Patents

Literature

32results about How to "Oxidation barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

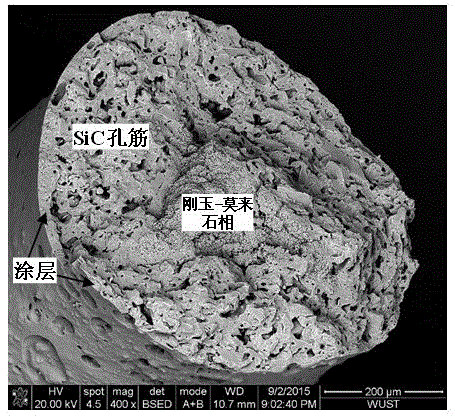

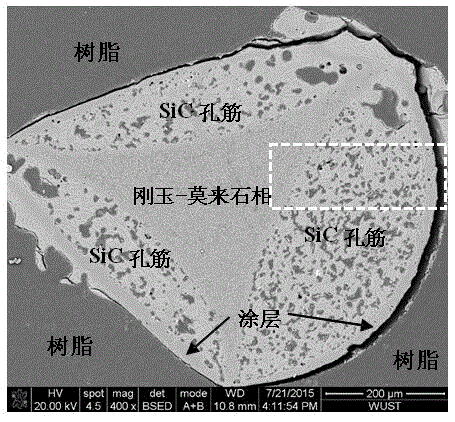

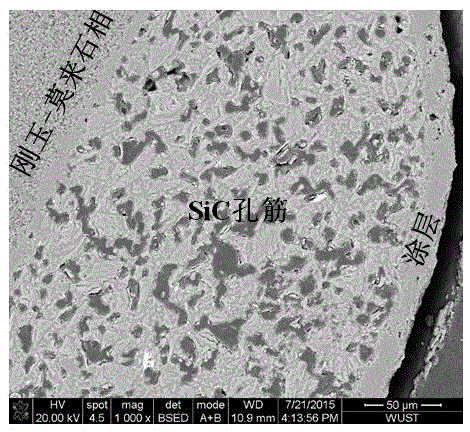

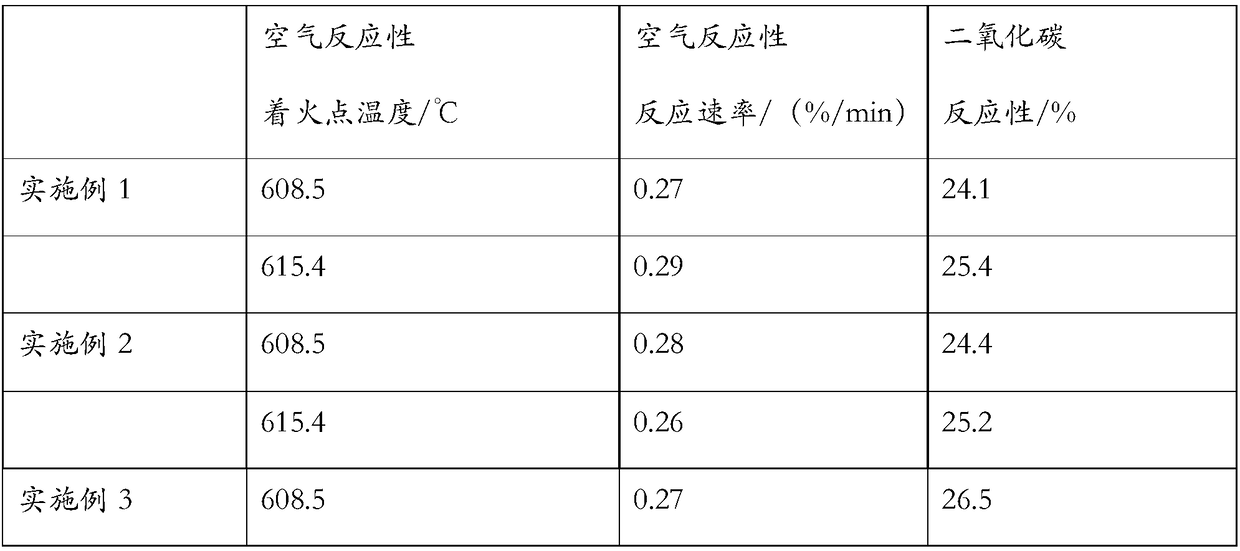

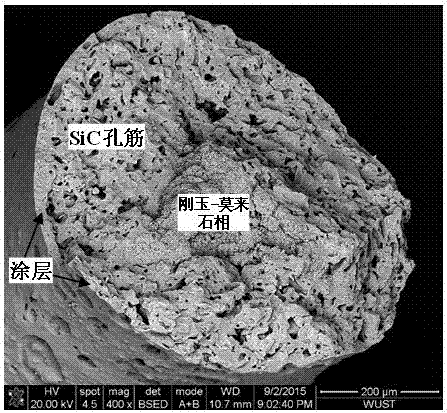

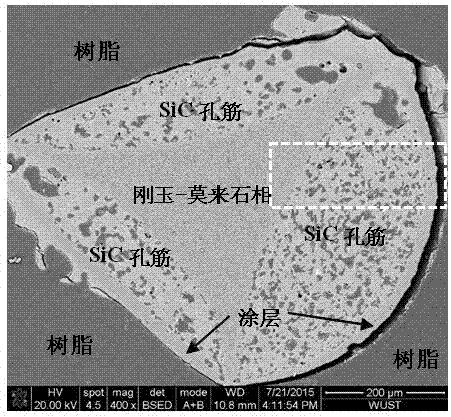

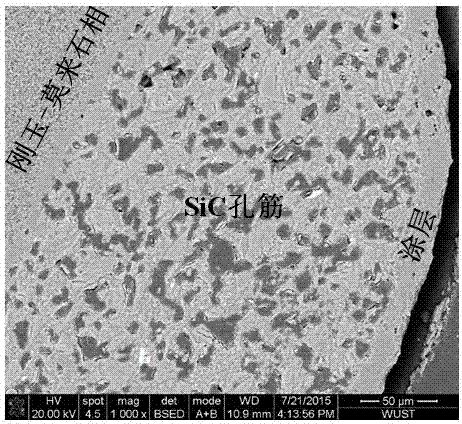

Silicon carbide-based composite foamed ceramic of multilayer hole rib structure and preparation method thereof

The invention discloses a silicon carbide-based composite foamed ceramic of a multilayer hole rib structure and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing silicon carbide, micro alumina powder, silicon powder, ammonium lignosulfonate, polycarboxylate and water so as to prepare slurry I; uniformly mixing micro alumina powder, a silicon source polycarboxylate and water so as to prepare slurry II; then dipping polyurethane sponge in the slurry I, and successively carrying out extruding or slurry centrifugation, drying and heat preservation at 600 to 850 DEG C for 0.5 to 3 h so as to obtain a presintered body of silicon carbide foamed ceramic; subjecting the presintered body of silicon carbide foamed ceramic to vacuum dipping in the slurry II and successively carrying out slurry centrifugation and drying so as to obtain a green body of silicon carbide-based composite foamed ceramic; and carrying out heat preservation at 1300 to 1500 DEG C in an air atmosphere for 2 to 4 h so as to prepare the silicon carbide-based composite foamed ceramic of the multilayer hole rib structure. The preparation method has the characteristics of simple process and low cost; and the prepared silicon carbide-based composite foamed ceramic of the multilayer hole rib structure has high mechanical strength, good thermal shock resistance and excellent high-temperature anti-oxidation performance.

Owner:WUHAN UNIV OF SCI & TECH

Processing method for inhibiting browning of dried fruit slices

ActiveCN105248626AOxidation barrierEasy to controlFood processingFruits/vegetable preservation by coatingPre coolingDrug biological activity

The invention discloses a processing method for inhibiting browning of dried fruit slices. The processing method comprises the following steps: raw material pretreatment, plant colloid embedding, liquid nitrogen pre-cooling, low-temperature mixed gas quick freezing, low-temperature vacuum lyophilization, heat pump drying and packaging. According to the processing method, the shortcomings of the existing dried fruit slice processing method and the quality defect of a product are overcome; the processing time is further shortened, the energy consumption is reduced, the production efficiency is improved, browning of the dried fruit slices is effectively inhibited, the drying quality is high, the color, the fragrance, the shape, the biological activity and the nutritional components of the dried fruit slices are retained to the maximum extent, and the preservation time is long.

