Method for deflection bottom tapping of revolving furnace

A converter and tapping hole technology, applied in the manufacture of converters, etc., can solve the problems affecting the desulfurization performance of slag, refining time, unavoidable slag entering molten steel, high content of slag ΣFeO, etc., to shorten the refining time, Effect of reducing inclusions and improving desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

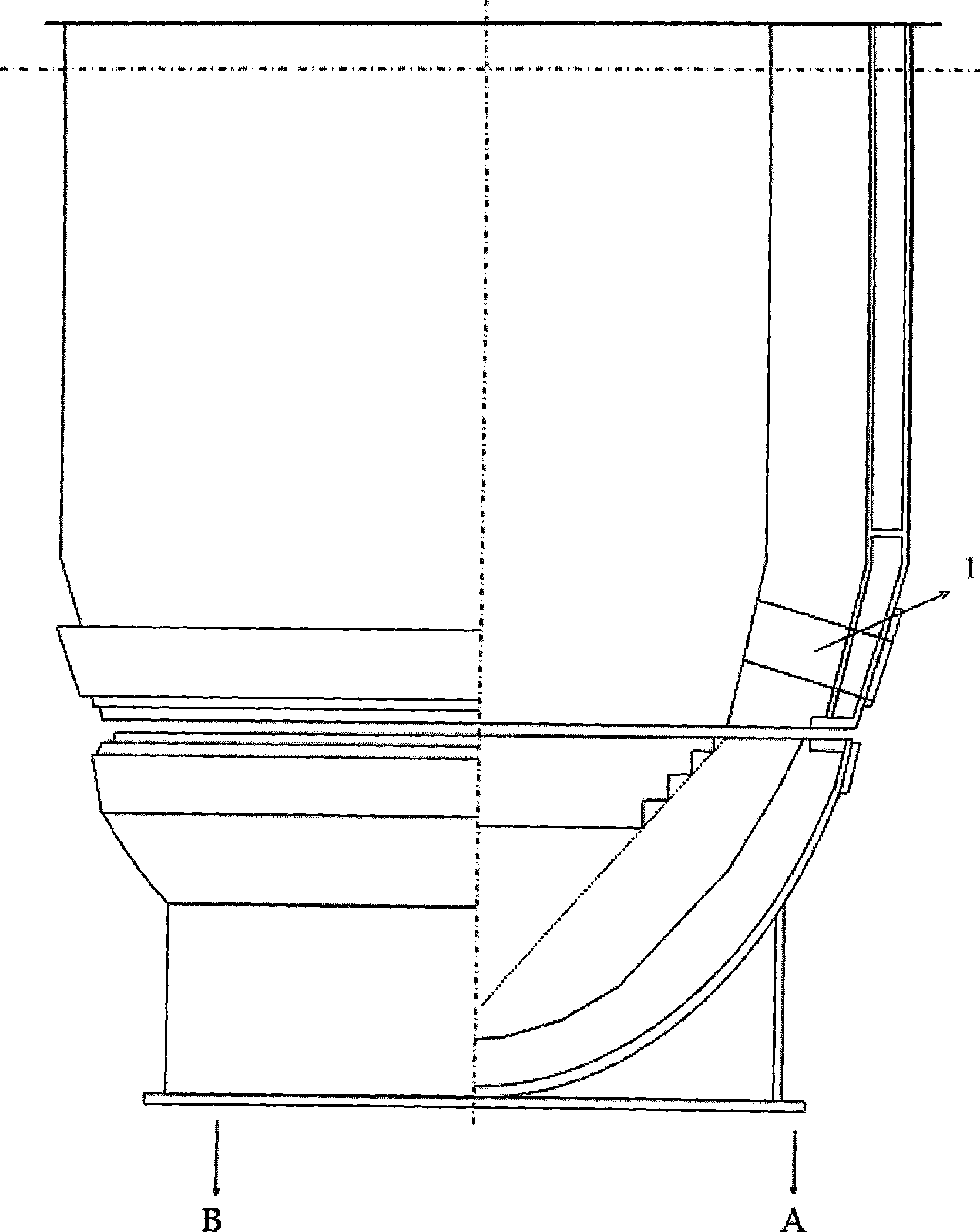

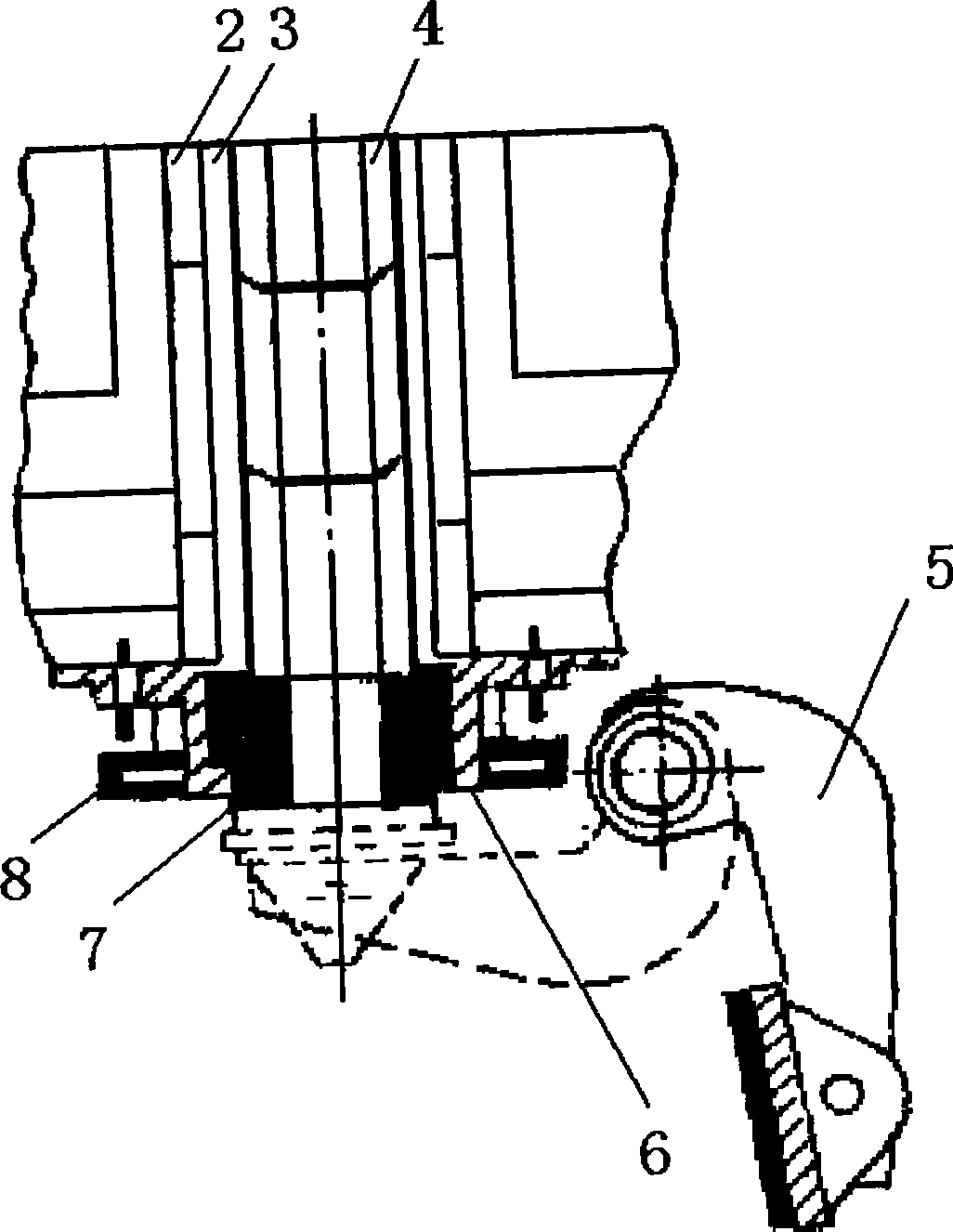

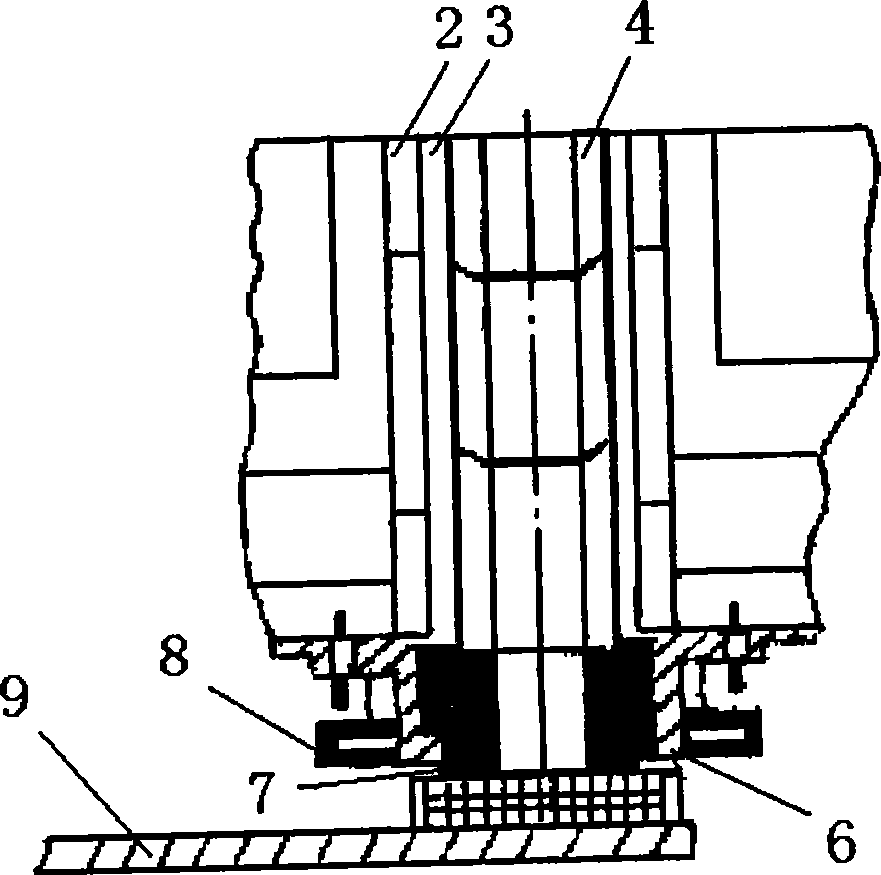

[0015] The operation steps for tapping are as follows: when the smelting reaches the end point, tilt the converter, place the tapping hole at the lowest point of the converter——open the sealing cover at the bottom of the tapping hole (completed by the opening and closing mechanism at the tapping hole)—— Tapping; after tapping, fill the taphole with mixed filler, close the sealing cover at the bottom of the taphole (the slag reaches the taphole, which can be determined by the vortex detection device or manually judged) - restore the converter to the vertical direction - Place the slag bag under the converter - Tilt the converter so that the mouth of the converter is vertically downward - Discharge the slag. After the slag is discharged, the converter is rotated to the normal position, and the smelting of the next furnace is started.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com