Patents

Literature

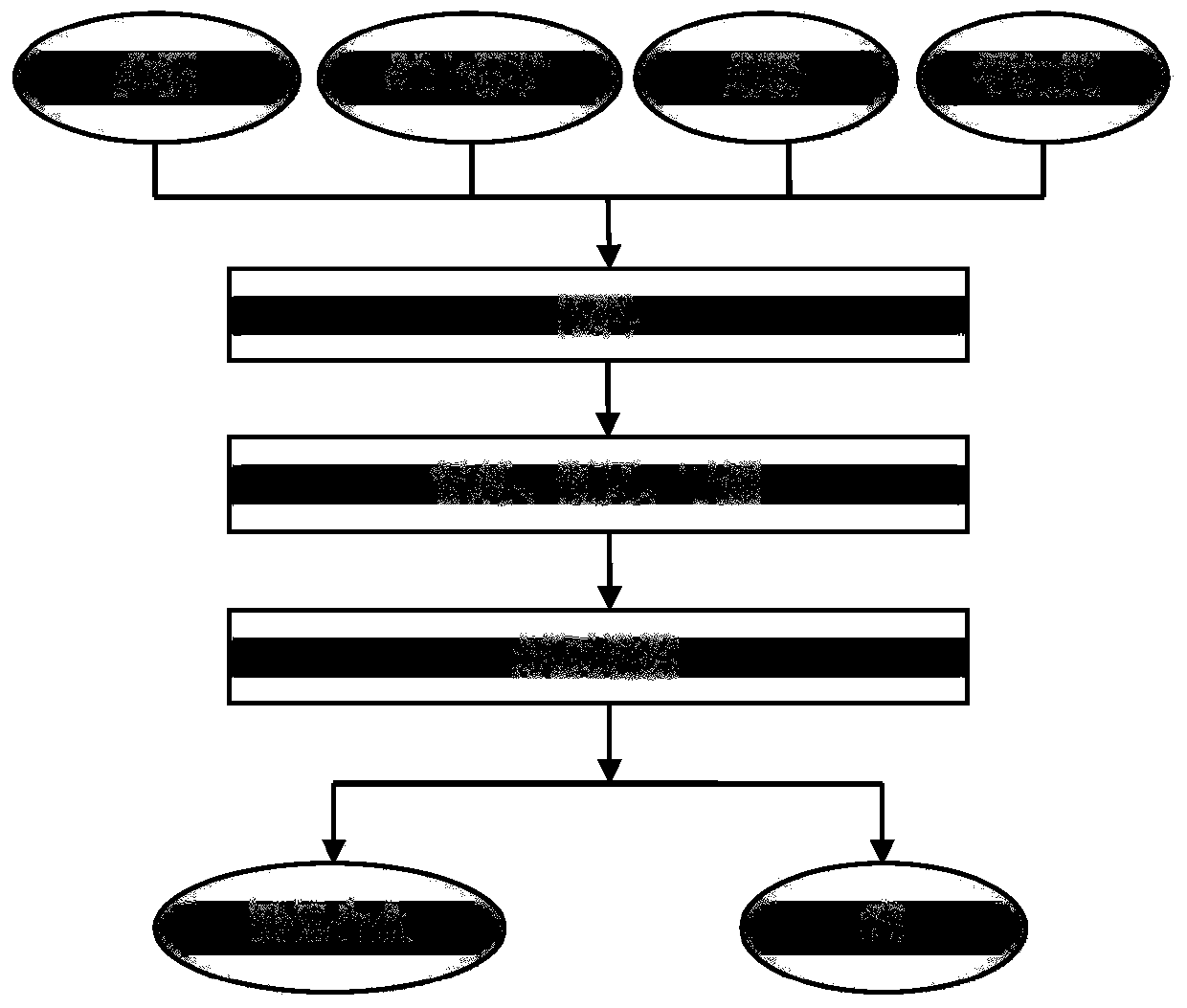

157results about How to "Reduce the amount of slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

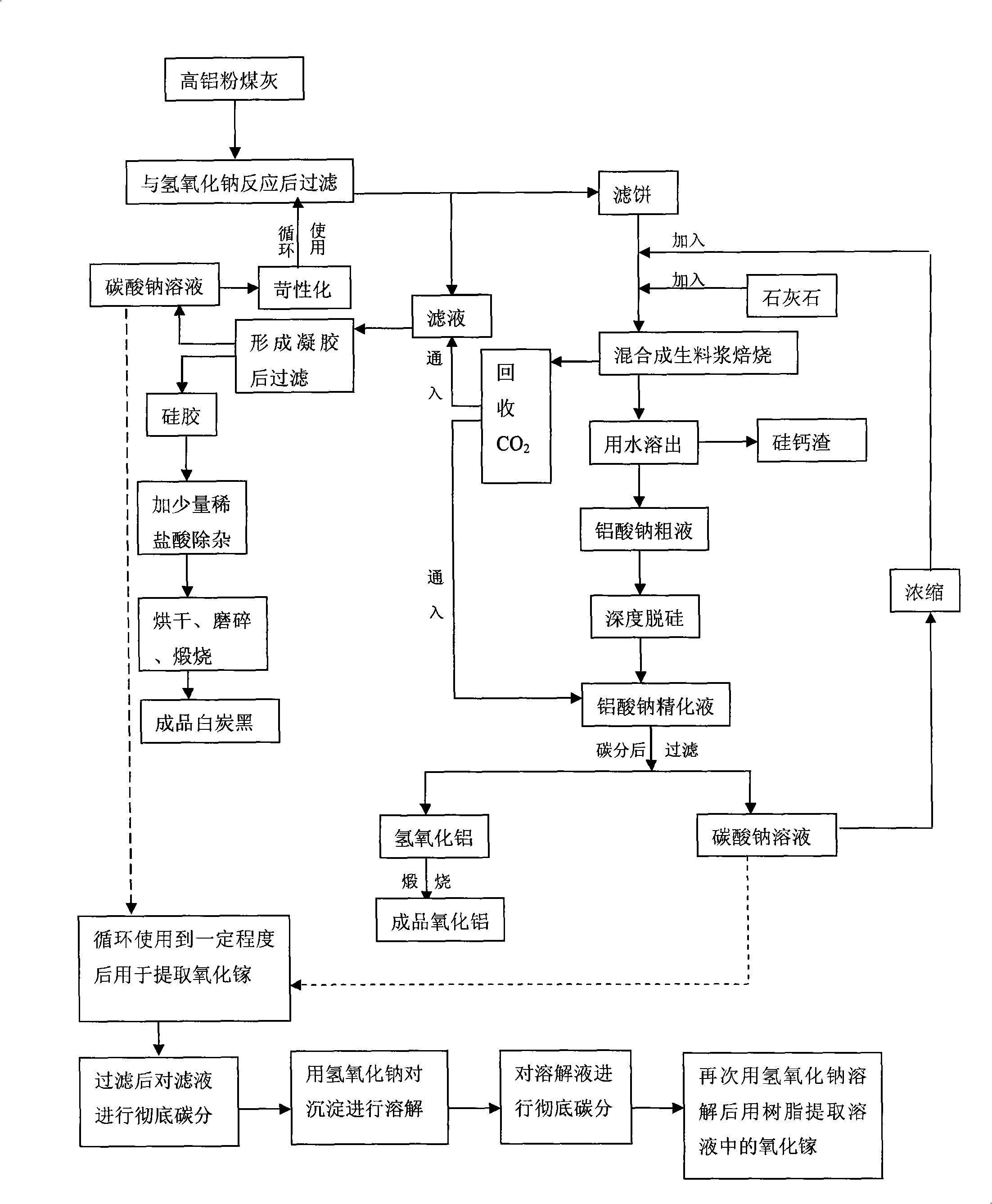

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

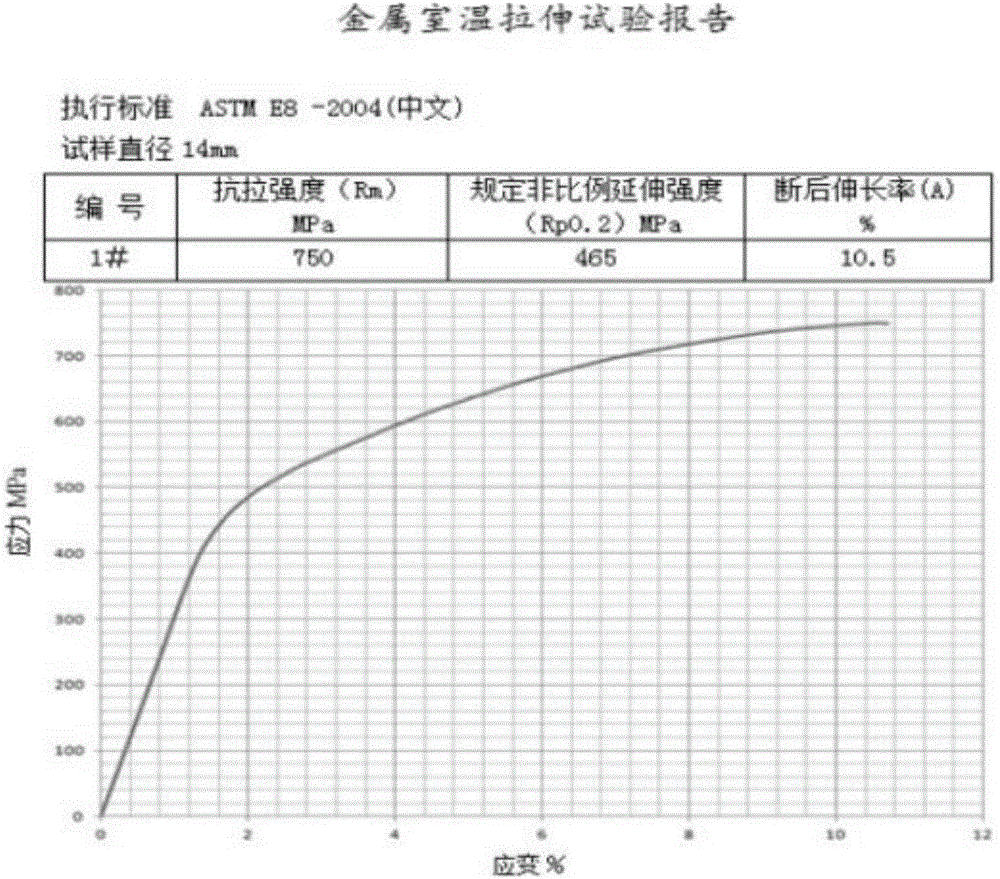

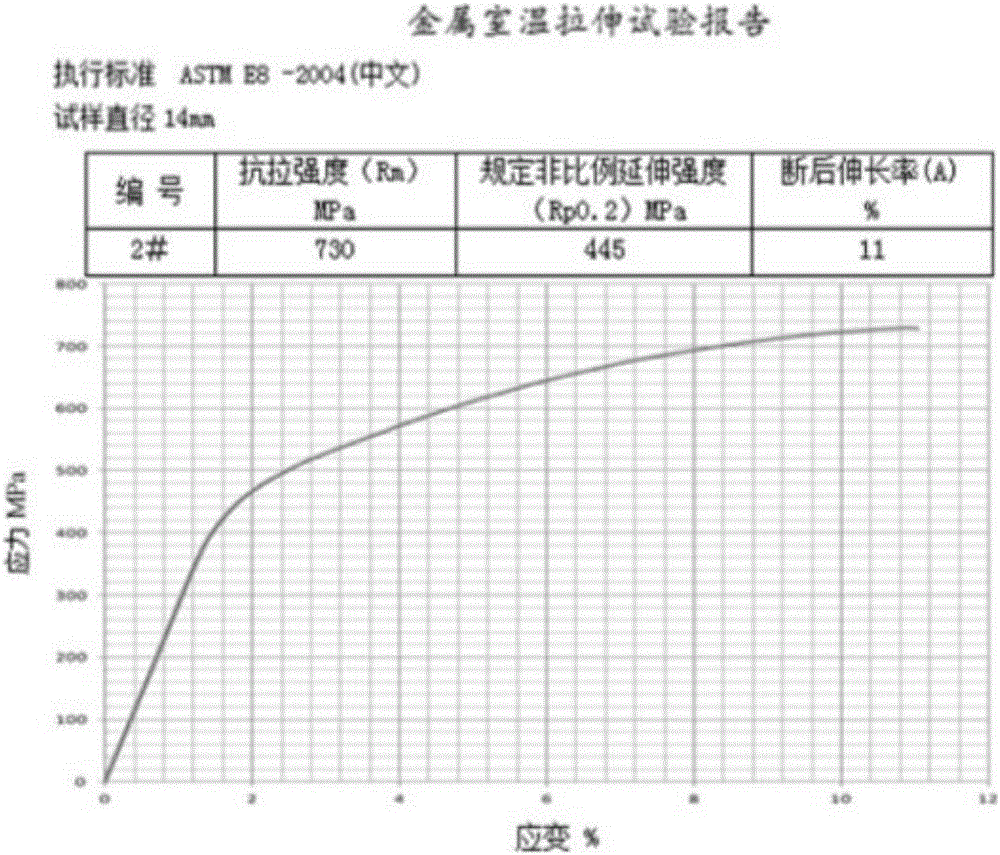

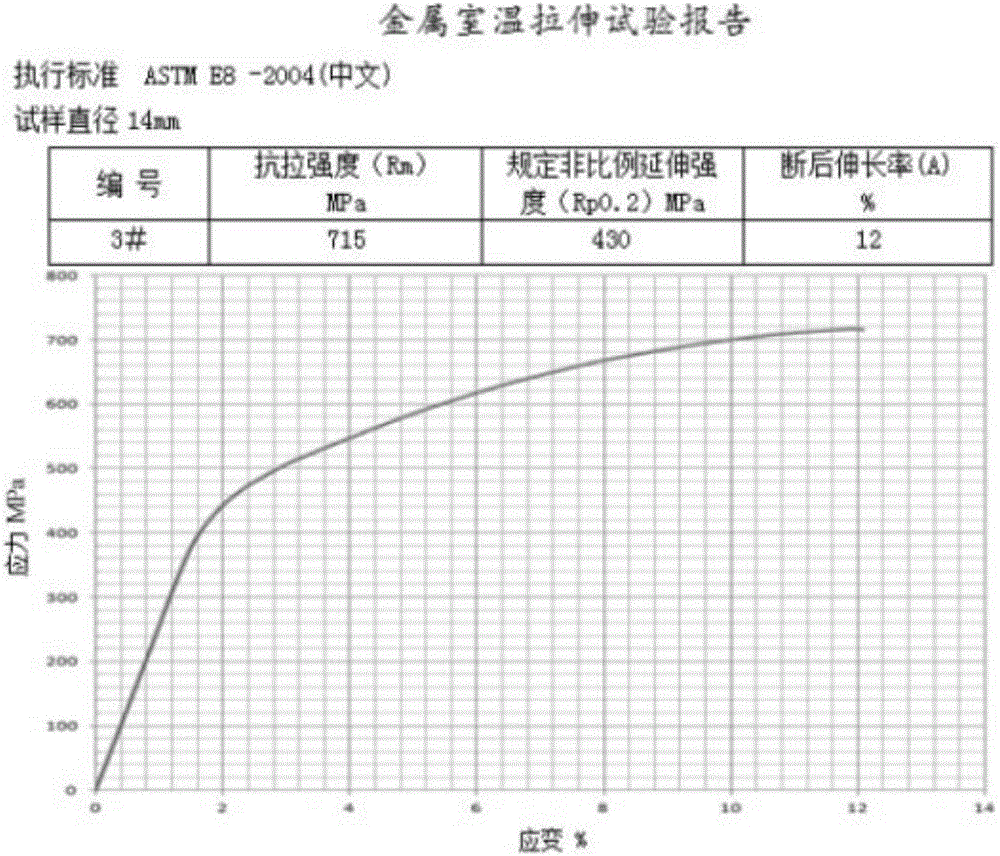

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

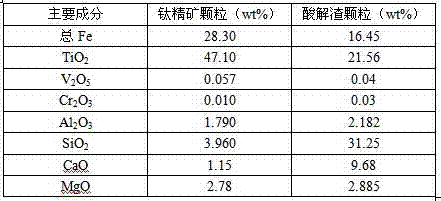

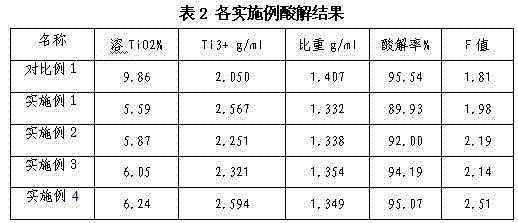

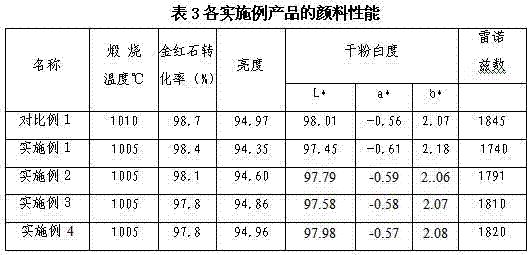

Pretreatment method in the process of preparing titanium dioxide by reusing acidolysis residues

InactiveCN102336433AHigh recovery rateEfficient reusePigmenting treatmentSolid waste disposalPretreatment methodTitanium

The invention discloses a pretreatment method in the process of preparing titanium dioxide by reusing titanium dioxide acidolysis residues, which comprises the following steps of: crushing dried acidolysis residues, mixing raw materials by an acid mine, raising the temperature for acidolysis reaction; carrying out maturation reaction to generate solid-phase mixture; watering and leaching; mixing and settling; and obtaining a required product. With the adoption of the technical scheme, the pretreatment method has the beneficial effects that the reuse of the acidolysis residues as well as waste acid in the production process of the titanium dioxide can be better realized, so that the acidolysis rate of the titanium dioxide contained in the acidolysis residues reaches above 80 percent; the product obtained by pretreatment can be directly used for a sulfuric acid process to prepare the titanium dioxide, so that the recovery ratio of titanium is improved above 3 percent, a vast majority of titanium elements in the acidolysis residues are effectively recovered, and more than 30 percent of residue piling amount is reduced. The pretreatment method changes wastes into valuables and has important significance on effective utilization of resources and environment protection.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

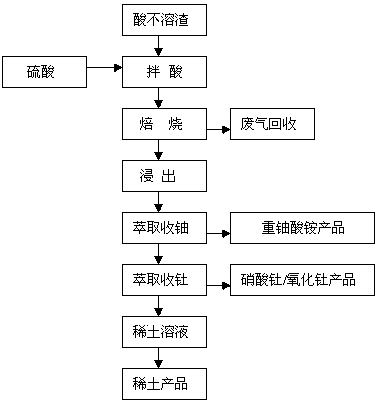

Method for recovering thorium, uranium and rare earth from monazite smelting acid-insoluble slag

The invention provides a separation method for recovering thorium, uranium and rare earth from monazite smelting acid-insoluble slag. The method comprises the following steps of mixing acid-insoluble slag and concentrated sulfuric acid to obtain a uniform mixture, carrying out constant-temperature roasting, adding water into the roasted slag, carrying out leaching at a room temperature, extracting uranium by a tertiary amine extraction agent, extracting thorium from the solution without uranium by a primary amine extraction agent, and carrying out alkali deposition on the solution without uranium and thorium to obtain a rare earth mixture product. The method has simple processes and large scale production feasibility, utilizes common chemical materials having low consumption, can effectively extract rare earth from residual acid-insoluble slag in a monazite smelting process, can acquire single thorium and uranium products, has a total yield more than 90% and slag consumption amount more than 50%, is environmentally friendly and has obvious social and economic benefits.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

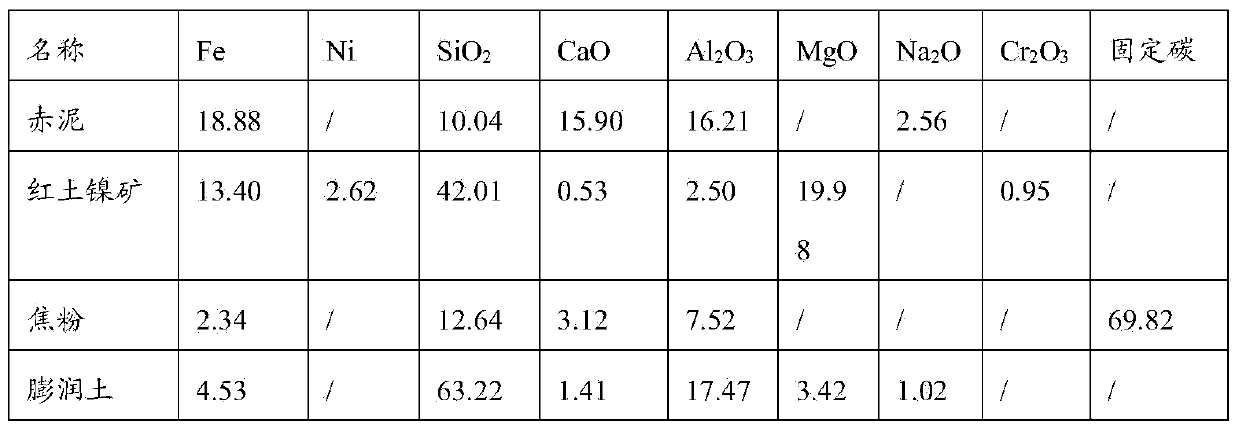

Method for preparing ferronickel by using red mud and laterite-nickel ore

ActiveCN104178624ARich in beneficial chemical ingredientsRealize secondary recyclingFluidised-bed furnacesRed mudLaterite

The invention provides a method for preparing ferronickel by using red mud and laterite-nickel ore. Meanwhile, a novel method is provided for recovery of iron in red mud and production of ferronickel from the red mud and the laterite-nickel ore. According to the method, iron-nickel reduction products in the red mud and the laterite-nickel ore are directly utilized, and low-cost ferronickel can be provided for stainless steel smelting production, ferroalloy casting and alloy steel production. The laterite-nickel ore also contains a little of chromium, and in the production method disclosed by the invention, chromium enters the iron-nickel alloy, so that beneficial chemical components of the iron-nickel alloy are enriched. The contained iron-nickel alloy produced by the method disclosed by the invention is iron-nickel alloy with low P and S content.