Owner:HANSHAN NORMAL UNIV +1

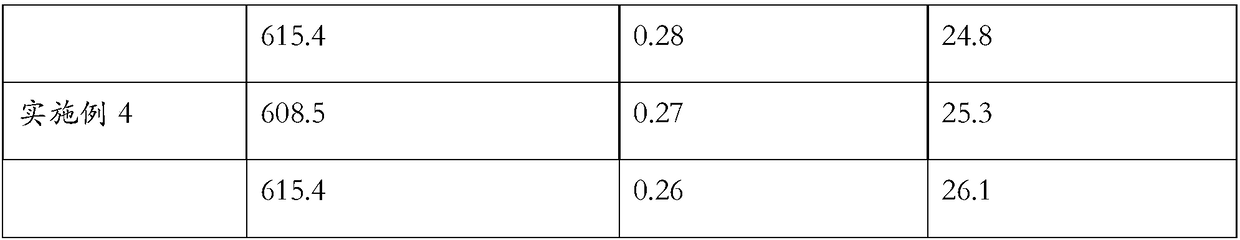

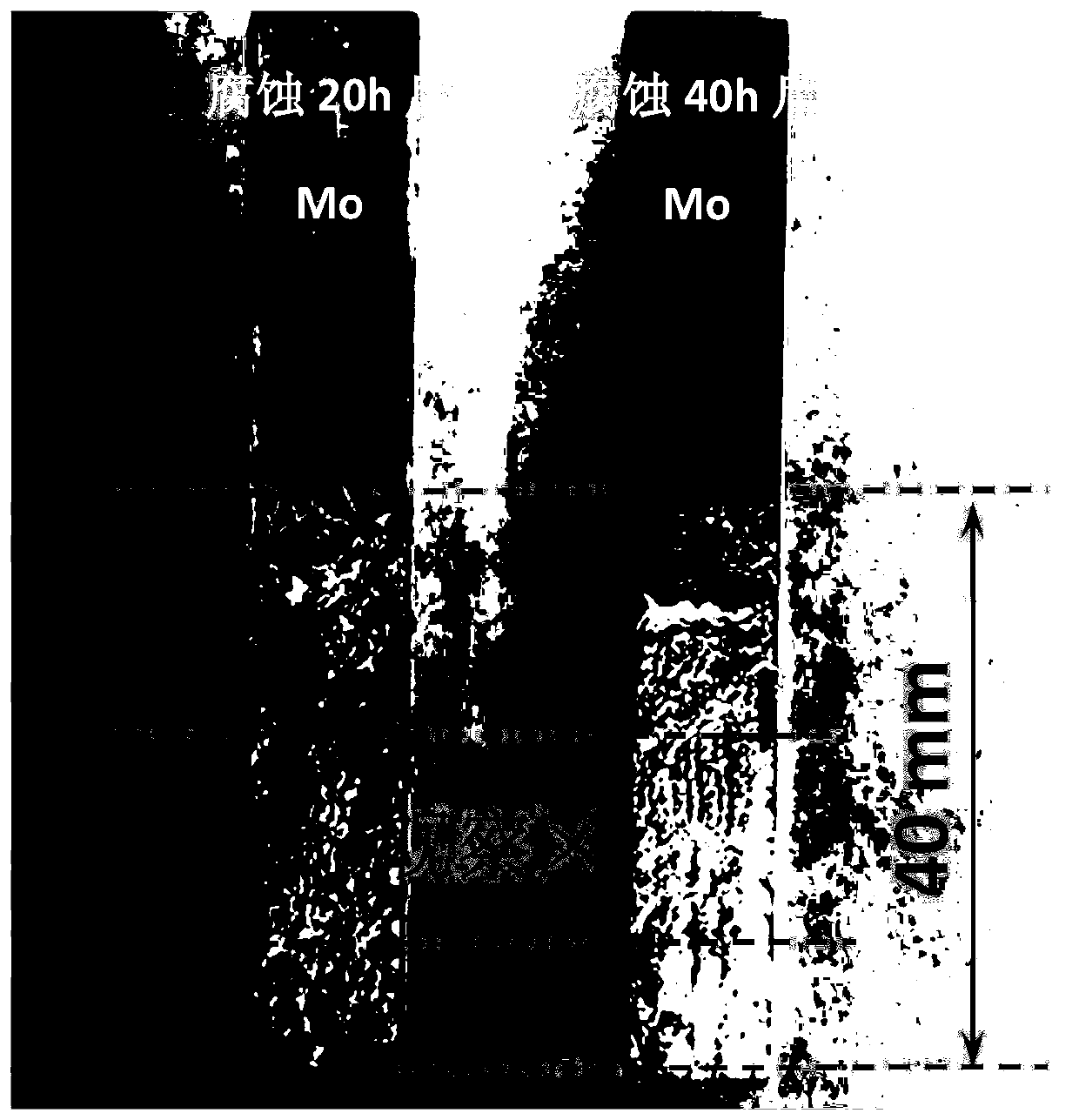

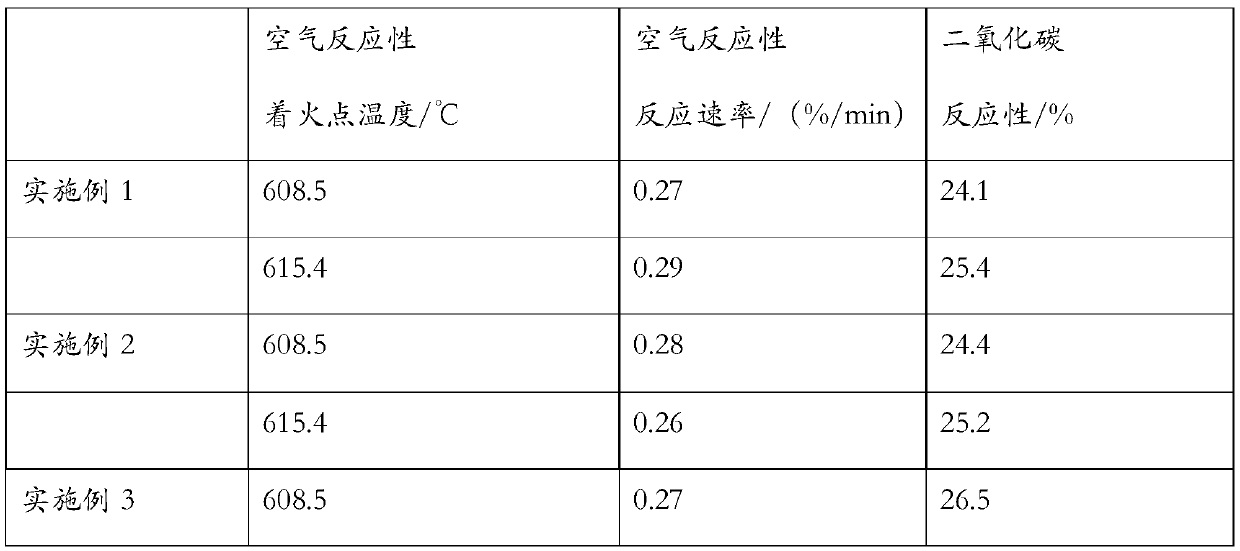

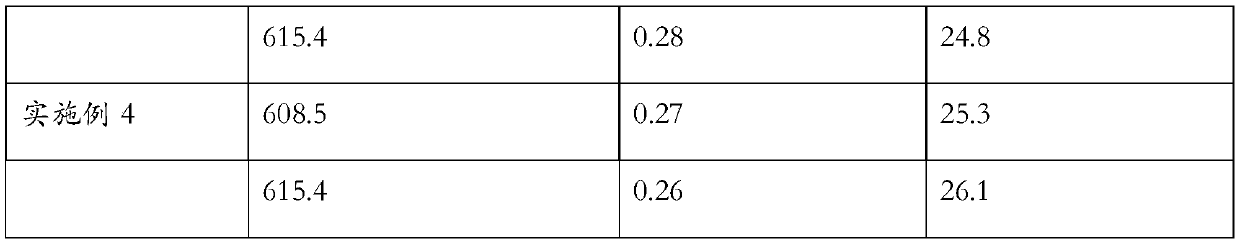

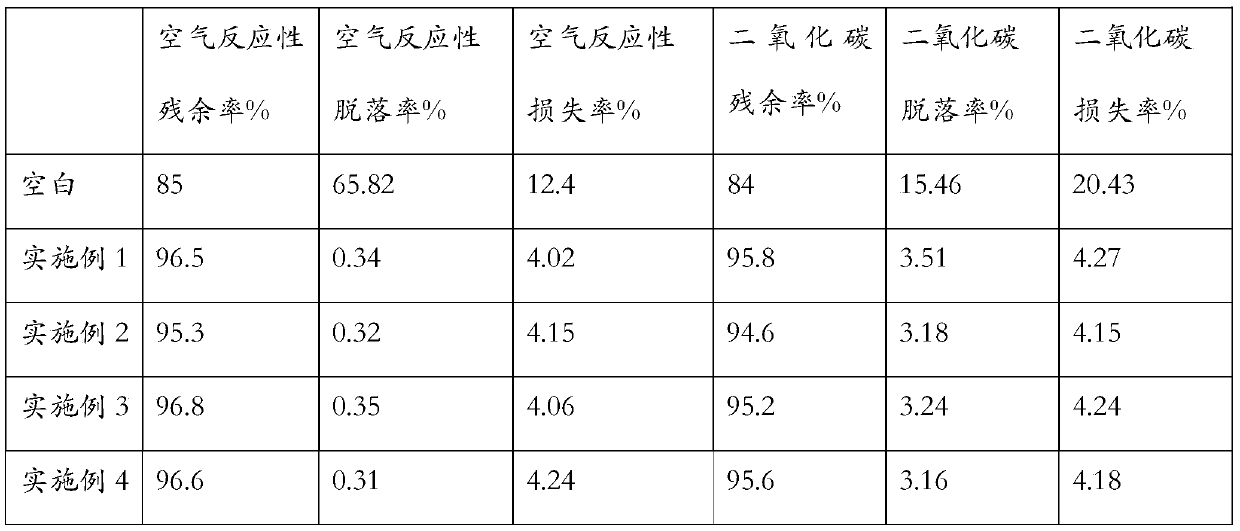

Preparation method of graphene composite protective layer for pre-baked carbon anode

The invention belongs to the field of carbon anode new materials for the electrolytic aluminium industry, and particularly relates to a preparation method of a graphene composite protective layer fora pre-baked carbon anode. The preparation method includes the steps of (1), adding graphene oxide in distilled water, stirring uniformly ultrasonically, adding phenolic resin with heating and stirring, performing redox reaction to obtain aqueous dispersion solution of graphene phenolic resin; (2) weighing a certain quantity of aqueous dispersion solution of graphene phenolic resin, sequentially adding graphite powder emulsion and nanometer aluminium oxide into the aqueous dispersion solution of graphene phenolic resin, and performing ultrasonic dispersion to obtain a graphene composite coating; (3), taking the graphene composite coating obtained the step (2), adding distilled water to dilute the graphene composite coating, covering the surface of the pre-baked carbon anode with the dilutedgraphene composite coating, and then drying naturally to obtain the graphene composite protective layer. The protective layer can effectively isolate oxidation action of air and carbon dioxide to carbon blocks; the carbon yield ratio in the air reactivity test is greater than 95%, and particularly the carbon yield ratio is greater than 96% after the CO2 reactivity test.

