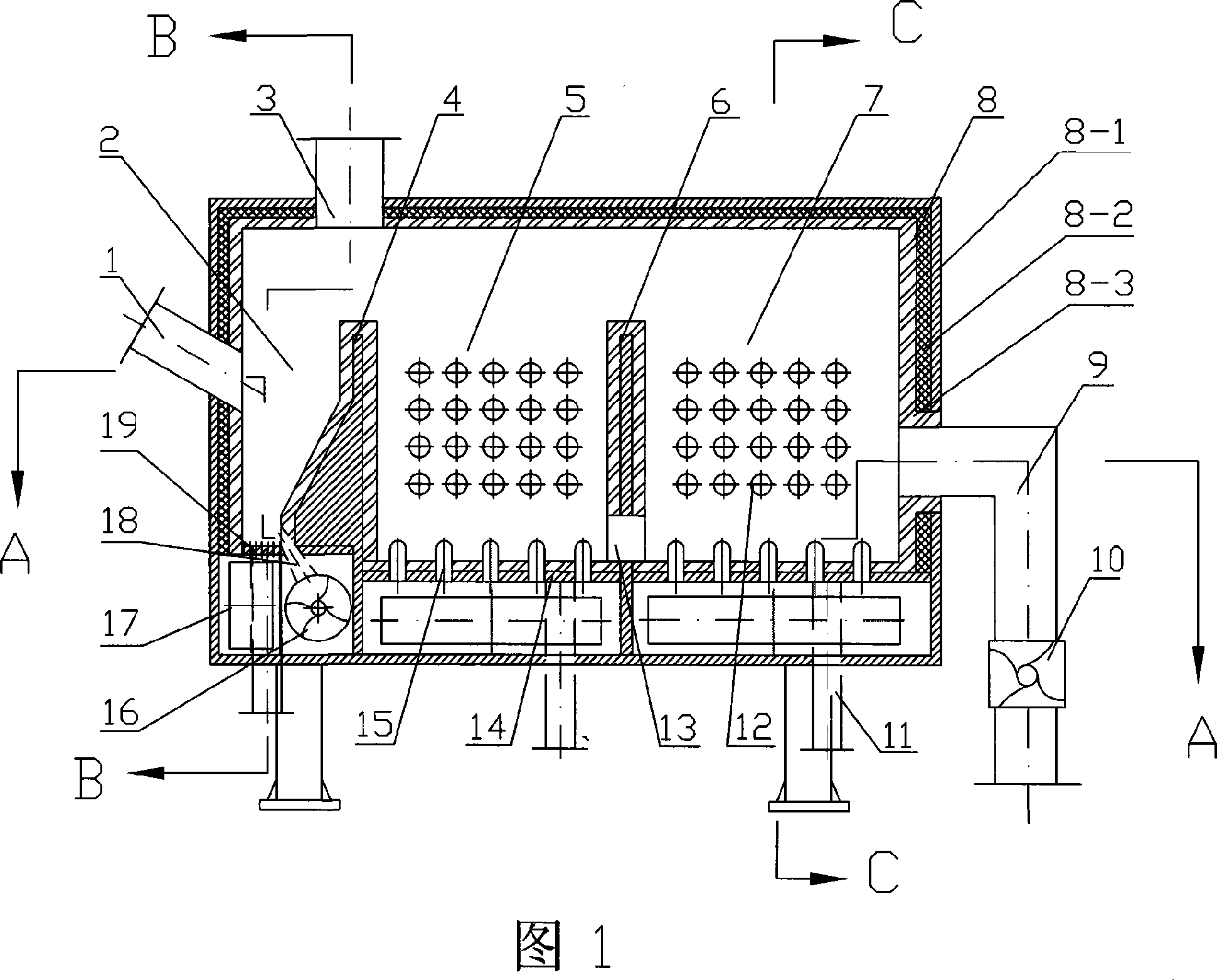

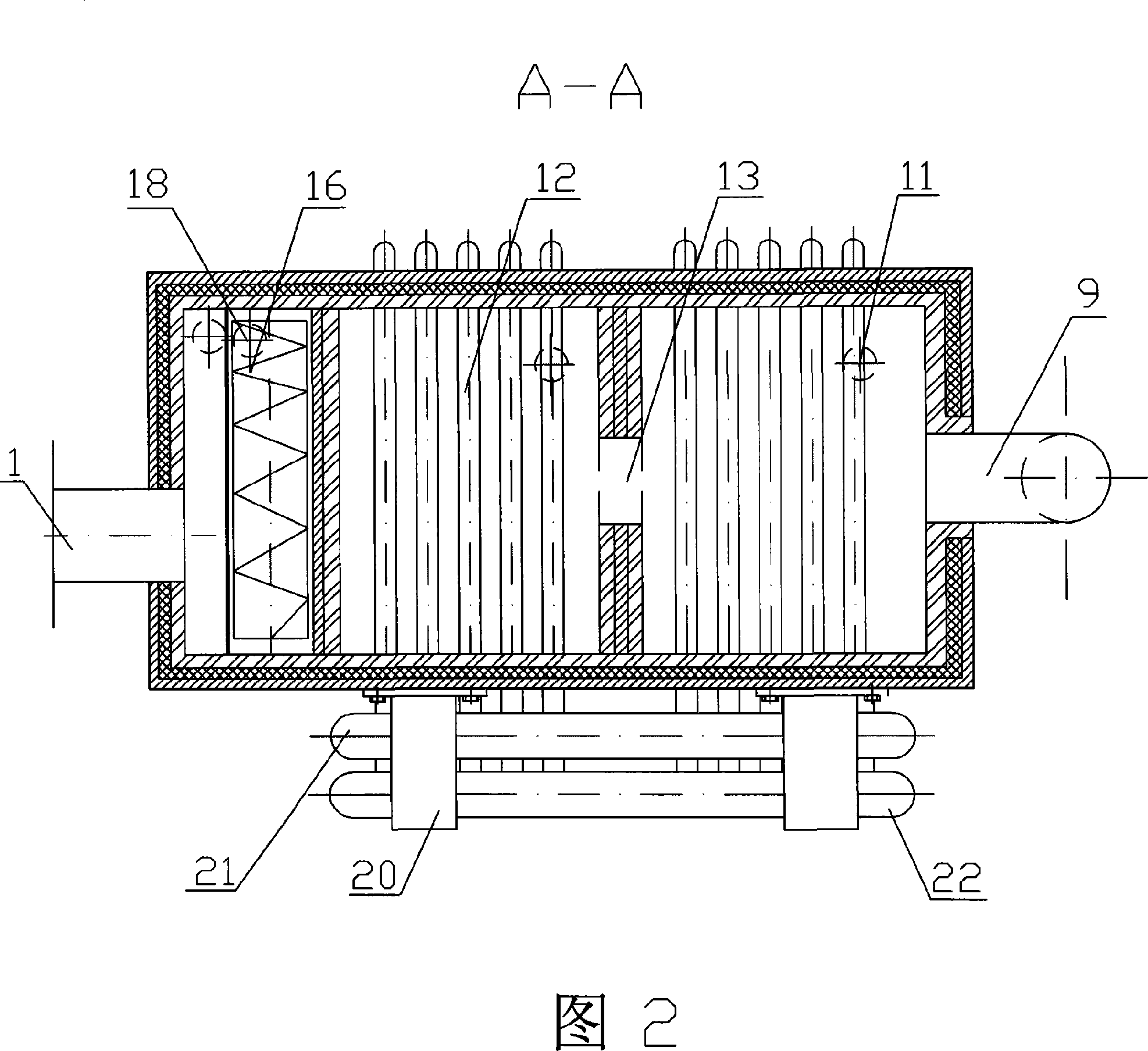

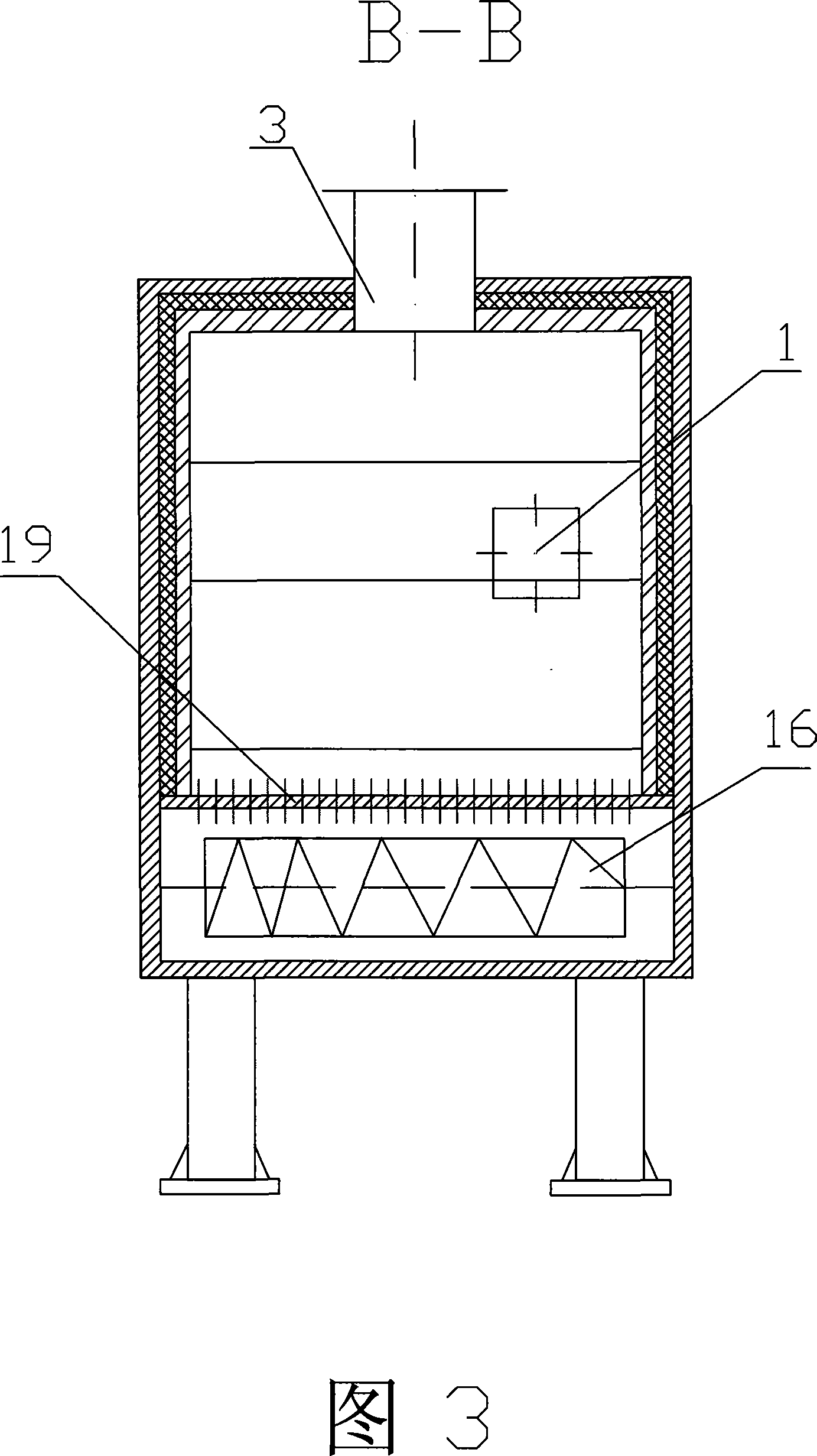

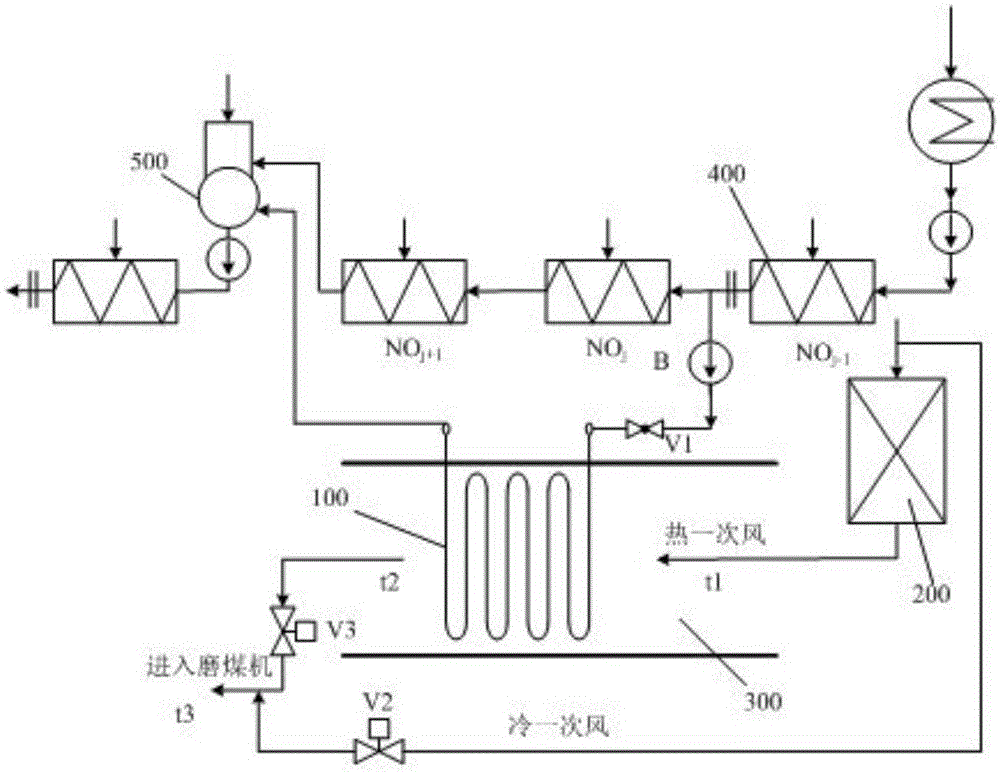

Primary air cooler heat regenerative system and controlling method

ActiveCN103438686AReduce cooling air volumeLower exhaust gas temperatureDrying gas arrangementsGrain treatmentsAir preheaterWater use

The invention discloses a primary air cooler heat regenerative system and a controlling method. According to the primary air cooler heat regenerative system and the controlling method, a primary air cooler is arranged in a primary heat air duct of an outlet of a boiler air heater, low-pressure supplied water used as cooling water is introduced by a coal-fired unit low-pressure water-supply heat regenerative system, heat of primary heat wind is absorbed, the heated supplied water is sent back to a unit deaerator, the flow of the cooling water is adjusted so as to enable the temperature of the primary wind to be reduced to meet the temperature requirement of drying medium at the inlet of a coal mill. By means of the technical scheme, the cold wind amount of a side road of a boiler air preheater can be greatly reduced, the smoke exhausting temperature of the boiler is reduced, the power-supply coal consumption of the unit is reduced, and the stable operation of the unit is not affected.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

Composite type cold slag device

InactiveCN101101113ACooperate wellMeet the needs of actual operationSolid fuel combustionCombustion apparatusTechnology developmentGranularity

The invention relates to combined type cold slag device. It includes cold slag room, air chamber, and water cooling packing auger cold slag machine. The cold slag room is set two divider to divide it into three cooling room. The second divider lower is set hole. The first cooling room is spouted bed structure of which bottom is set close-hole type grid plate on which the main slag discharge pipe is set. The back two cooling rooms are set water cooling tube bank, and funnel cap type grid plate at the bottom. The invention can satisfy the demands of big feeding coal granularity, actual motion and macro-scale operations technology development for circulating fluidized bed boiler.