Owner:GUANGXI UNIV

Method for smelting low-carbon aluminium-killed steel and method for continuously casting low-carbon aluminium-killed steel

The invention provides a method for smelting low-carbon aluminium-killed steel, comprising the following steps: carrying out primary smelting by adopting a converter top and bottom combined blowing way, and then tapping molten steel obtained by the primary smelting into a steel ladle; blocking slag and predeoxidising in the tapping process, wherein the slag is blocked to ensure that the total content of FeO and MnO which enter the steel ladle is 3-5wt% of the molten steel entering the steel ladle, and the predeoxidising operation comprises the step of adding ferro-aluminium deoxidizer into the molten steel and can ensure that the oxygen content of the molten steel is 10-100ppm; carrying out primary aluminium feeding on the molten steel in the steel ladle before the molten steel in the steel ladle is refined after tapping is completed; refining the molten steel after the primary aluminium feeding is completed, and carrying out secondary aluminium feeding in the refining process; and removing impurities floating on the liquid surface of the molten steel. The invention also provides a method for continuously casting the low-carbon aluminium-killed steel, comprising the following steps: pouring the molten steel obtained by adopting the method for smelting the low-carbon aluminium-killed steel into a crystallizer, and continuously pulling and cooling. By adopting the method for smelting the low-carbon aluminium-killed steel, the purity of the molten steel can be obviously improved, and the accretion in the continuous casting process can be reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

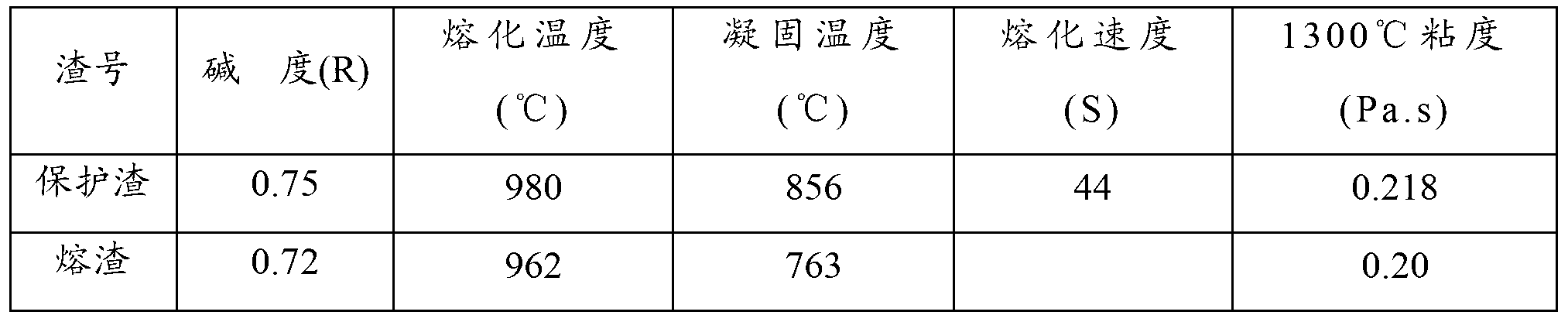

Continuous casting crystallizer covering slag for high-carbon steel

The invention relates to a continuous casting crystallizer covering slag for high-carbon steel. The continuous casting crystallizer covering slag comprises the following components in percentages by weight: 22.90-37.0% of SiO2, 22.5-27.0% of CaO, 4.35-5.0% of MgO, 1.8-6.0% of Al2O3, 2.2-3.0% of Fe2O3, 9.0-12.0% of Na2O, 5.2-6.0% of F, 6.5-9.0% of C, not more than 2.0% of K2O, not more than 1.9% of Li2O, and the balance of water and impurities. According to the continuous casting crystallizer covering slag for high-carbon steel disclosed by the invention, the using amounts of Na2O and CaF2 are properly reduced, K2O and Li2O fluxing is added, and the slag not only has proper physicochemical performance but also has good glass property and lubricating property, so that the quality and yield of casting blanks are greatly improved, and the covering slag has high economic benefit and social benefit.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

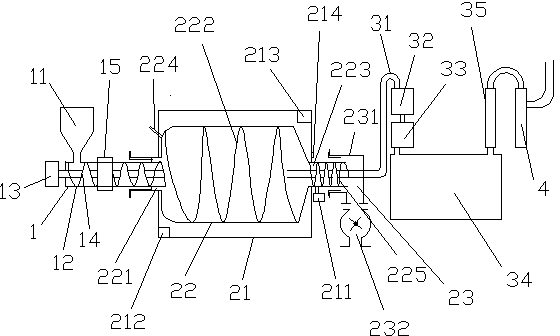

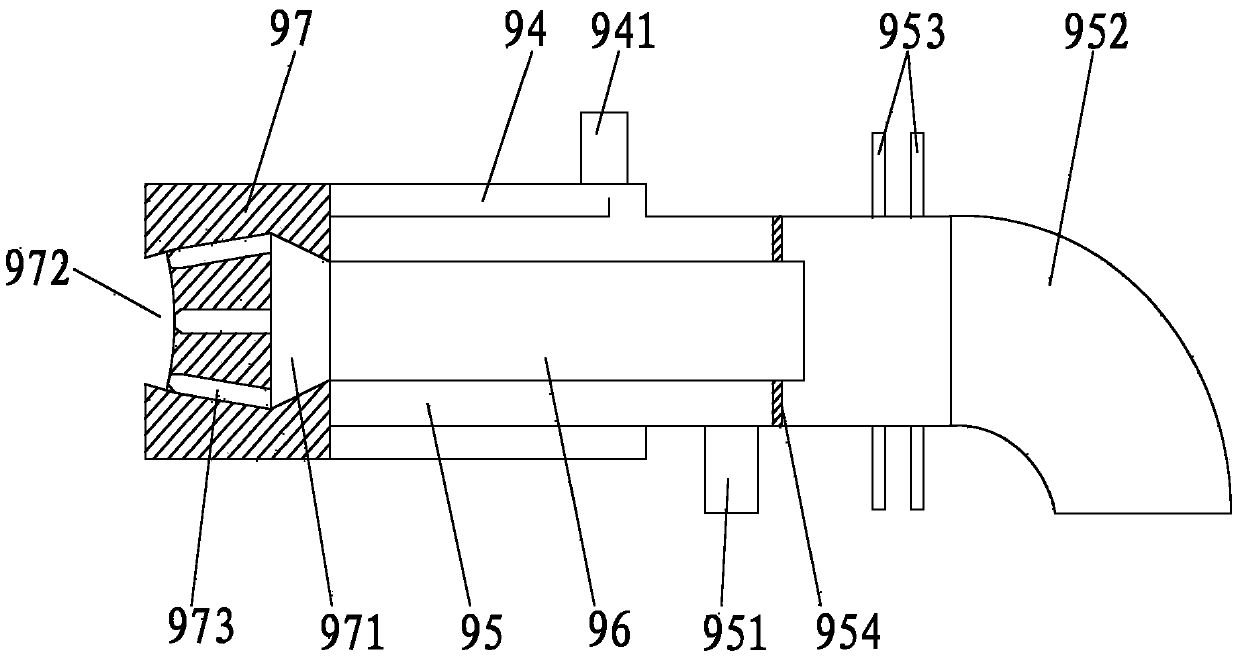

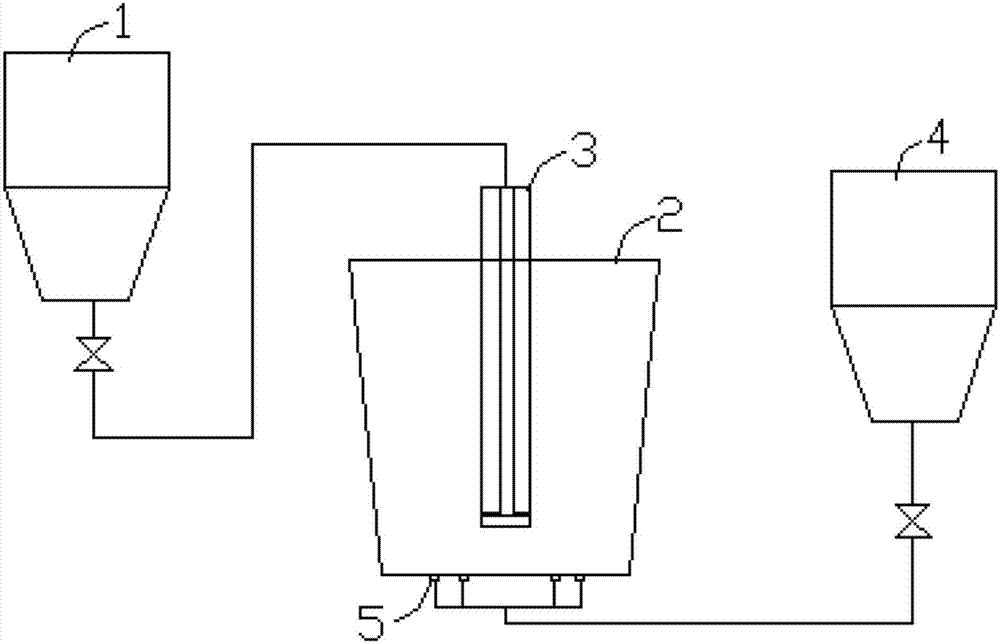

Rotary spiral waste organic glass propelling and continuous splitting decomposition method and device

ActiveCN104211984AGood choiceEmission reductionOrganic compound preparationCarboxylic acid esters preparationDecompositionHearth

The invention relates to a rotary spiral waste organic glass propelling and continuous splitting decomposition method and device and belongs to the field of chemical engineering. The raw material splitting decomposition efficiency and product recovery rate can be improved, and energy consumption and pollutant discharge can be reduced. The device comprises a feeding device, a splitting decomposition device, a condensing device and a waste gas treatment device which are sequentially connected, and further comprises a pressure limiting valve, a residue discharging pipe, a star-shaped valve, a feeding port, guide blades and a discharging port, wherein the pressure limiting valve is used for controlling pressure intensity in a splitting decomposition kettle. The feeding port is movably connected with a feeding pipe. The guide blades are fixedly arranged in the splitting decomposition kettle, and materials are spirally propelled from the feeding port to the discharging port. A hearth is provided with a thermometer. The discharging port is movably connected with the residue discharging pipe, and the residue discharging pipe is connected with the star-shaped valve. The condensing device is connected with the splitting decomposition device through a guide pipe, the guide pipe penetrates through the residue discharging pipe to extend into the discharging port, the guide pipe, a water-cooling device, a storage tank and a copious cooling device are connected in sequence, and the storage tank is arranged at the lower end of the water-cooling device and the lower end of the copious cooling device. The waste gas treatment device is connected with the copious cooling device.

Owner:杭州临安清云环保设备有限公司

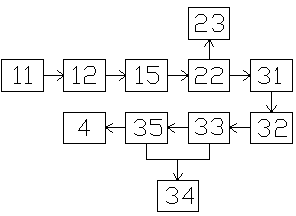

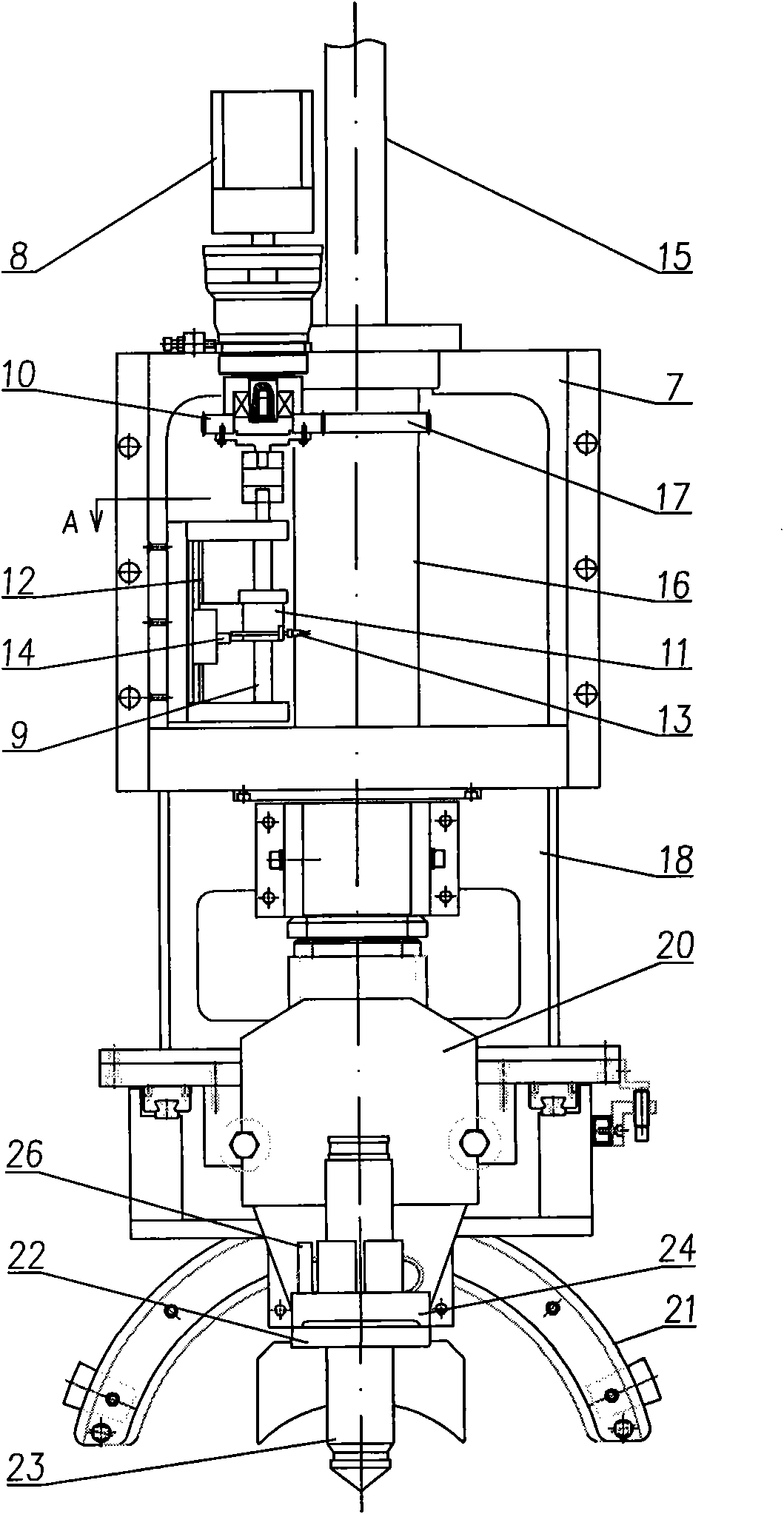

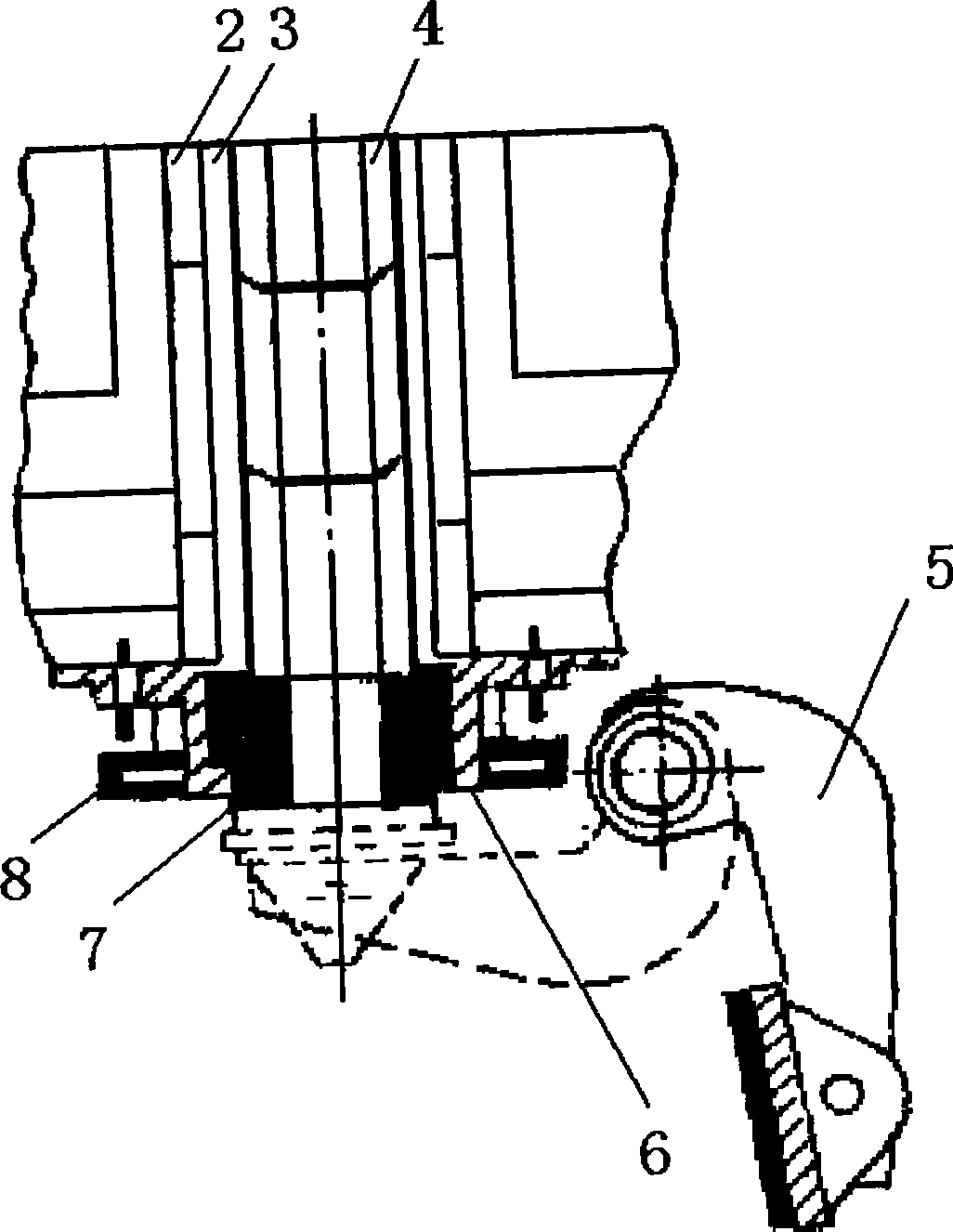

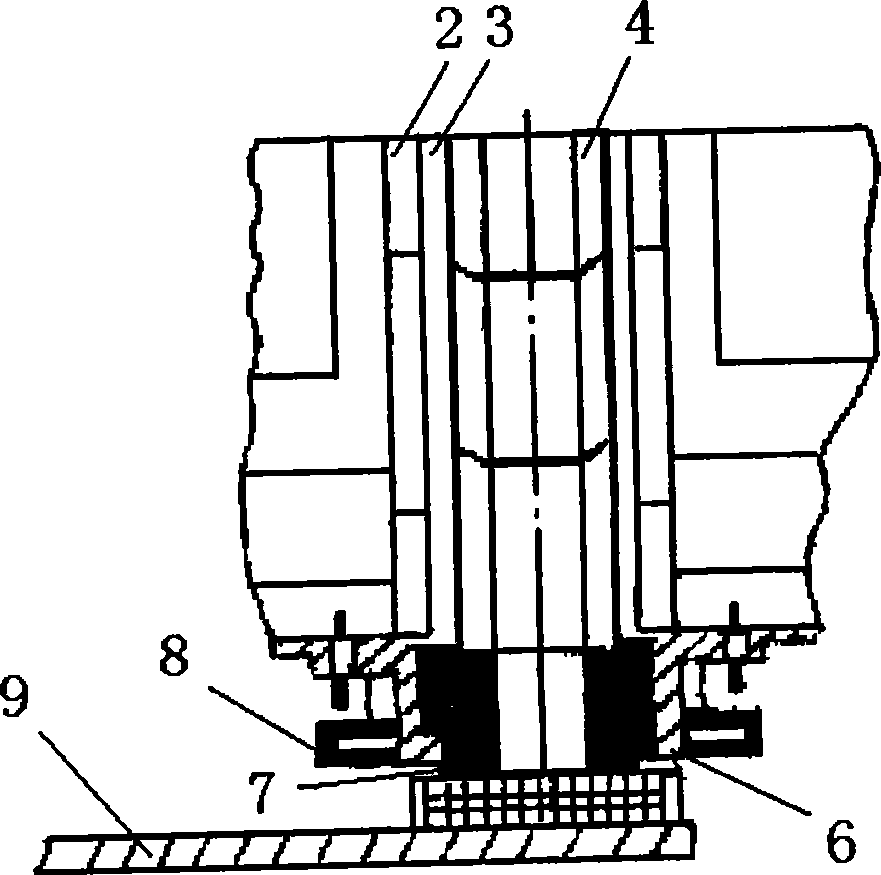

Numerical control plasma six-shaft five-linkage groove cutting machine

InactiveCN101947686AImprove cutting accuracyImprove the finishPlasma welding apparatusMagnetEngineering

The invention discloses a numerical control plasma six-shaft five-linkage groove cutting machine. A rotating motor is installed on the top of a case of a host machine and connected with a ball screw rod in the case; the upper end of the ball screw rod is provided with a small gear, and the middle is in thread connection with a sliding block; one end of the sliding block is matched with a concave-convex groove of a vertical guide rail on the side wall of the case, and the other end is connected with a reset approaching switch; the reset approaching switch corresponds to a limiting block on the side wall of the case; the case is also provided with a hollow rotating shaft, and a big gear is connected to the rotating shaft; the big gear is meshed with the small gear; the lower end of the rotating shaft is fixed to the upper end of a C-shaped connecting piece; a reduction box driven by a swinging motor is installed on the C-shaped connecting piece and meshed with a semicircular rack by the gears; a cutting torch seat is installed on the rack; a cutting torch clamp is arranged on the contact surface of the cutting torch seat; a magnet is inlaid on the contact surface of the cutting torch seat; and a touch resistant approaching switch is vertically installed in a through hole of the clamp. The invention has the characteristics of accurate rotary resetting, verticality online compensation and high cutting precision.