Owner:SUNSTONE DEV

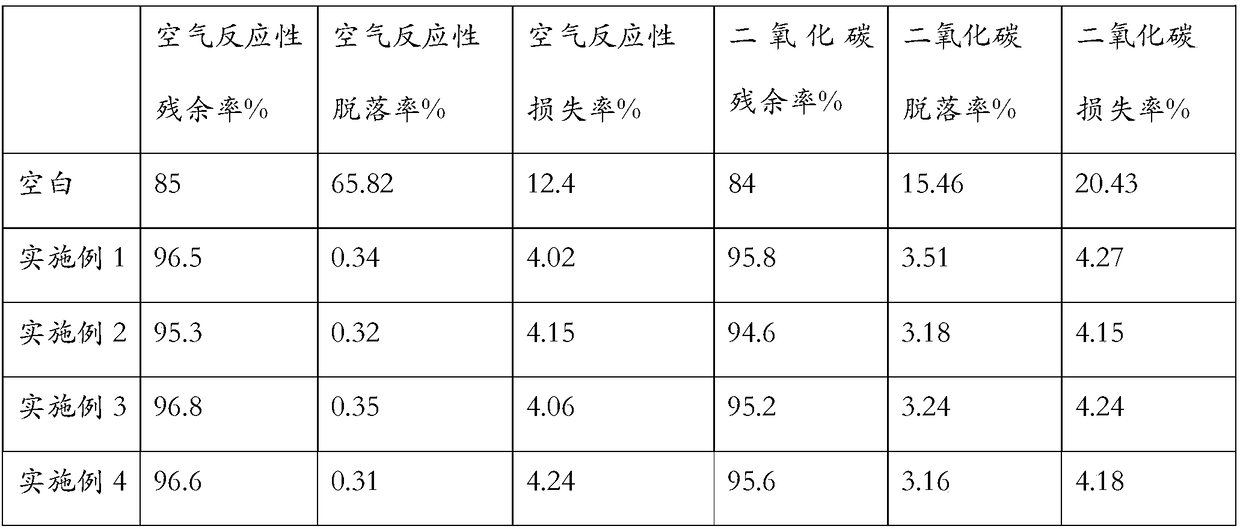

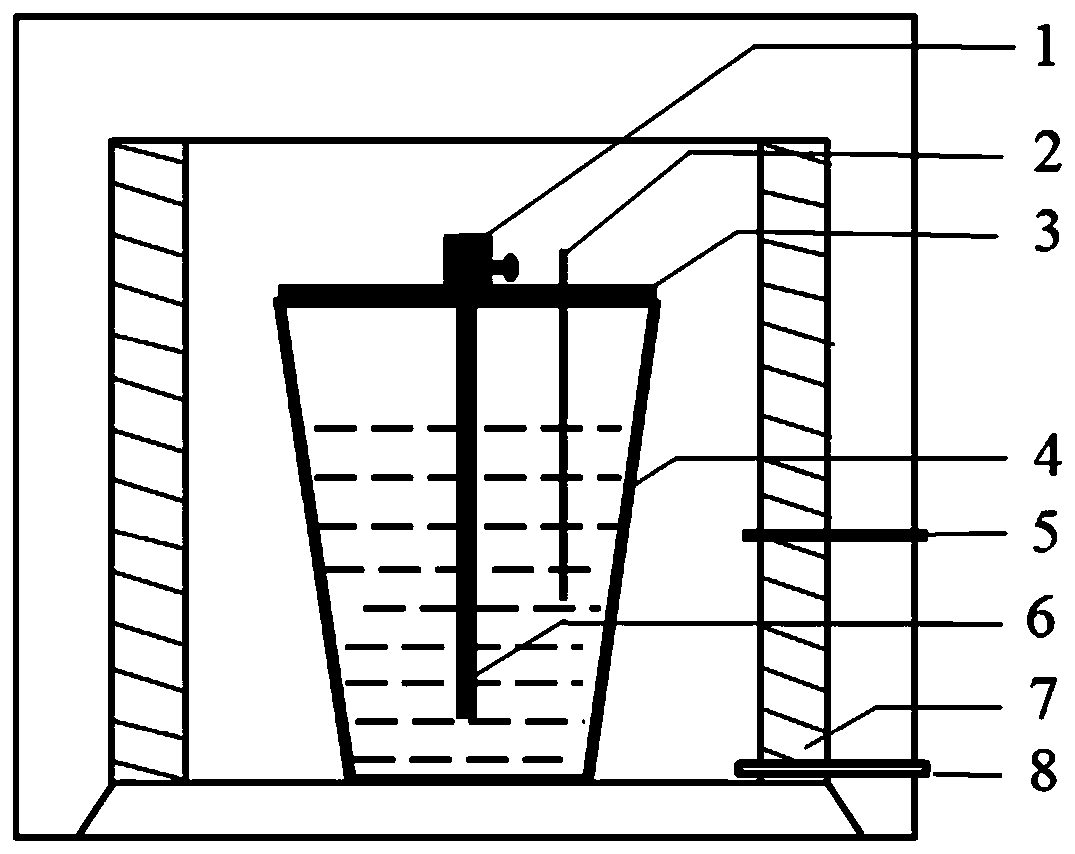

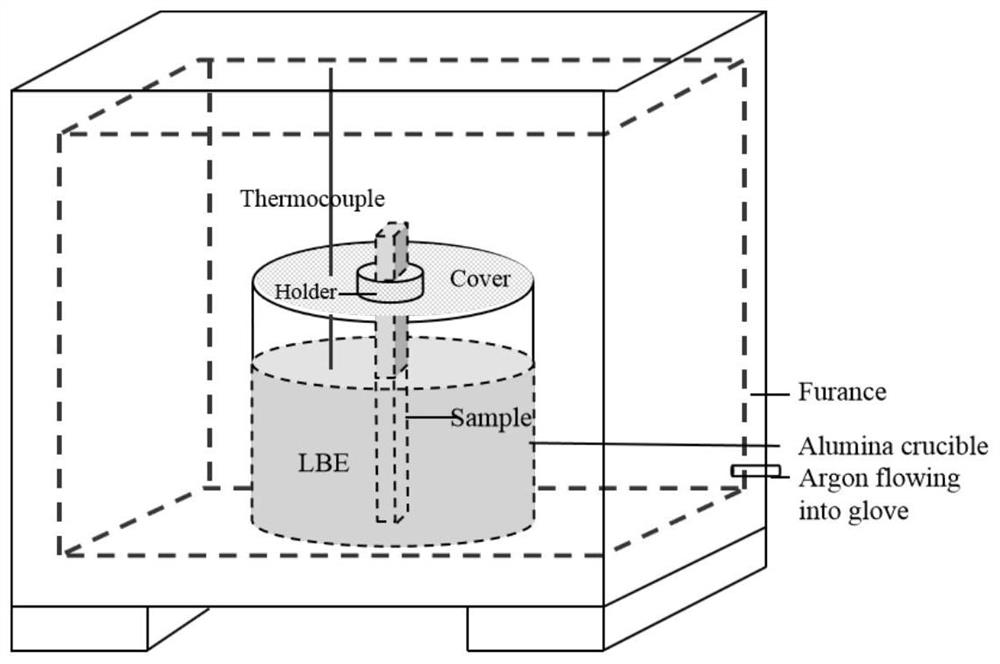

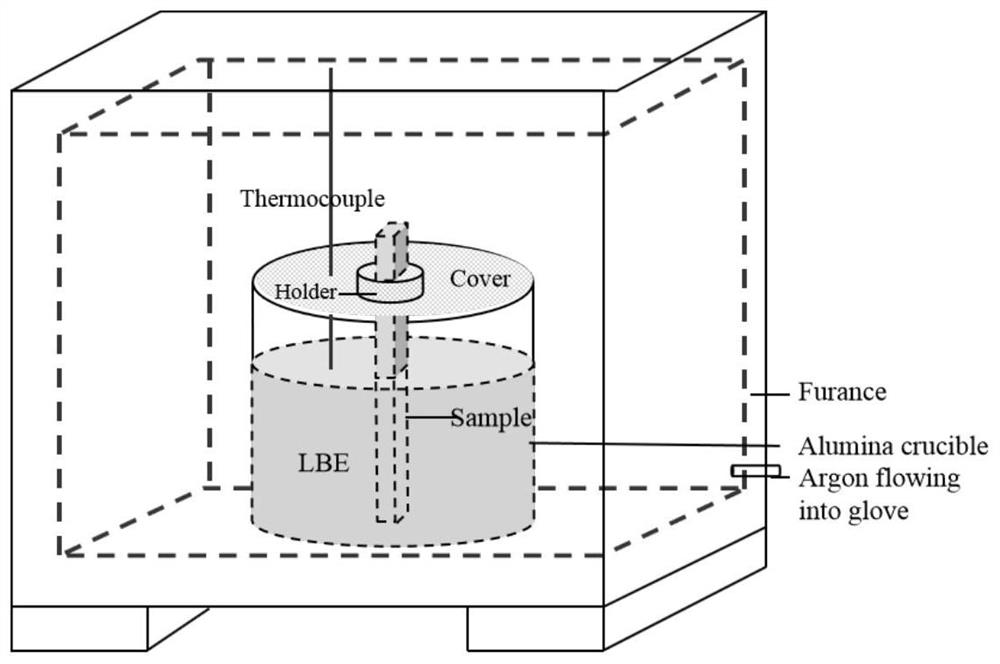

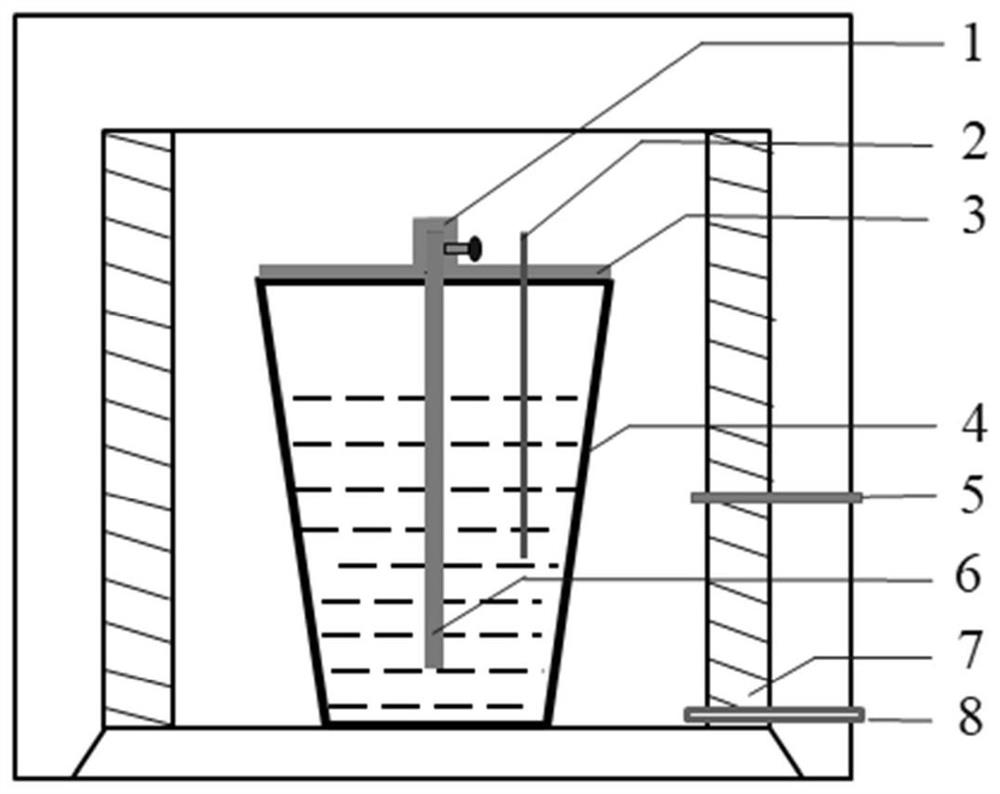

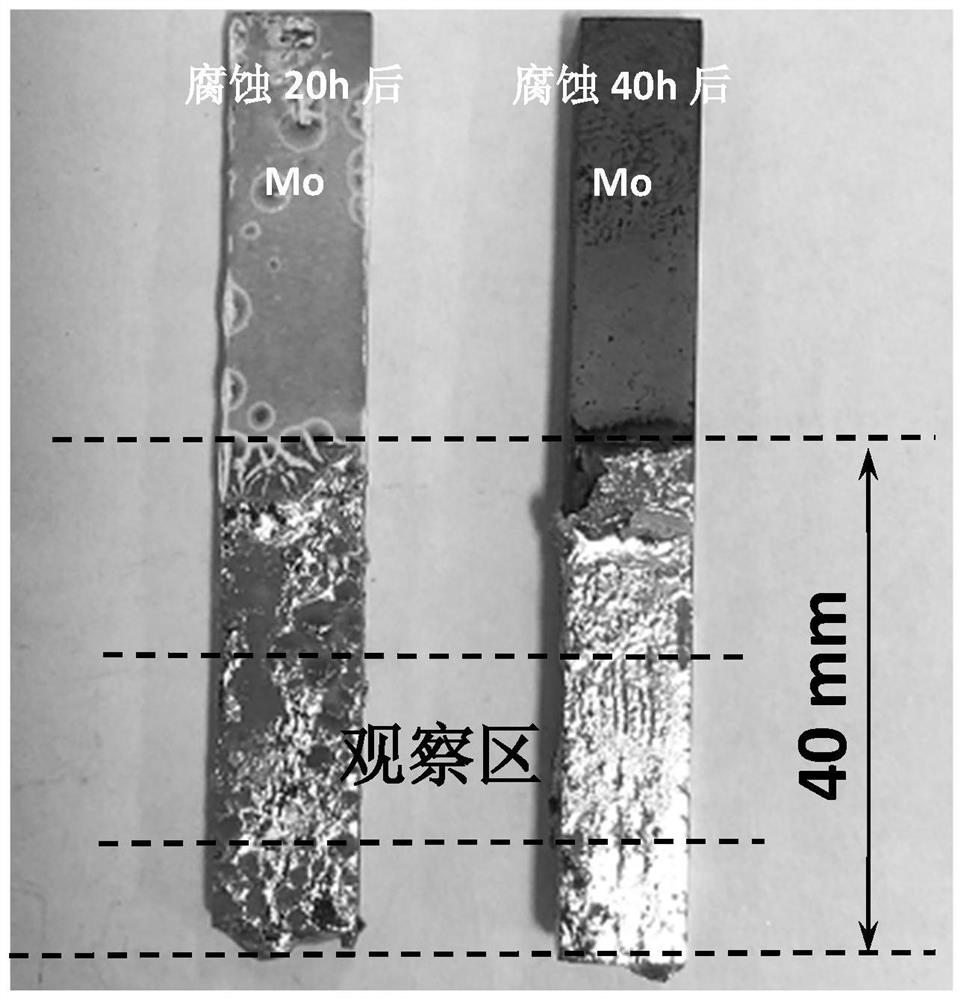