Owner:CHONGQING UNIV

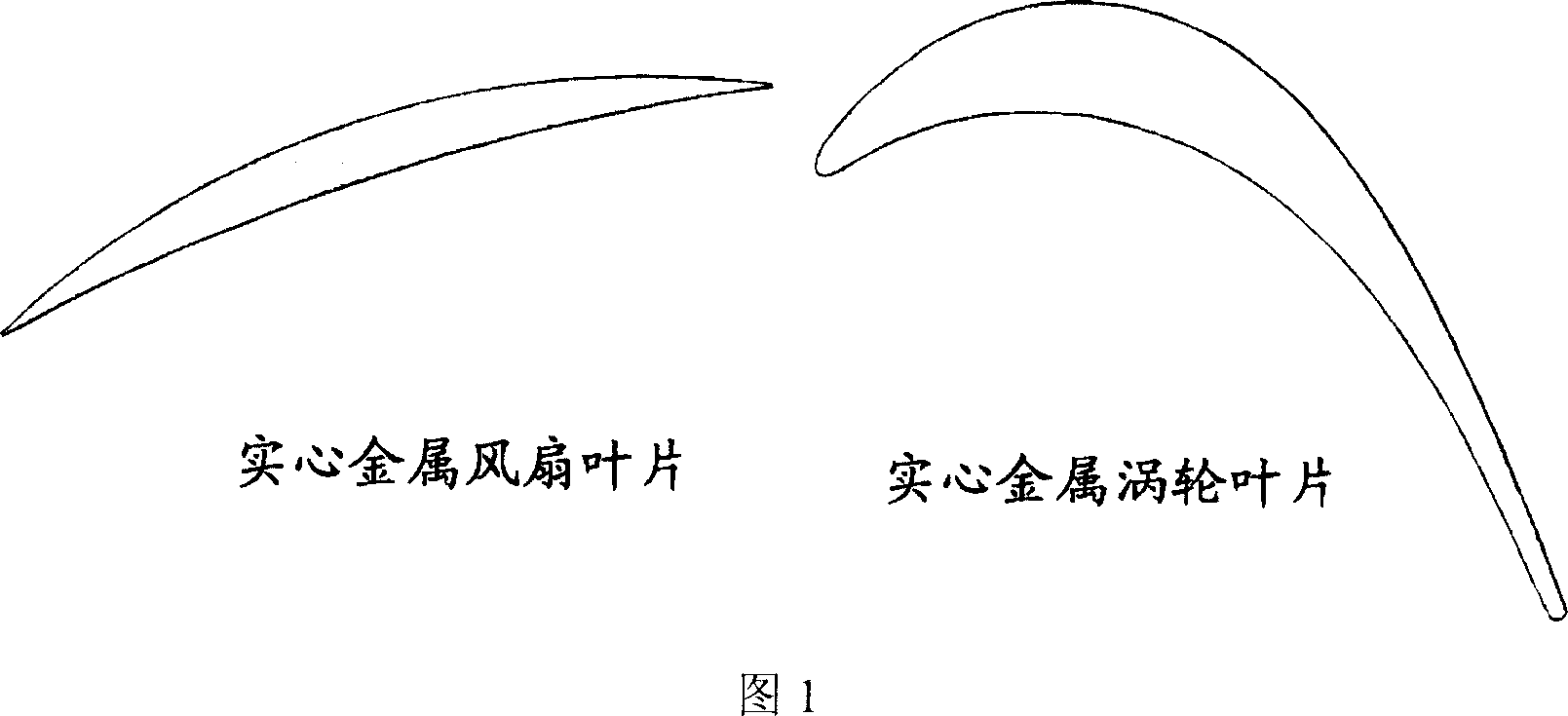

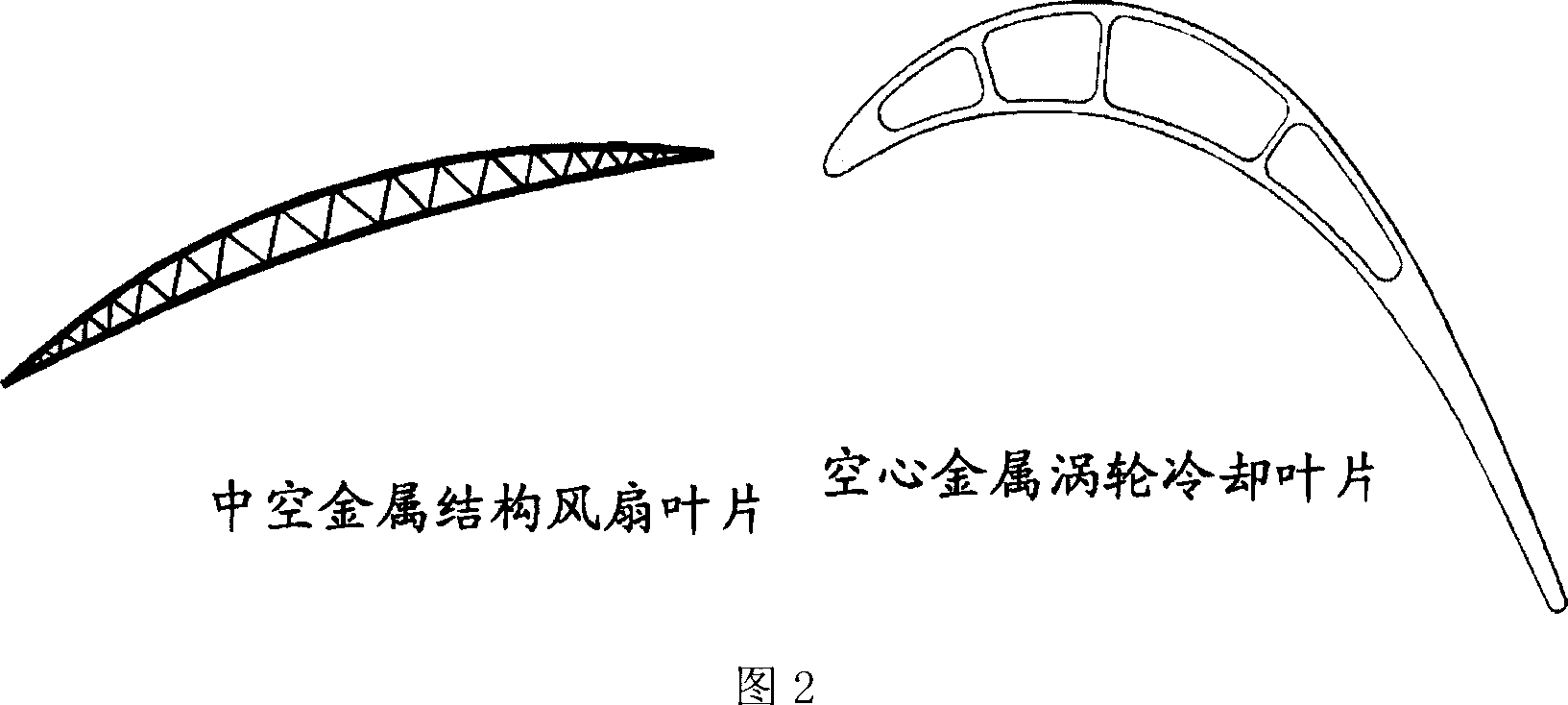

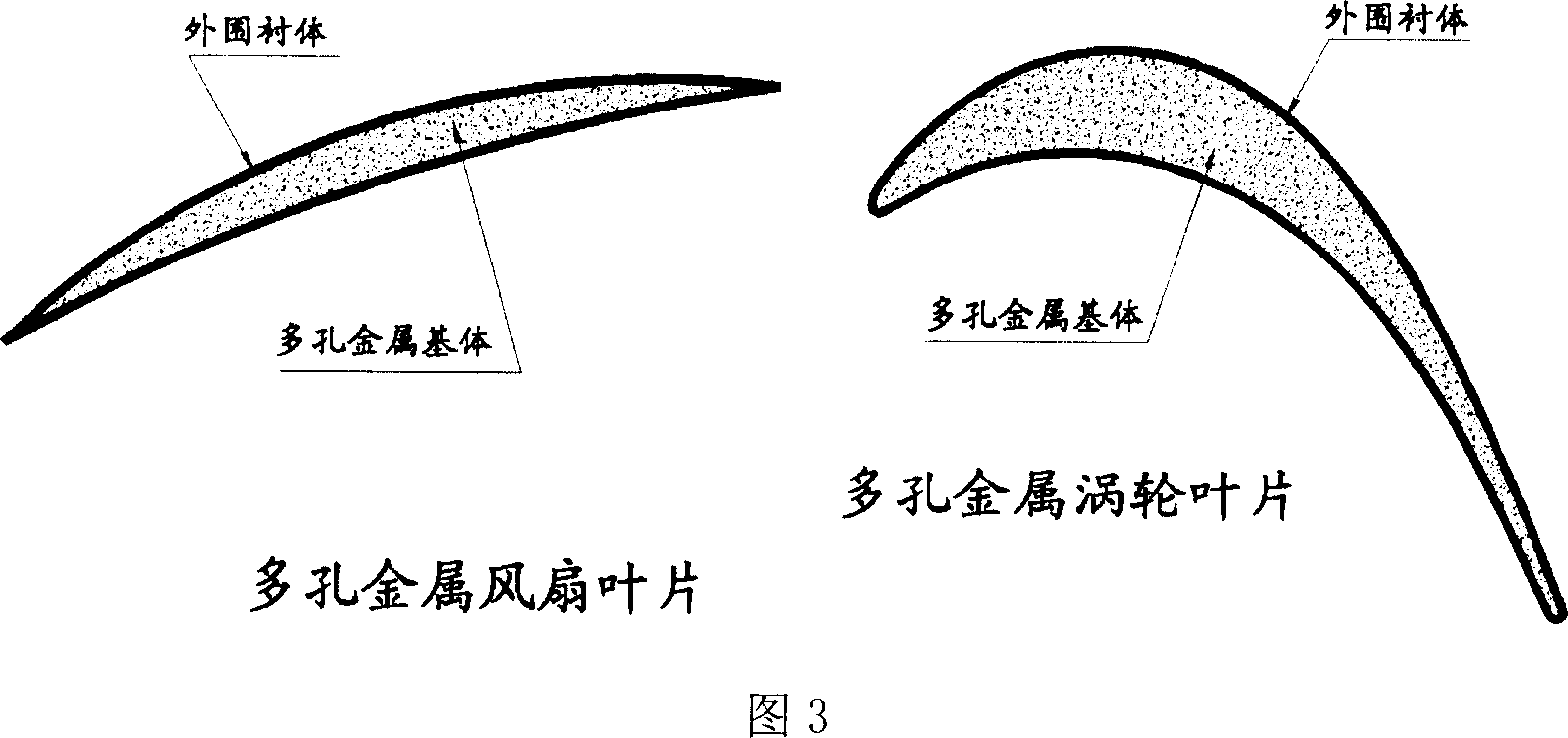

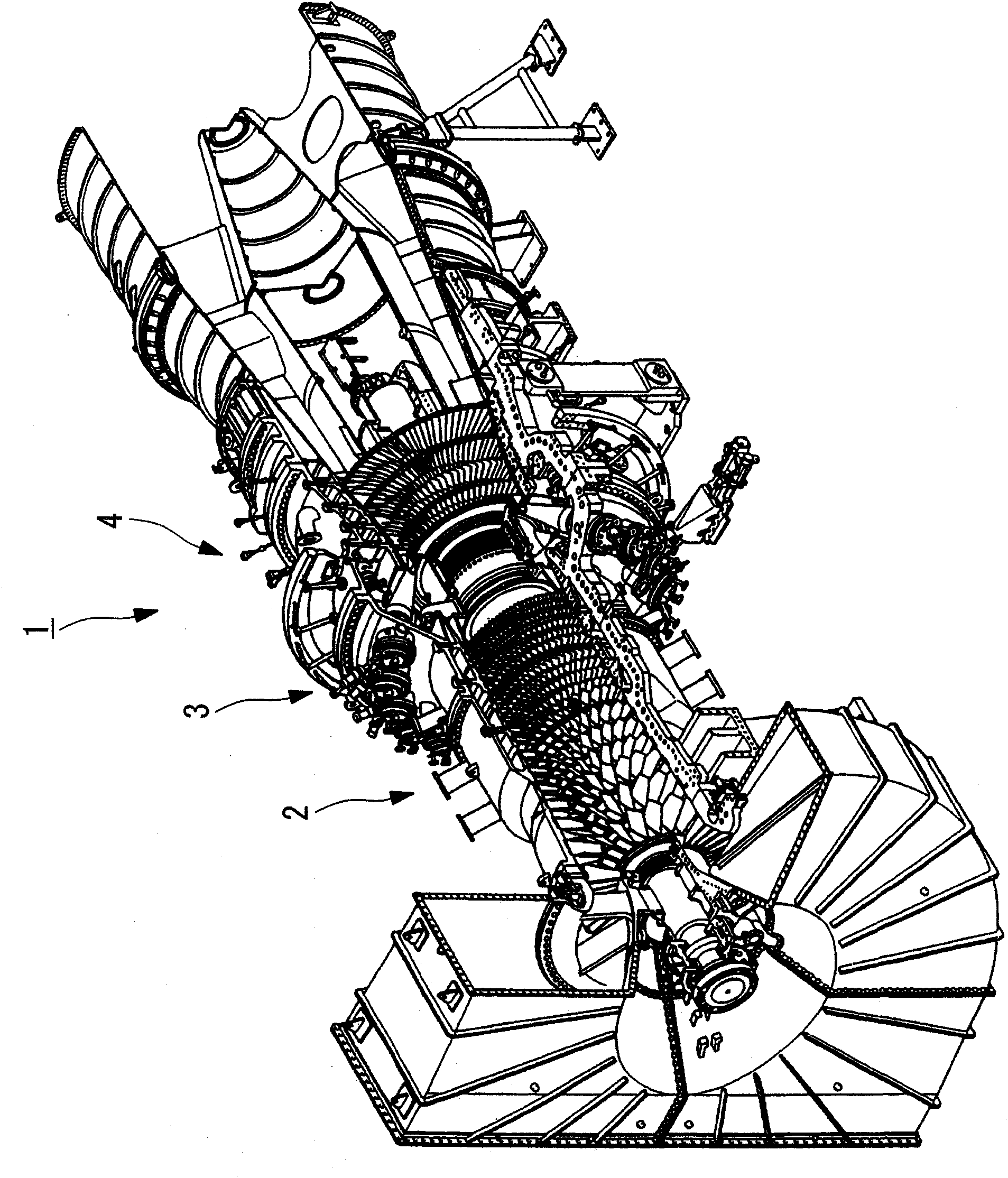

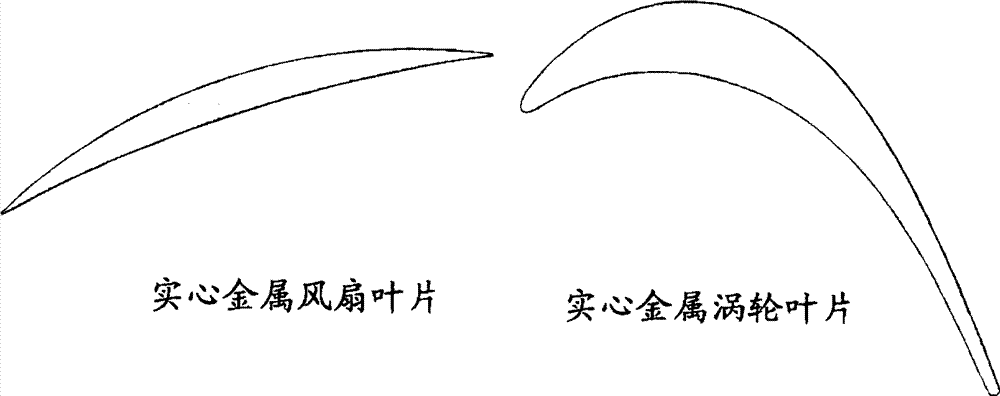

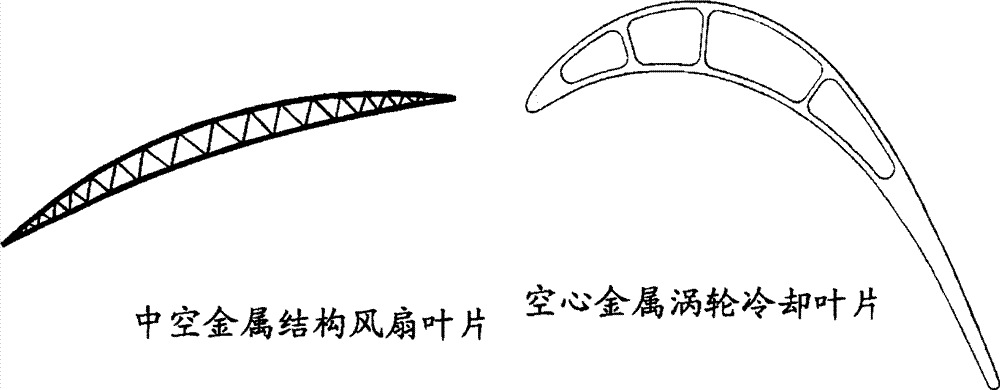

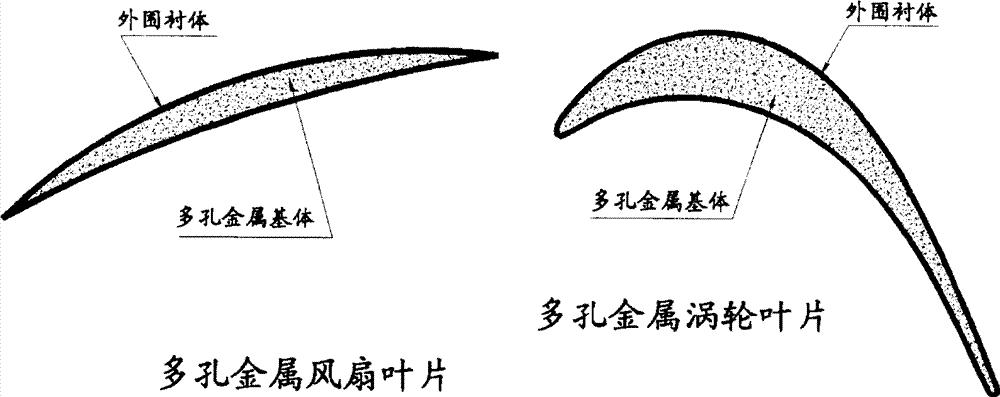

Porous metal vane coupling design method

InactiveCN101078354AImprove performanceExtended service lifePump componentsBlade accessoriesState of artImpeller

The invention relates to a design method for porous metal blade. The method combines porous metal material with design of blade and the manufacturing process. By the high specific strength characteristic of porous metal material and adjusting porosity of said material, blade coupling design of process, strength, vibration, and pneumatic thermal force is carried out so as to improve the specific strength of blade and satisfy the flow control demand of blade boundary layer. The method conquers the lack of solid or hollow blade in prior technology. The good performance of porous metal material is used. Blade material characteristic, strength, vibration and pneumatic thermal force performance are considered in synthesis. The coupling design method for blade process, strength, vibration, pneumatic thermal force of porous metal is provided and part performance of aeroengine and gas turbine can be improved greatly. At the same time the invention provides a blade designed by the method, aeroengine and gas turbine comprising blade mentioned above.