Owner:安徽西锐重工科技有限公司

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

Pre-melting buried arc composite refining slag and method for making same

InactiveCN101012489AExtend your lifeImprove performanceProcess efficiency improvementGranularitySlag

The invention discloses a premelting buried arc composite refining slag and making method, which comprises the following steps: adopting premelting slag with grain size at 2-30mm as basic material; adding 10-30% foaming buried arc material; blending completely through machine; obtaining the product.

Owner:赵佳云

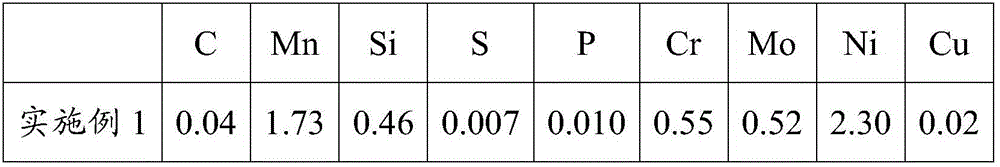

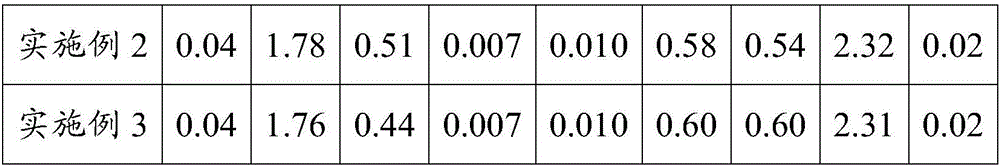

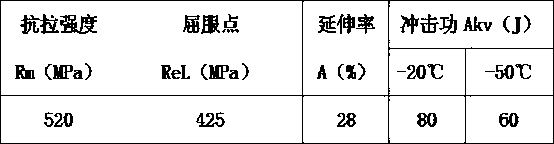

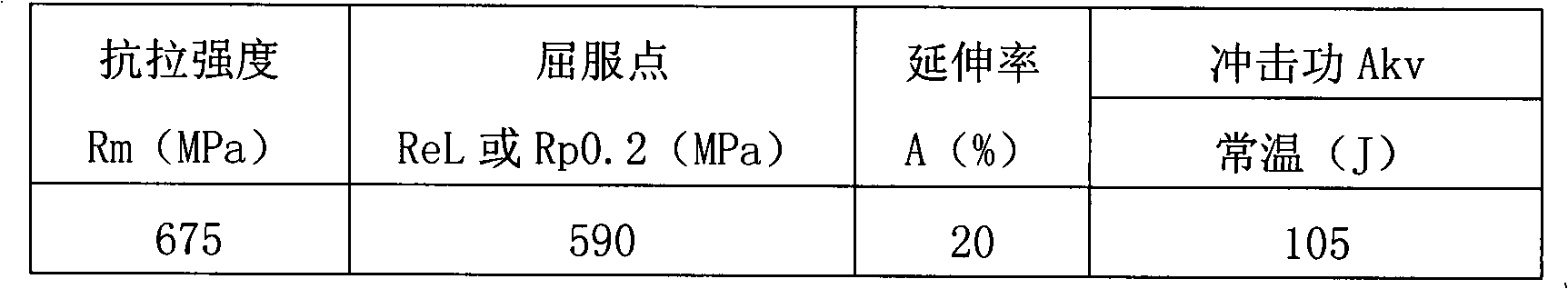

Metal powder flux-cored wire for 1000 MPa high-strength steel and production process thereof

ActiveCN106216882AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaManganeseAlloy

The invention discloses a metal powder flux-cored wire for 1000 MPa high-strength steel and a production process thereof. The flux-cored wire comprises a steel cover and a flux core; the flux core comprises the following components in percentage by mass: 3-6 wt% of silicon manganese alloy, 3-8 wt% of silicon iron powder, 0.5-2.2 wt% of titanium iron powder, 0.01-0.28 wt% of fluoride, 10-19 wt% of manganese powder, 10-18 wt% of nickel powder, 6-10 wt% of molybdenum iron, 3-8 wt% of chromium powder, and the balance of iron powder and inevitable impurities; and the flux core is 12-18 wt% of total mass of the flux-cored wire. The production process comprises the following steps: all the components of the flux core are positioned on the steel core after uniform mixing in proportion, and are wrapped or wound as wires for drawing and diameter reduction to obtain welding wires with predetermined specifications, so that the metal powder flux-cored wire for 1000 MPa high-strength steel is prepared.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

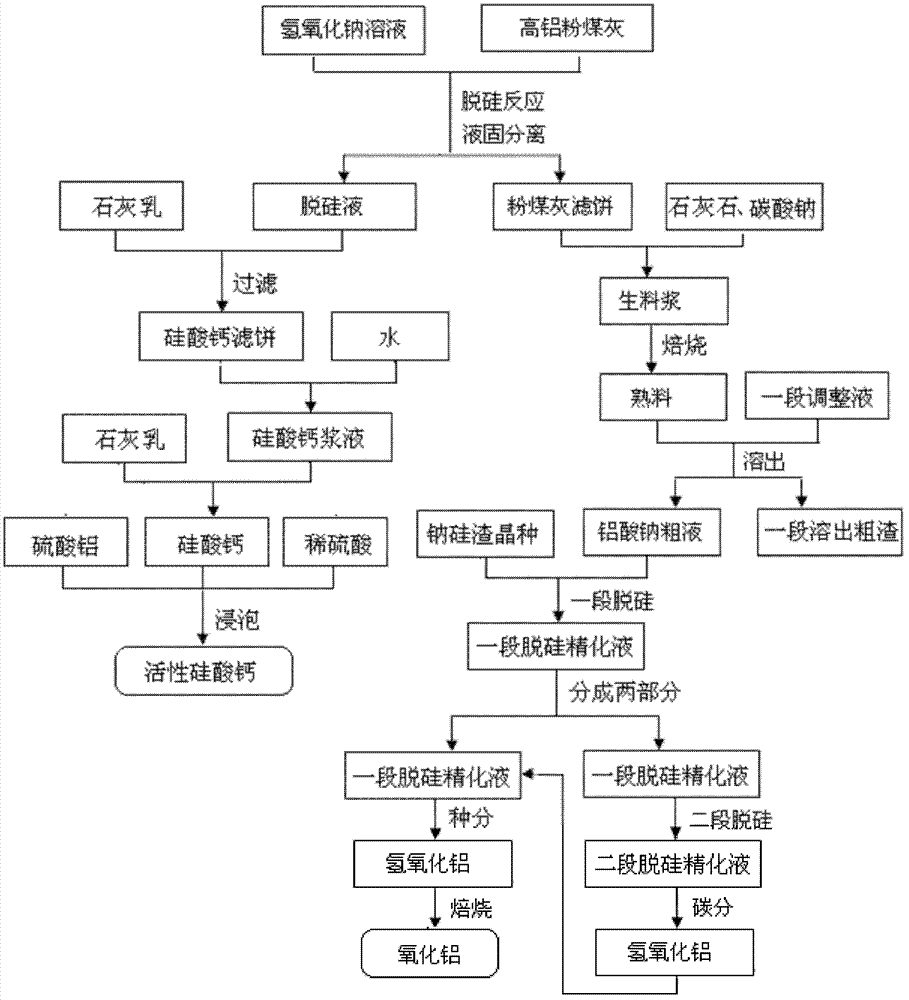

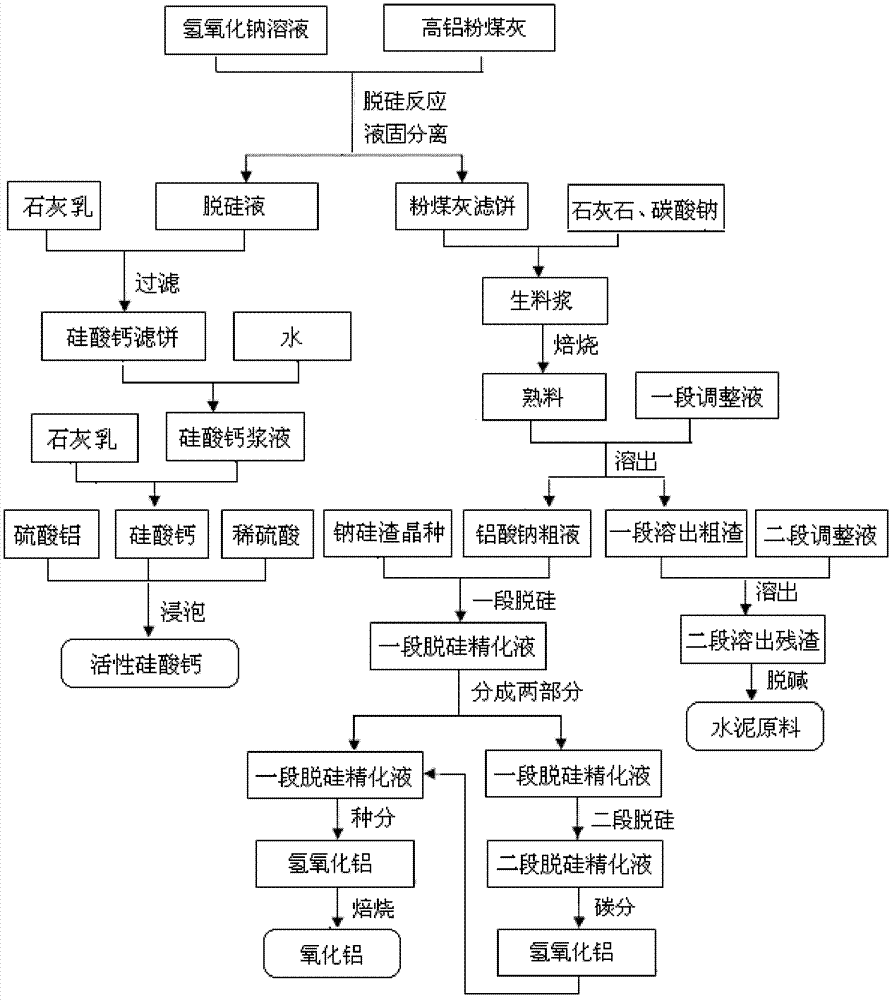

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253BExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateChemical industry

The invention provides a method for producing alumina and co-producing active calcium silicate with high-alumina fly ash. The steps include: first reacting high-alumina fly ash with sodium hydroxide solution to perform pre-desilication to obtain liquid-phase desiliconization liquid and Desiliconized fly ash in solid phase; add milk of lime to the desiliconized liquid for causticization reaction, the solid phase is active calcium silicate, and the finished product is obtained by pressure filtration and flash drying; add limestone and carbonic acid to the desiliconized fly ash The sodium solution is formulated into a qualified raw slurry, and then the qualified raw slurry is roasted into clinker, and the liquid phase dissolved in the clinker is sodium aluminate crude solution; the sodium aluminate crude solution is desiliconized, carbonized, and seeded in the first and second stages. Metallurgical grade alumina that meets the requirements can be obtained after processes such as calcination and roasting. The invention overcomes the defects in the prior art, realizes less material flow and slag formation, relatively low energy and material consumption and production costs, high alumina extraction rate, and co-produces active calcium silicate with high added value, which can be used Widely used in chemical industry.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

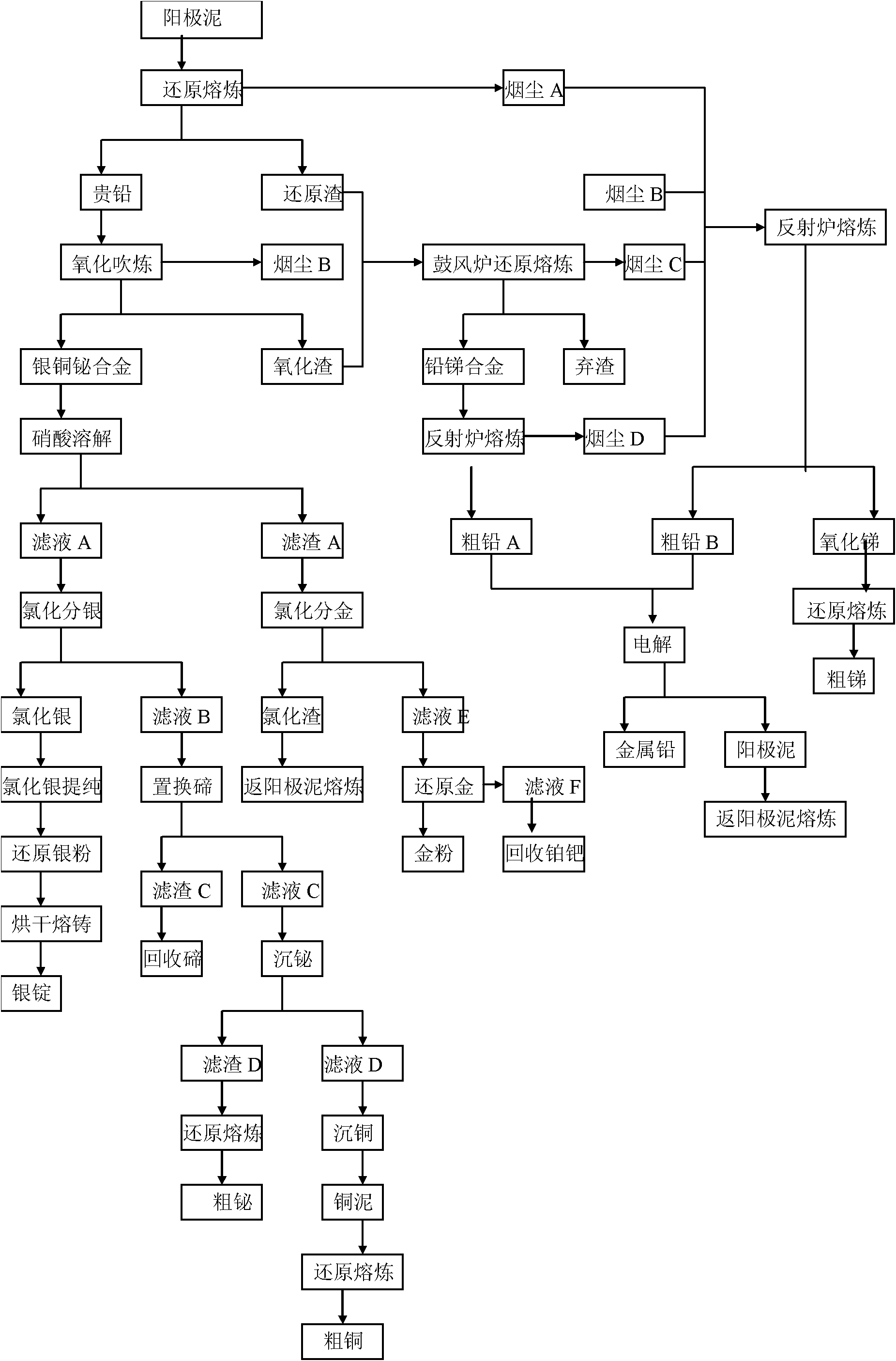

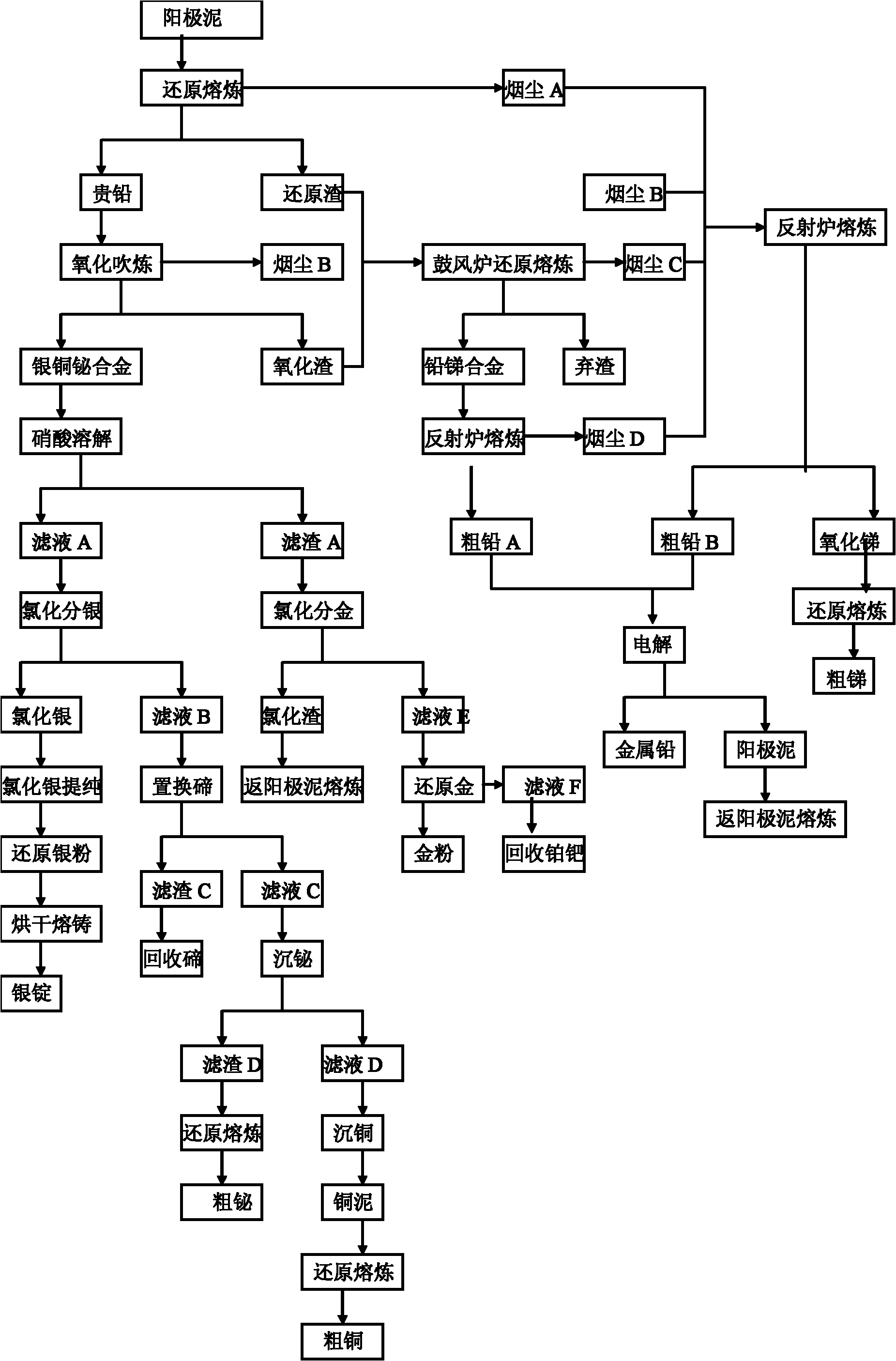

Smelting and separating method of noble lead

InactiveCN102061395AReduce entryImprove direct yieldProcess efficiency improvementSilver copperAntimony

The invention discloses a smelting and separating method of noble lead, comprising the following steps of: oxidizing and converting the noble lead till a silver-copper-bismuth alloy with the total content of lead and stibium, lower than 5 percent by weight, smoke dust B and oxidized slag are generated; dissolving the silver-copper-bismuth alloy with a nitric acid, and filtering to obtain filter liquor A and filter residues A; separating the silver by chloridizing the filter liquor A, and filtering to obtain filter liquor B and silver chloride; purifying the silver chloride to reduce the silver; displacing tellurium contained in the filter liquor B, then depositing bismuth and copper step by step, and recovering the bismuth and the copper; separating gold from the filter liquor A with an aqueous solution chlorination method, and reducing a solution to obtain gold powder; recovering platinum and palladium from the gold-separated solution, and returning gold-separated chlorination slag to an anode mud smelting process; and recovering the lead and the stibium from the oxidizing slag and the smoke dust B. In the invention, the silver-copper-bismuth alloy with the total content of the lead and the stibium lower than 5 percent by weight is produced through oxidization and converting, and the lead and the stibium enter the oxidized slag and the smoke dust B, therefore, not only are the conditions for the recovery of the lead and the stibium created, but also the valuable metal is basically concentrated in the silver-copper-bismuth alloy by reducing the valuable metal entering the smoke dust B and the oxidized slag; in addition, various metals are extracted from the silver-copper-bismuth alloy step by step by using a wet method, the direct recovery rate of the silver and the gold is higher than 99 percent, the direct recovery rate of selenium and the tellurium is higher than 80 percent, and the direct recovery rate of the platinum and the palladium is higher than 95 percent.