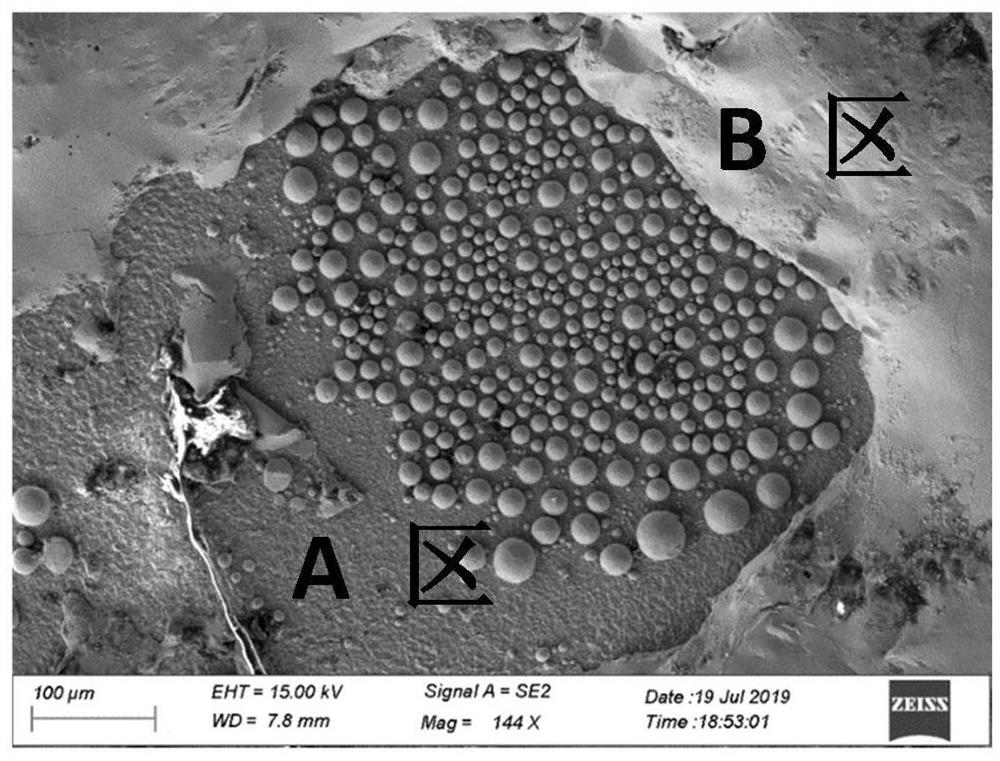

Preparation method of refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion

ActiveCN111020552AGood stabilityGood combinationMetallic material coating processesMuffle furnacePowder metallurgy