Owner:BEIHANG UNIV

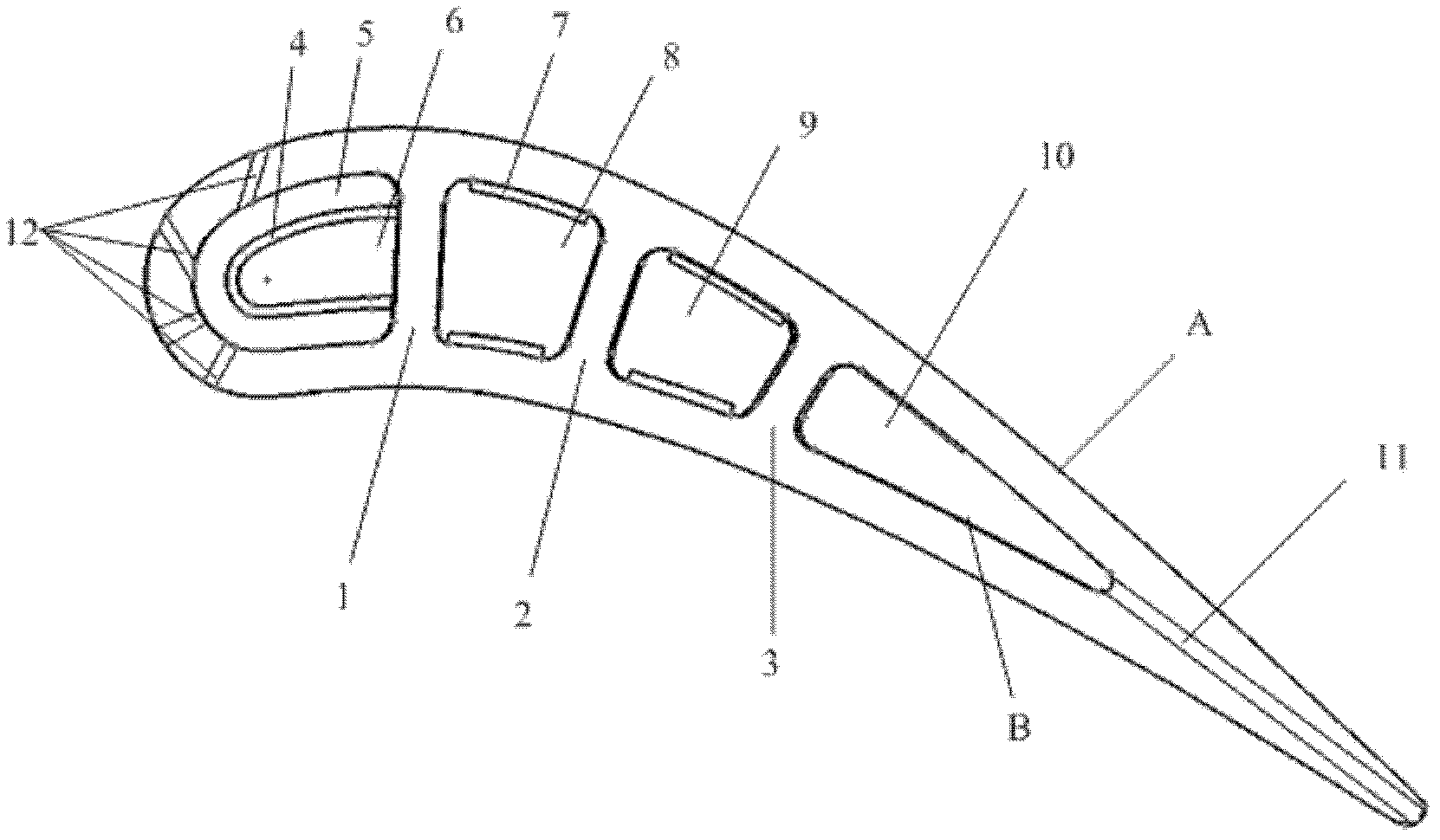

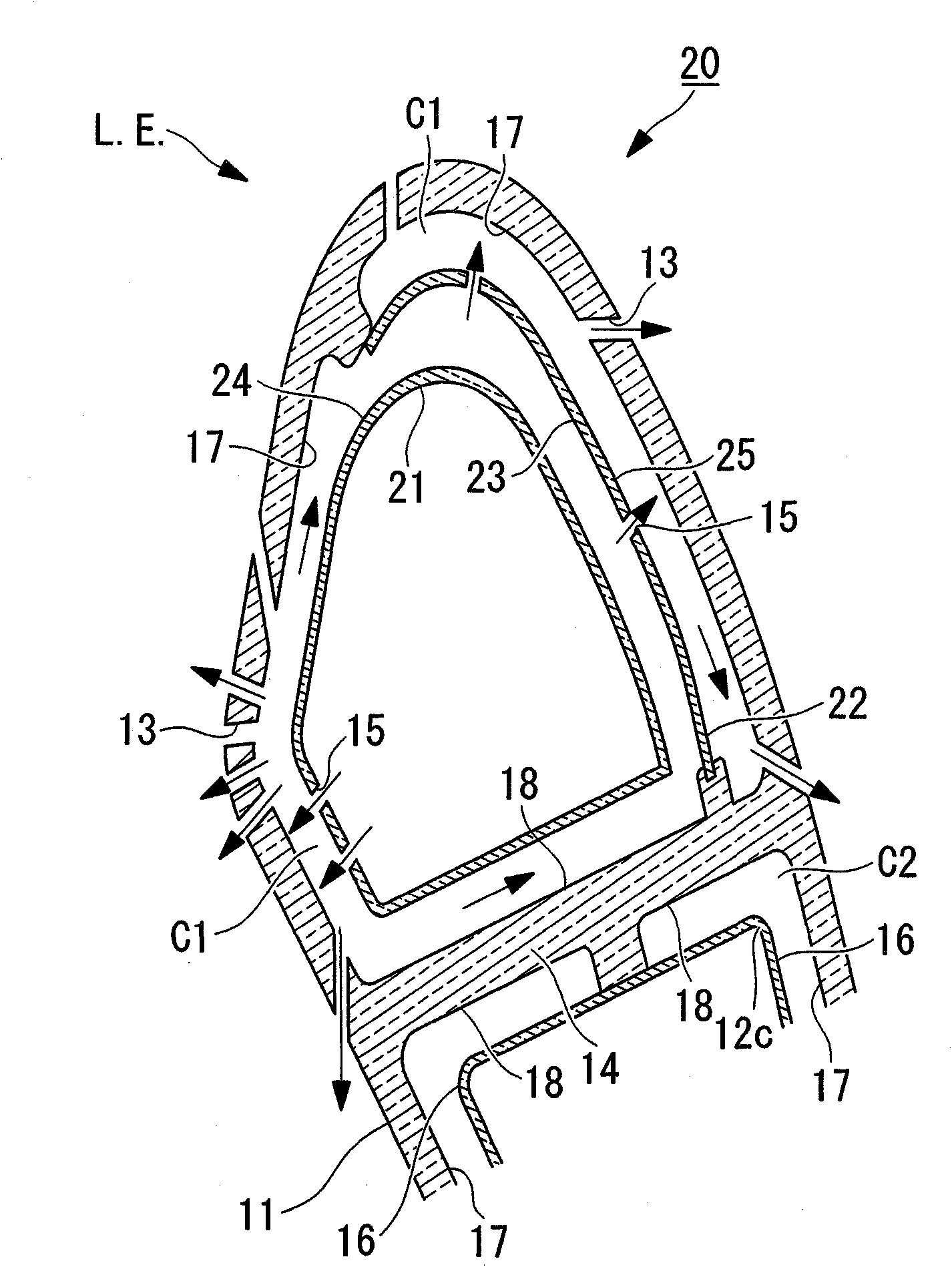

Heavy-type combustion engine high-temperature turbine double-medium cooling blade

ActiveCN102425459AUniform surface temperature distributionExtend your lifeTurbine/propulsion engine coolingBlade accessoriesCombustionCooling effect

The invention relates to a heavy-type combustion engine high-temperature turbine double-medium cooling blade, which is characterized in that: a first separation plate and a third separation plate are sequentially arranged from the front edge and the end edge of a blade inner cavity to divide the blade inner cavity into a front cooling space, a middle cooling space and a rear cooling space to be independent from one another along the radial direction of the blade, the blade front cooling space is divided by a fourth separation plate into a first cooling cavity and a second cooling cavity, impact cooling holes are equally distanced to one another to be arranged on the fourth separation plate, the front edge of the blade is provided with four rows of gas film cooling holes which are alternatively arranged, spoiler ribs which are arranged at equal intervals are arranged on a blade inner wall B of the middle cooling space, the middle cooling space is divided by a second separation plate into a third cooling cavity and a fourth cooling cavity, which are communicated with each other, the rear cooling space is a fifth cooling cavity, and the fifth cooling cavity is connected through fin-shaped vent holes which are equally distanced to one another; and the middle cooling space adopts a steam closed-type cycling cooling way to be combined with the air cooling way of the front and the rear cooling spaces, so the cooling fluid has high heat exchanging coefficient on each position of the blade, the cooling effect can be improved, and the unit heat efficiency can be improved.

Owner:XI AN JIAOTONG UNIV

Composite cooling structure for wall of combustion chamber flame tube of aero-engine

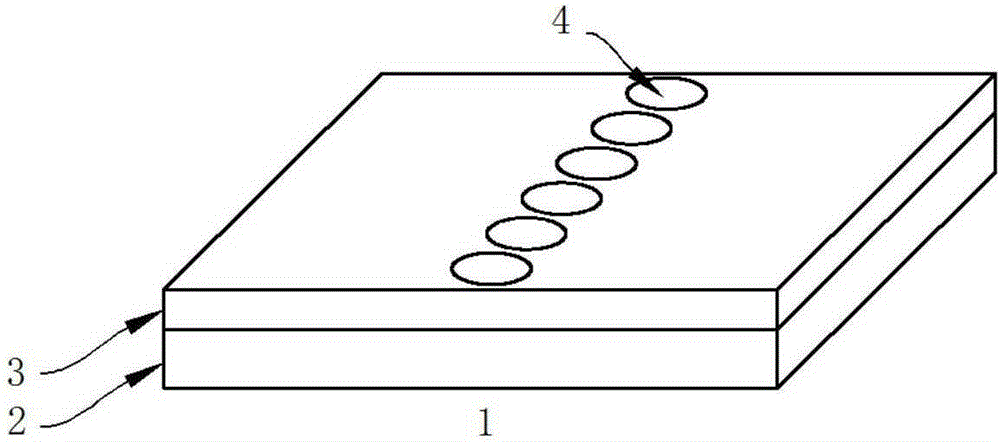

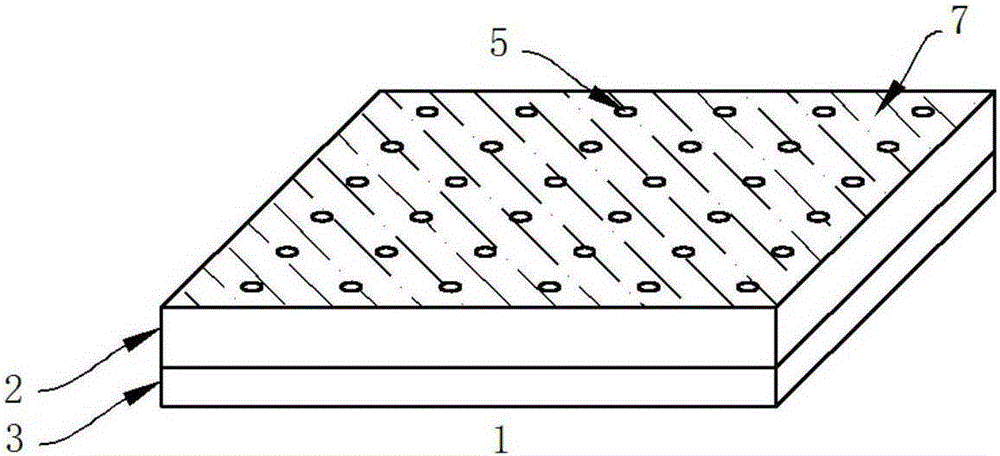

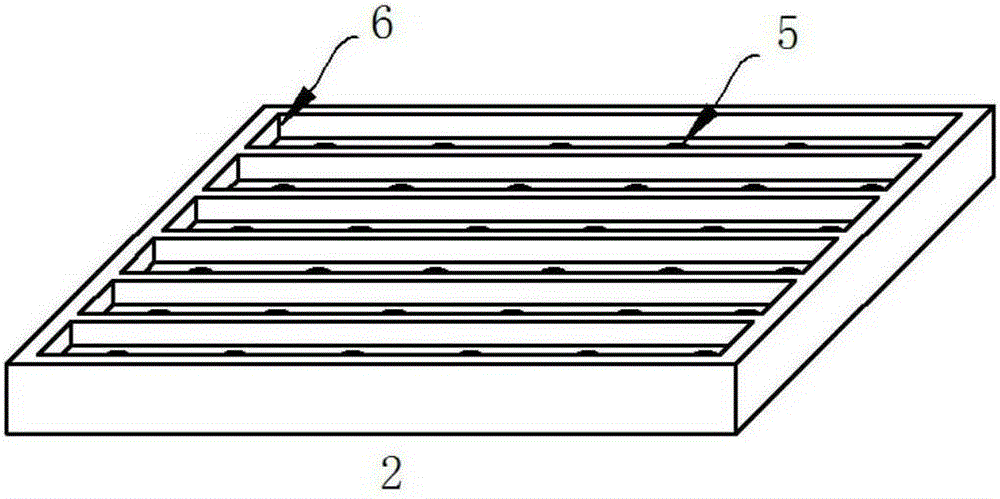

InactiveCN105276620AImprove heat transfer effectSmall structure sizeContinuous combustion chamberCombustion chamberScale structure

The invention discloses a composite cooling structure for the wall of a combustion chamber flame tube of an aero-engine. The composite cooling structure is composed of a bottom plate wall (2) and a cover plate wall (3). The interior of the bottom plate wall (2) is cut into six parallel-connection micro-scale channel grooves (6) in the flowing direction of the flame tube, and six small air outlet through holes (5) are formed in the center line of each cut micro-scale channel groove (6). Large air inlet through holes (4) are formed in the position, corresponding to each cut micro-scale channel groove (6), of the cover plate wall (3). The bottom plate wall (2) and the cover plate wall (3) are welded into a whole, after welding is finished, bending treatment is carried out in the circumferential direction of the flame tube, and the side wall of the bottom plate wall (2) is coated with a heat barrier coating (7). According to the cooling structure, micro-scale channel cooling and diffusion hole air film cooling are combined, the micro-scale structure is fully utilized for enhancing heat transfer, and the cooling capacity of cooling air flow is achieved. The structural design and machining are simple, and the cooling structure can be achieved easily in actual machine types.