Owner:SIHUI CITY HONGMING PRECIOUS METALS +1

Method for preparing Dy-Fe alloy through oxide molten salt electrolysis

The invention discloses a method for preparing a Dy-Fe alloy by electrolyzing an oxide molten salt. The method comprises the following steps of: adding a mixture of Dy2O3 and Fe2O3 into a fluoride molten salt electrolyte system; and electrolyzing to prepare the Dy-Fe alloy. In the invention, a tungsten rod is utilized as a cathode, and element Fe is obtained from electrolyzing ferric oxide, thus the distribution of Dy and Fe in the produced Dy-Fe alloy is strong in controllability, and the error is less than 1%. As a high-density cathode current is utilized, during the electrolysis production process, the slagging amount is greatly reduced, the yield is improved, and the production cost is reduced; no self-consumption ferric cathode is utilized, thereby reducing the labor intensity of frequently replacing the ferric cathode; and a 10000A-30000A large-scale electrolysis stove can be used for production, thereby greatly improving alloy consistency.

Owner:カン州晨光希土新材料有限公司

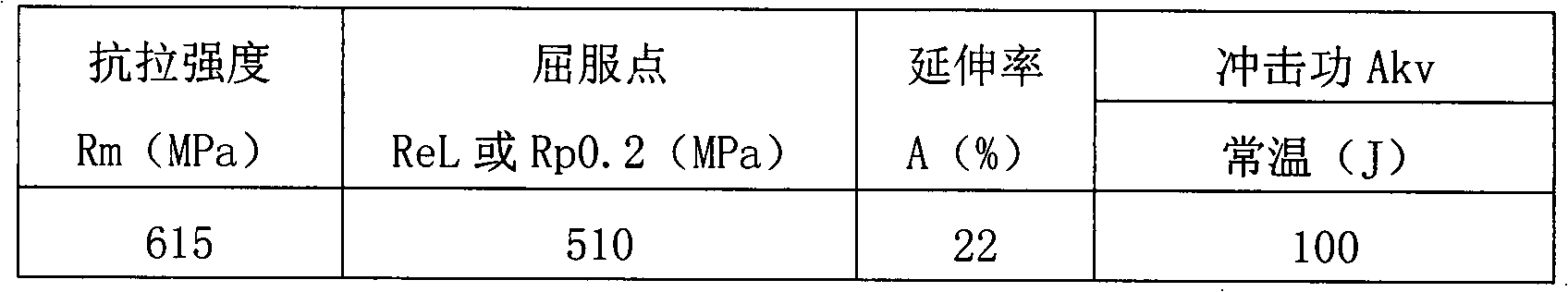

High-toughness and anti-hydrogen induction sulfide stress corrosion crack metal powder flux-cored wire and preparation method

ActiveCN103071941AImprove efficiencyImprove welding efficiencyWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention discloses a high-toughness and anti-hydrogen induction sulfide stress corrosion crack metal powder flux-cored wire which comprises outer skin and a flux core; the outer skin is a low-carbon steel thin strip; the weight of the flux core accounts for 12 percent to 20 percent of the total weight of the wire; and the diameter of the flux core is 1.20mm to 2.4mm. According to the wire welding process, the process performance and physical and chemical properties are good, the amount of slag after welding is effectively reduced, welding of a plurality of layers is carried out without clearing the slag, so that the overall performance and the welding efficiency of a welding seam are effectively improved, the performance of the welding process is good, the electric arc is stable, splashing seldom occurs, the welding seam has attractive appearance, such purposes as vertical downward welding can be achieved through short-circuit transition; and good mechanical properties and the anti-hydrogen induced crack purpose are achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Hot braising method for phosphorus removed slag and carbon removed slag

ActiveCN103397120AGood for turning overEasy to crushRecycling and recovery technologiesSlagEconomic benefits

The invention provides a hot braising method for phosphorus removed slag and carbon removed slag. The method comprises the following steps of: pouring hot phosphorus removed slag into a slag braising pit to parch the slag braising pit; pouring the phosphorus removed slag or the carbon removed slag into multiple parched slag braising pits respectively, turning over, dewatering and breaking the slag in each slag braising pit, then pouring another slag respectively, and repeating the operations of turning over, dewatering and breaking the slag till each slag braising pit is full of the slag; and covering the slag braising pits full of the slag with slag braising covers, and braising the slag in a three-section dewatering and braising mode. The hot braising method for the phosphorus removed slag and the carbon removed slag is simple and feasible, can reduce the potential safety hazard of blasting of the slag braising pits and effectively improve the slag braising efficiency and slag braising quality, and has remarkable economic benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

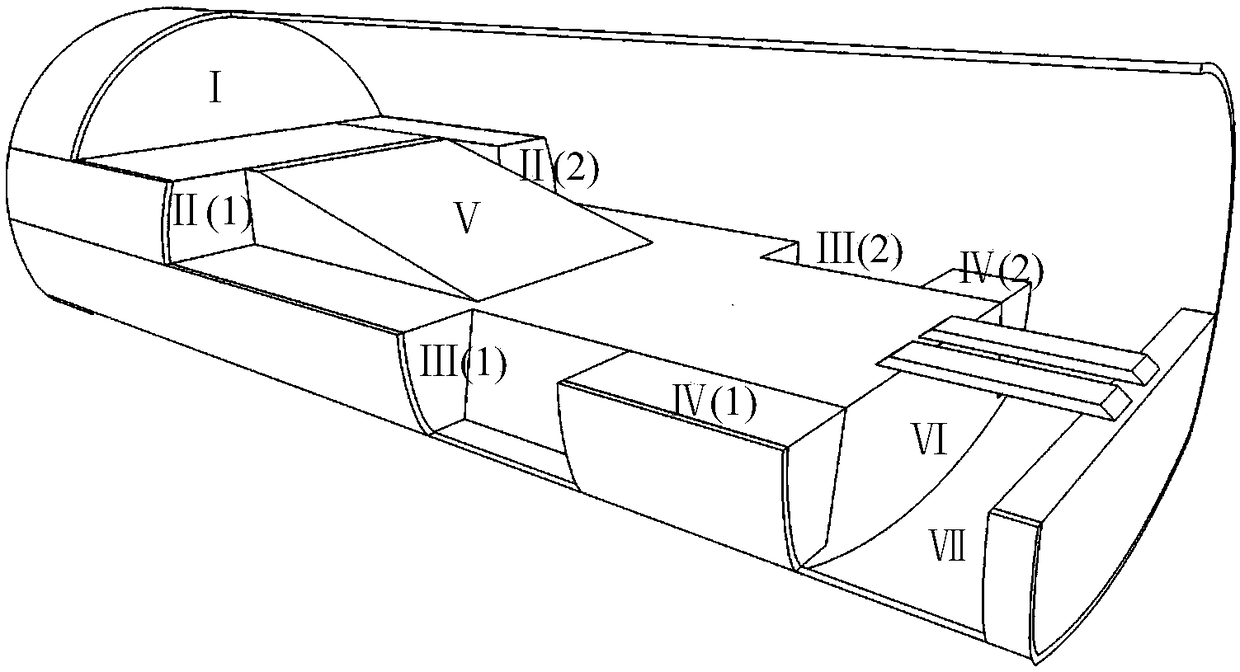

Support method of large-section soft rock large-deformation tunnel

ActiveCN108798702AStrengthen vertical connectionsImprove stabilityUnderground chambersTunnel liningLarge deformationBuilding construction

A supporting method of a large-section soft rock large-deformation tunnel comprises the steps that after excavation is conducted by one footage, concrete is initially sprayed, then hole drilling is conducted, first restraining rods are fed into holes and grouted, and thus an upper initial lining support is formed; under the upper initial lining support, middle steps are excavated on the two sidesin a staggered mode, and then concrete is initially sprayed; after hole drilling, second restraining rods are fed into holes, concrete is re-sprayed to the designed thickness; lower steps are excavated on the two sides in a staggered mode, and then concrete is initially sprayed; after drilling, third restraining rods are fed into holes, the left sides and the right sides of the lower steps are backfilled; and a middle step reserved core soil part and a lower step reserved core soil part are excavated, then, an inverted arch is excavated, and the next cycle of construction is conducted till thetunnel breaks through. According to the support method of the large-section soft rock large-deformation tunnel, the support type is converted from internal supporting into external supporting, thus the space in the tunnel is saved, the safety and durability of the support structure are guaranteed, the safer, more economic and more durable effects and high operability are achieved while large deformation of the tunnel is effectively controlled, and the construction period is effectively shortened.

Owner:CHANGAN UNIV

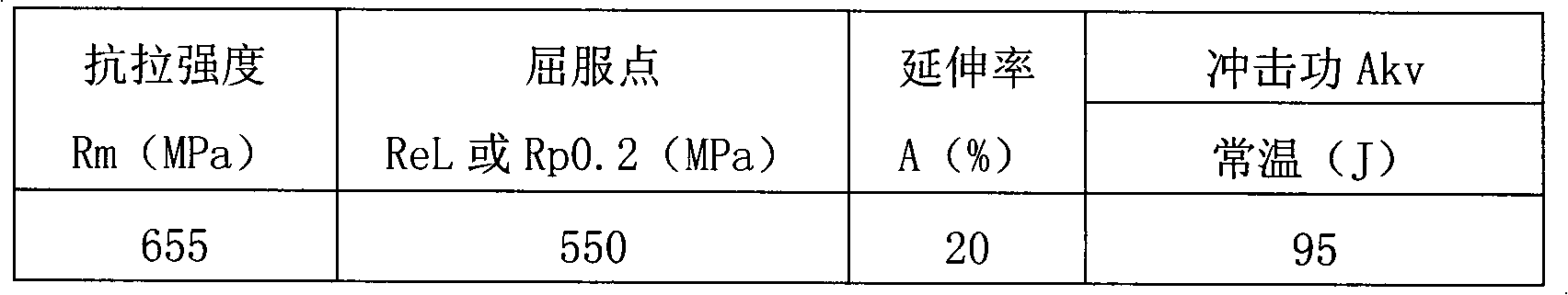

Gas protective welding flux cored wire for welding heat resistant steel

ActiveCN102489901ALow diffusible hydrogen contentImprove performanceWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

The invention belongs to a gas protective welding flux cored wire for welding heat resistant steel. The gas protective welding flux cored wire comprises low-carbon steel metal skin and a flux core, wherein the low-carbon steel metal skin comprises the following components in percentage by weight: 0.01 to 0.1 percent of C, 0.1 to 0.4 percent of Mn, 0.01 to 0.03 percent of Si, 0.005 to 0.015 percent of S, 0.005 to 0.015 percent of P and the balance of iron; the flux core accounts for 14 to 25 percent of the total weight of the welding wire and comprises the following components in percentage by weight: 1.2 to 3.0 percent of medium-carbon ferromanganese, 0.20 to 2.0 percent of ferrosilicon powder, 0.05 to 0.5 percent of magnesium powder, 1.5 to 2.0 percent of metal chromium powder, 0.2 to 2.0 percent of ferromolybdenum powder, 0.05 to 0.2 percent of electrically fused magnesia, 0.01 to 0.3 percent of fluoride and 7 to 15 percent of iron powder; and the components are mixed uniformly, the mixture is coiled on a thin steel strip made of low-carbon steel to form strips, and the strips are drawn to form wires. The gas protective welding flux cored wire has the characteristics of no molten slag on deposited metal after welding, capability of performing continuous multi-layer welding without slag removal, high welding process property, stable electric arcs, small splatter, attractive appearance of weld joints and the like, the welding efficiency is improved by 20 to 40 percent, and vertical downward welding can be realized by short circuiting transfer.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

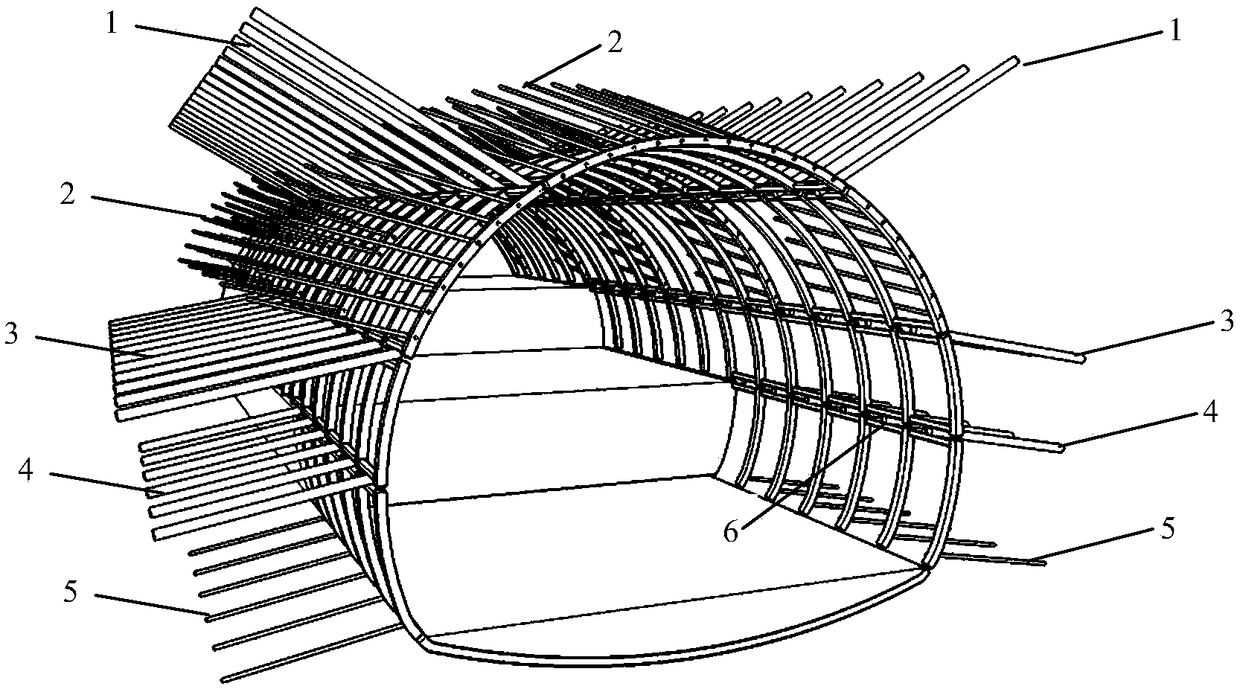

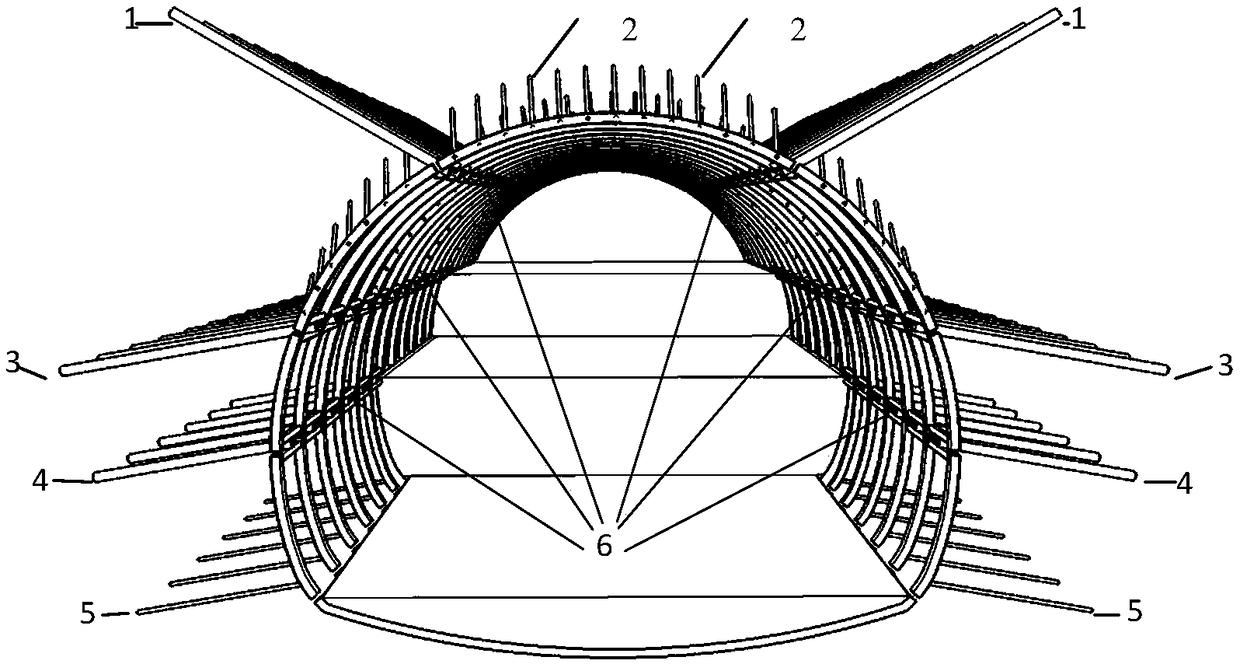

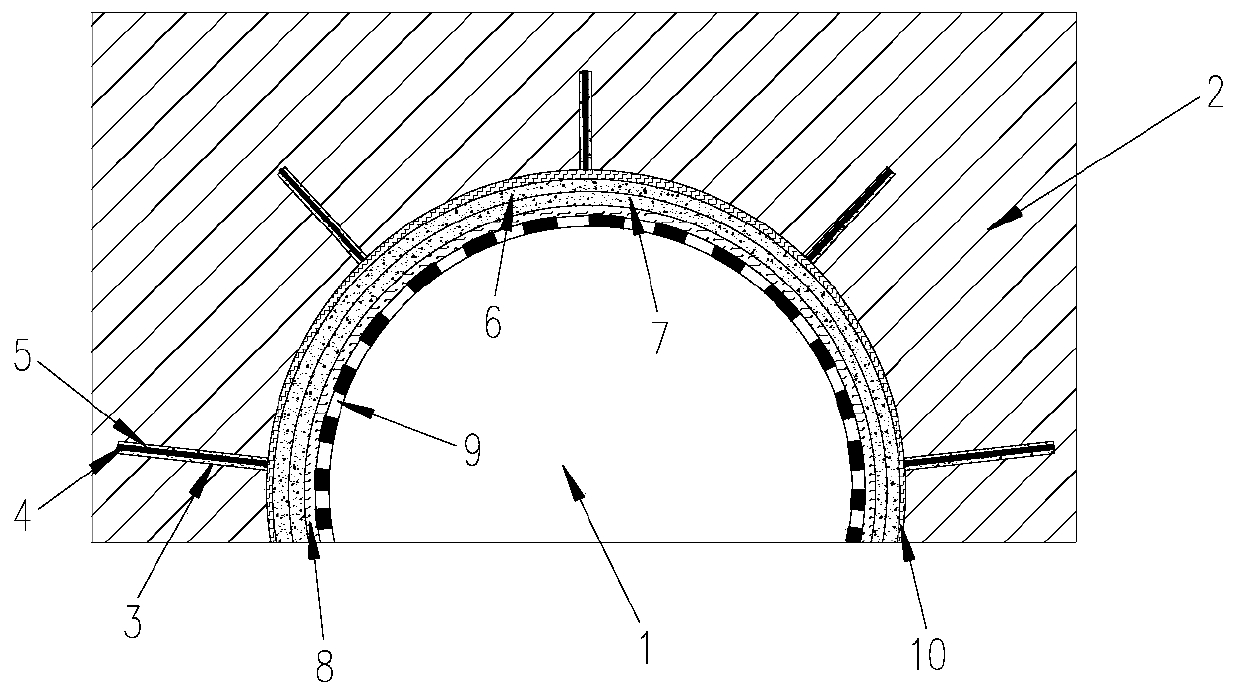

UHPC lining structure used for tunnel and construction method of UHPC lining structure

PendingCN110905555AHigh compressive strengthImprove flexural strengthUnderground chambersDrainageArchitectural engineeringMesh reinforcement

The invention discloses a UHPC lining structure used for a tunnel and a construction method of the UHPC lining structure. The UHPC lining structure is a composite lining structure composed of anchor rod supporting bodies and a UHPC lining supporting layer. Each anchor rod supporting body comprises an anchor rod hole, an anchor rod and a UHPC hole channel grouting material. The UHPC lining supporting layer comprises a water draining blind pipe, an injection UHPC lining layer, a decoration layer and a tunnel outline light reflecting bar. The UHPC lining structure used for the tunnel and the construction method of the UHPC lining structure have the following beneficial effects that the UHPC injection concrete supporting layer has high pressure resisting strength, high bending resisting strength, high toughness, high durability and good microcrack self-healing capability, UHPC is adopted as the tunnel project lining material, the lining structure construction speed is high, the supportingperformance is good, the thickness of the lining structure can be reduced obviously, and therefore the practical excavation sectional area and the slag generation amount of the tunnel can be reduced effectively, and the construction difficulty is lowered; and compared with a traditional tunnel supporting structure, the arrangement of a reinforcement net, a waterproof layer and a steel frame can beomitted, the construction efficiency is effectively improved, and the manufacturing cost is reduced.

