Coal-fired boiler hot primary wind heating system

A technology of coal-fired boiler and heating system is applied in the field of air supply device of pulverized coal boiler to achieve the effects of improving the operating economy of the unit and reducing the temperature of the exhaust gas of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

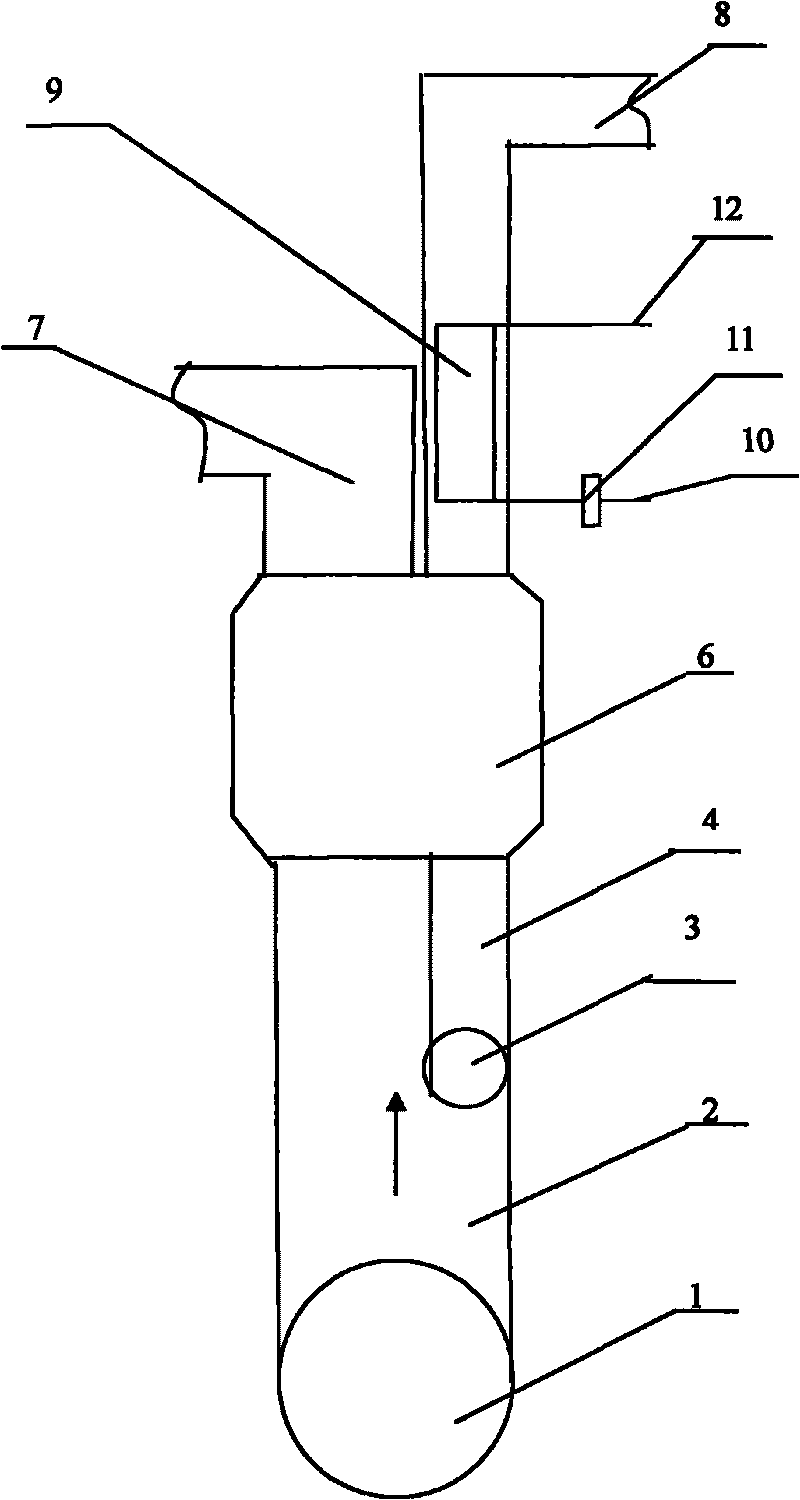

Embodiment 1

[0018] Embodiment 1: see figure 1 , this embodiment includes blower 1 and air preheater 6, between blower 1 and air preheater 6 is provided with air preheater secondary air inlet duct 2, air preheater primary air inlet duct 4 and air The secondary air inlet duct 2 of the preheater is connected, and a hot primary fan 3 is installed at the entrance of the primary air inlet duct 4 of the air preheater, and a hot secondary air duct 7 is respectively installed at the outlet of the air preheater 6 And hot primary air duct 8.