Owner:中航空天发动机研究院有限公司

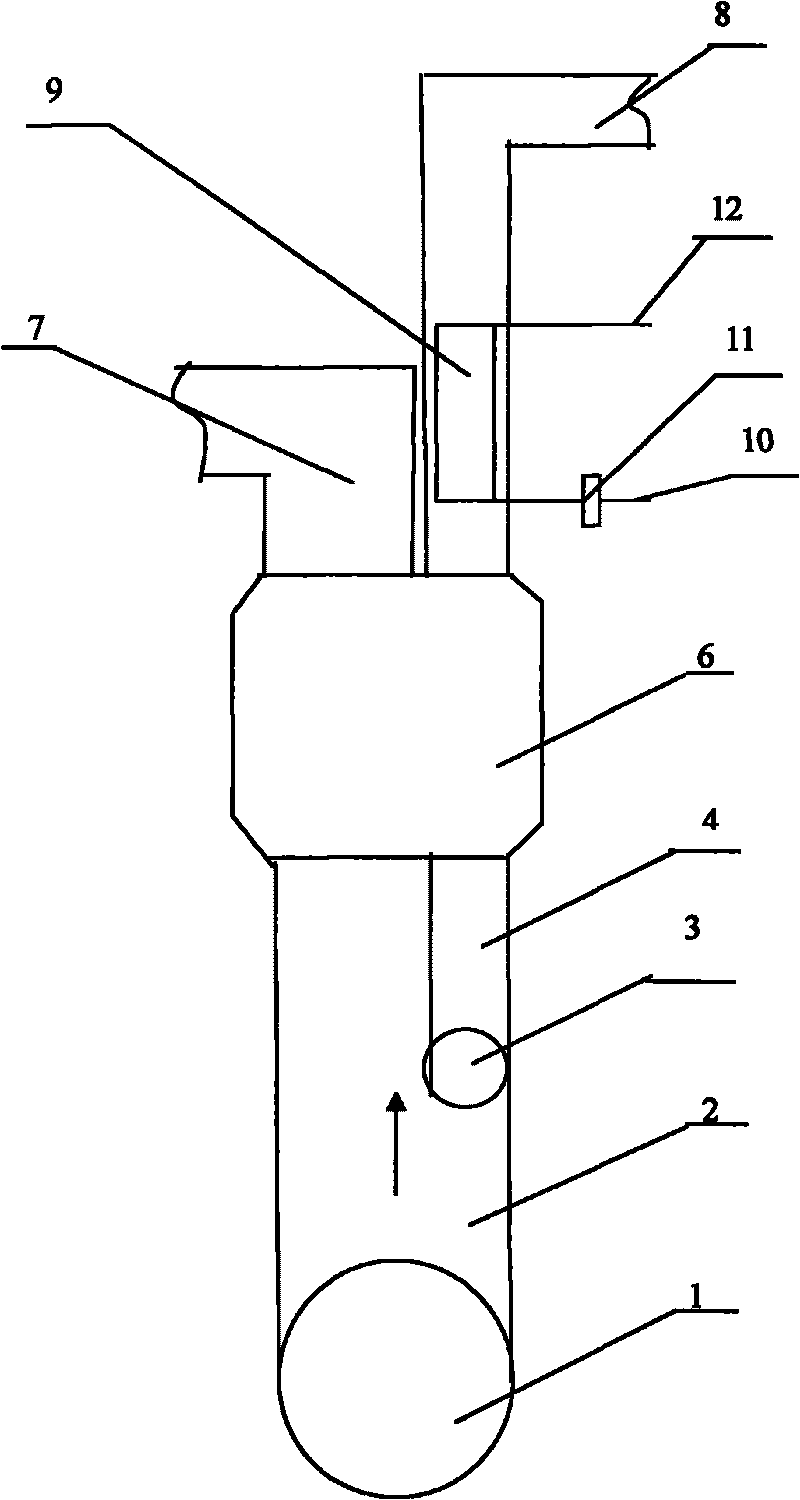

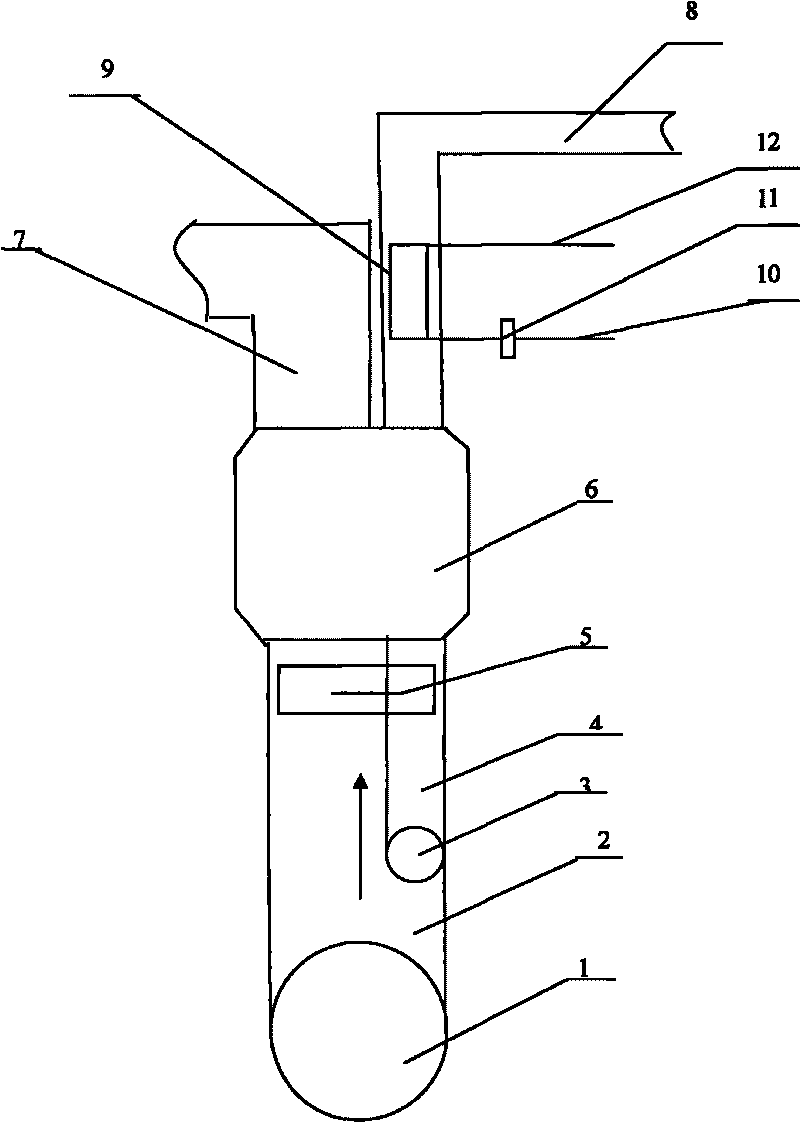

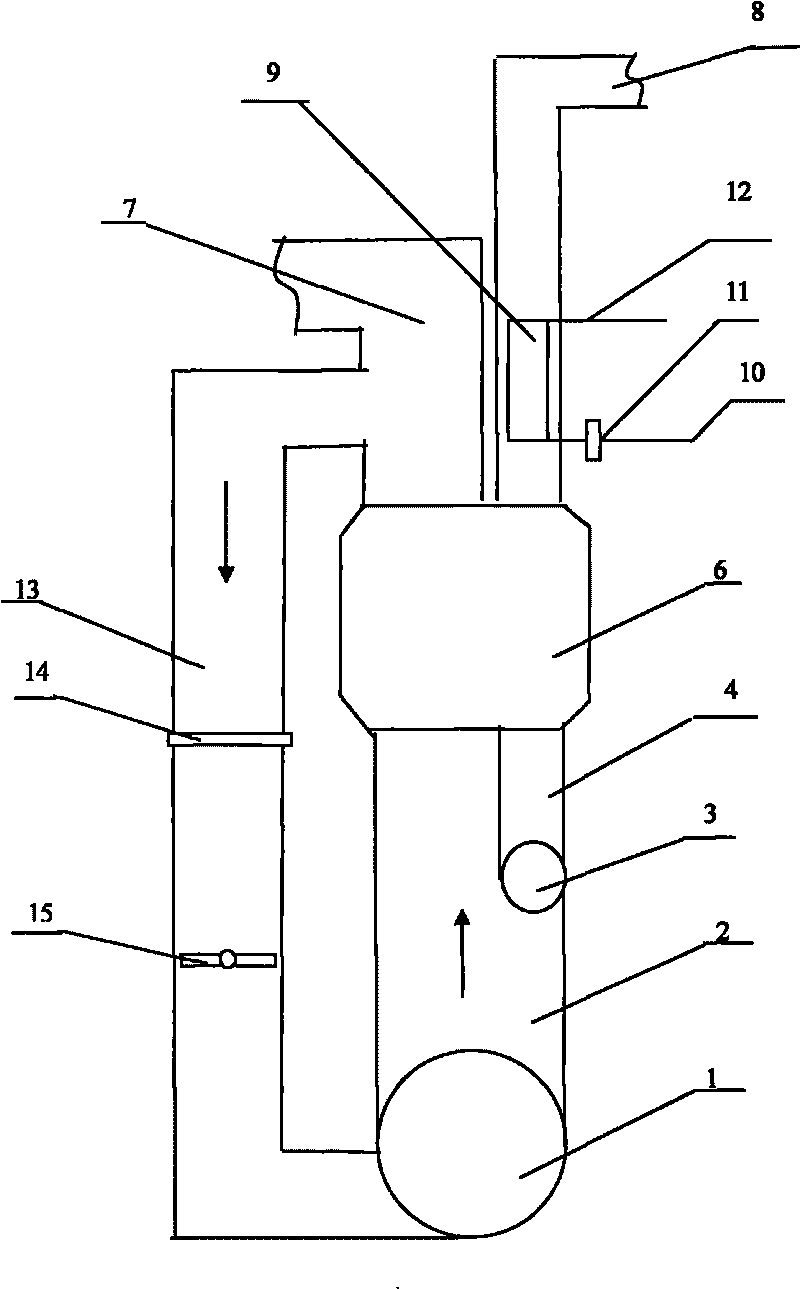

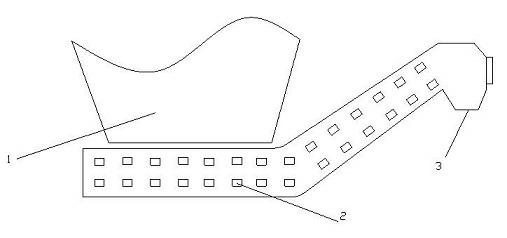

Ventilation control system and method applicable to dry type slag extractor

The invention relates to a ventilation control system and method applicable to a dry type slag extractor, which have simple structure and can effectively control the quantity of cold air entering a boiler. The ventilation control system comprises a slag extractor which is divided into a horizontal section and an inclined section, wherein ventilating devices are respectively arranged at the horizontal section and the inclined section; a tail end of the inclined section is a slag falling port; the ventilating devices are connected with a ventilation control unit; meanwhile, a first stage of temperature measuring device and a second stage of temperature measuring device are respectively arranged on an intersected part of the horizontal section and the inclined section and an upper part of the inclined section; and two stages of temperature measuring devices are both connected with the ventilation control unit.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

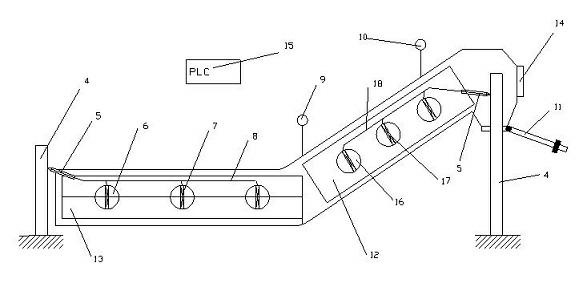

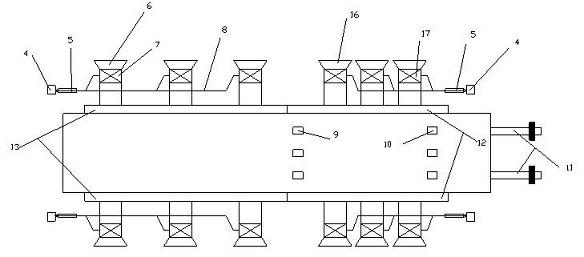

Dry-type deslagging system capable of adjusting cooling air

InactiveCN104132355AReduce demandReduce the amount of slagLighting and heating apparatusAir volumeEngineering

The invention relates to a cooling air dry-type deslagging system, in particular to a dry-type deslagging system capable of adjusting cooling air. The problem that the volume of cooling air entering a hearth is too large according to an existing dry-type deslagging system, and therefore the operating efficiency of a boiler is reduced is solved. One end of a hot air exhausting pipeline is communicated with a horizontal section, and the other end of the hot air exhausting pipeline is communicated with a primary air inlet flue. A hot air exhausting fan inlet isolation door, a hot air exhausting fan inlet adjusting door, a hot air exhausting fan and a hot air exhausting fan outlet isolation door are sequentially arranged on the hot air exhausting pipeline. A cooling air adjusting baffle is obliquely arranged over a hydraulic opening-closing door, and the opening degree of the cooling air adjusting baffle ranges from 0 to 100%. A motor is arranged on the outer side wall of the boiler. The motor and the cooling air adjusting baffle are in driving connection through a valve rod. The dry-type deslagging system capable of adjusting cooling air is used for comprehensively adjusting cooling air inside the hearth of the boiler.