Owner:XIANGTAN UNIV

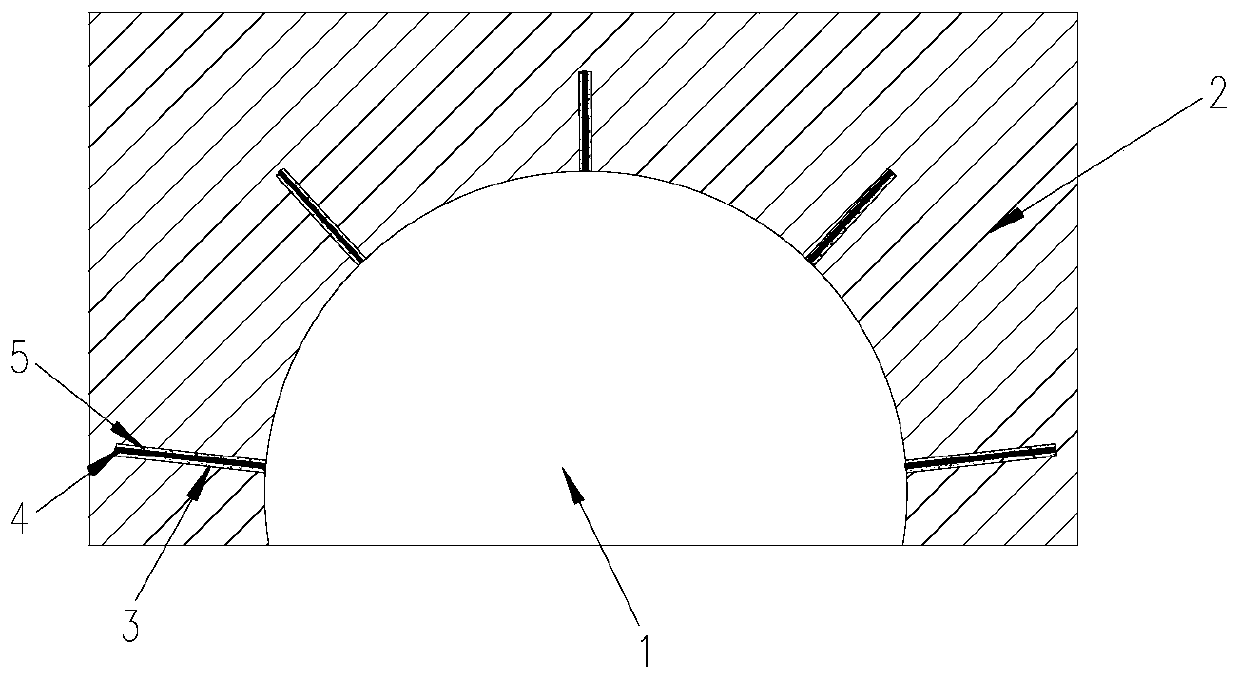

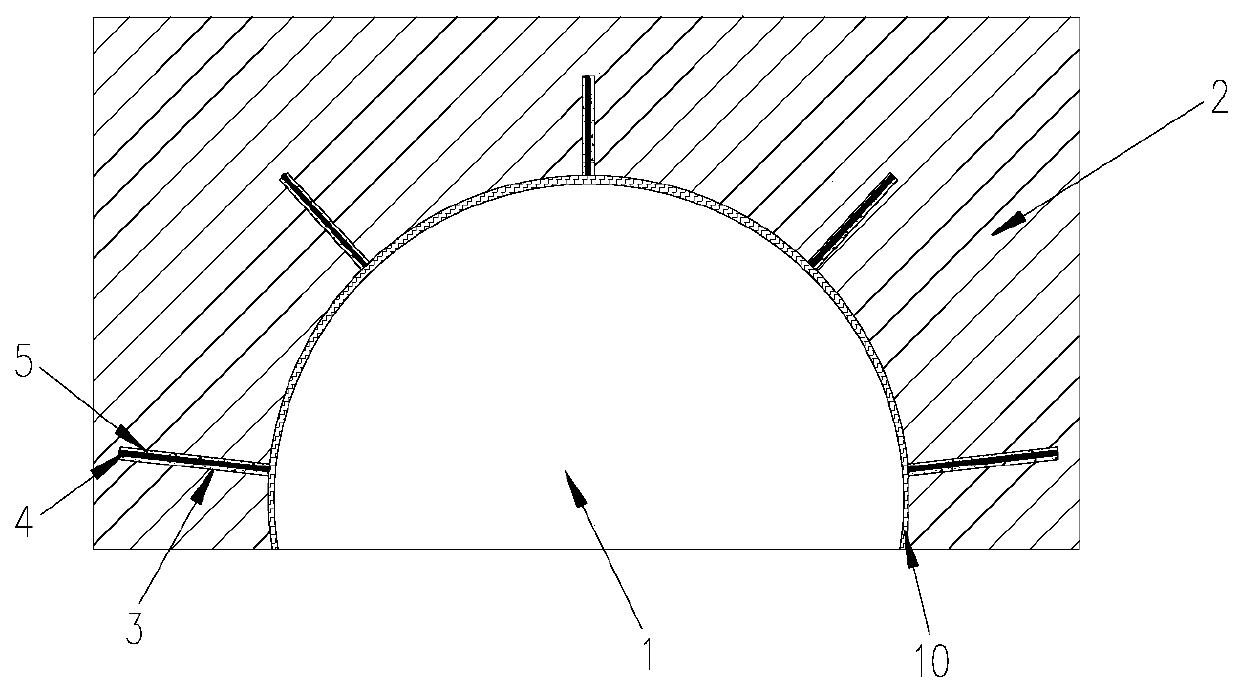

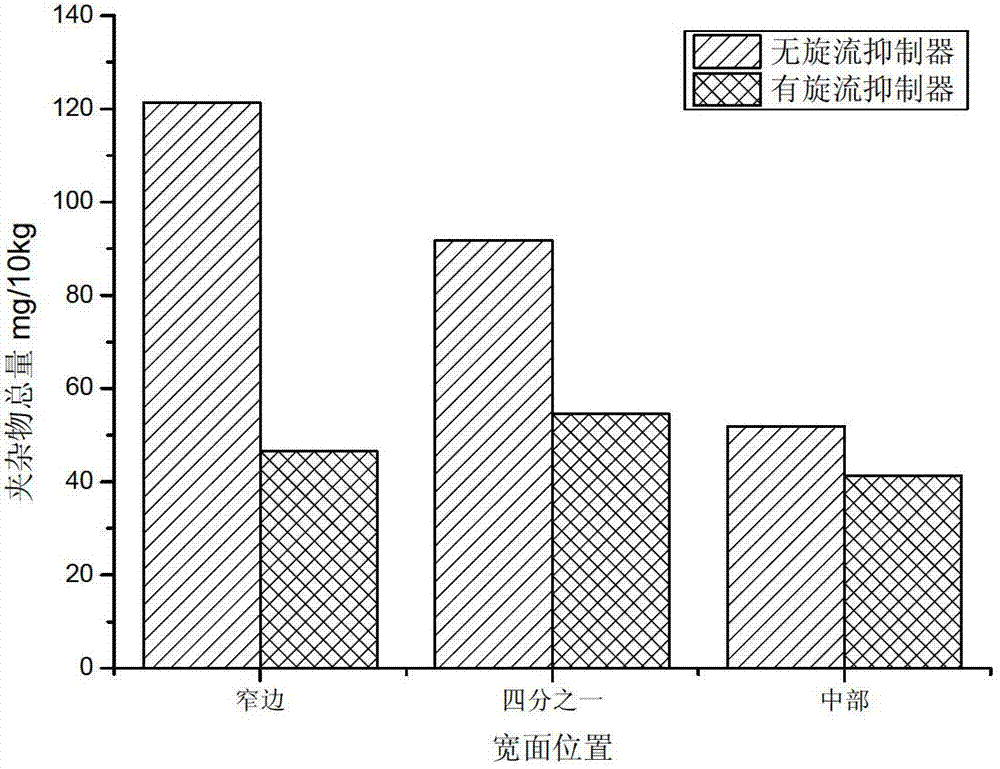

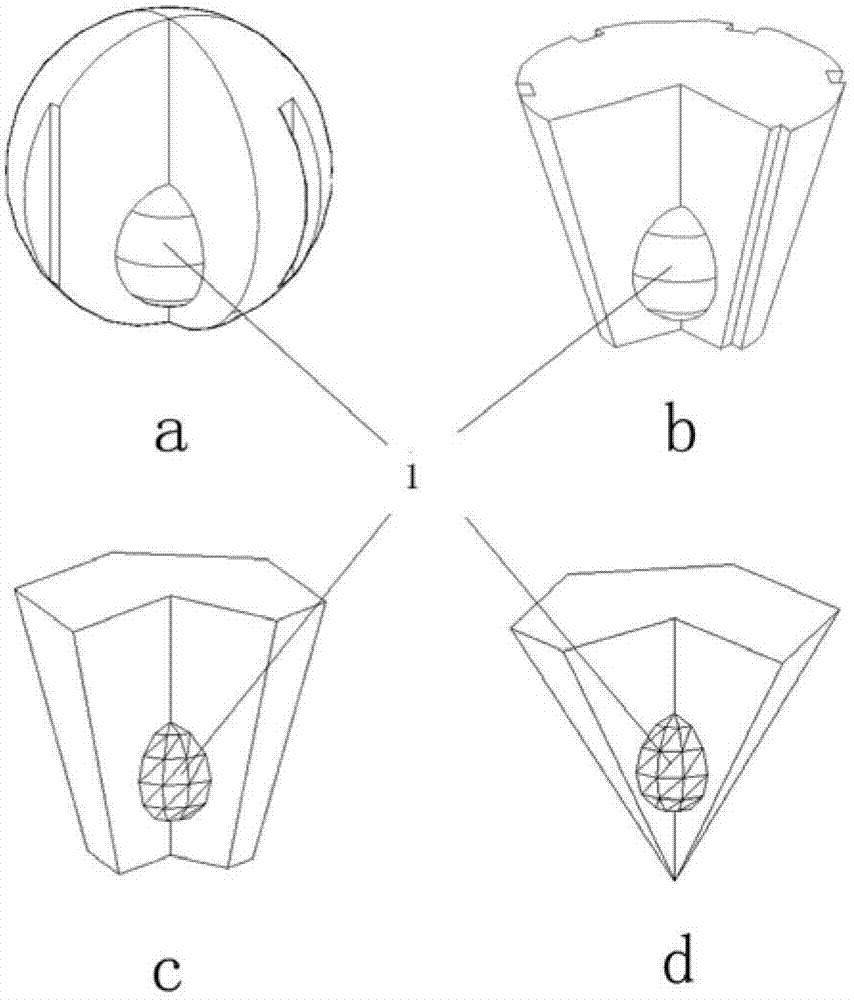

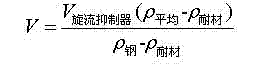

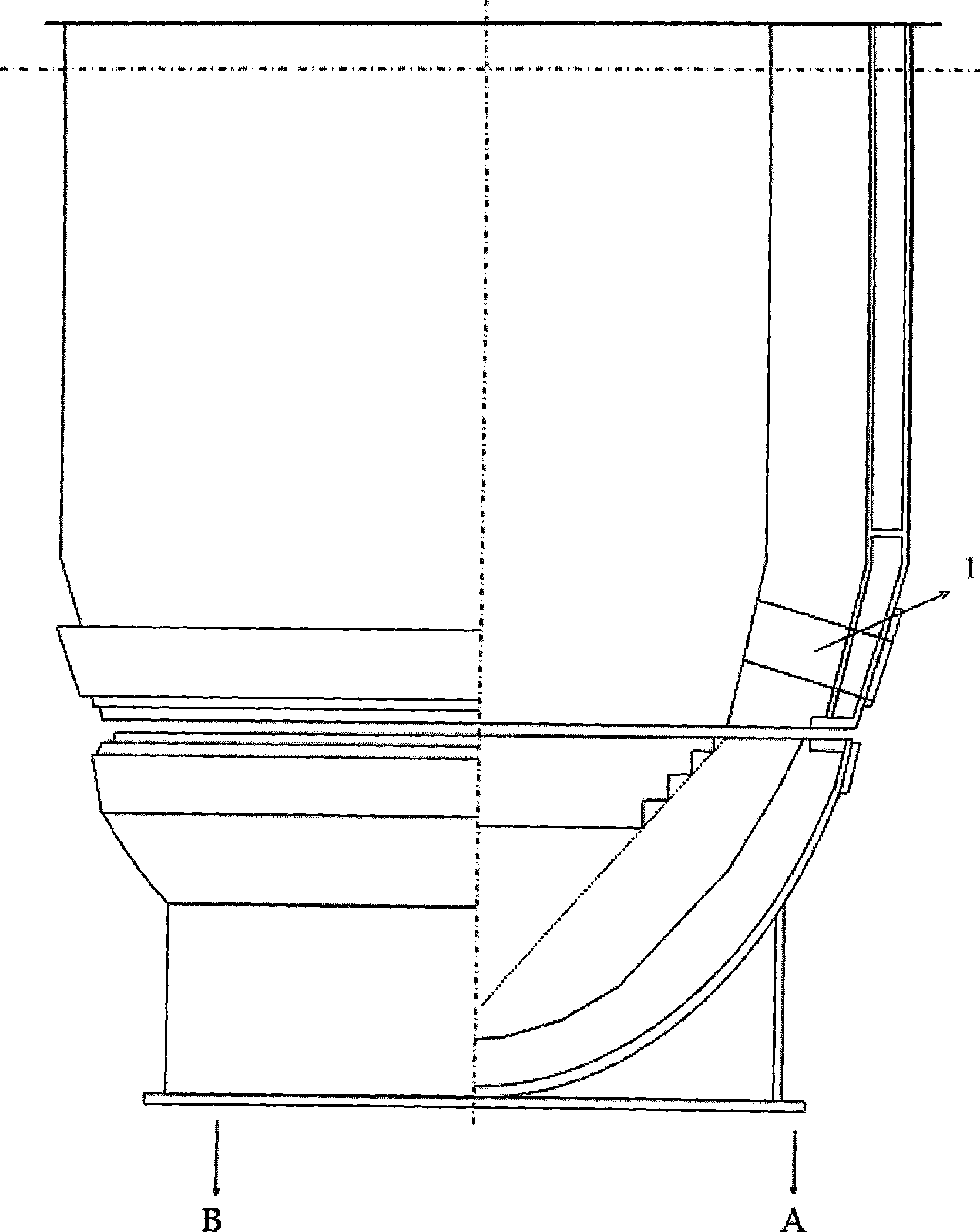

Method for restraining rotational flow of roughing slag in steel ladle during steel releasing of steel ladle

The invention belongs to the technical field of metallurgy and particularly relates to the technology of restraining of rotational flow in a steel ladle. A method for restraining the rotational flow is provided for avoiding the rotational flow generated during steel releasing of the steel ladle, reducing roughing slag quantity, shortening roughing slag height and improving molten steel use rate. The method includes that density measuring is conducted on protective slag and contained molten steel in the steel ladle, a density range of a rotational flow restraining device is determined, and a rotational flow restraining device body is manufactured by selecting appropriate materials. According to the actual size of the steel ladle and the actual size of a steel releasing port, relevant size of a pyramid-shaped rotational flow restraining device is designed and includes taper angles and taper height. The rotational flow restraining device meeting the requirements of buoyancy force and gravity is designed so that half of the rotational flow restraining device is soaked in a liquid slag layer, half of the rotational flow restraining device is soaked in the molten steel, a purpose that a flow field at the position of a scrap steel interface is disturbed, rotational flow can not be developed fully at the scrap steel interface, and the roughing slag quantity is reduced is achieved. The restraining device should meet the requirement that when the rotational flow restraining device is put in the steel releasing port, the steel releasing port can not be plugged, and the rotational flow restraining device is resistant to corrosion of the slag and the molten steel.