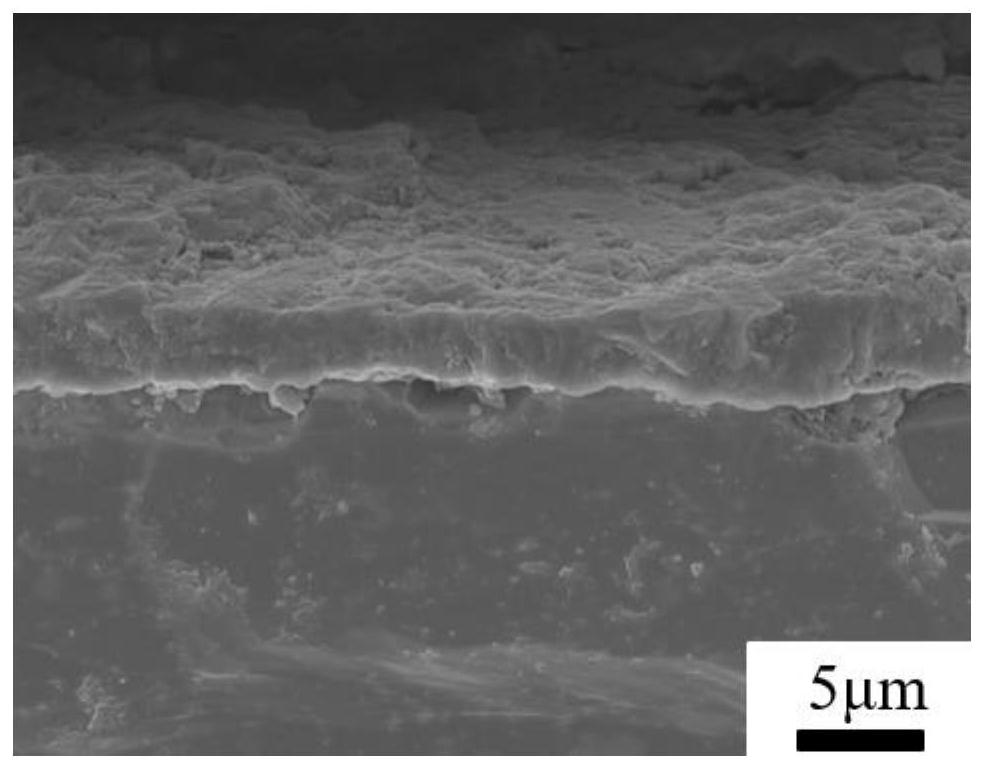

The invention discloses a preparation method of a refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion. The preparation method comprises the steps of preparing molybdenum by a powder metallurgy method, forging, extruding and processing the molybdenum into a rod, cutting the rod into an experimental sample, and performing annealing; placing a lead-bismuth alloy in a muffle furnace to be melted into liquid lead-bismuth alloy; inserting the molybdenum rod experimental sample into a crucible containing a liquid lead-bismuth alloy, keeping the temperature and the oxygen concentration in the crucible in a saturated state, and performing corroding; cooling the liquid lead-bismuth alloy, rapidly taking out the molybdenum rod experimental sample, and placing the molybdenum rod experimental sample on a stainless steel sheet for rapid cooling; and obtaining a compact PbMoO4 / Pb2MoO5 double-layer structure metal protective film. Through detection and characterization,specific components, morphology, thickness, compactness and other comprehensive information of the protective film are obtained. The PbMoO4 / Pb2MoO5 double-layer protective film prepared by the methodgreatly prolongs the service life of the refractory metal molybdenum in the liquid lead and bismuth, and accelerates the application of the refractory metal molybdenum in the liquid lead and bismuth.

Owner:XI AN JIAOTONG UNIV

High-pressure internal thread ball valve and machining process thereof

InactiveCN109055807AHigh tensile strengthIncreased freezing temperature rangePlug valvesFurnace typesRare-earth elementEngineering

The invention provides a high-pressure internal thread ball valve. The high-pressure internal thread ball valve comprises a valve body, a valve cap, a valve rod, a valve ball and a pressing cap, and is characterized in that the valve body, the valve cap, the valve rod, the valve ball and the pressing cap are made from the same main material, wherein the main material comprises, by mass, 7-9% of Zn, 1-3% of Pb, 2-4% of Si, 0.12 -0.15% of Ti, 0.1-0.3% of Fe, 0.1-0.3% of Al, 0.15-0.19% of C, 0.05-0.07% of B, 1.0-2.0% of Cr, 0.01-0.03% of Sb, 0.25-0.28% of Mn, 0.05-0.07% of Nb, 0.01-0.03% of V, 0.001-0.002% of Bi, 0.003-0.005% of S, 0.005-0.006% of P, 0.01-0.02% of rare earth elements, and the balance Cu and inevitable impurities, and the sum of the components is 100%. A machining process of the high-pressure internal thread ball valve is simple and easy to implement, and low in cost, and the machined ball valve has good high-temperature resistance and corrosion resistance performance, andis long in service life.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