Owner:STATE GRID CORP OF CHINA +1

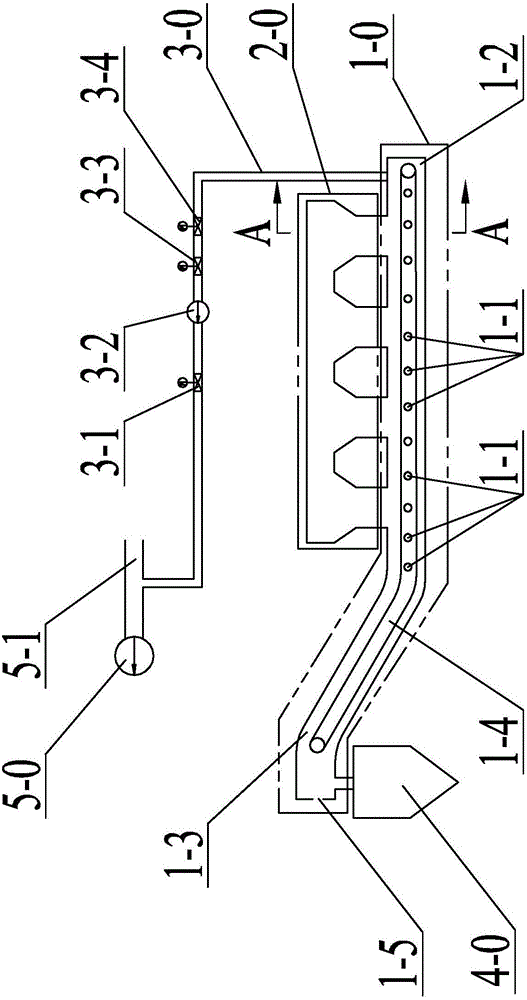

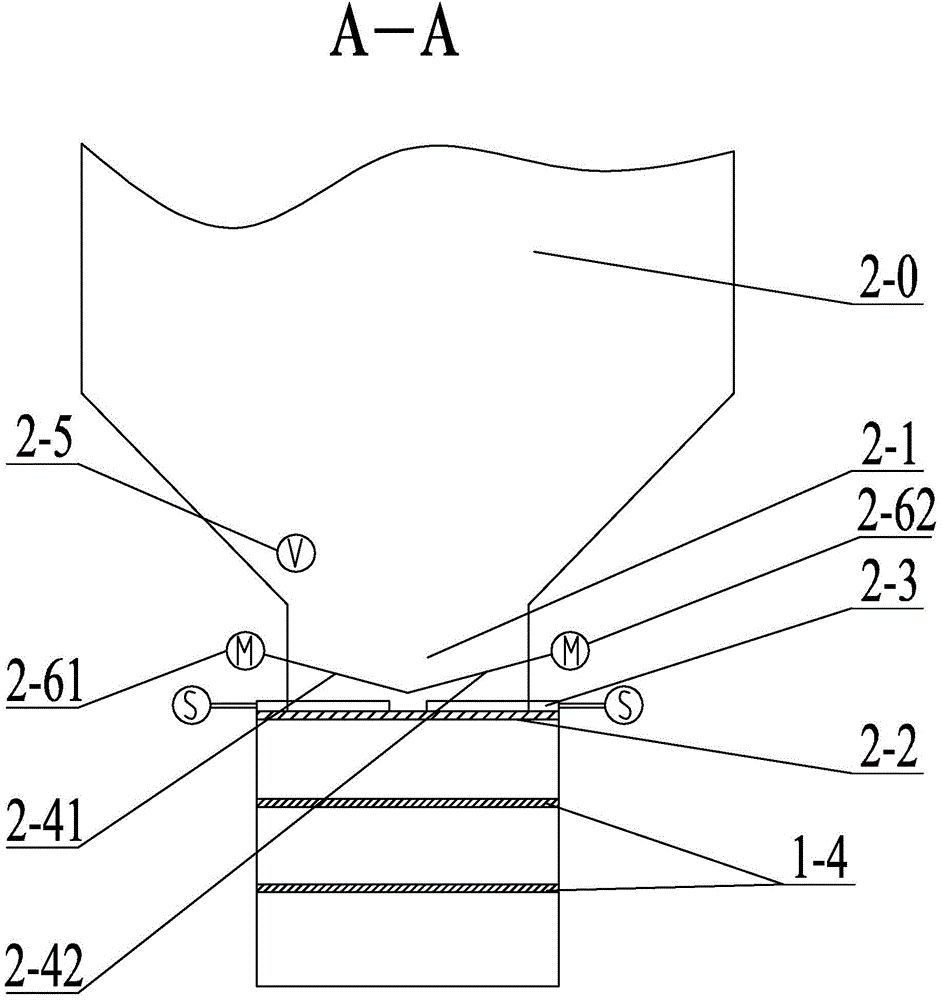

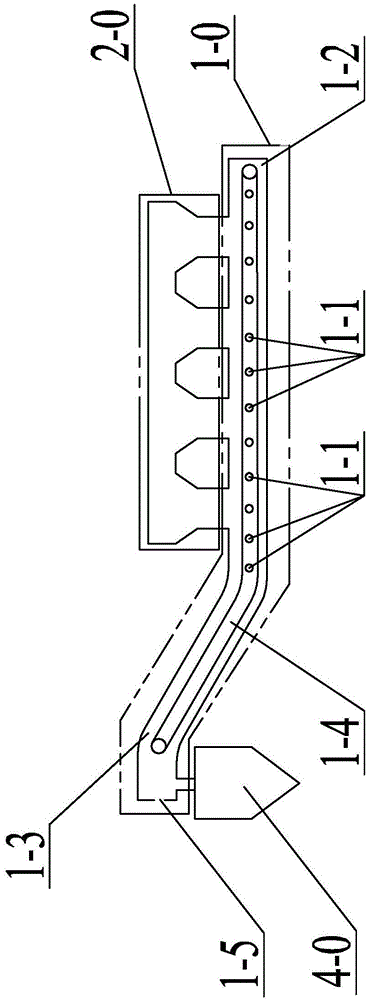

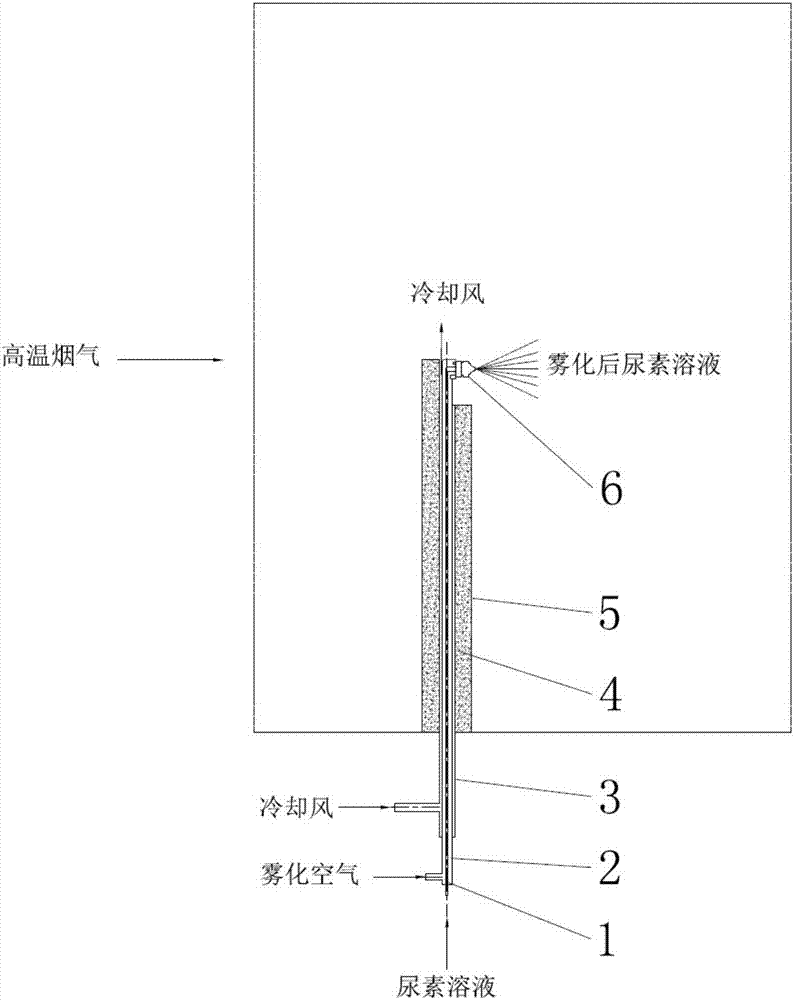

Dual-fluid spraying gun structure suitable for flue-type urea direct injection pyrolysis process

PendingCN106955593ASolve the problem of steaming dry clogged spray gunImprove atomization effectDispersed particle separationLiquid spraying apparatusAir volumeLiquid state

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

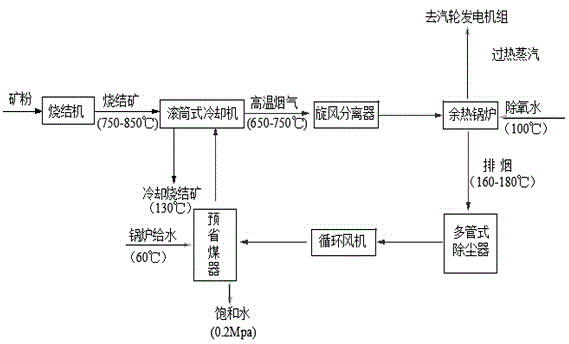

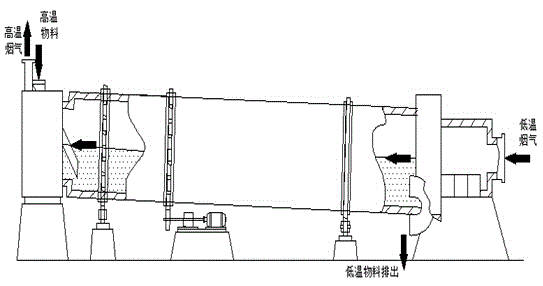

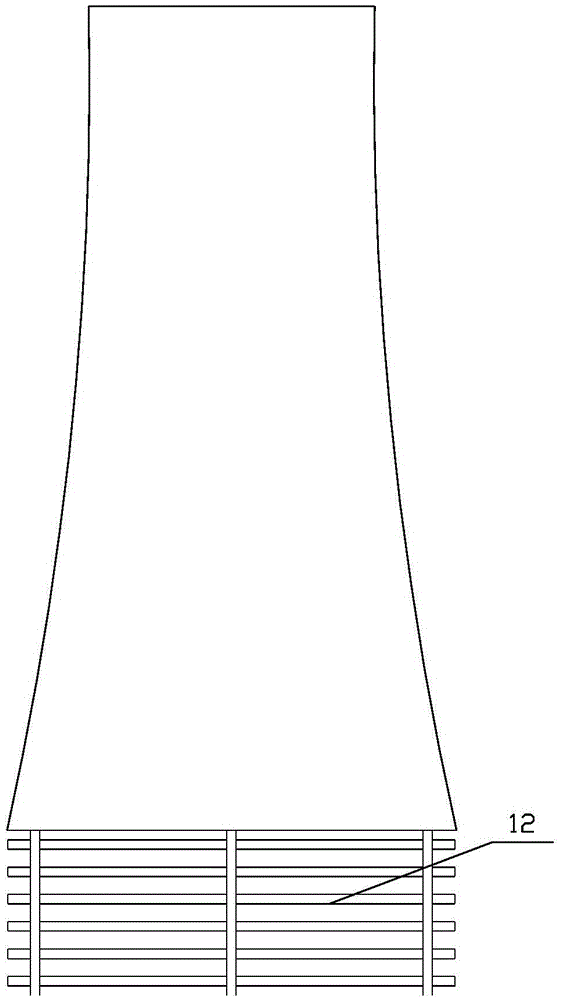

Novel efficient sinter sensible heat recovery technology

InactiveCN104990421ASolve serious air leakageImprove utilization efficiencyEnergy industryIncreasing energy efficiencyPulp and paper industrySuperheated steam

The invention discloses a novel efficient sinter sensible heat recovery technology. The novel efficient sinter sensible heat recovery technology comprises a roller type cooler, a waste heat boiler, a cyclone dust remover, a multi-pipe type dust remover and a pre-economizer. After high-temperature sinter with the temperature of 750 DEG C to 850 DEG C enters the roller type cooler, high-temperature smoke with the temperature of 650 DEG C to 750 DEG C enters the waste heat boiler after passing the cyclone dust remover; the waste heat boiler absorbs the sensible heat of the high-temperature smoke and generates overheat steam of 4.5 MPa and 450 DEG C; the temperature of the smoke at the outlet of the boiler is reduced to 160 DEG C to 180 DEG C, secondary dust removing is carried out through the multi-pipe type dust remover, and then the smoke enters the roller type cooler. The high-temperature sinter is cooled in the roller type cooler, the high-temperature hot air is generated and conveyed to the waste heat boiler, and the overheat steam is generated for power generation. Meanwhile, a full-closed form is adopted in a cooling circulation system, and the quality of recycled waste heat is improved. The two-level dust removing technology mode is adopted, the recycling rate of mineral powder is increased, and the environment is protected.

Owner:WUXI YIEN TECH

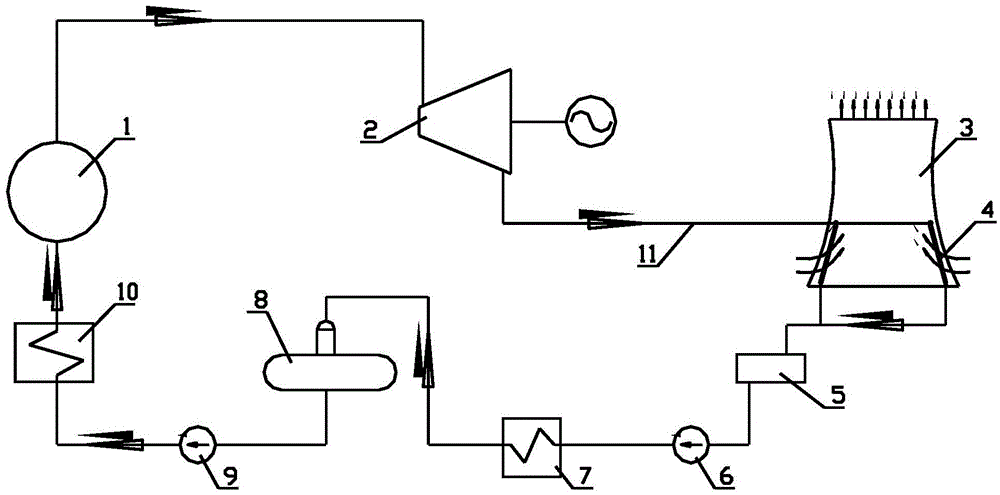

Direct-air-cooling power generation system with natural ventilation cooling tower

InactiveCN105464725ASmall footprintReduce power consumptionSteam/vapor condensersEngine componentsNatural ventilationCooling tower

The invention discloses a direct-air-cooling power generation system with a natural ventilation cooling tower. The direct-air-cooling power generation system comprises a boiler, an air-cooling condenser and the natural ventilation cooling tower. A plurality of air inlets are evenly formed in the bottom of the natural ventilation cooling tower in the circumferential direction. An air outlet is formed in the top of the natural ventilation cooling tower. The air-cooling condenser comprises a heat exchange pipe bundle which is composed of multiple heat exchange pipes. The heat exchange pipe bundle is arranged on the inner sides or the outer sides of the air inlets. Threads or grooves are formed in the inner surfaces of the heat exchange pipes. Fins are arranged on the outer sides of the heat exchange pipes. Multiple sets of shutters are arranged on the portion, on the peripheries of the air inlets, of the natural ventilation cooling tower. Each set of shutters include a plurality of blades which are horizontally arranged. By means of the direct-air-cooling power generation system, the power consumption of the direct-air-cooling power generation system can be lowered, the influences of natural air on running of the air-cooling system and a power generation set are reduced as much as possible, and the direct-air-cooling power generation system has important significance in improving operating economy, stability and reliability of a power plant.