Owner:UNIV OF SCI & TECH BEIJING

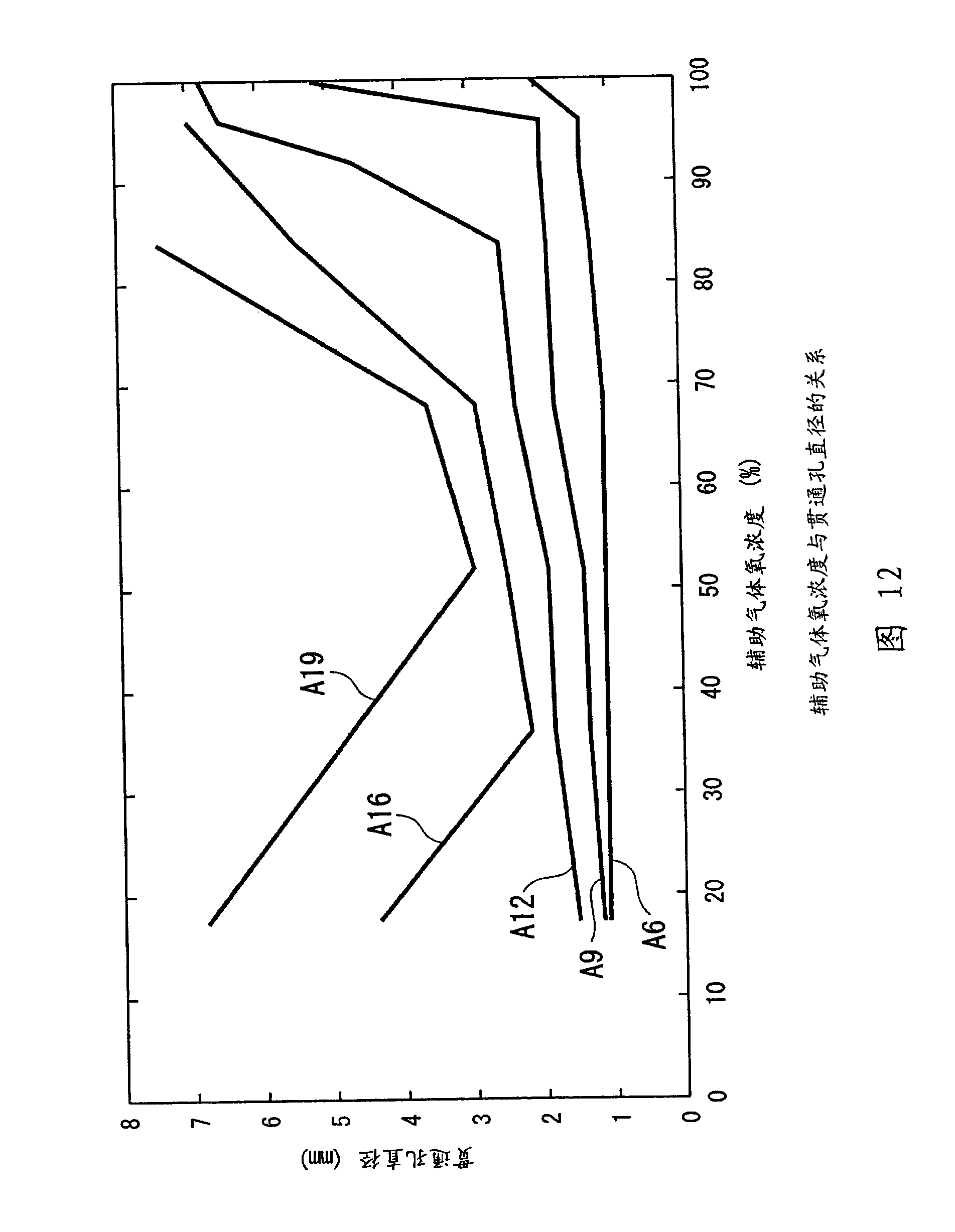

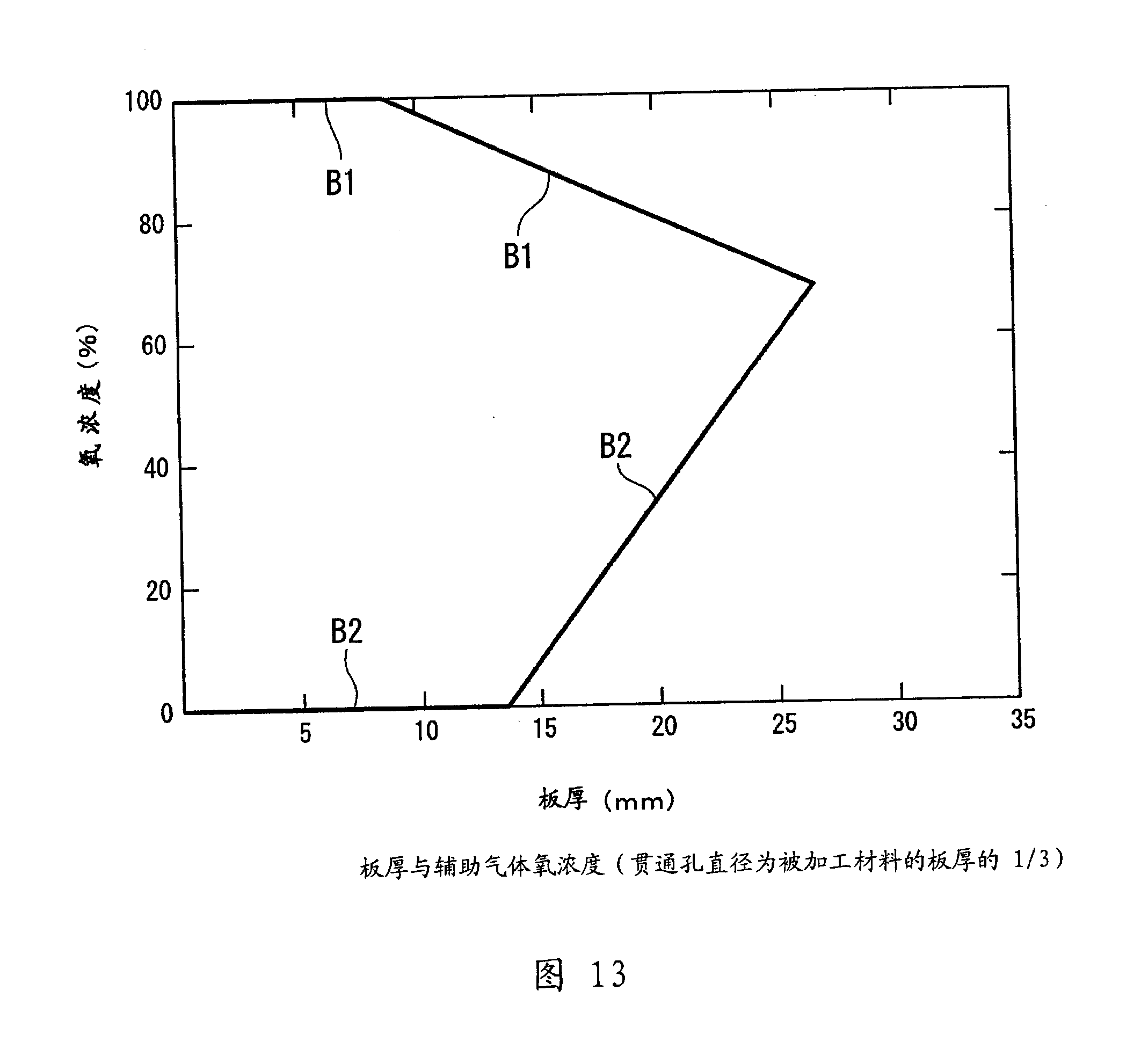

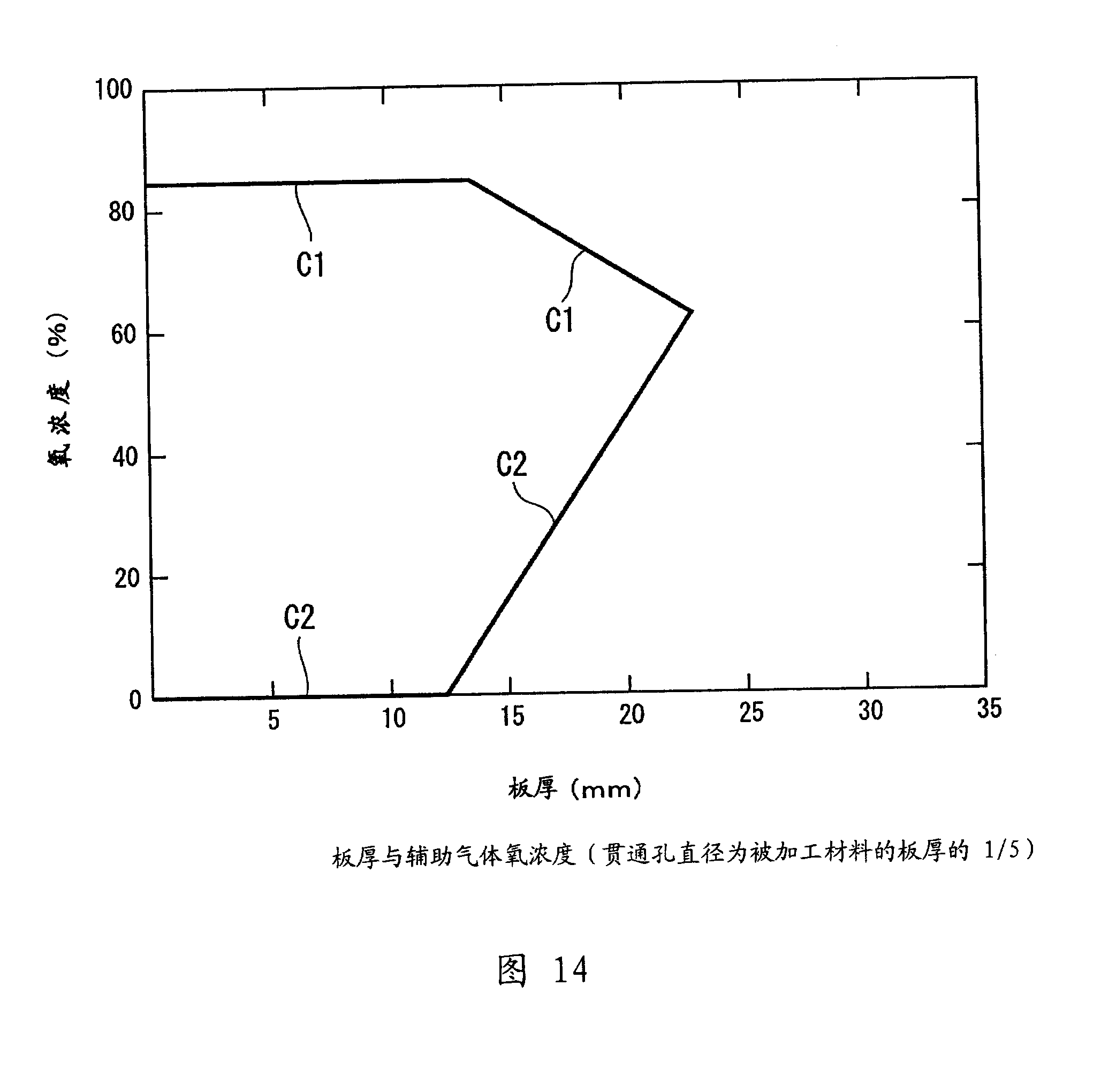

Laser piercing method, and machining apparatus

ActiveCN101218063AUnbalanced pressure balanceAvoid expansionWelding/soldering/cutting articlesLaser beam welding apparatusProcess equipmentEngineering

In processing equipment, a machining portion of a subject (W) to be machined is irradiated with a laser beam (L2), an assist gas (G) is jetted toward the machining portion from a nozzle (3) coaxially arranged with the laser beam (L2) to cover the machining portion with the assist gas (G), and a piercing hole (H) is machined at the machining portion. The machining equipment is provided with a control means (10) for machining the piercing hole (H) while shifting the nozzle (3) within a range from a machining start point to 5mm, after starting irradiation of the laser beams (L2).

Owner:NISSAN TANAKA

Production technology of 6-series alloy bar for anodic oxidation

The invention relates to a production technology of a 6-series alloy bar for anodic oxidation. The production technology of the 6-series alloy bar for anodic oxidation includes the following steps that (1) mixing is performed; (2) refining is performed; (3) blowing is performed, specifically, after blowing is performed on an alloy aluminum liquid, the liquid is left to stand at 730-750 DEG C; (4)online degassing is performed; (5) double filtration is performed; and (6) casting is performed, specifically, cooling water casting is performed after the alloy aluminum liquid passes through an oil-gas slip casting flow table. According to the production technology of the 6-series alloy bar for anodic oxidation, an advanced oil-gas slip casting production line in China at present is used as a core, the industrial pure aluminum liquid with the purity being 99.85% is used, methods of semi-continuous casting, in-furnace homogenization treatment and double-filtering equipment are adopted, the 6-series aluminum alloy bar product for anodic oxidation can be prepared finally, grain distribution in a cast bar is uniform, the content of aluminum alloy slag is low through high-magnification structure inspection, and segregation tumors, cold shut and other phenomena do not exist on the surface of the alloy bar.

