Turbine blade

一种叶片、涡轮的技术,应用在燃气轮机领域,能够解决燃气轮机气体温度下降、燃气轮机热效率降低等问题,达到提高热效率、提高性能、减少总体冷却空气量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

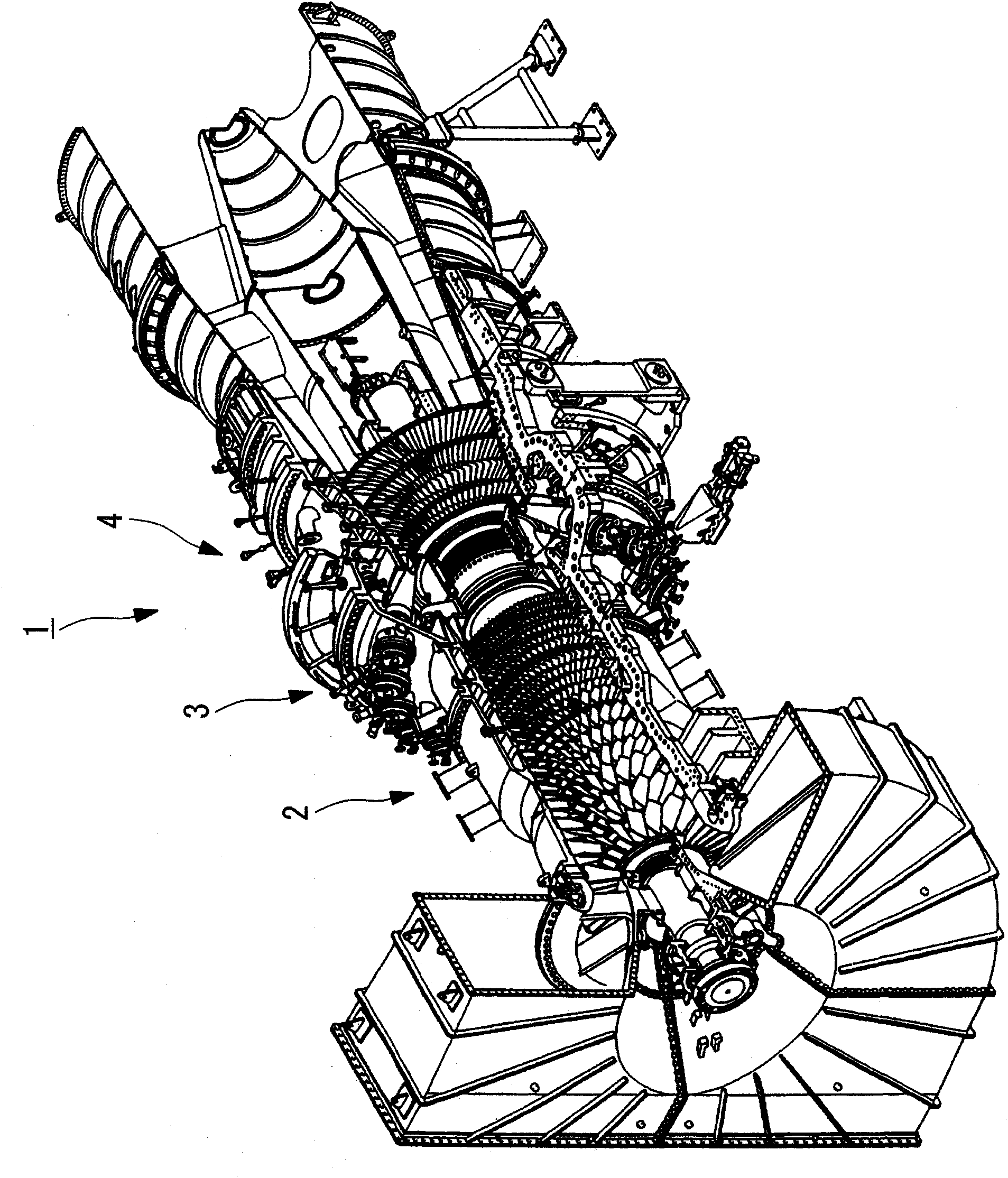

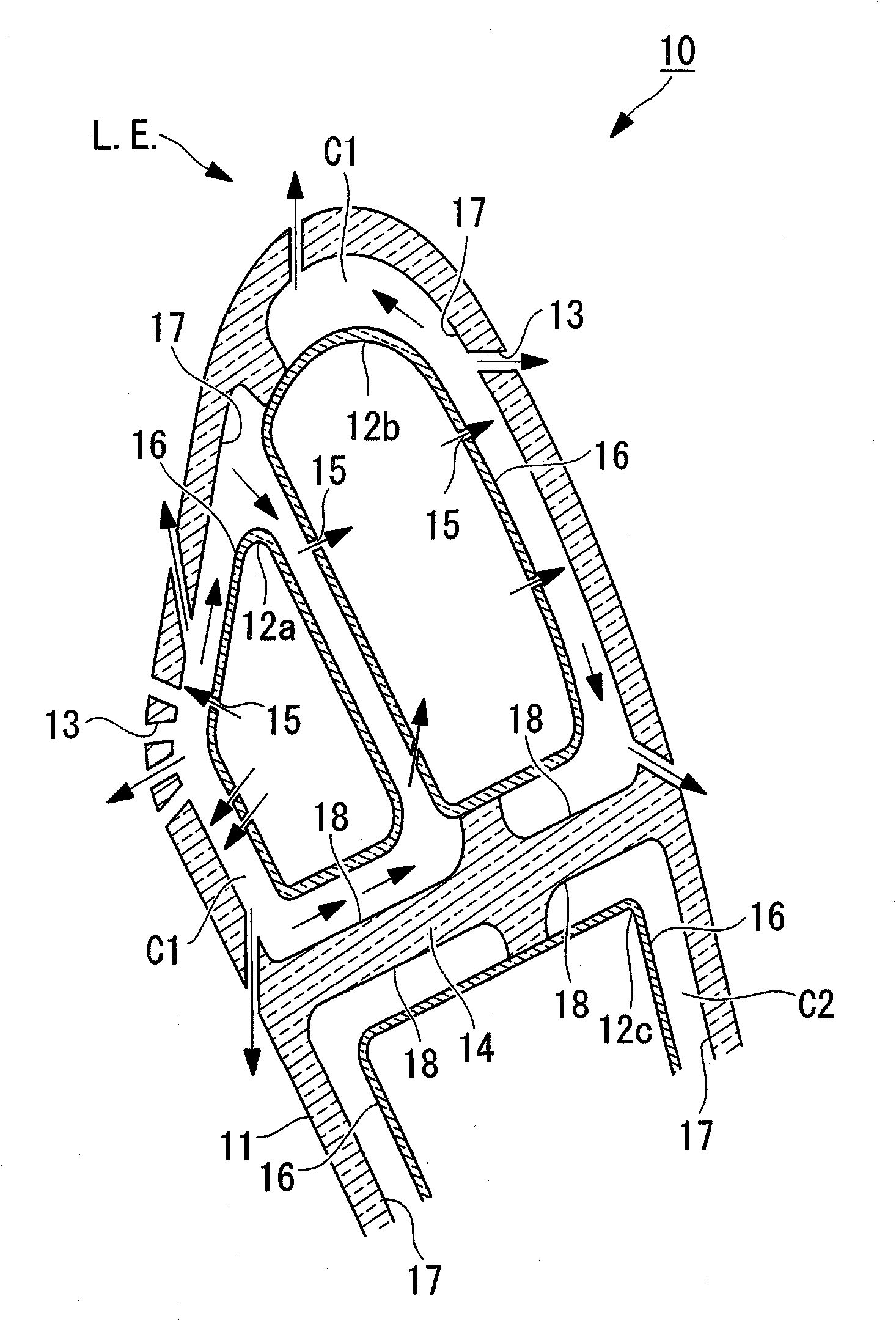

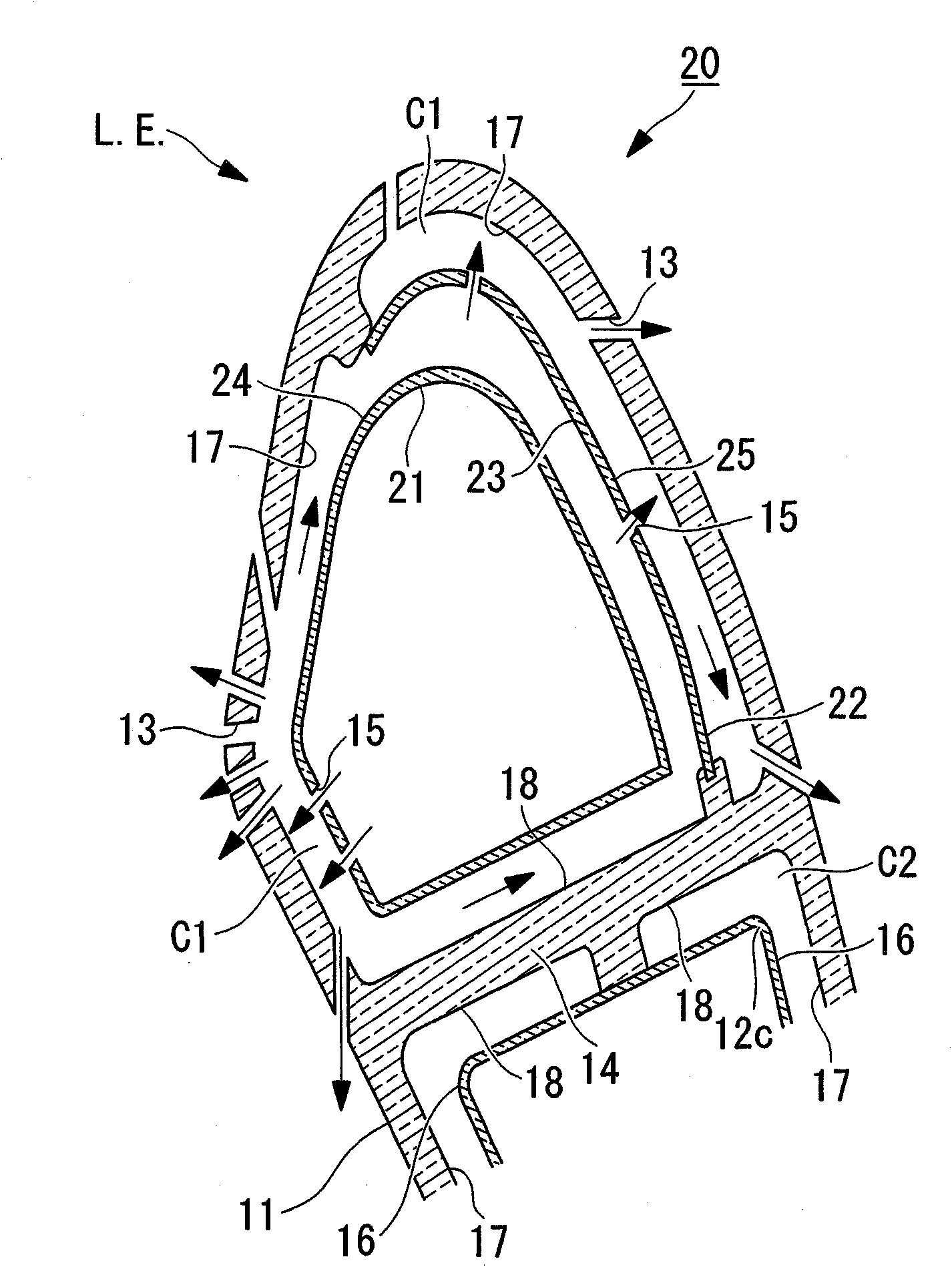

[0027] Below, refer to figure 1 and figure 2 One embodiment of the turbine blade according to the present invention will be described.

[0028] figure 1 It is a schematic perspective view showing a gas turbine 1 provided with a turbine blade 10 according to the present invention, showing a state where the upper half of the wheel house is removed, figure 2 It is a cross-sectional view of a main part of the turbine blade 10 according to the present embodiment, when the substantially central portion is cut along a plane substantially perpendicular to the axis in the direction in which it is erected.

[0029] Such as figure 1 As shown, the gas turbine 1 mainly includes: a compression part 2 that compresses combustion air, a combustion part 3 that injects fuel into the high-pressure air sent from the compression part 2 and burns it to generate high-temperature combustion gas, and is located in the combustion part. The turbine part 4 is driven by the combustion gas blown out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com