Owner:WUHAN KAIDI ELECTRIC POWER ENG

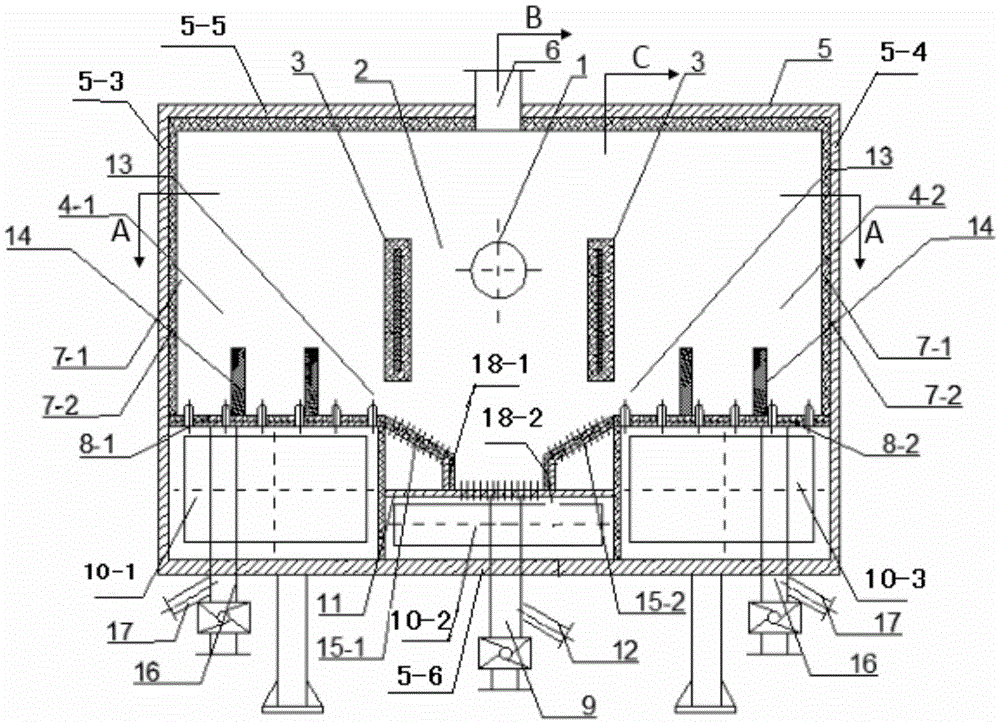

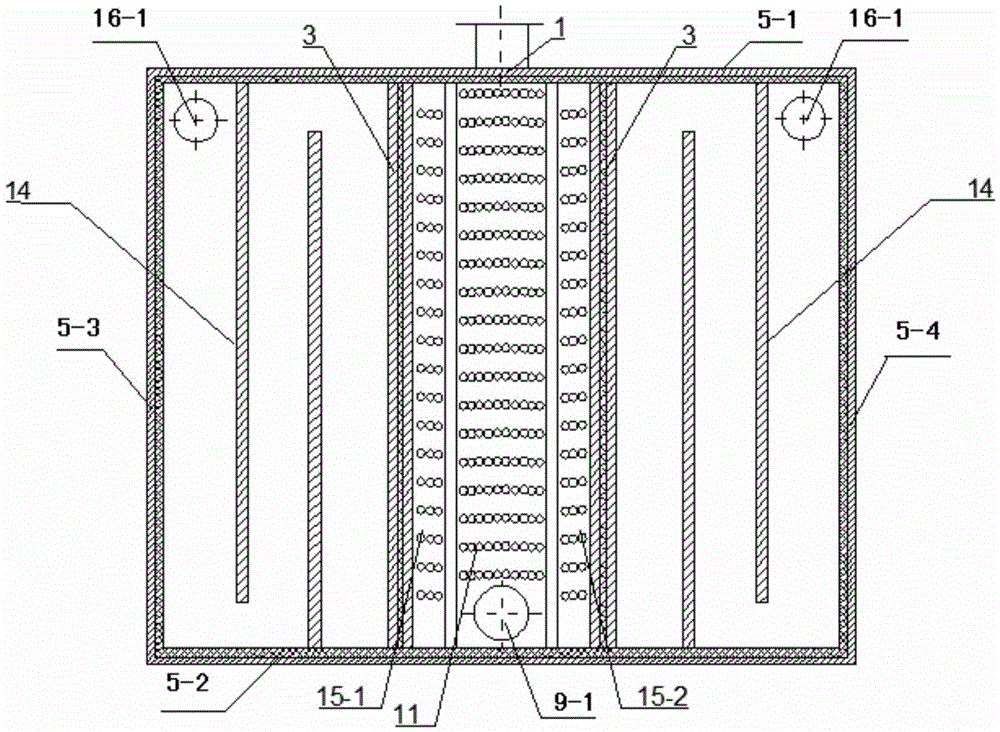

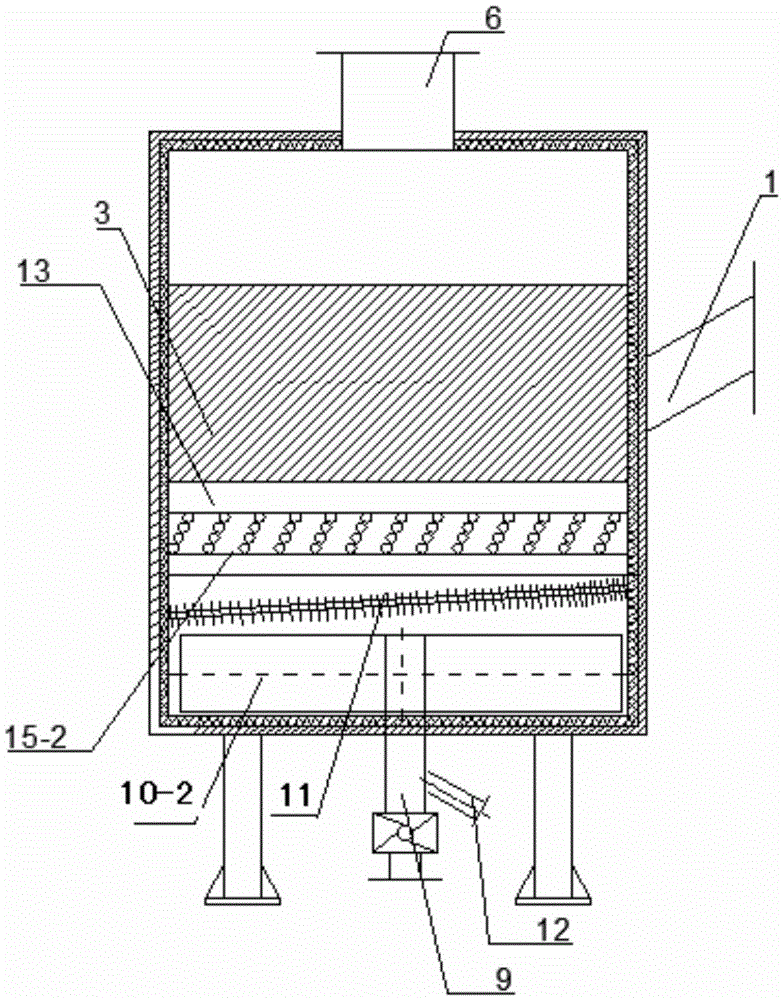

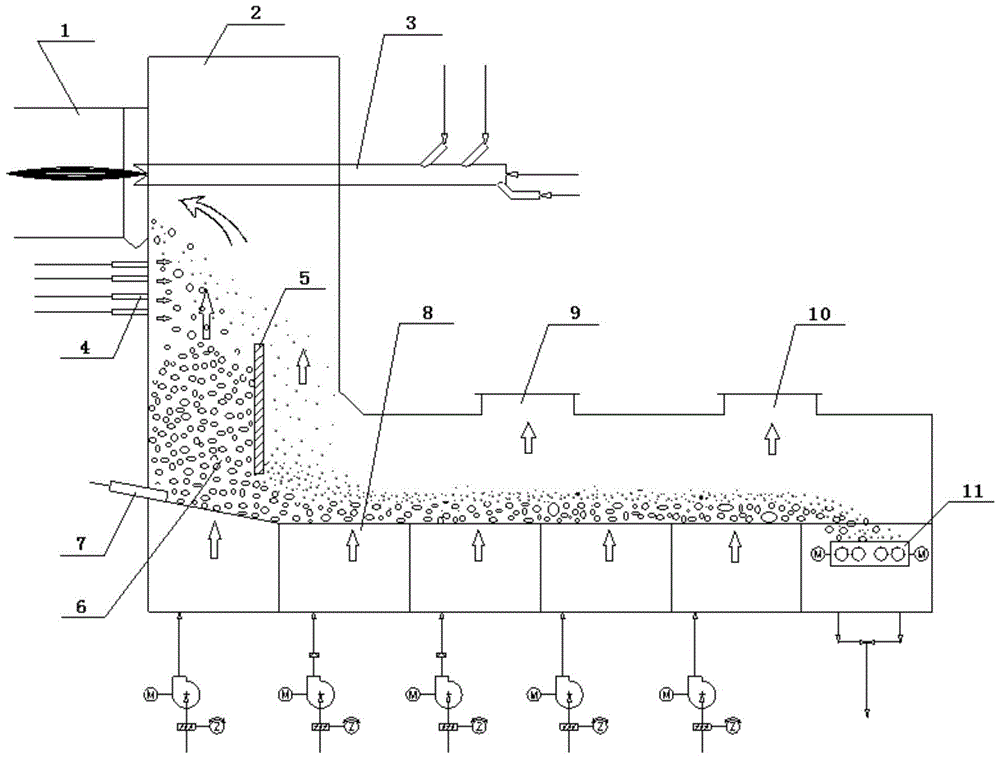

Combined fluidized bed type gas-solid heat exchange device utilizing waste heat of furnace slag

ActiveCN105567890AImprove adaptabilityImprove heat transfer effectFluidised bed heat exchangersGas solidSlag

The invention discloses a combined fluidized bed type gas-solid heat exchange device utilizing waste heat of furnace slag. The device comprises a gas-solid heat exchange body, and an air outlet is arranged at the top of the gas-solid heat exchange body. The device is characterized in that two partition walls are arranged in the gas-solid heat exchange body, connect a front faceplate with a rear faceplate of the same and divide a cabin inside the gas-solid heat exchange body into a left bubbling bed cabin, a spouted bed cabin and a right bubbling bed cabin, the left and right bubbling bed cabins are symmetrically arranged on two sides of the spouted bed cabin, the upper portions and the lower portions of the three cabins are communicated respectively, an independent air chamber is arranged at the bottom of each cabin, a dense-hole-type air distribution plate is arranged above the air chamber in the spouted bed cabin, a left air-cap-type air distribution plate and a right air-cap-type air distribution plate are arranged at the tops of the air chambers in the left and right bubbling bed cabins respectively, and the left air-cap-type air distribution plate is connected with the dense-hole-type air distribution plate through a second dense-hole-type air distribution plate and a first orthostomous section. The combined fluidized bed type gas-solid heat exchange device has good gas-solid heat exchange effect and can be widely applied in the field of steel and iron and power.

Owner:CHONGQING UNIV

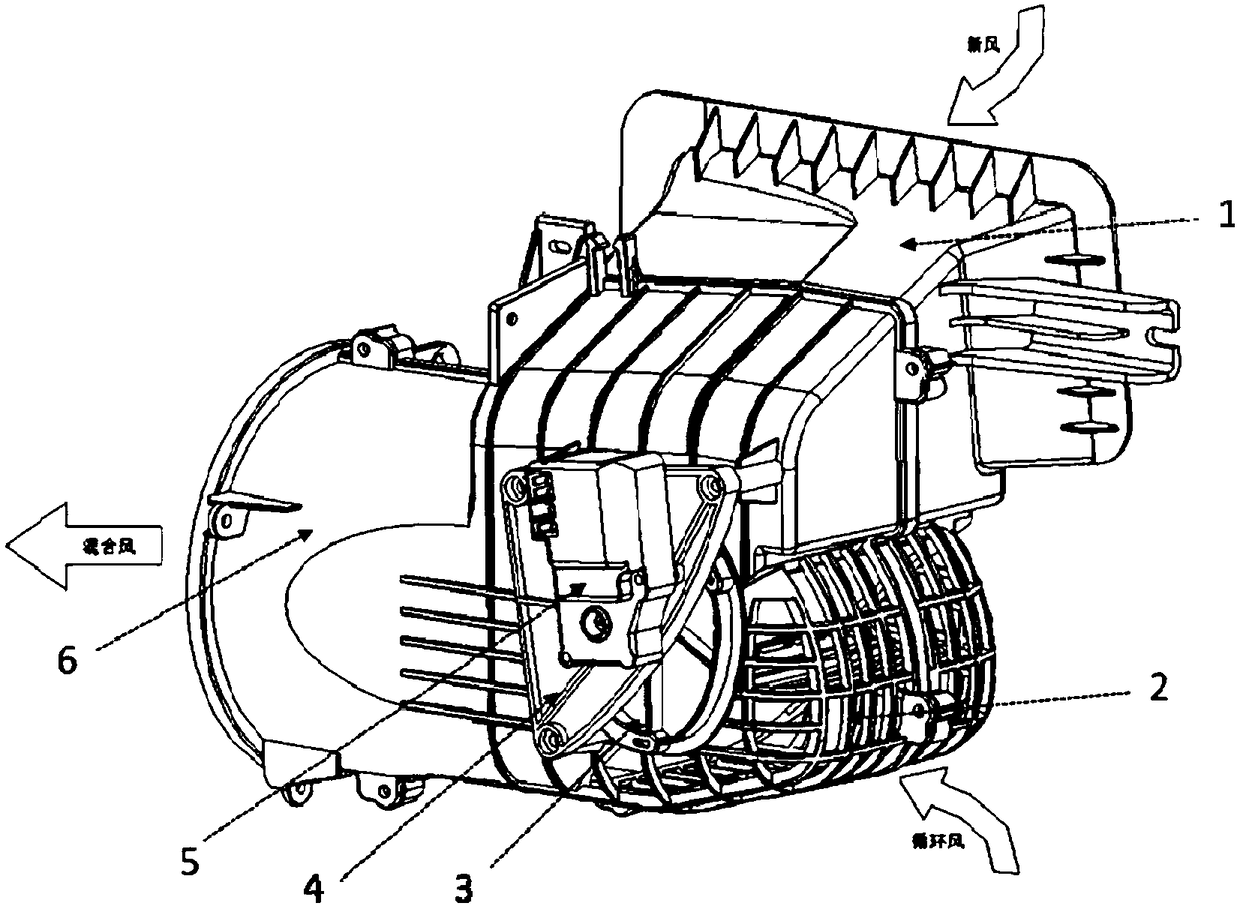

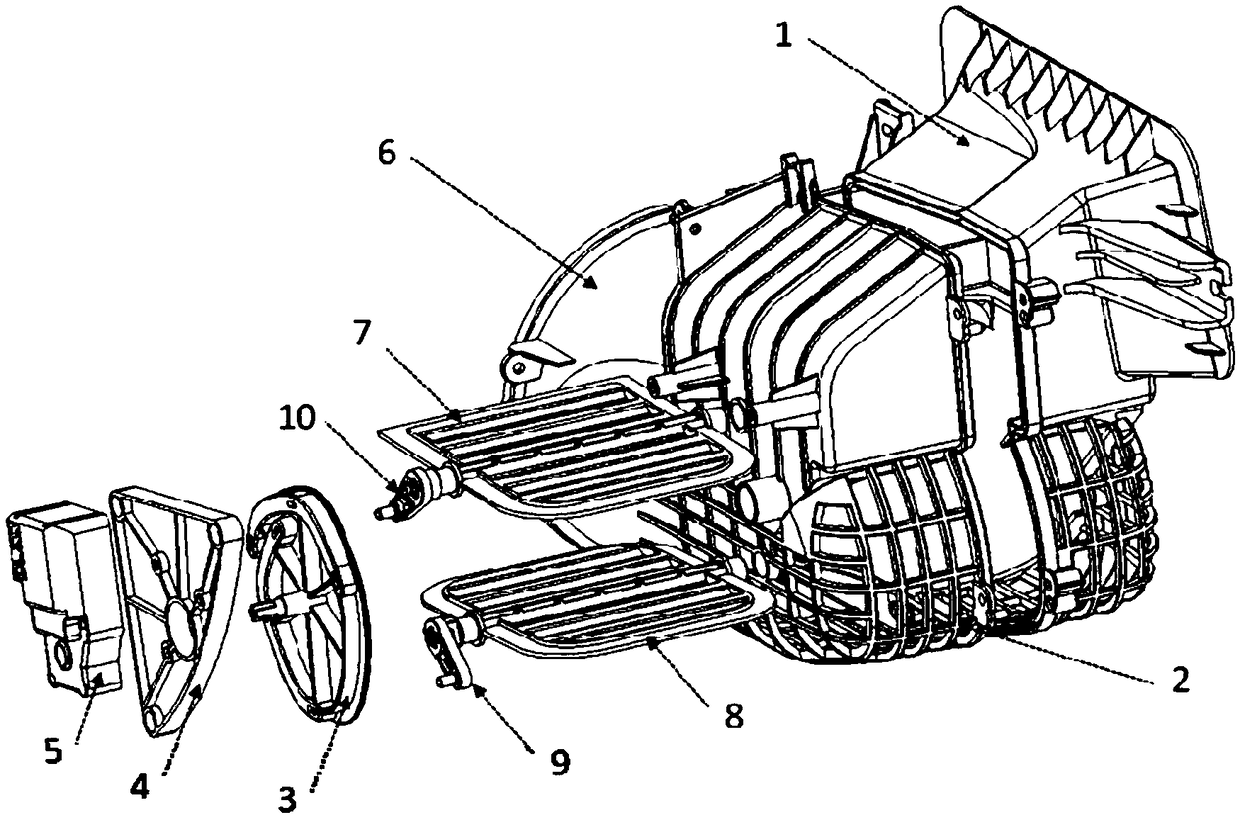

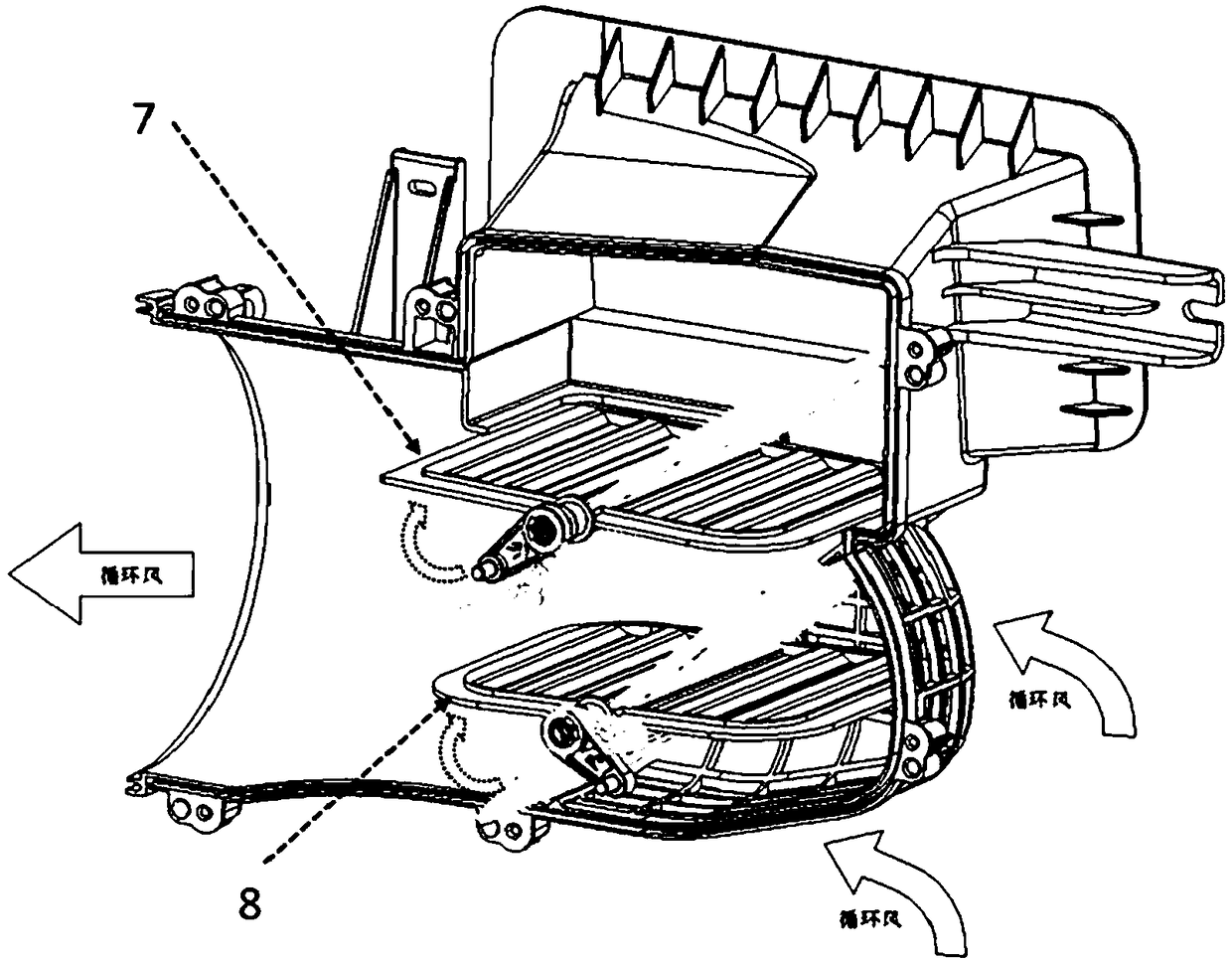

Method for improving heating performance of automobile air conditioner

ActiveCN108749509AIncrease temperatureIncrease water temperatureAir-treating devicesVehicle heating/cooling devicesElectricityAutomobile air conditioning

The invention discloses a method for improving the heating performance of an automobile air conditioner, wherein the air inlet of the automobile air conditioning system has three states, which are aninternal circulation state, an external circulation state and an intermediate compensation state, and the method mainly utilizes the intermediate compensation state to improve the heating performance;the method comprises the following steps of: judging whether the current temperature setting is of a heating state in response to the vehicle being electrically connected to the ON gear; if not in aheating state, judging whether the current mode of the air inlet of the heating ventilation air conditioner is set to the external circulation state, if so, controlling a circulation air door to be inthe external circulation state, if not, controlling the circulation air door to be in the internal circulation state; if in a heating state, judging whether the current mode of the air inlet of the heating ventilation air conditioner is set to the external circulation state, if not, controlling the circulation air door to be in the internal circulation state, if yes, judging whether the current gear of the blower is larger than a preset gear, if so, then controlling the circulation air door to be in the intermediate compensation state, and if not, controlling the circulation air door to be inthe external circulation state. The method can effectively improve the heating performance of the air conditioner.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