Owner:XINJIANG JOINWORLD CO LTD

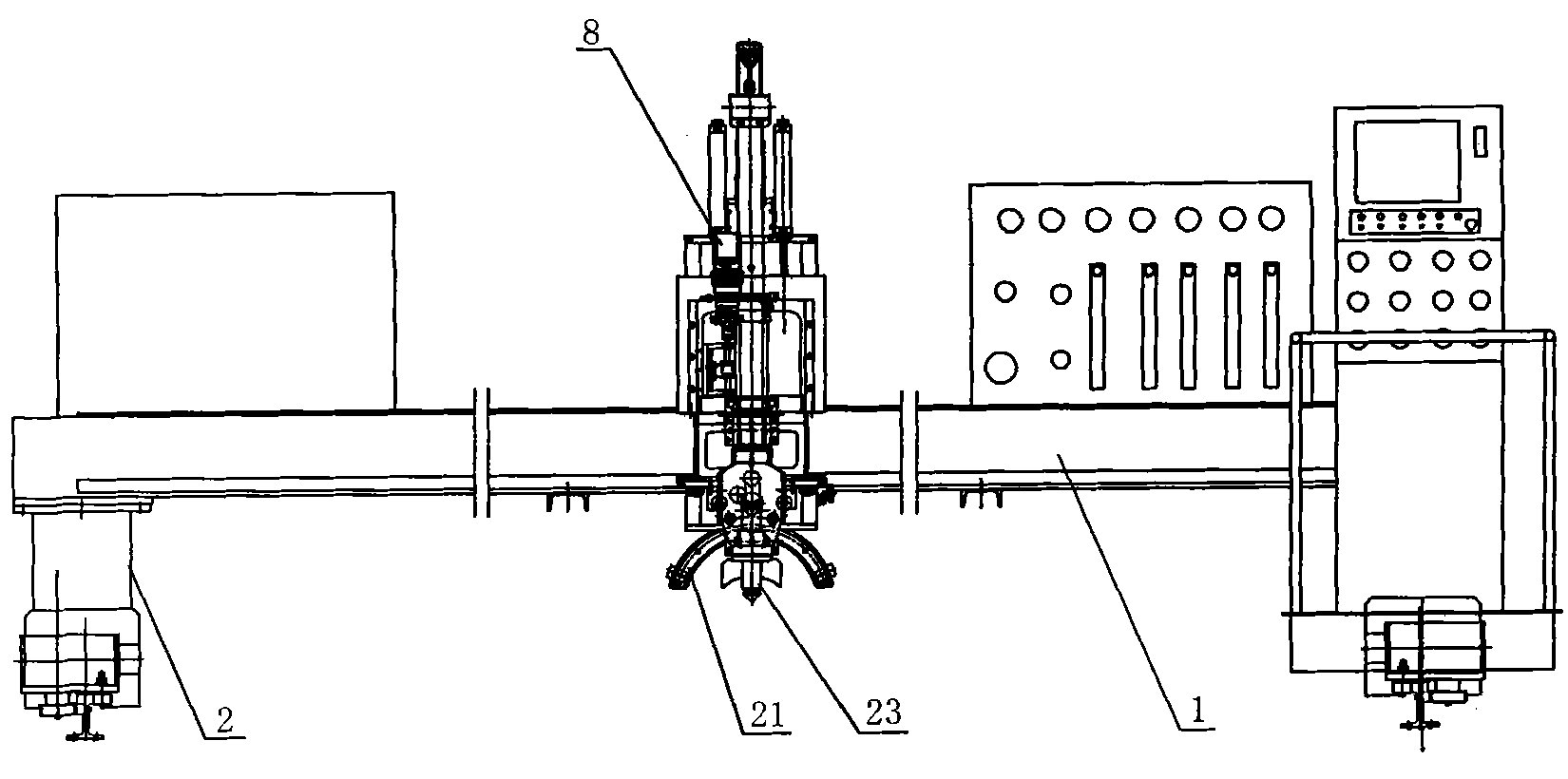

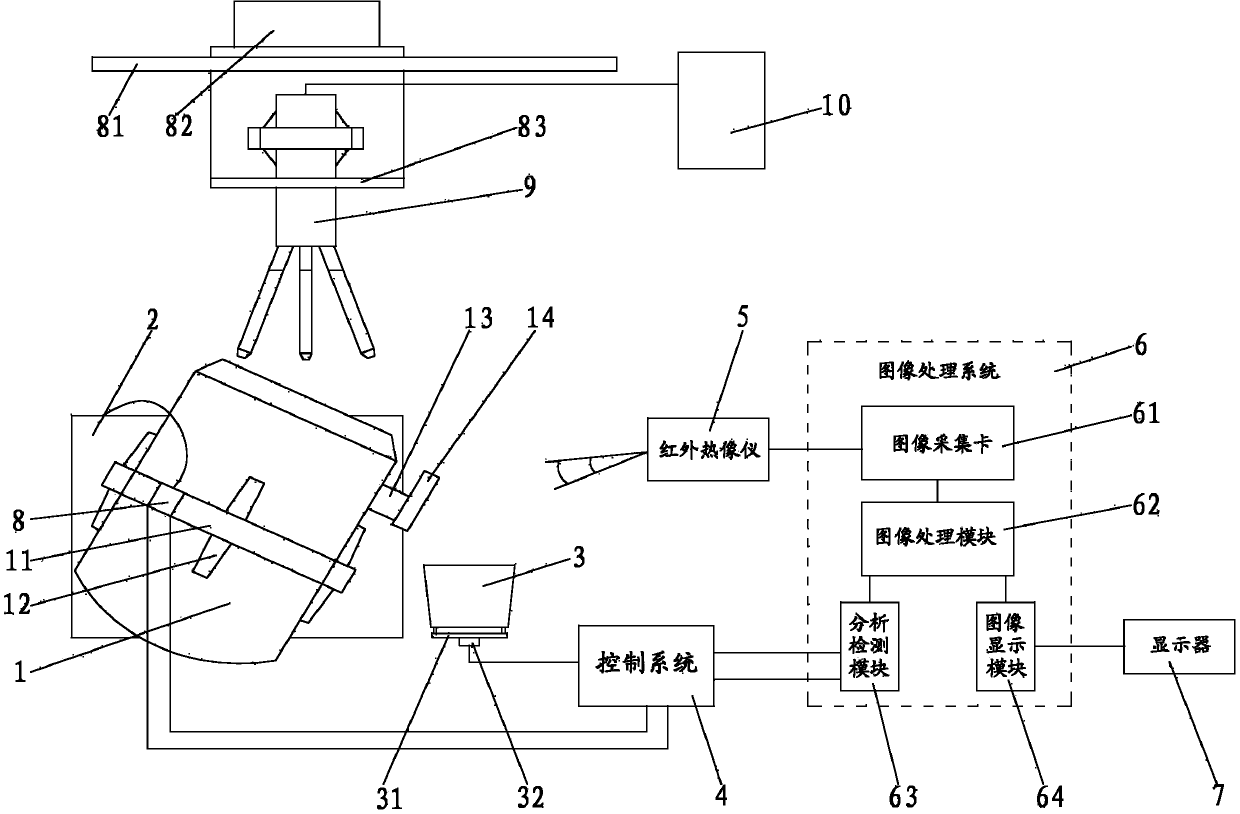

High-efficiency steelmaking converter system

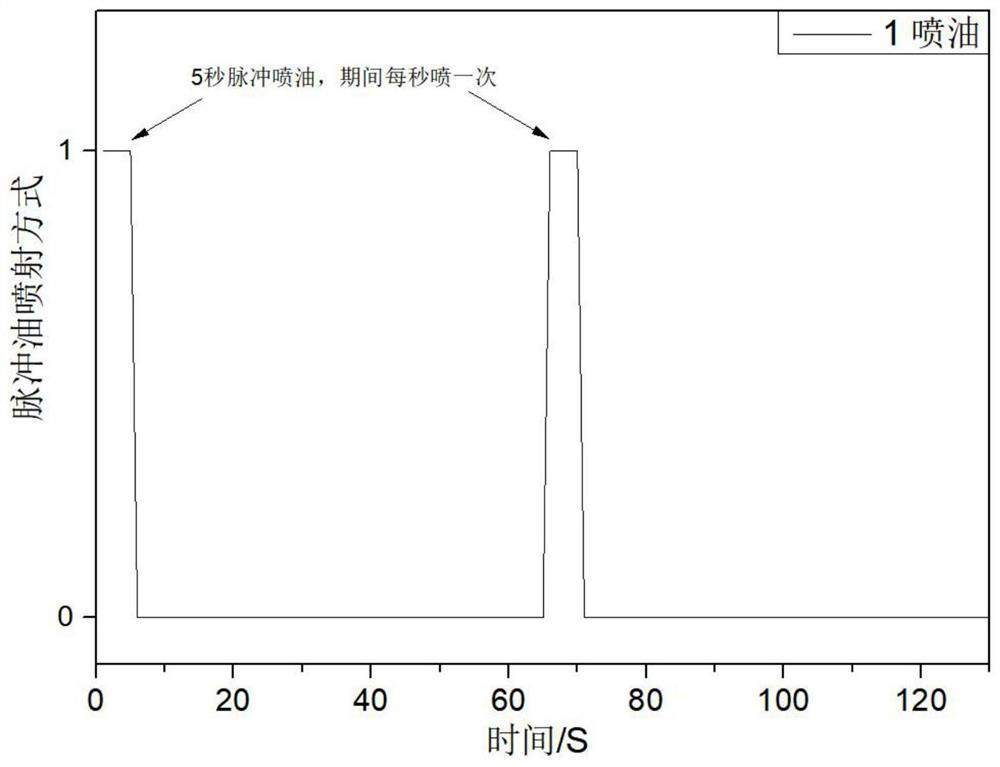

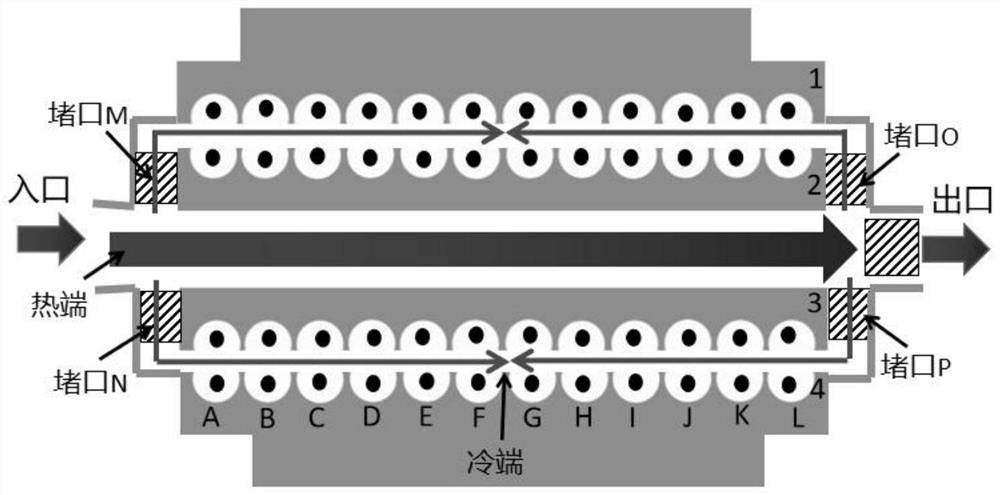

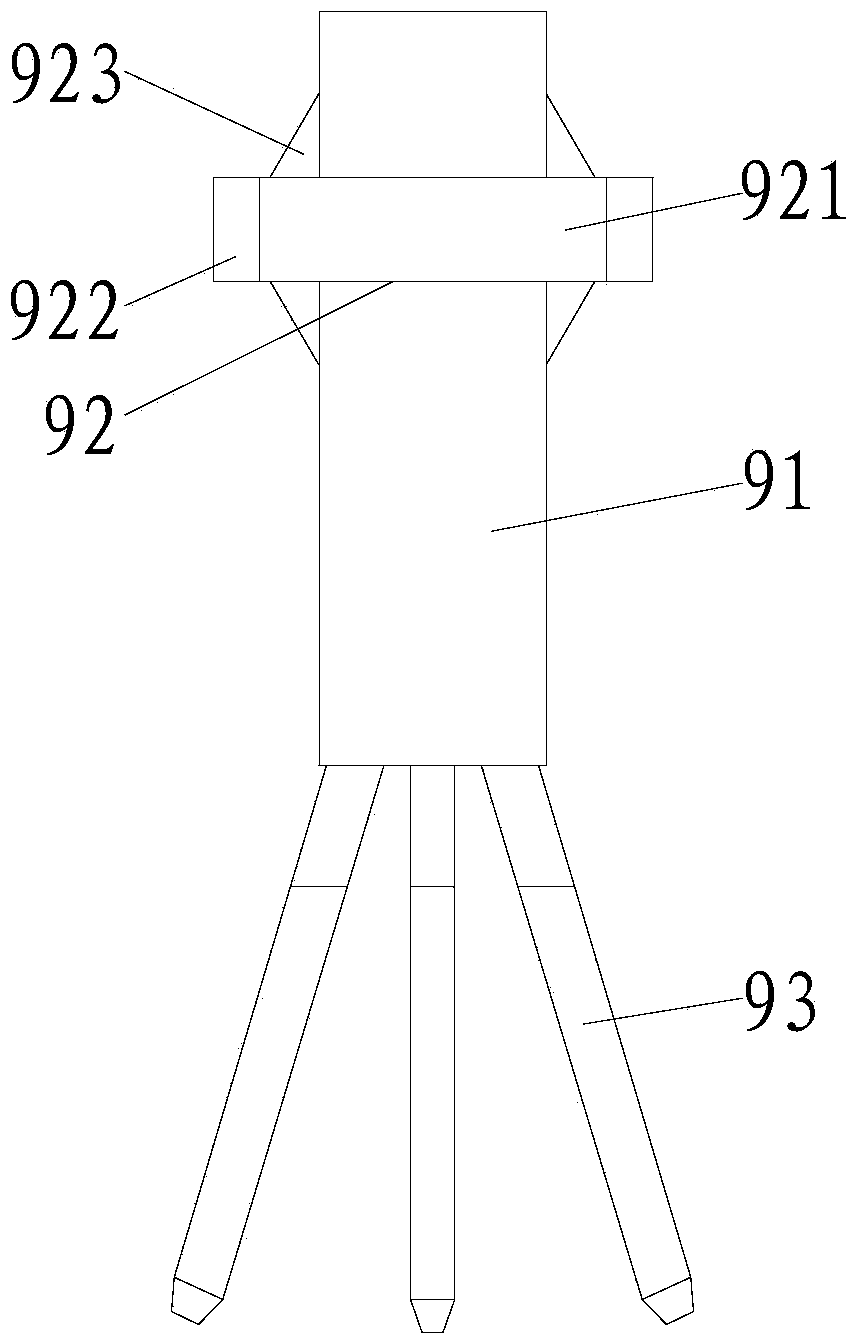

InactiveCN104195285AReduce consumptionReduce contentManufacturing convertersOxygen supplyImage processing

The invention discloses a high-efficiency steelmaking converter system. The high-efficiency steelmaking converter system comprises a converter, an oxygen lance system, an oxygen supply system, a tilting mechanism, a steel ladle, a control system, a thermal infrared imager, an image processing system and a display; the oxygen lance system is located above the converter, and is composed of a suspension rod, a hydraulic control system and an oxygen lance assembly; the hydraulic control system is mounted on the suspension rod; the oxygen lance assembly is mounted on the suspension rod by use of a lifting device; a backing ring is mounted on the converter; one side of the backing ring is connected with the tilting mechanism; an angle encoder is mounted on the other side of the backing ring; the angle encoder is connected with the tilting mechanism and the control system; the steel ladle is located between the converter and the thermal infrared imager; the thermal infrared imager is connected with the image processing system; the control system is connected with the image processing system; the display is further connected to the image processing system. The high-efficiency steelmaking converter system is capable of effectively improving the quality of molten steel and reducing the steelmaking cost.

Owner:ZHEJIANG TIANXIANG ENVIRONMENTAL PROTECTION EQUIP

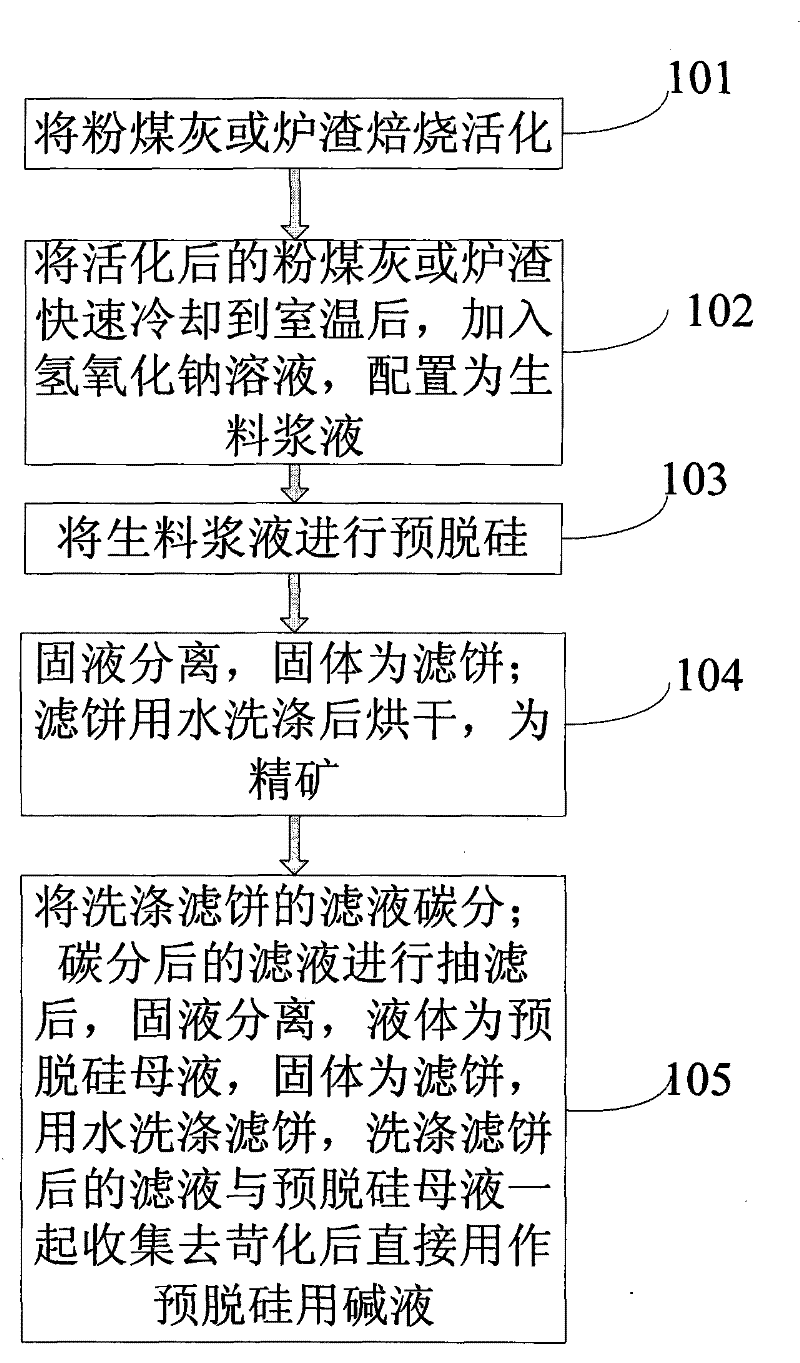

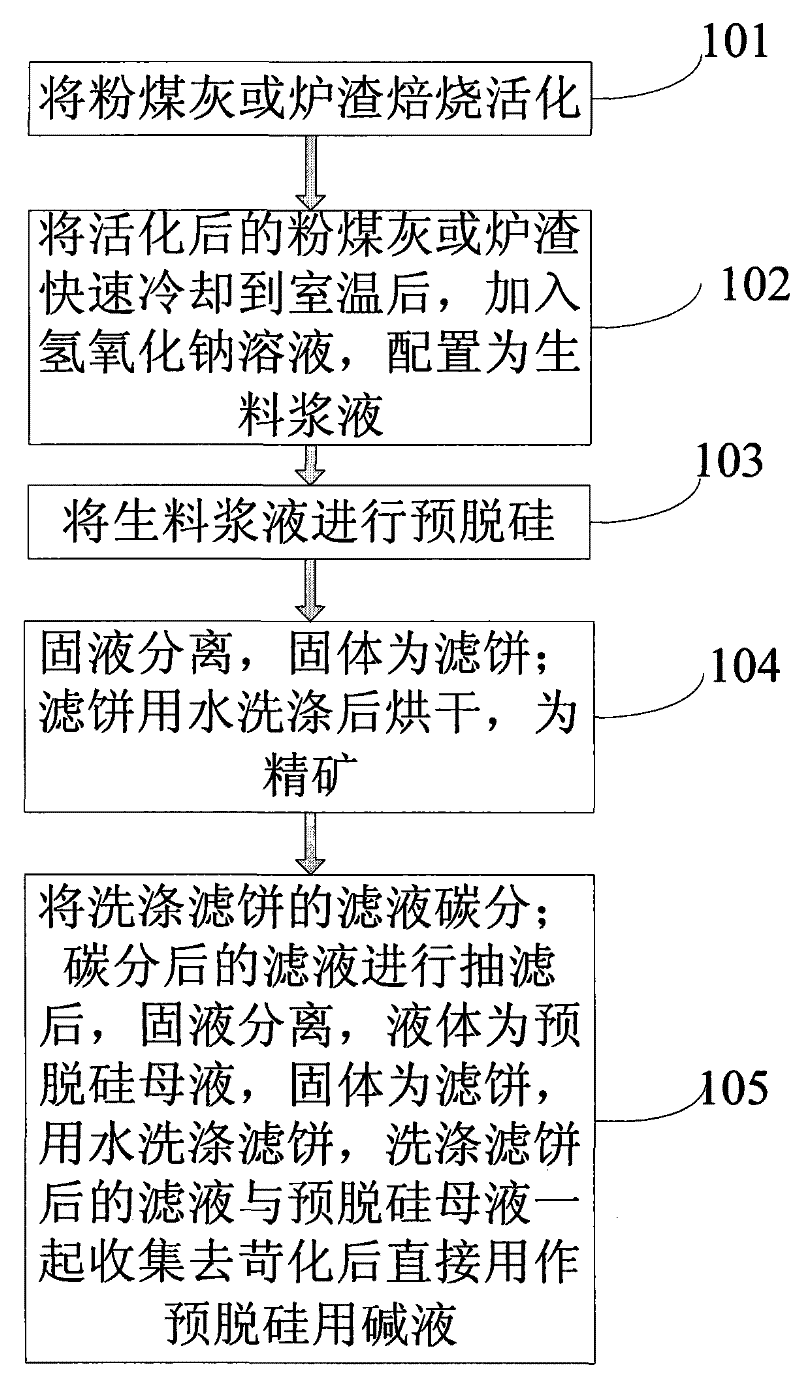

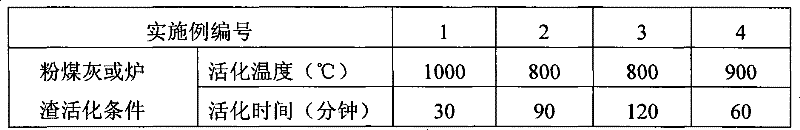

Pre- desiliconizing method from fly ash or slag

ActiveCN101306928BIncrease Al-Si RatioReduce the amount of raw material to be burnedSolid waste managementCooking & bakingSlag

The invention relates to a method for the comprehensive application of fly ash or slag, in particular to a method for the predesilication of the fly ash or the slag. The method mainly comprises the process flows including the baking and the activation of the fly ash or the slag, the formula process of the raw meal of activated the fly ash or the slag and a sodium hydroxide solution and the production of white carbon black. Through adopting a technological line during which the fly ash or the slag are baked and activated at first and then a sodium hydroxide solution is used to extract noncrystalline silicon oxide at a low temperature, the method ensures that the mass ratio of aluminum oxide and silicon oxide of desilicated fly ash reaches to 2.14; therefore, the method breaks a new path totake the fly ash or the slag as a raw material source for extracting metallurgical-grade aluminum oxide, thereby increasing the comprehensive utilization value of the fly ash and the slag.

Owner:北京世纪地和控股有限公司

Protecting pouring method of crystallizer feeding steel belt

The invention discloses a protecting pouring method of a crystallizer feeding a steel belt. The method comprises the following steps that (1) the liquid surface of the crystallizer is divided by a baffling board into a feeding area and a normal area, (2) when the crystallizer feeds the steel belt, casting powder is added in the normal area and the feeding area, hollow fireproof material balls are added in the feeding area, the width of the steel belt fed by the crystallizer is 10-20% of the width of the crystallizer, the thickness of the steel belt is 0.1-1% of the length of the crystallizer, and the feeding speed is 0.3-0.6m / s. The method is low in cost, simple and effective.

Owner:SHANDONG IRON & STEEL CO LTD

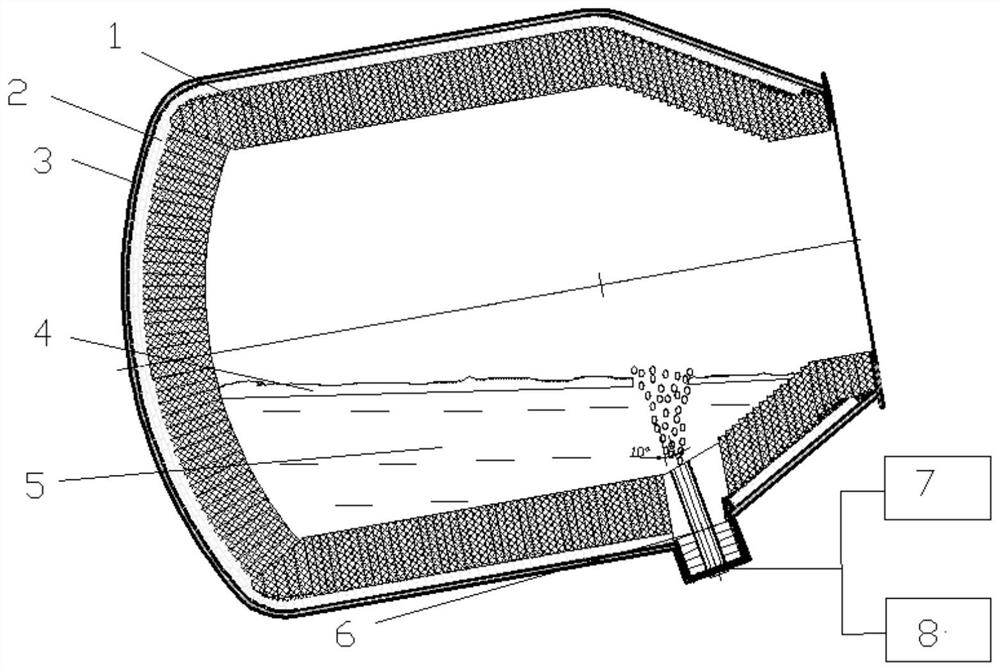

Method for deflection bottom tapping of revolving furnace

InactiveCN101368223ASolve the problem of slagReduce back phosphorusManufacturing convertersSlagEngineering

The invention discloses a method used for tapping through deflecting the bottom of a convertor, which is characterized in that the tapping opening of the converter is designed at the lower part of the converter; the position at the upper end of the tapping opening is arranged below a molten liquid surface; the lower end is higher than the slag surface after tapping in the convertor only with the slag left by 10 to 20cm; the diameter of the tapping opening is between 10 and 20cm; when the smelting reaches the end point, the converter is deflected by 20 to 60 degrees; the rotated angle leads the position of the tapping opening to be arranged at the lowest side of the converter; then the tapping opening is opened, the molten steel flows into a ladle arranged below the tapping opening; after the molten steel flows out, the converter is resumed to the normal vertical position and the ladle is removed, then the liquid surface of slag is lower than the lowest position of the tapping opening of the converter; then the ladle is arranged below the converter and the converter is deflected to lead the opening of the converter to face the lower side; and then the slag is spilled out from the opening of the converter. The method used for tapping through deflecting the bottom of a convertor solves the problem of slag during the tapping of the converter, ensures the slag amount of the converter to be lower than 0.5kg / t. Not only the rephosphorization of the molten steel can be reduced and the alloy recycling rate is improved, but also the occluded foreignsubstance in the steel can be reduced and the cleanness of the molten steel can be improved. Besides, the refining time can be shortened and the desulfurization degree can be improved.