[0019] In this embodiment, a hot primary air heater 9 is newly added in the original hot primary air pipeline 8. The hot primary air heater 9 is a general-purpose air-water heat exchanger, and a cooling medium is provided on the hot primary air heater 9. The inlet pipeline (10) and the cooling medium outlet pipeline (12), the cooling medium inlet pipeline 10 is equipped with a regulating valve 11 for adjusting the cooling medium flow. In order to adjust the ...

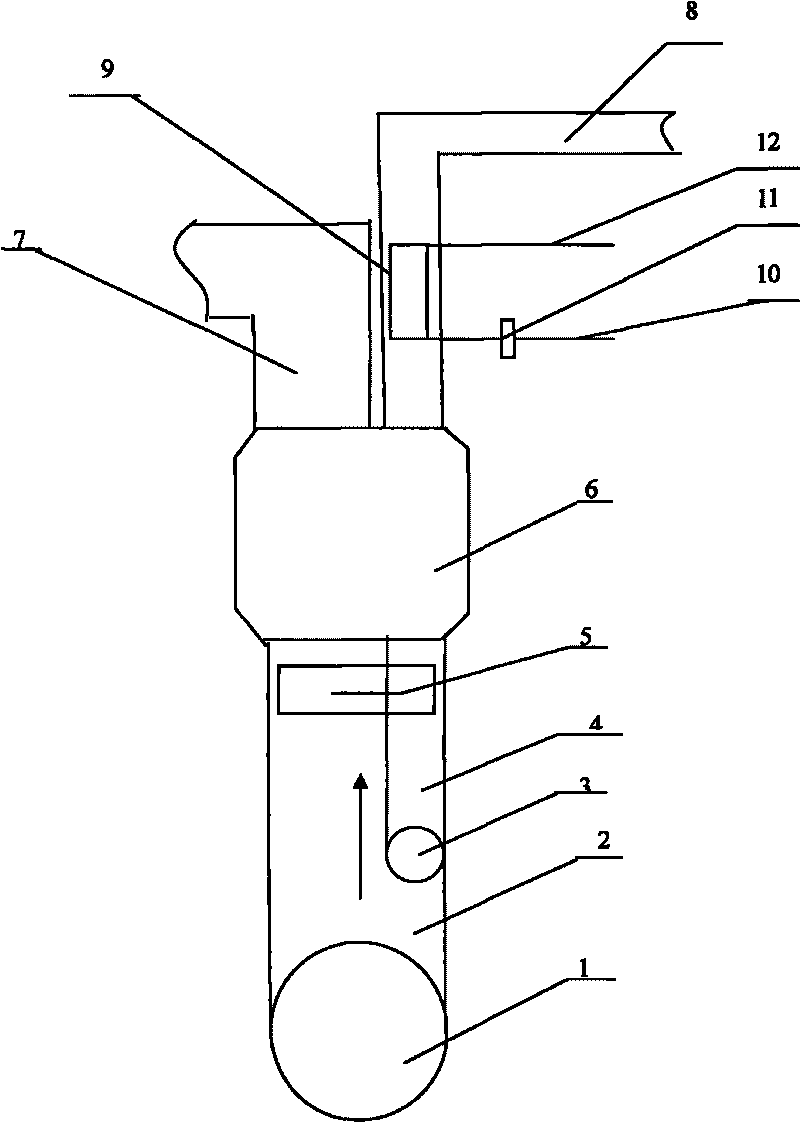

Embodiment 2

[0020] Example 2: see figure 2 In this embodiment, an air heater 5 is also provided on the secondary air inlet duct 2 of the air preheater and the primary air inlet duct 4 of the air preheater. Other connections are the same as in Embodiment 1.