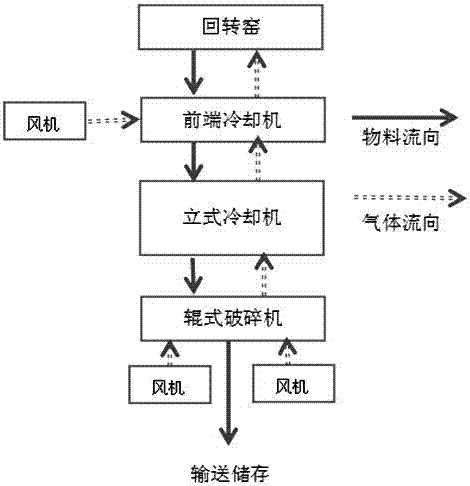

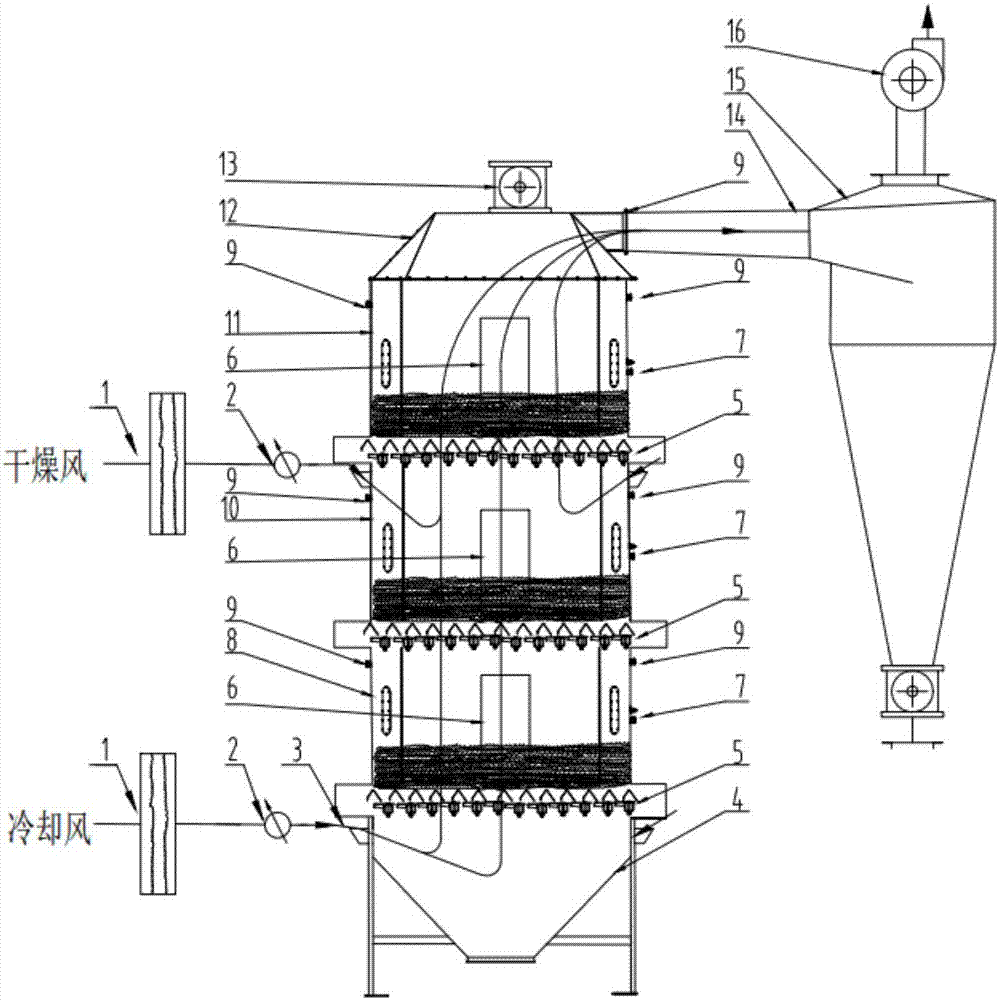

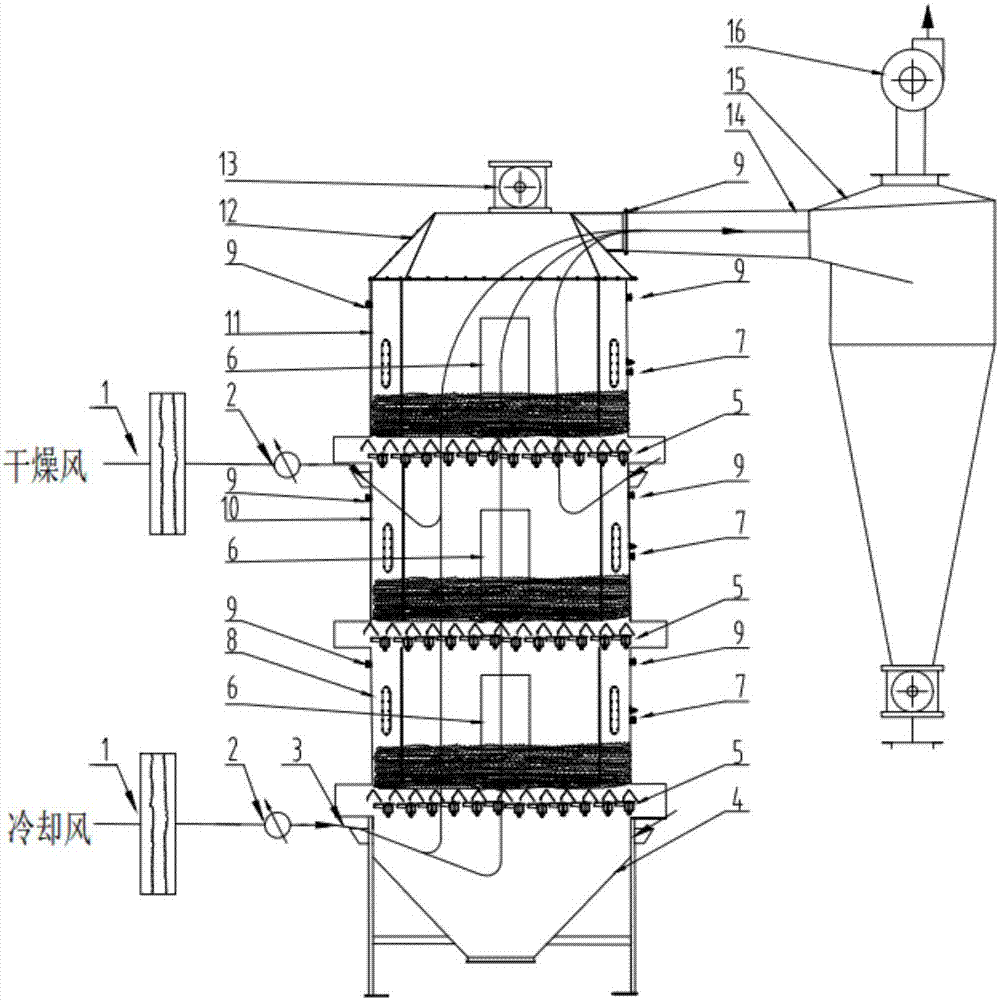

Efficient composite vertical cement calcined clinker cooler and cooling method

PendingCN107883776AReduce the temperatureQuality improvementIncreasing energy efficiencyHandling discharged materialExchange timeCrusher

The invention relates to an efficient composite vertical cement calcined clinker cooler and a cooling method, and belongs to cement clinker coolers and cooling methods. The efficient composite vertical cement calcined clinker cooler comprises a front-end cooling device, a vertical cooling device and a crushing and air-locking device. The cooling method comprises the following steps that clinker enters the front-end cooling device from a rotary kiln at a calcination temperature of 1200-1400 DEG C; (2) the high-temperature clinker enters the vertical cooling device to be cooled continuously after being subjected to quenching; (3) the clinker which is subjected to vertical re-cooling enters a roller crusher to be extruded and crushed; and (4) the cooled and crushed clinker is discharged intoa clinker warehouse for storage through the air-locking device. The cooling method has the advantages that a traditional clinker cooling mode is integrated with a vertical cooling mode, so that the quality and the grindability of the clinker are greatly improved; the contact and heat exchange time between the clinker and the gas is longer, so that the heat exchange is more sufficient; cooling airvolume for the unit clinker is small, transmission power is not needed, power consumption is low, maintenance is easy, equipment is more reliable in operation, and the use cost is low; and the technology is simple in process, energy consumption is low, and standard emission is achieved.

Owner:XUZHOU CUMT BACKFILL TECH

Drying and cooling system for production of cured powdery feed

PendingCN107990653AStrong penetrating powerImprove efficiencyFeeding-stuffDomestic cooling apparatusAir volumeCounter flow

The invention provides a drying and cooling system for production of cured powdery feed. A cooling tank of a cooler is divided into multiple layers, a turning plate type discharge mechanism as well asan upper material level device and a lower material level device for controlling material layer height is arranged independently on each tank layer, and an independent compressed air blowing system is arranged on each tank layer. The drying and cooling system is provided with a cooling air inlet pipe and a drying air inlet pipe, and steam heat exchangers and automatic doors capable of controllingtemperature and air volume are mounted on the pipes respectively. Compared with the conventional counter-flow type pellet feed cooler, the drying and cooling system has the advantages that penetrating power of cooling air is strong, the cooling air can be contacted uniformly with the powdery feed, and the cooling efficiency is increased greatly; the powdery feed on each layer can play a filter role, so that powder return rate is reduced; the system has integrated cooling and drying function and is applicable to all weather conditions.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

Cooling system and method for high-temperature ammonia spraying denitration air cooling spray gun of coal-fired boiler

PendingCN113369034AImprove cooling effectAchieve coolingDomestic cooling apparatusLighting and heating apparatusFlue gasProcess engineering

The invention discloses a cooling system and method for a high-temperature ammonia spraying denitration air cooling spray gun of a coal-fired boiler. According to the cooling system and method, cooling air enters a cooling air cavity through a cooling air connector and then is divided into two paths, one path enters a near-wall cooling air chamber through a cooling air opening channel and then is sprayed into the boiler through a near-wall cooling air nozzle in the direction parallel to a spray gun pipeline, the effect of cooling smoke around the spray gun pipeline is achieved, the other path of air flows to the end part of the spray gun along the cooling spray gun pipeline and exchanges heat with the wall surface of the cooling spray gun pipeline in the process to reduce the wall temperature, the cooling air reaches the head of the spray gun and is sprayed towards the direction of the fixed structure through a cooling air nozzle at the end part, so that the effect of cooling the flue gas around the spray gun is also achieved, and a thermocouple induction end monitors the temperature of the spray gun head so as to control the flow of cooling air. The method can effectively reduce the surface temperature of the spray gun in the flame, increase the extending distance of the spray gun in the flame, increase the coverage area of a reducing agent, and solve the problem that the surface temperature of the spray gun rapidly rises to influence the efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

Primary air cooler heat recovery system and control method

ActiveCN103438686BReduce cooling air volumeLower exhaust gas temperatureDrying gas arrangementsGrain treatmentsAir preheaterWater use

The invention discloses a primary air cooler heat regenerative system and a controlling method. According to the primary air cooler heat regenerative system and the controlling method, a primary air cooler is arranged in a primary heat air duct of an outlet of a boiler air heater, low-pressure supplied water used as cooling water is introduced by a coal-fired unit low-pressure water-supply heat regenerative system, heat of primary heat wind is absorbed, the heated supplied water is sent back to a unit deaerator, the flow of the cooling water is adjusted so as to enable the temperature of the primary wind to be reduced to meet the temperature requirement of drying medium at the inlet of a coal mill. By means of the technical scheme, the cold wind amount of a side road of a boiler air preheater can be greatly reduced, the smoke exhausting temperature of the boiler is reduced, the power-supply coal consumption of the unit is reduced, and the stable operation of the unit is not affected.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401BReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

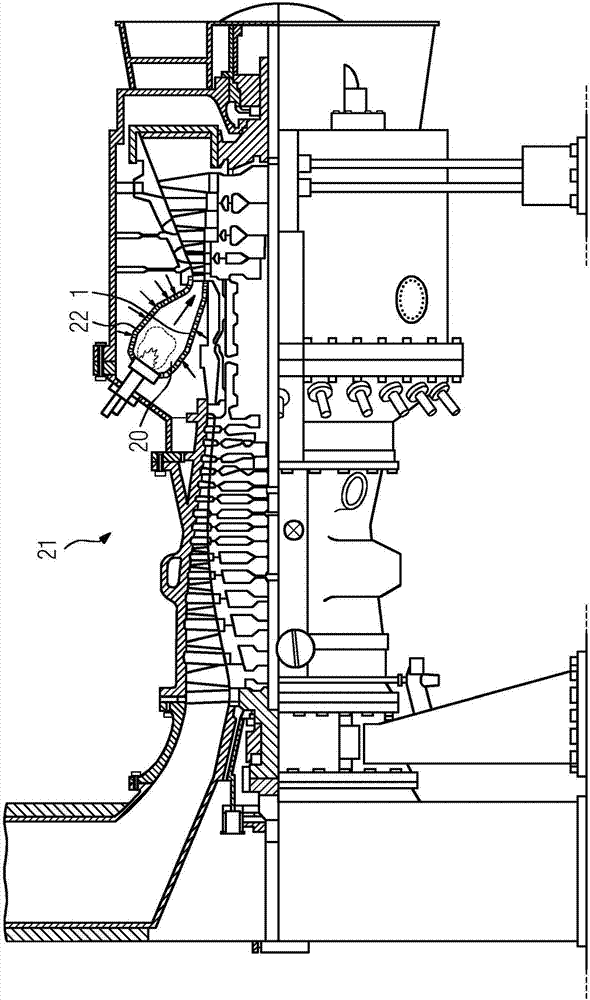

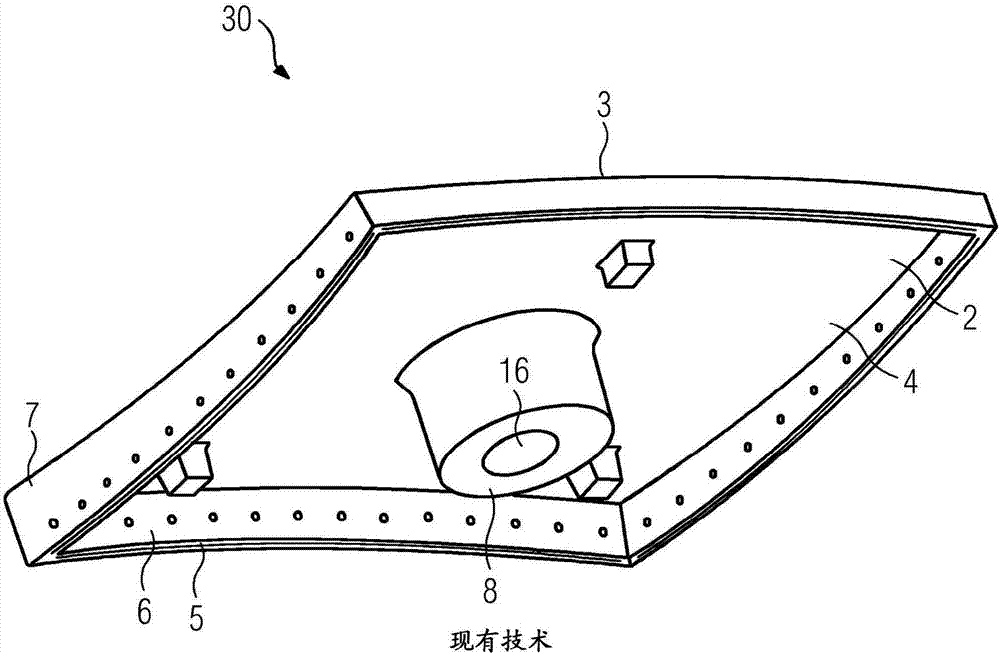

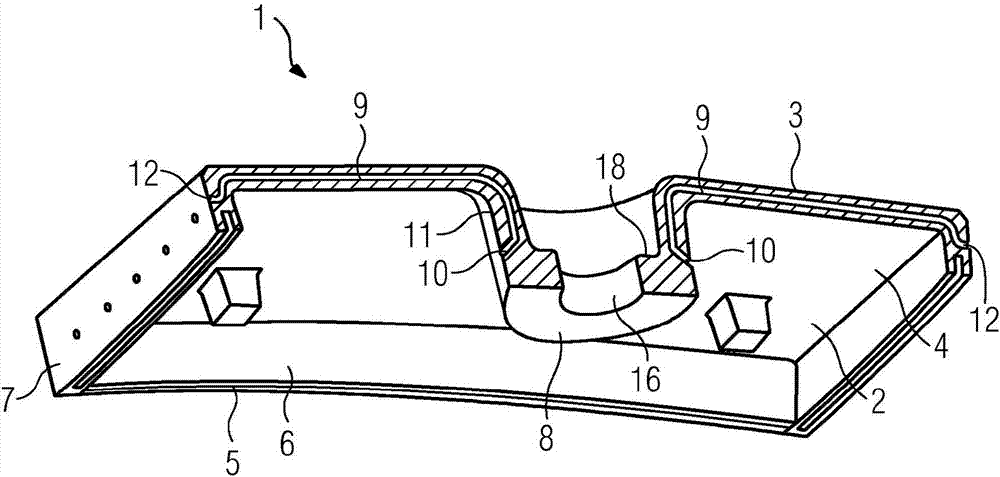

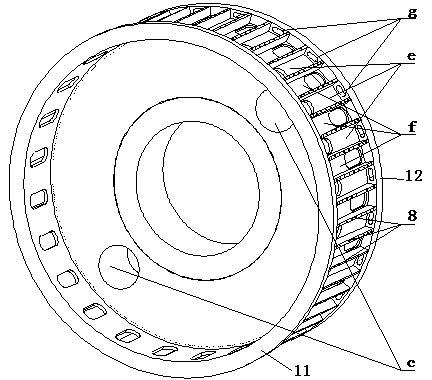

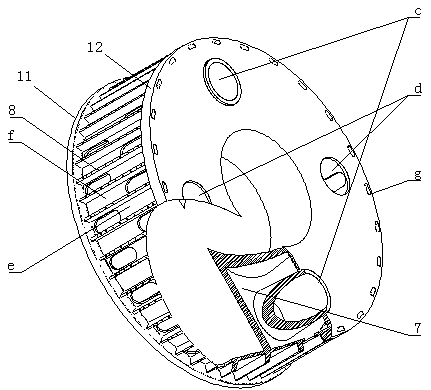

Heat shield element and method for the production thereof

ActiveCN107076414ASmall thermal burdenReduce cooling air volumeContinuous combustion chamberCasings/liningsCooling channelGas turbines