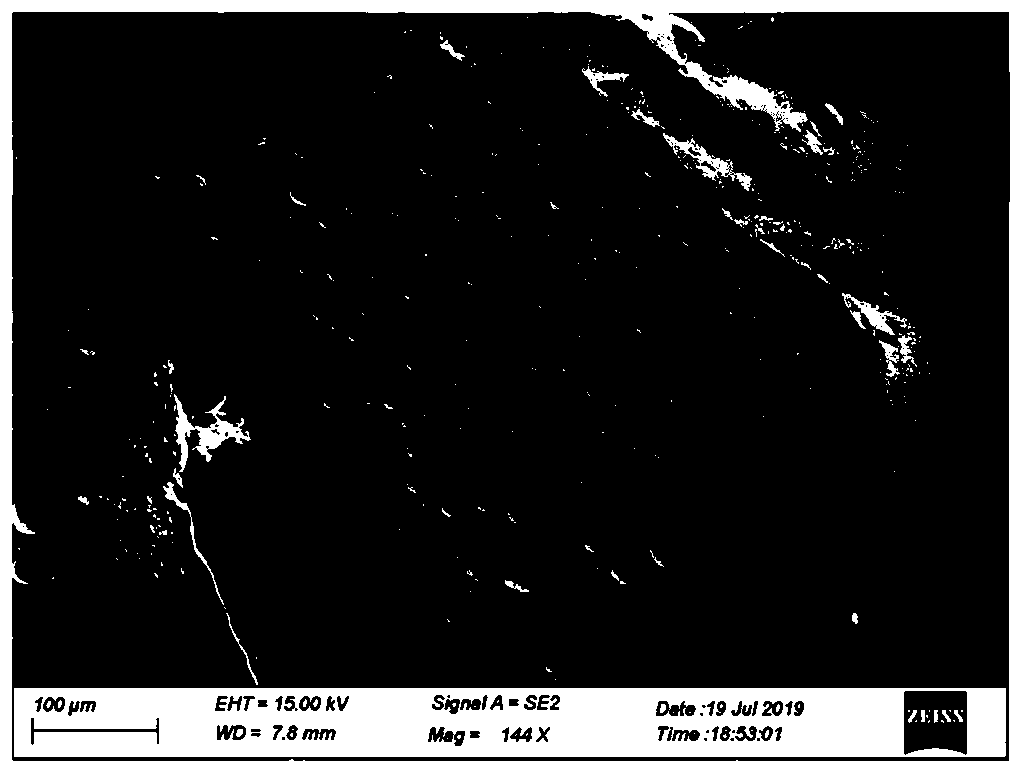

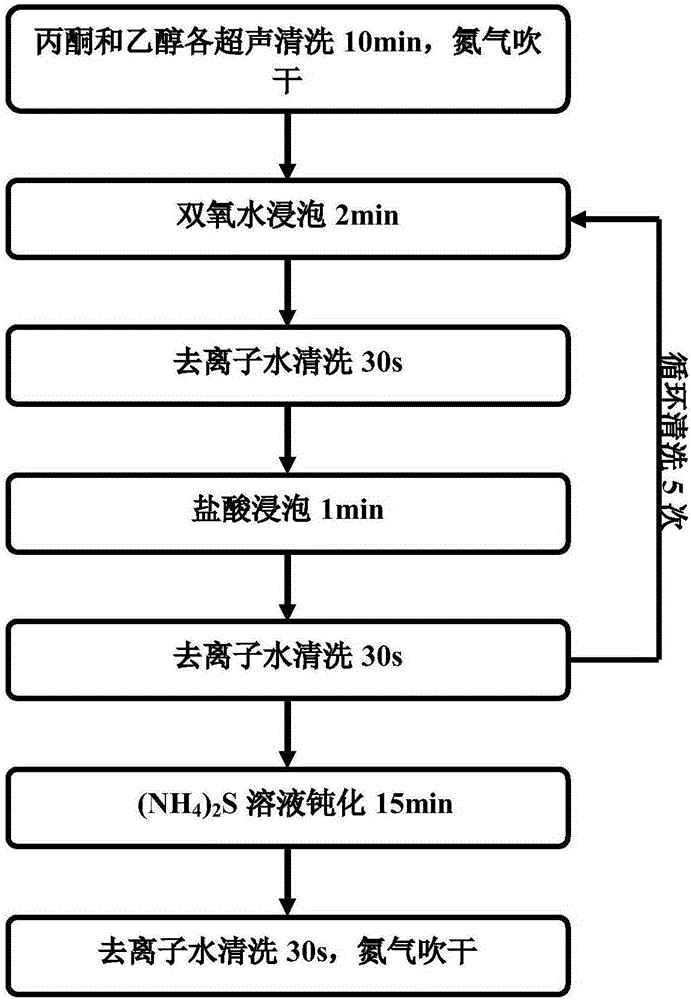

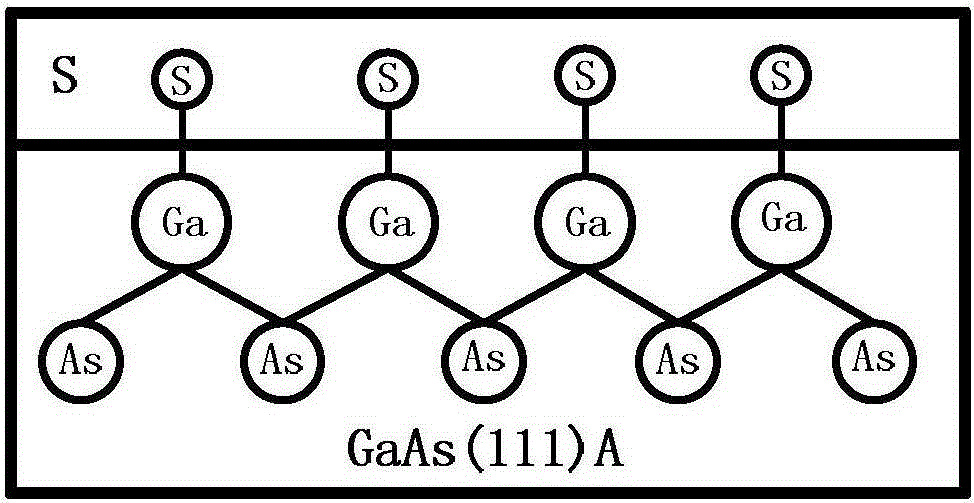

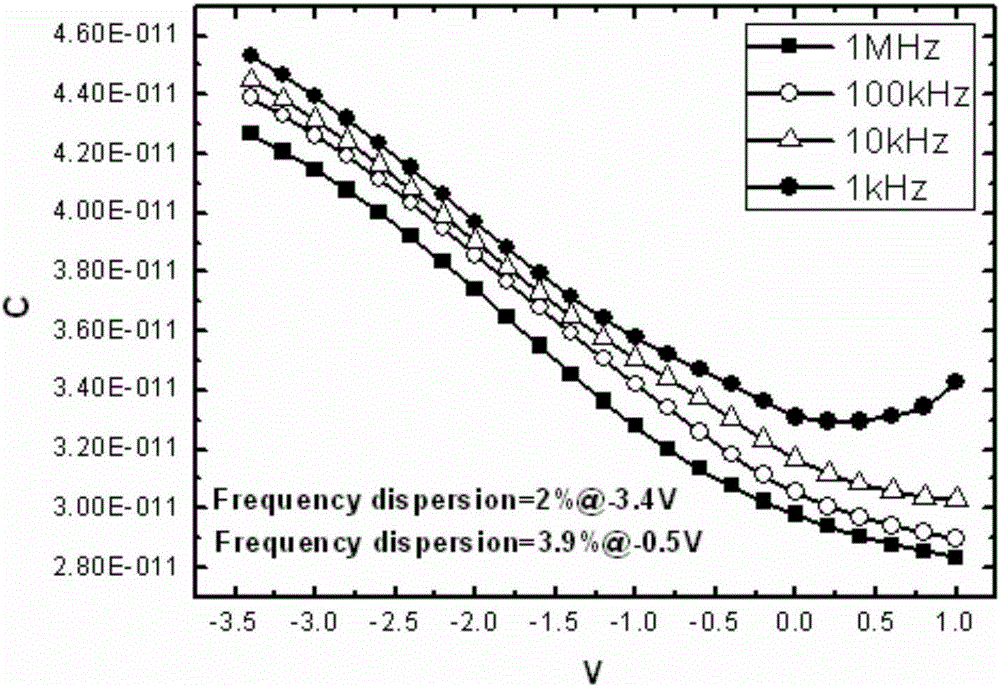

GaAs (111) wafer cleaning method

InactiveCN105161398AEfficient removalReduce in quantitySemiconductor/solid-state device manufacturingAmmonium sulphideOrganic solvent

The invention discloses a GaAs (111) wafer cleaning method. The GaAs (111) wafer cleaning method comprises steps that, a GaAs (111) substrate is treated by an organic solvent to remove oil stain and organic matters on the surface; the GaAs (111) substrate is immersed in hydrogen peroxide, is then taken out, is cleaned by deionized water, is immersed in hydrochloric acid, is taken out and is cleaned by deionized water; the acquired GaAs (111) substrate is immersed in hydrogen peroxide, is cleaned by deionized water, is immersed in hydrochloric acid and is cleaned by deionized water for at least one time. According to the method, the surface of the GaAs (111) substrate is treated by the hydrogen peroxide to acquire a structured nature oxide layer and is then corroded by the hydrochloric acid, as the GaAs (111) surface is the structured nature oxide layer, GaAs defects with bad quality in the surface can be effectively removed, so oxide quantity and roughness of the GaAs surface can be greatly reduced. The cleaning method is employed in combination with an ammonium sulphide solution for passivation, so the clean GaAs surface can be prevented from being oxided by oxygen in the air for long time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Anti-oxidation treatment technology before steel structure material heat treatment

ActiveCN110773721AAccelerated corrosionImprove wear resistanceMolten spray coatingSurface roughnessOxidation resistant

The invention discloses an anti-oxidation treatment technology before steel structure material heat treatment. The anti-oxidation treatment technology specifically comprises the following steps of (1)steel structure material pretreatment, (2) steel structure material roughening treatment, and (3) steel structure material surface spraying treatment. According to the anti-oxidation treatment technology, by processing a steel structure material, on the premise that the strength of the steel structure material meets the industrial requirement, the grain size of the steel structure material is increased as much as possible, the surface height of the steel structure material is made to be different, and accordingly, the surface roughness of the steel structure material is improved; then, spraying powder is sprayed onto the surface of the steel structure material, an anti-oxidation coating is formed, oxygen is stopped from scattering into the steel structure material, and the situation thatthe steel structure material oxidizes in the heat treatment process, and oxide scale is generated is effectively prevented; and in addition, the corrosion resistance and the abrasion resistance of thesteel structure material can be improved through the coating subjected to heat treatment, influence on direct using or follow-up machining of workpieces is avoided, and the wide application prospectis achieved.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

MoS2-based organic or inorganic hybrid lubricating coating with atomic oxygen resistance as well as preparation method

ActiveCN105153927AImprove wear resistanceOxidation barrierPretreated surfacesAnti-corrosive paintsAdhesivePolyamide-imide

The invention provides a MoS2-based organic or inorganic hybrid lubricating coating with atomic oxygen resistance as well as a preparation method of the organic or inorganic hybrid lubricating coating. The MoS2-based organic or inorganic hybrid lubricating coating with atomic oxygen resistance comprises components including an adhesive, a solid lubricant, an antioxidant modifier, a dispersing agent, a mixed solvent and modified silica sol. The MoS2-based organic or inorganic hybrid lubricating coating with atomic oxygen resistance can solve the problem that an adhesive and a lubricant of a PAI (polyamide-imide) bonding MoS2 solid lubricating coating for space are prone to atomic oxidation and is particularly suitable for surface lubrication and cold welding resisting processing of friction pairs such as gears, screw-nuts, shaft-shaft sleeves, slides and the like of movable parts of an aircraft in a spatial low-orbit environment.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