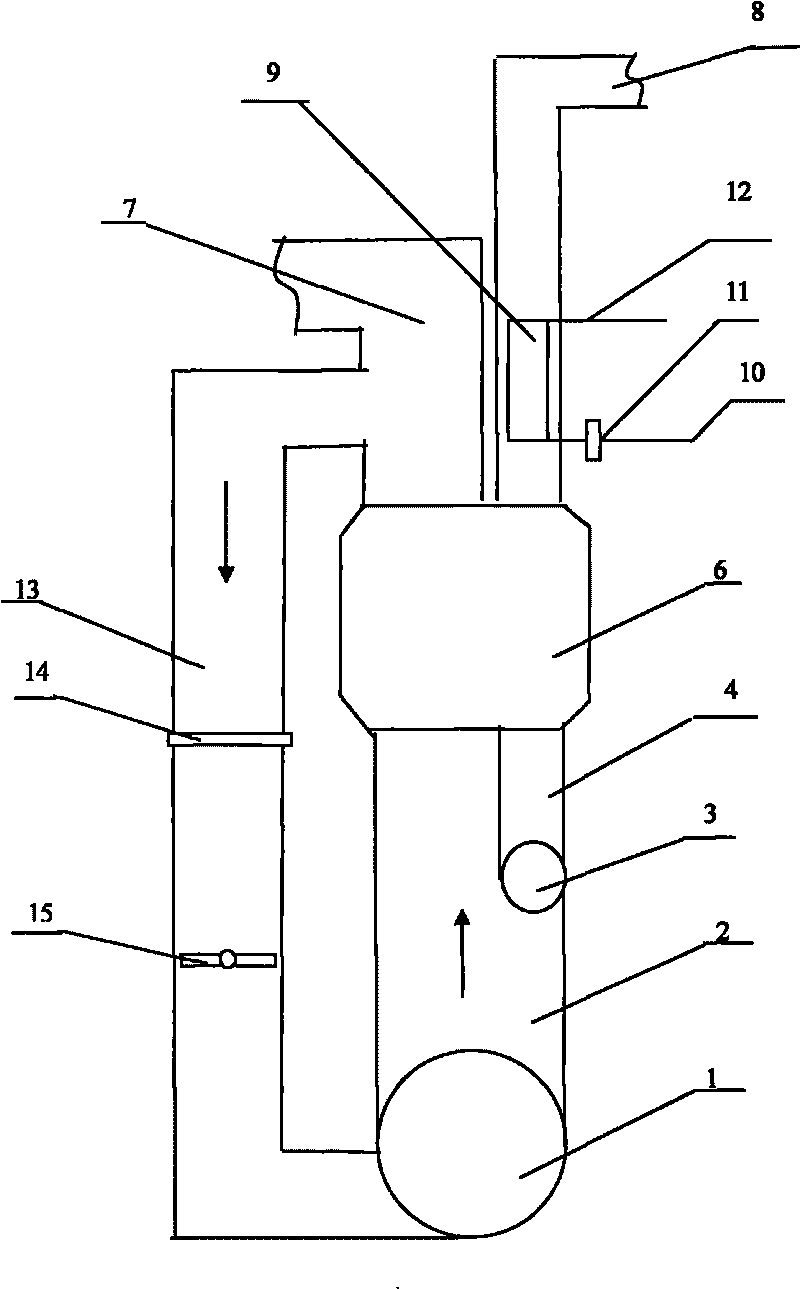

Embodiment 3

[0021] Embodiment 3: see image 3 In this embodiment, a hot air recirculation pipe 13 connected to the blower 1 is also provided on the hot secondary air pipe 7, and a hot air recirculation pipe shut-off valve 14 and a hot air recirculation pipe adjustment valve 13 are also provided on the hot air recirculation pipe 13. Damper 15. Other connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com