The invention relates to a heat shield element (1) comprising a wall (2) having a hot side (3) and an opposing cold side (4), a peripheral edge (5) having an inner side (6) and an outer side (7), and a securing device (8) arranged substantially in the middle of the cold side (4) of the wall (2), said securing device extending substantially perpendicularly away from the wall (2), wherein cooling channels (9) are arranged in the securing device (8), wall (2) and edge (5), extending over at least two of the three. The invention also relates to a combustion chamber (20) and a gas turbine plant (24). The invention further relates to a method for producing a heat shield element (1) of this type.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

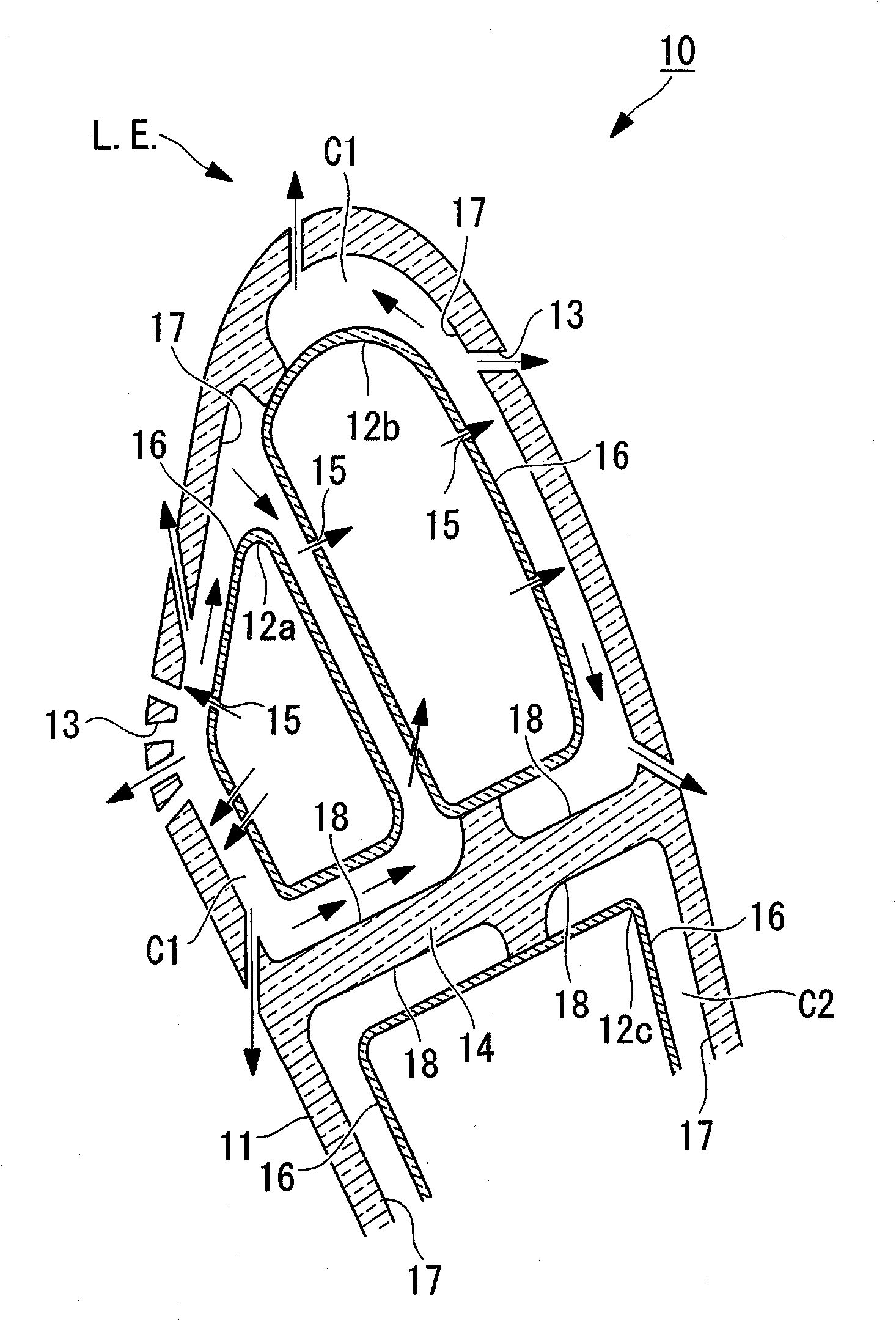

Turbine blade

InactiveCN102099550AImprove performanceHigh thermal efficiencyEngine fuctionsBlade accessoriesTurbine bladeCooling medium

The invention provides a turbine blade which can reduce an amount of cooling air (cooling medium), and in addition, prevent cooling air at a low temperature from being blown out from a film cooling hole. After part of the cooling medium which has impinge-cooled an inner peripheral surface (17) located on a front of a blade body (11) further impinge-cools the inner peripheral surface (17) located on a back of the blade body (11), it is blown out from the film cooling hole (13) located on the back of the blade body (11).

Owner:MITSUBISHI HEAVY IND LTD

Flame detection cooling air system used for preventing coking of coal-fired boiler and work method thereof

PendingCN109959026AFully mixed reactionReduce cooling air volumeCasings/liningsFlame detectionEngineering

The invention relates to a flame detection cooling air system used for preventing coking of a coal-fired boiler and a work method thereof. A flame detection fan A and a flame detection fan B are connected with a flame detection cooling air mother pipe, the flame detection cooling air mother pipe is connected with a flame detector, a cold primary air mother pipe is connected with the flame detector, a decoking agent storage box communicates with a first mixed opening through a first decoking agent pipeline and the flame detection cooling air mother pipe, a first pipeline filter net and a firstdecoking agent adjusting valve are sequentially arranged on the first decoking agent pipeline, the decoking agent storage box communicates with a second mixed opening through a second decoking agent pipeline and a cold primary air branch pipe, and a second pipeline filter net and a second decoking agent adjusting valve are arranged on the second decoking agent pipeline in sequence. Through the flame detection cooling air system, the decoking agent is sprayed into the boiler, the decoking agent vaporization heat absorbing is used for achieving the effect of effectively cooling the flame detector, and the flame detection cooling air system can evenly spray the decoking agent into the boiler to achieve the effect of sufficiently mixing and reacting with pulverized coal air flow.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

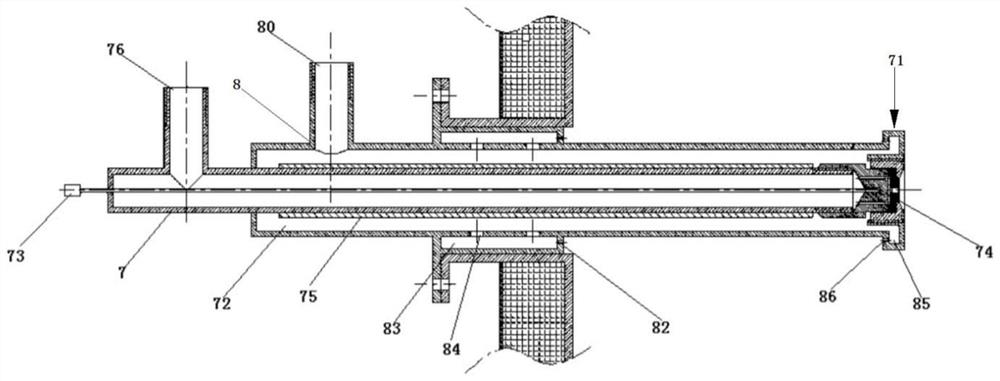

Method and device for graded cooling of high-temperature granular materials

ActiveCN105180662BIncrease material bed thicknessReduce resistanceHandling discharged materialThermodynamicsEngineering

The invention discloses a high-temperature particulate material stage cooling method. According to the method, a feed inlet of a cooling material bed is transversely divided into an upper area and a lower area by a retaining wall the bottom of which is suspended, particle classification and quenching are conducted on high-temperature particulate materials discharged from a rotary kiln with airflow, coarse particulate materials obtained after classification fall into the upper area of the feed inlet of the cooling material bed to form a coarse particle material bed for thick material bed countercurrent heat exchange, fine particulate materials obtained after classification fall into the lower area of the feed inlet of the cooling material bed, and the coarse particulate materials subjected to countercurrent heat exchange enter the lower area of the feed inlet of the cooling material bed through the bottom of the retaining wall to be cooled on the cooling material bed together with the fine particulate materials in the lower area. The invention further discloses a high-temperature particulate material stage cooling device adopting the method. The high-temperature particle classification technique is adopted, the coarse particles are cooled on the thick material bed, the amount of cooling air can be reduced, the heat recovery efficiency of a system can be improved, and then energy is saved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

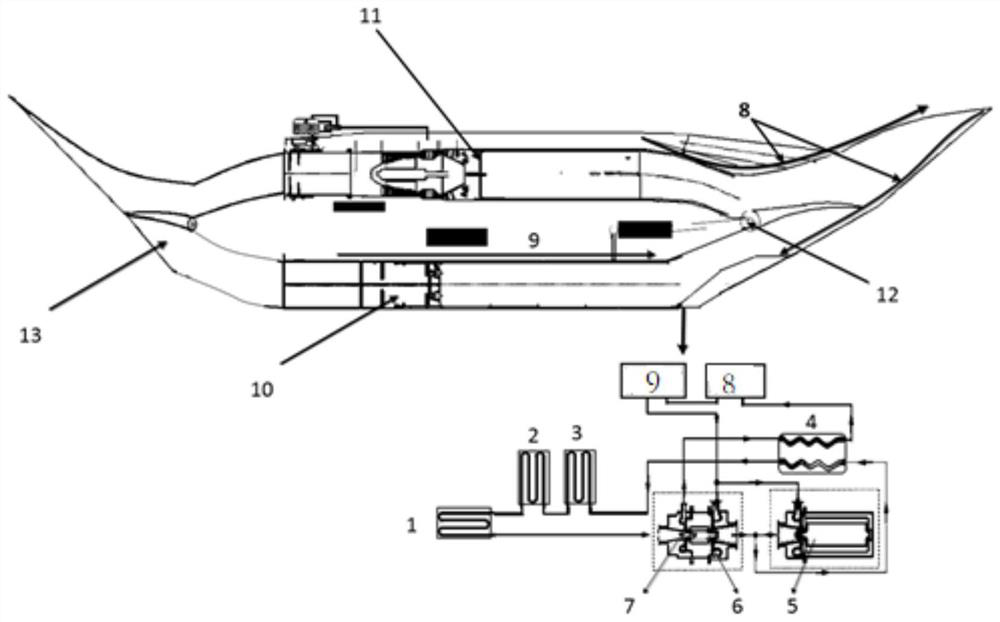

Closed cycle heat management integrated system based on supercritical medium

InactiveCN112160837AReduce temperature riseReduce complexityTurbine/propulsion engine coolingSteam engine plantsHeat managementIntegrated energy system

The invention provides a closed cycle heat management integrated system based on a supercritical medium. The system comprises an engine cooling subsystem, a cooling medium compression subsystem, a power output subsystem, a regenerative subsystem and a fuel oil heat exchange subsystem. According to the closed cycle heat management integrated system based on the supercritical medium, supercritical carbon dioxide serves as the medium, and a micro-channel efficient heat exchanger is adopted so that power can be output while the wall temperature of a hot end is reduced. Compared with a fuel oil direct cooling scheme, the fuel oil temperature rise can be reduced, the gasification coking risk of fuel oil is avoided, and the problems of insufficient fuel oil heat sink and the like are solved. Thesupercritical carbon dioxide subjected to heat absorption can utilize turbine expansion to output power or generate electricity. About 30%-40% of heat (the current domestic closed cycle efficiency isabout 30%) can be converted into shaft work or electricity to be utilized, and the problem about power extraction of a comprehensive energy system can be solved.

Owner:AECC SICHUAN GAS TURBINE RES INST

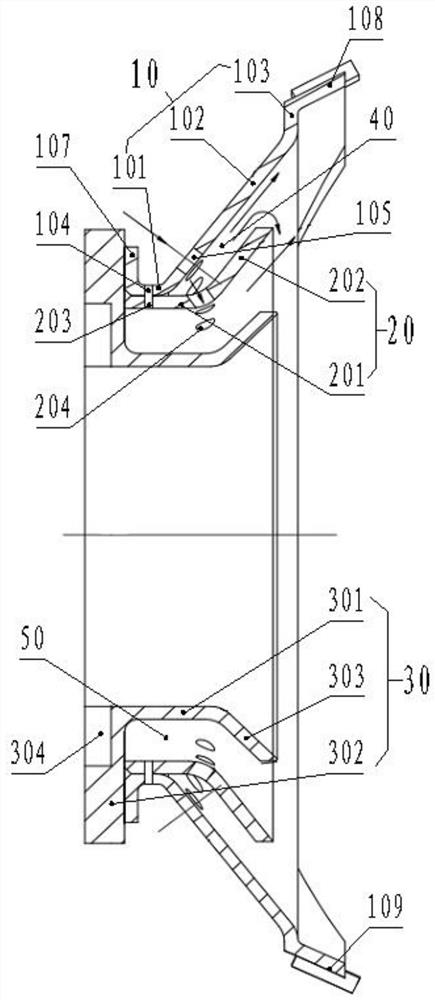

Cooling structure for head of flame tube of combustion chamber of medium-thrust aero-engine

ActiveCN114110657AAvoid it happening againReduce cooling air volumeContinuous combustion chamberThermodynamicsCombustion chamber

A cooling structure for the head of a flame tube of a combustion chamber of a medium-thrust aero-engine comprises a flow guide hole plate, a flow guide shield and a sleeve. The flow guide hole plate, the flow guide shield and the sleeve are coaxially arranged to form a first cooling gap and a second cooling gap, a plurality of first cooling holes are formed in the front section of the flow guide hole plate, a plurality of second cooling holes are formed in the conical section of the flow guide hole plate, and a plurality of third cooling holes are formed in the outlet section of the flow guide hole plate; a fourth cooling hole is formed in the front section of the flow guide shield; the first cooling hole and the fourth cooling hole are coaxially arranged and are communicated to the second cooling gap; and the second cooling hole is communicated with the first cooling gap. According to the invention, the generation of an invalid high-temperature trapped vortex area of fuel gas on the head of the combustion chamber close to the wall surface can be avoided, the cooling gas amount required by the head of the flame tube is reduced, the coverage area of head cooling gas flow is increased, the cooling efficiency is improved, the wall temperature of the head of the flame tube can be efficiently reduced, and the reliability of the head structure of the flame tube is improved.

Owner:中国航发贵阳发动机设计研究所

Wind driven generator

ActiveCN102332780BImprove work efficiencySmall sizeMagnetic circuit stationary partsCooling/ventillation arrangementCold airWind driven

Owner:DONGFANG ELECTRIC MACHINERY

Horizontal cement clinker grate type particle grading cooler and cooling method

PendingCN110715547AImprove cooling effectImprove heat transfer efficiencyGas current separationRotary drum furnacesAir volumeProcess engineering

The invention belongs to the field of cement firing equipment, and discloses a horizontal cement clinker grate type particle grading cooler and a cooling method. The upper layer of the cooler is provided with a kiln door cover; one side of the kiln door cover is connected to a rotary kiln and a tertiary air pipe; the tertiary air pipe communicates with a decomposition furnace; the end, far away from the tertiary air pipe, of the kiln door cover is provided with a fine particle sedimentation chamber; the end, connected to the kiln door cover, of the rotary kiln is provided with a discharge slope; the bottom end of the discharge slope is connected to a particle grading air duct, and the particle grading air duct is located on the side facing the rotary kiln and below the kiln door cover; thebottom of the particle grading air duct is connected to a horizontal grate cooler; a plurality of air chambers are arranged at the lower end of the horizontal grate cooler; a discharging ash hopper is connected below the fine particle sedimentation chamber; and the bottom end of the discharging ash hopper is connected to an inlet of a single-cylinder cooler through a discharging trough. By meansof the horizontal cement clinker grate type particle grading cooler and the cooling method, cement clinker particles are graded to be cooled separately, so that the heat exchange efficiency of gas andmaterials is greatly improved, the ventilation resistance of material layers is reduced, the amount of cooling air is reduced, the heat recovery efficiency is improved, and the heat consumption of afiring system is reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Porous metal vane coupling design method

InactiveCN101078354BImprove performanceExtended service lifePump componentsBlade accessoriesState of artImpeller

The invention relates to a design method for porous metal blade. The method combines porous metal material with design of blade and the manufacturing process. By the high specific strength characteristic of porous metal material and adjusting porosity of said material, blade coupling design of process, strength, vibration, and pneumatic thermal force is carried out so as to improve the specific strength of blade and satisfy the flow control demand of blade boundary layer. The method conquers the lack of solid or hollow blade in prior technology. The good performance of porous metal material is used. Blade material characteristic, strength, vibration and pneumatic thermal force performance are considered in synthesis. The coupling design method for blade process, strength, vibration, pneumatic thermal force of porous metal is provided and part performance of aeroengine and gas turbine can be improved greatly. At the same time the invention provides a blade designed by the method, aeroengine and gas turbine comprising blade mentioned above.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com