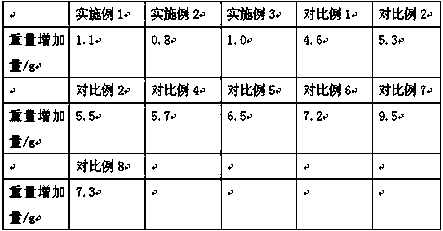

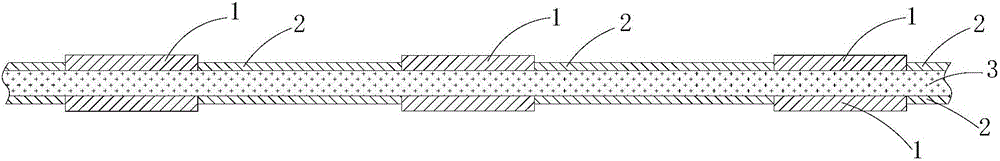

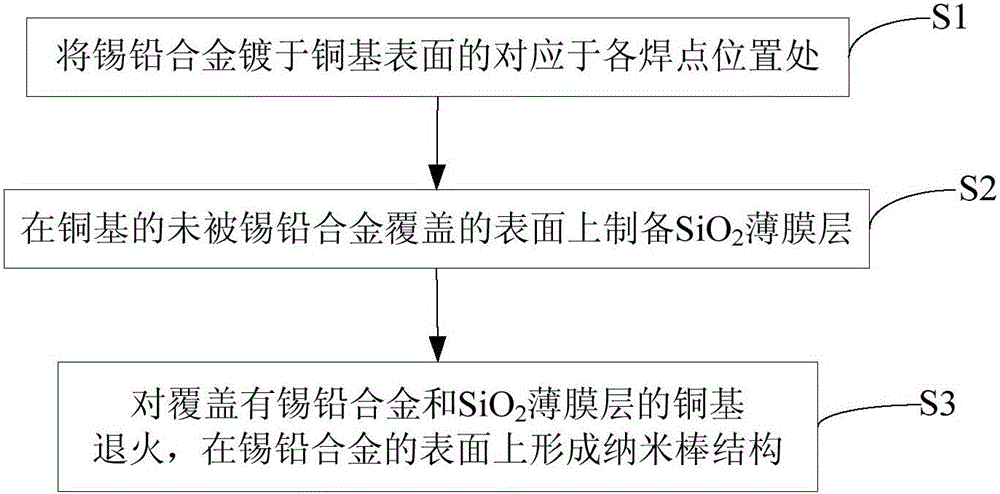

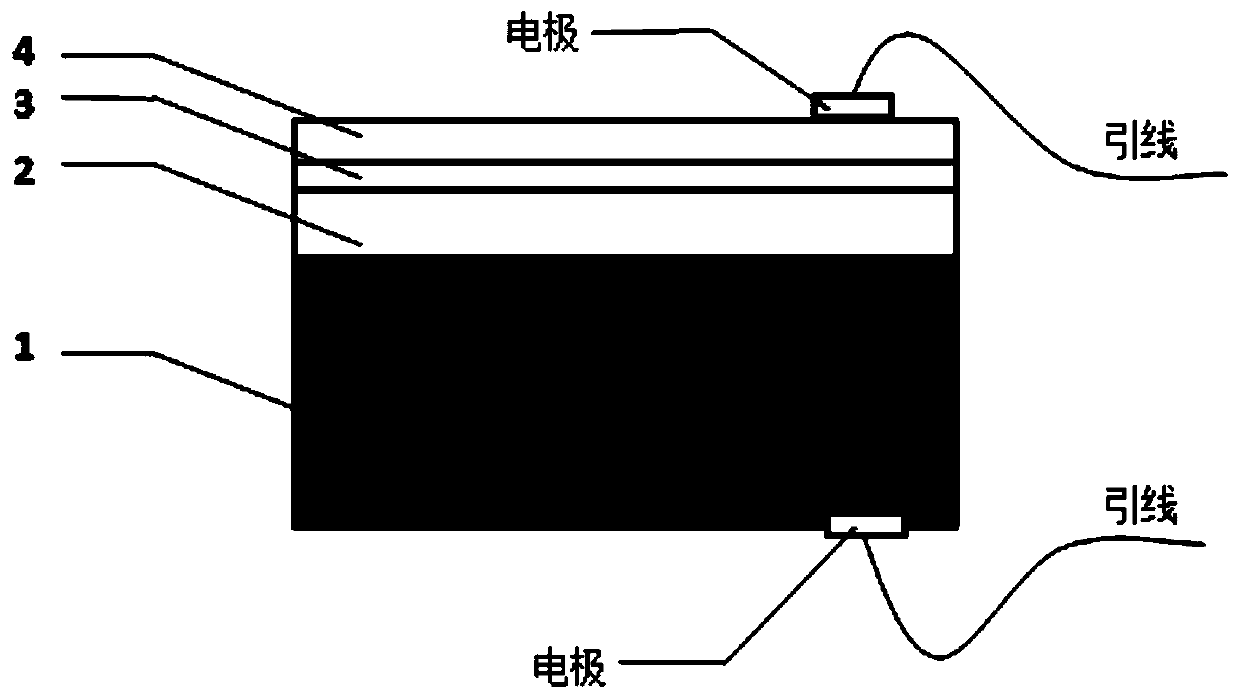

Photovoltaic welding strip and preparation method thereof

ActiveCN106653910ACorrosion resistanceOxidation barrierFinal product manufacturePhotovoltaic energy generationCopperMetal

The invention discloses a photovoltaic welding strip and a preparation method thereof. The oxidation resistance and corrosion resistance of the welding strip are improved. In the photovoltaic welding strip, an SiO2 thin film layer is formed on the area, except the positions of welding spots, on the surface of the photovoltaic welding strip. The photovoltaic welding strip comprises a copper base, a plurality of welded metal parts and the SiO2 thin film layer, wherein the welded metal parts are formed at the positions, corresponding to the welding spots, on the surface of the copper respectively; the SiO2 thin film layer is formed on the surface, with which the welded metal parts are not covered, of the copper base; and the surface of the copper base is completely covered with the welded metal parts and the SiO2 thin film layer. The preparation method of the photovoltaic welding strip comprises the following steps: S1, plating welded metal at the positions, corresponding to the welding spots, on the surface of the copper base; and S2, preparing the SiO2 thin film layer on the surface, with which the welded metal is not covered, of the copper base.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

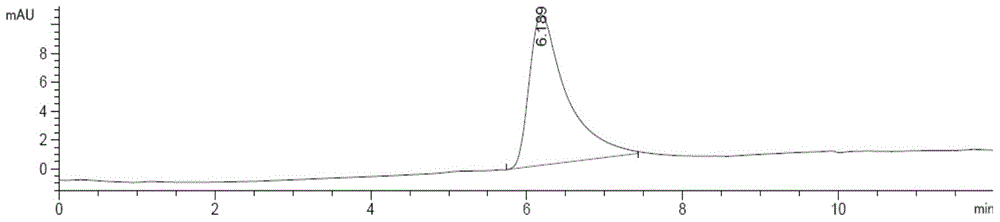

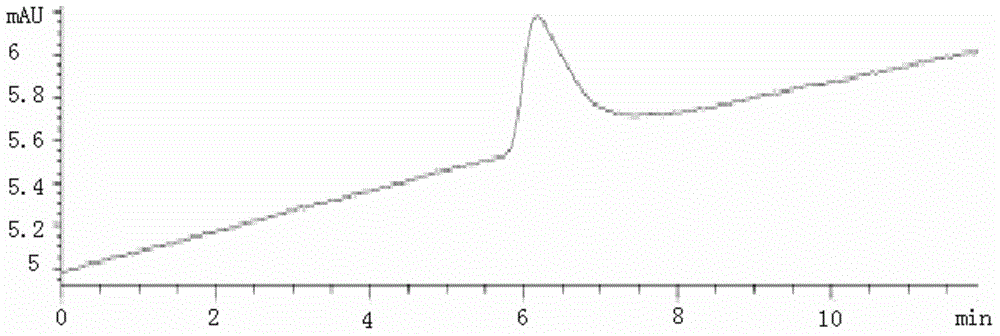

Radionuclide labelled specific sentinel node photographic developer and preparation method thereof

ActiveCN104667307APrecise positioningUnlimited imagingRadioactive preparation carriersSentinel nodeRadionuclide imaging

The invention provides a radionuclide labelled specific sentinel node photographic developer and a preparation method thereof and belongs to the technical field of radioactive drug labeling and nuclear medicine. The radionuclide labelled specific sentinel node photographic developer provided by the invention is prepared by the following steps: by taking a rituximab monoantibody as a parent, separating, purifying and reducing the rituximab monoantibody to obtain a photographic developer precursor; preparing the precursor into a medicine box, wherein the storage life can reach 24 months; carrying out 99mTc radionuclide labeling on the photographic developer precursor to obtain the specific sentinel node photographic developer drug 99mTc-SLN-F, wherein the labeling rate is equal to or greater than 95%. The photographic developer prepared can precisely position the specific sentinel node, the development and biopsy times are not limited, and the photographic developer can develop well in a time interval of 30 minutes to 24 hours after injection. In addition, the photographic developer is low in uptake in a secondary lymph gland and low in retention at injection points. The photographic developer has a good application prospect in treating and diagnosing breast cancer.