Owner:UNIV OF SCI & TECH BEIJING

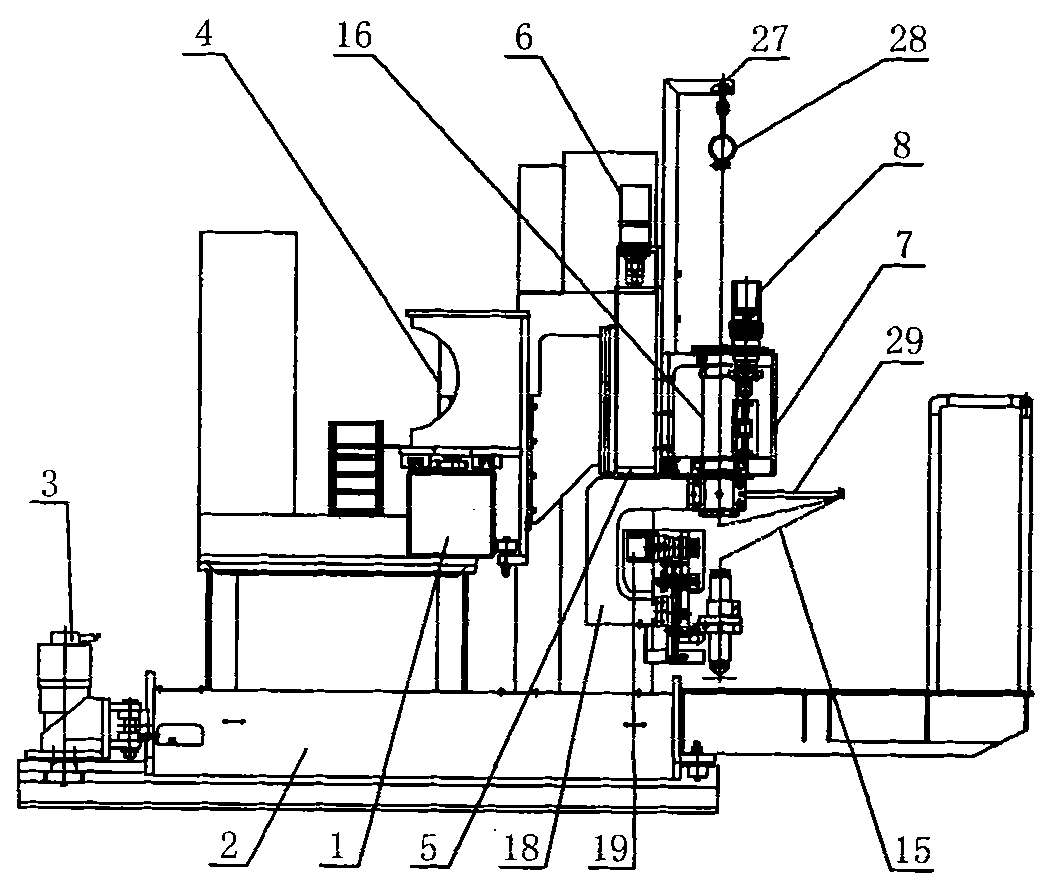

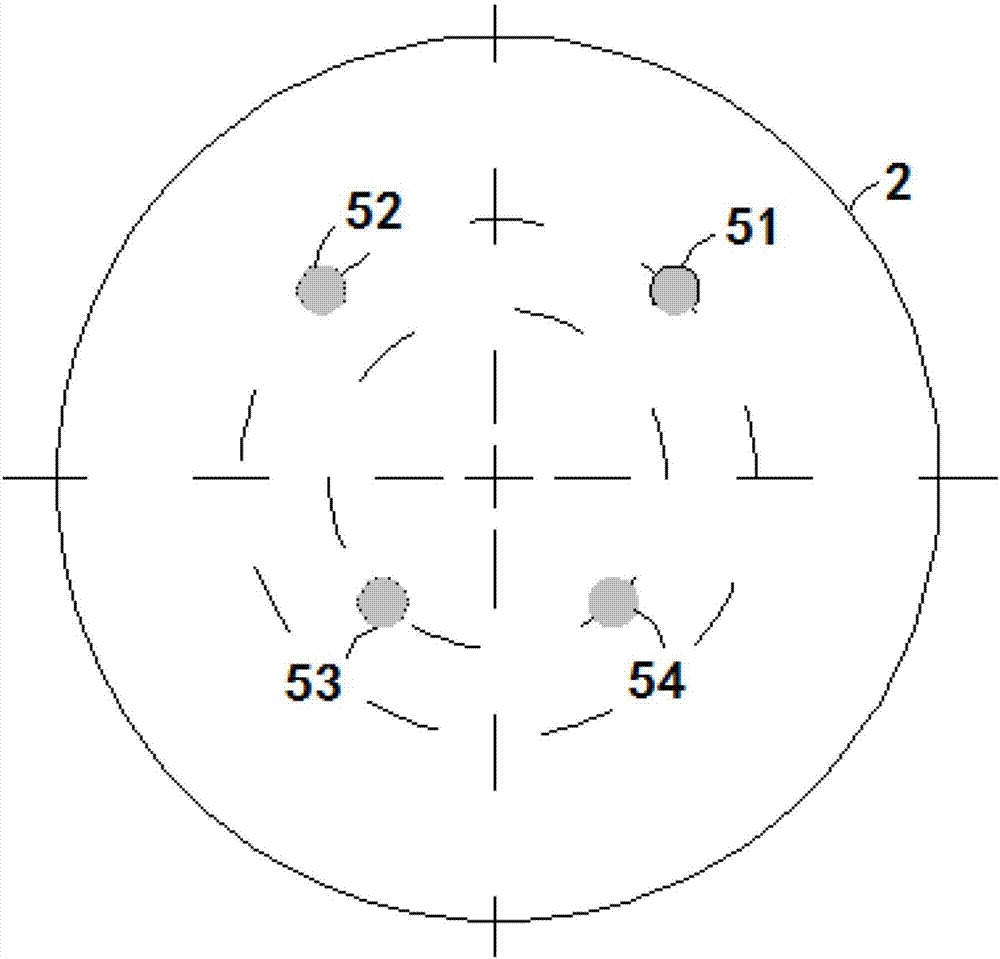

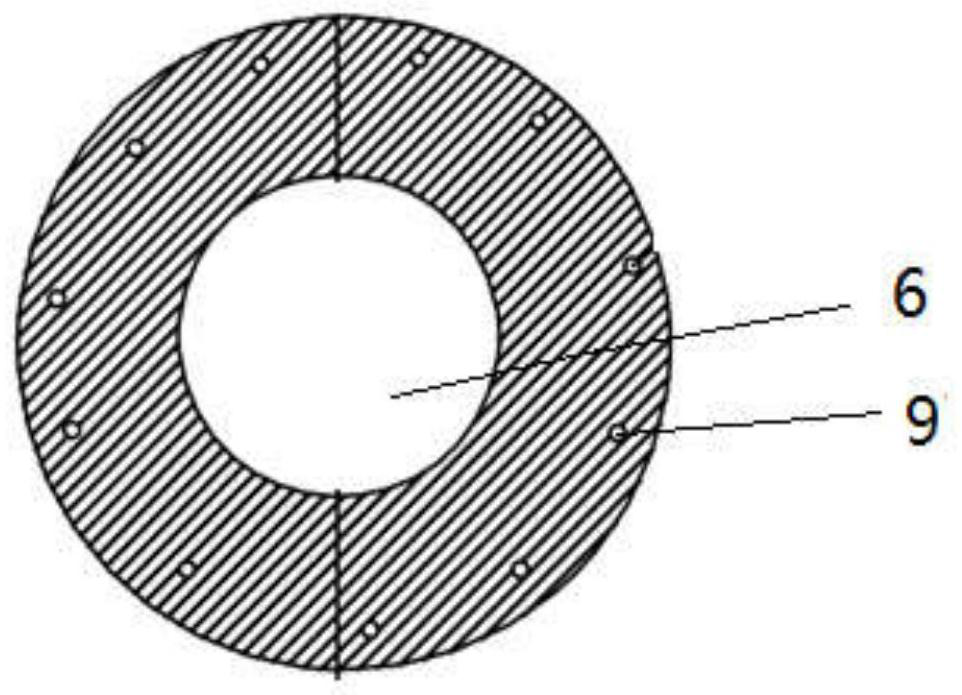

Molten iron tank top and bottom composite blowing desulfurization method

The invention belongs to the technical field of steel-making pre-desulfurization and discloses a molten iron tank top and bottom composite blowing desulfurization method. Adopted equipment comprises a top-blowing structure arranged in a molten iron tank and a bottom-blowing structure arranged at the bottom of the molten iron tank. The bottom-blowing structure comprises a first bottom-blowing ventilation element, a second bottom-blowing ventilation element, a third bottom-blowing ventilation element, a fourth bottom-blowing ventilation element and a blowing device connected with the four bottom-blowing ventilation elements. The first bottom-blowing ventilation element and the second bottom-blowing ventilation element are arranged in the portions, at a one-second distance from the circular center radius, of the bottom of the molten iron tank, and the circle center angles of the first bottom-blowing ventilation element and the second bottom-blowing ventilation element to the circle center are each 90 degrees. The third bottom-blowing ventilation element and the fourth bottom-blowing ventilation element are arranged in the portions, at a one-third distance from the circular center radius, of the bottom of the molten iron tank, and the circle center angles of the third bottom-blowing ventilation element and the fourth bottom-blowing ventilation element to the circle center are each 90 degrees. According to the molten iron tank top and bottom composite blowing desulfurization method, the flow field dynamics in the blowing process of the molten iron tank is optimized, and the thermodynamic and dynamic conditions required for deep desulfurization are met.

Owner:SHOUGANG CORPORATION

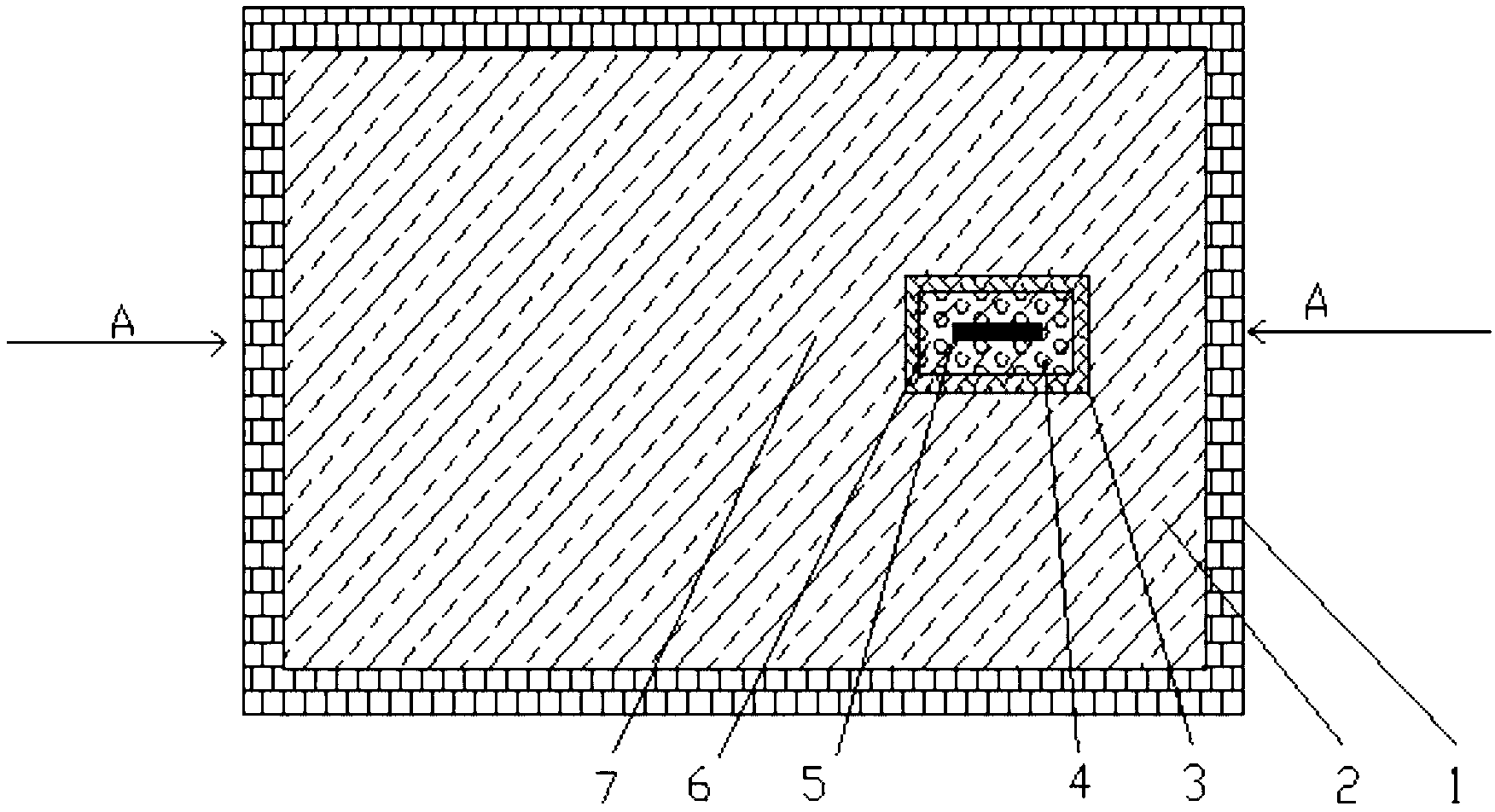

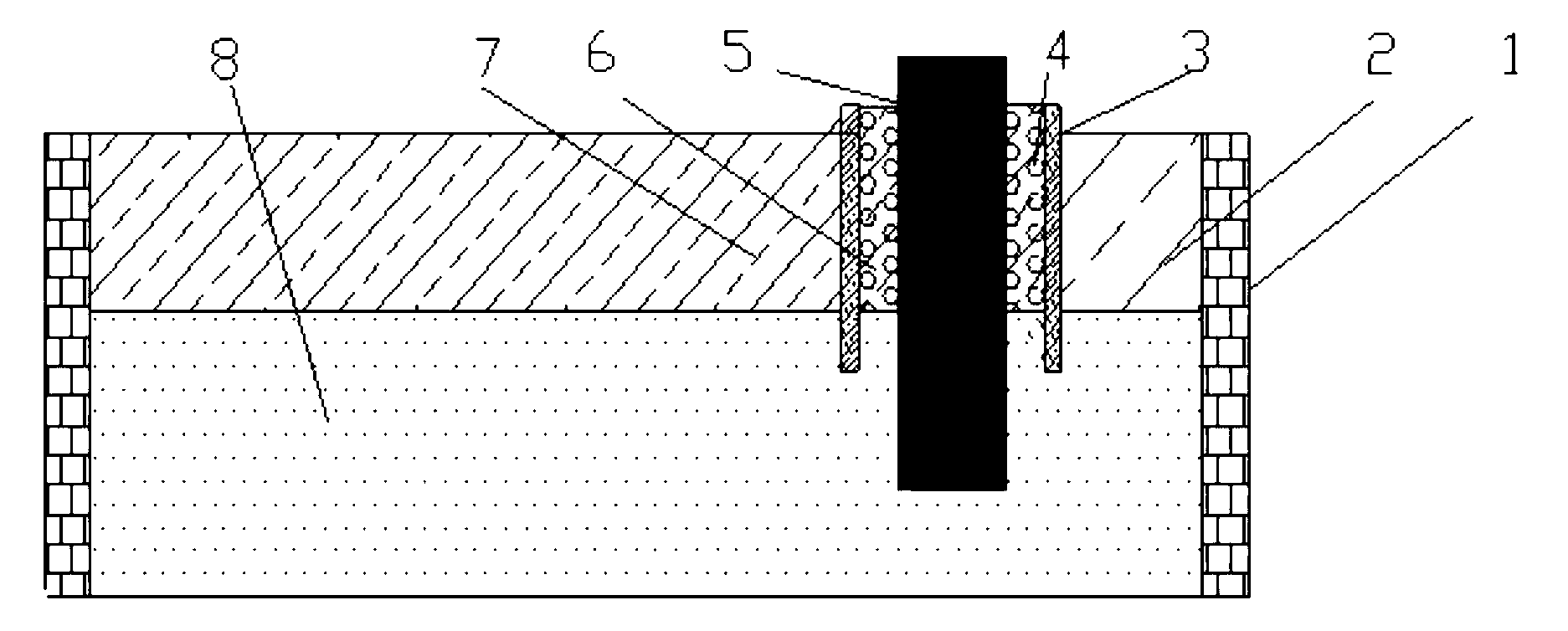

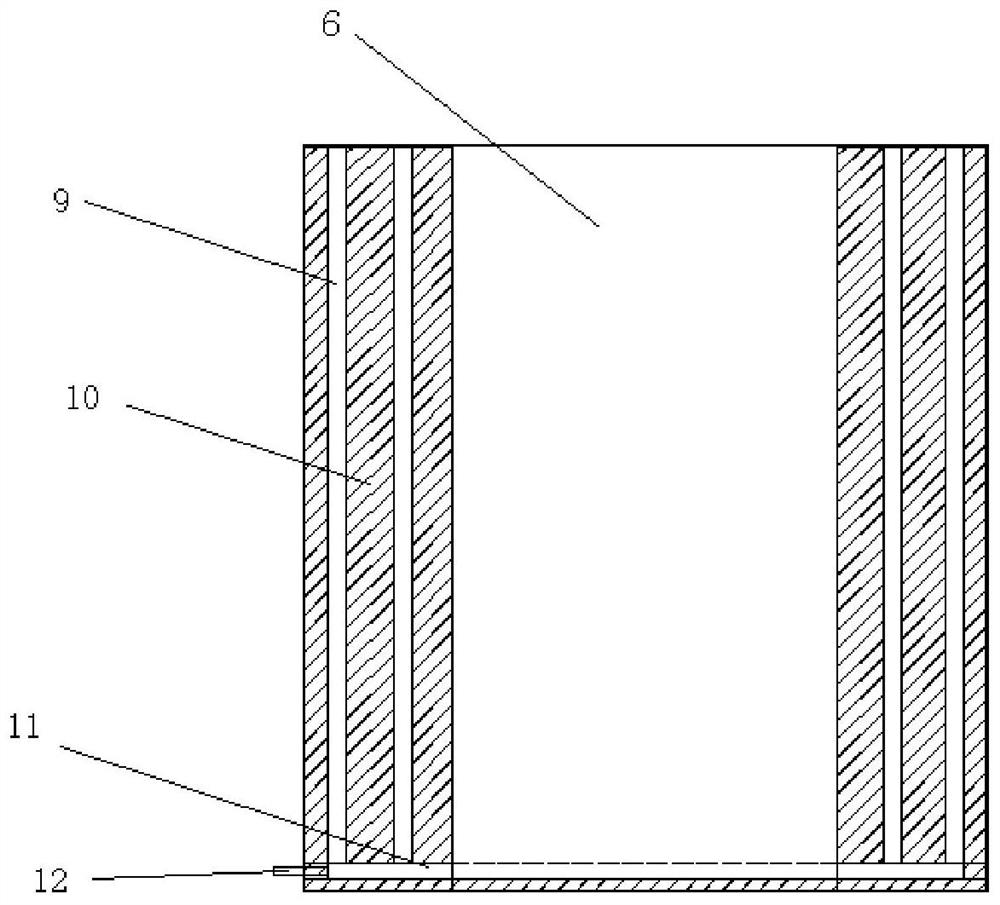

Device and method for reducing slag amount in tapping process of steelmaking converter

PendingCN112593043AReduce back phosphorusReduce sticky residueManufacturing convertersSteelmakingBrick

The invention belongs to the technical field of converter smelting, and particularly provides a device for reducing the slag amount in the tapping process of a steelmaking converter. The device comprises a converter, a converter tapping hole and a gas source structure, wherein a converter lining is arranged on the inner wall of the converter, a magnesite brick permanent layer is adopted as the converter lining, and working layer bricks are built on the converter lining; and a refractory material pipe with thickness is arranged at the tapping hole, a plurality of uniformly distributed air inletslots are formed in the wall of the refractory material pipe, an annular air chamber is arranged at the bottom of the refractory material pipe, and the bottom ends of the plurality of air inlet slotsrespectively communicate with the annular air chamber. The device is simple in structure, convenient to operate and low in investment, vortex slag entrapment in the tapping process can be effectivelyinhibited, the slag amount in the tapping process of the steelmaking converter is reduced, molten steel rephosphorization can be reduced, the alloy yield is increased, inclusions in steel can be reduced, the molten steel cleanliness is improved, steel ladle slag adhesion can be reduced, the service life of a steel ladle is prolonged, and good conditions can be provided for molten steel refining,so that the quality of molten steel is improved.

Owner:BENGANG STEEL PLATES

Method for Al-Si-Fe alloy preparation and magnesium reduction in Pidgeon-process magnesium reduction process

InactiveCN107090547AAchieve reduction efficiencyLow costProcess efficiency improvementSmelting processReaction temperature

The invention discloses a method for Al-Si-Fe alloy preparation and magnesium reduction in a Pidgeon-process magnesium reduction process. The method comprises the following steps: (1) mixing calcined dolomite, powdered aluminium, silicon iron and calcium fluoride, pressing the mixture into balls to obtain mixed balls, then filling a magnesium reduction tank with the mixed balls, and enabling heating reaction; and (2) performing cooling after finish of reaction, performing vacuum breaking, and collecting volatilized magnesium in the format of elemental magnesium, wherein the mass percents of calcined dolomite, powdered aluminium, silicon iron and calcium fluoride in the mixed balls in the step (1) are 80-85%, 1-12%, 4-15% and 1-3%; and the reaction temperature in the step (1) is 1,000-1,300 DEG C, and the heat preservation reaction time is 1-12 h. According to the method, in the Pidgeon-process magnesium reduction process, aluminum and silicon iron react to produce Al-Si-Fe alloy, and the Al-Si-Fe alloy serves as a reductant in the traditional Pidgeon-process magnesium smelting process to reduce magnesium oxide in calcined dolomite; and the cost caused by using the Al-Si-Fe alloy in the magnesium reduction process is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com