Owner:YANTAI LANNACHENG BIOTECHNOLOGY CO LTD

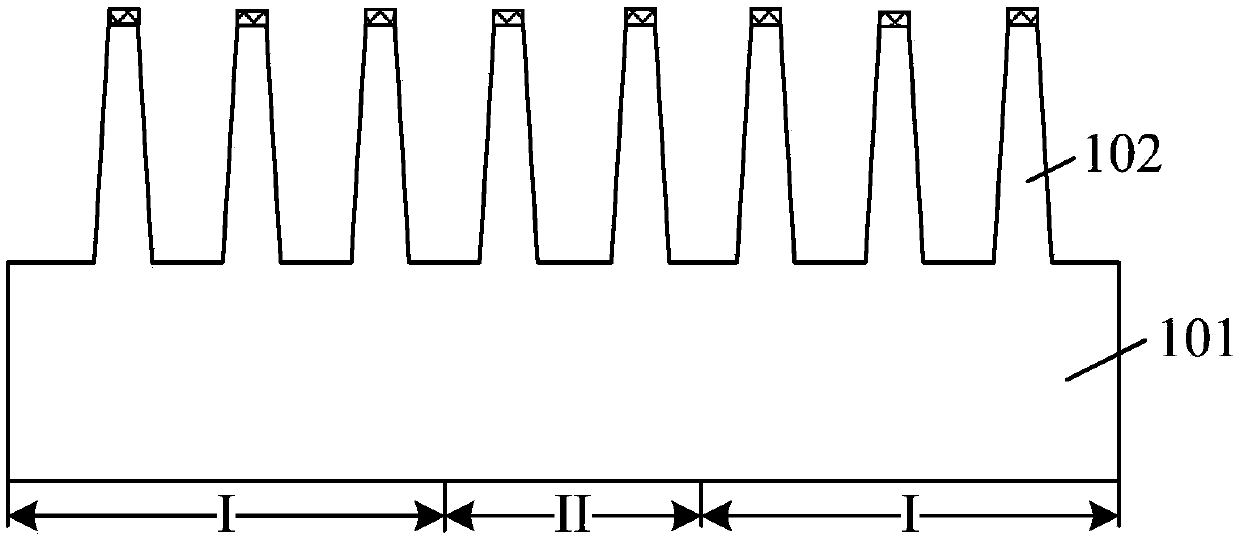

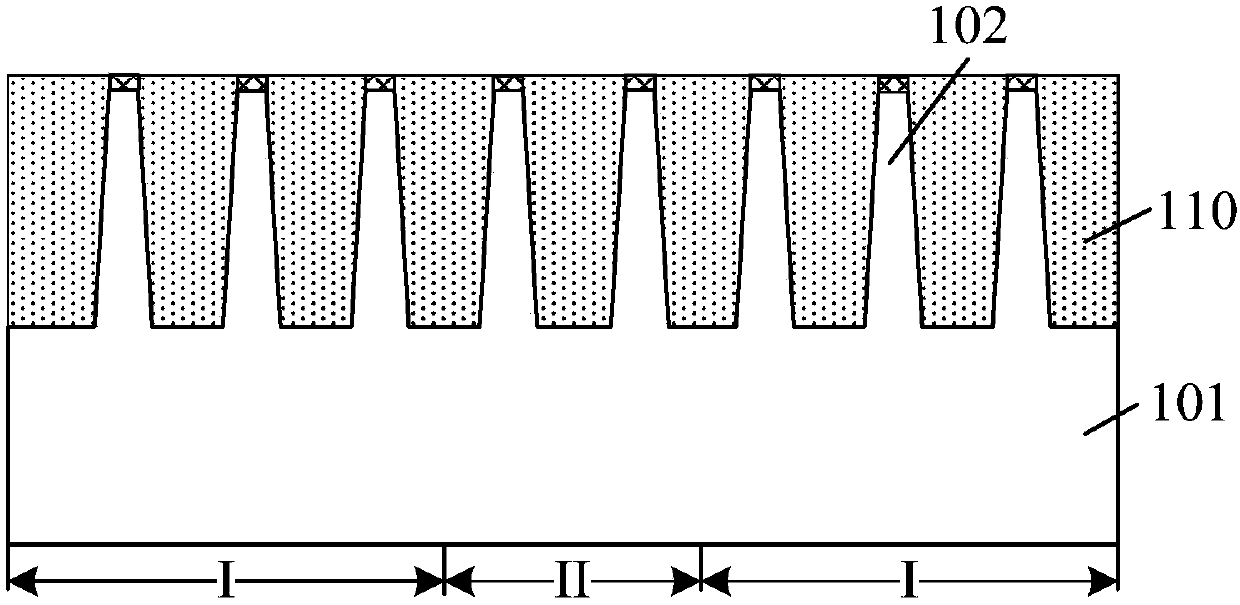

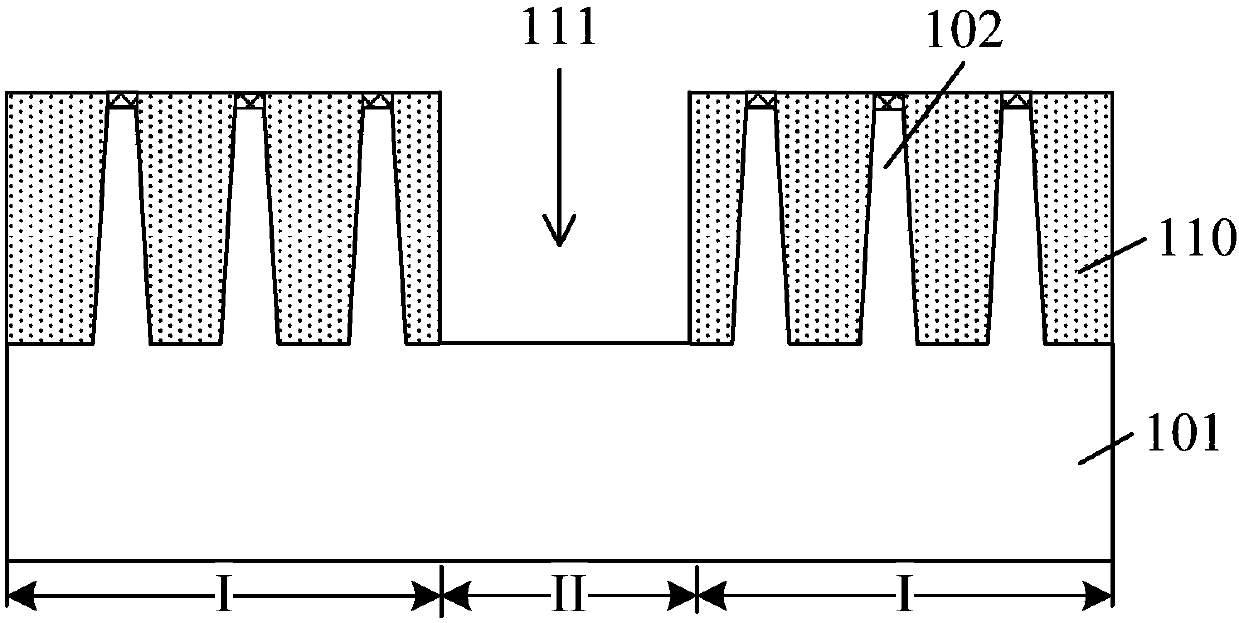

Semiconductor structure and formation method thereof

InactiveCN107731688AImprove performanceSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureIsolation layer

The invention provides a semiconductor structure and a formation method thereof. The formation method comprises the following steps: providing a substrate, wherein the substrate comprises device areasand an isolation area, the device area substrate having fin portions and an initial isolation structure, the initial isolation structure covering side walls of the fin portions, the side walls, adjacent to the isolation area, of the initial isolation structure and the isolation area substrate forming an isolation groove; carrying out ion implantation on the side walls of the isolation groove to inject doping ions, and forming a barrier layer on the surfaces of the side walls of the isolation groove; after ion implantation, forming an isolation layer filling the isolation groove; and after forming the isolation layer, etching the initial isolation structure to expose the top portions and partial side wall surfaces of the fin portions and forming an isolation structure. The formation methodcan reduce the problem of inconsistency of fin portion width, and thus the performance of the semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

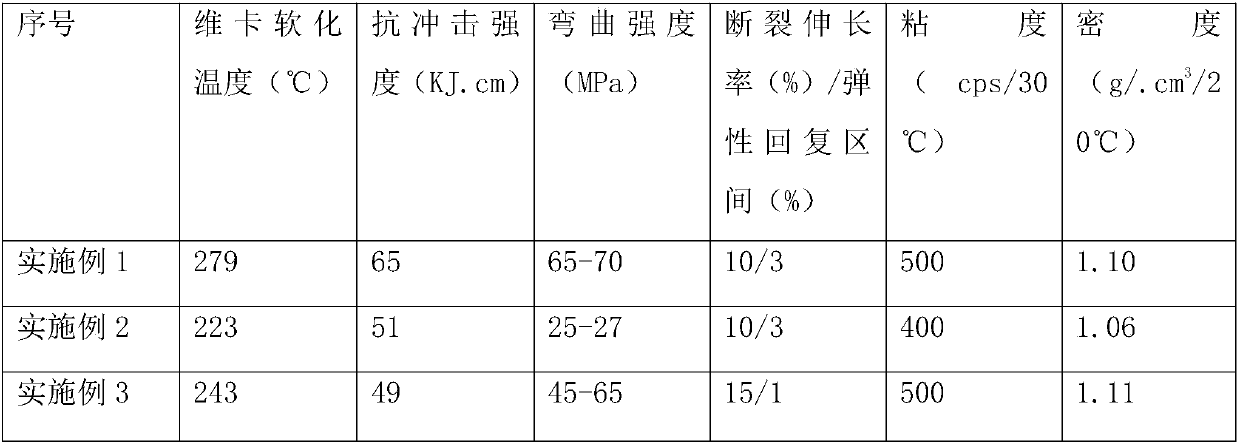

Polyacrylate resin 3D printing material and preparation method thereof

InactiveCN110157275AOxidation barrierStrong temperature resistanceAdditive manufacturing apparatusAntifouling/underwater paintsFiberCarbon fibers

The invention discloses a polyacrylate resin 3D printing material, and a preparation method thereof. The polyacrylate resin 3D printing material comprises, by weight, 15 to 20% of a photosensitive resin polymer monomer, 10 to 20% of a photosensitive resin prepolymer, 0.5 to 5% of a photoinitiator, 1 to 2.5% of a terminator, 5 to 10% of functionalized nanoparticles, 5 to 10% of a color additive, 10to 25% of a high molecular polymer, 3.5 to 5% of a high molecular additive, 5 to 10% of metal powder, 0.5 to 2% of carbon fiber, 0.5 to 1% of an adhesive, 1.5 to 3% of an inorganic filler, 2 to 5% ofa compatibilizer, 20 to 30% of polyacrylate resin, 11 to 20% of ABS plastic masterbatch, and 10 to 15% of PLA. The adopted polyacrylate resin is a high elasticity polyacrylate resin, a formed film after film forming is compact, the surface of the 3D printing material is provided with the compact protective film, so that water and oxygen insulation effect and 3D printing material oxidation effectare achieved, the temperature resistance is excellent, the cohesive force is large, the clunging force is high, and stain resistance and water resistance are excellent.

Owner:广东华斓汽车材料研究院

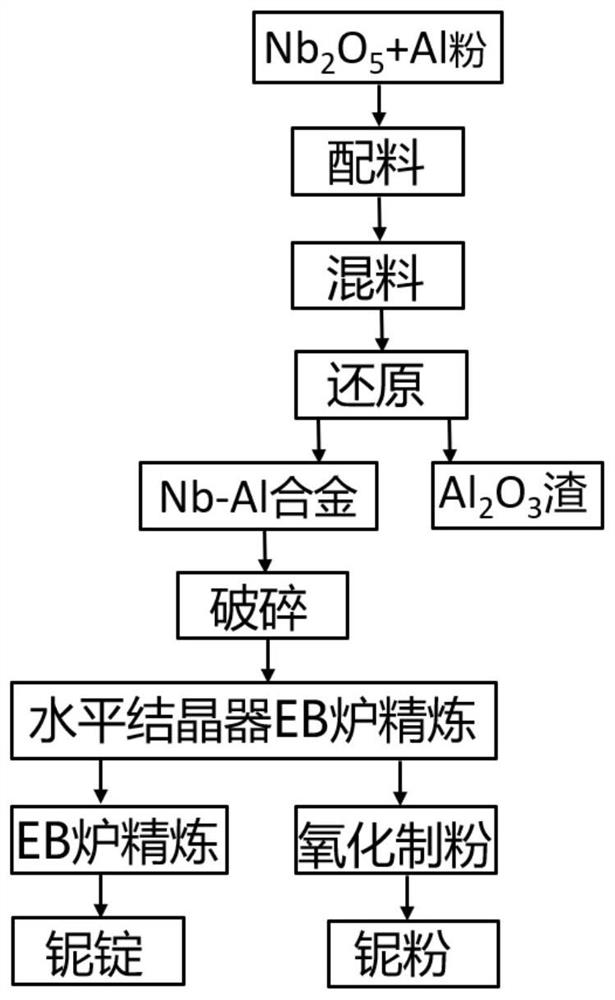

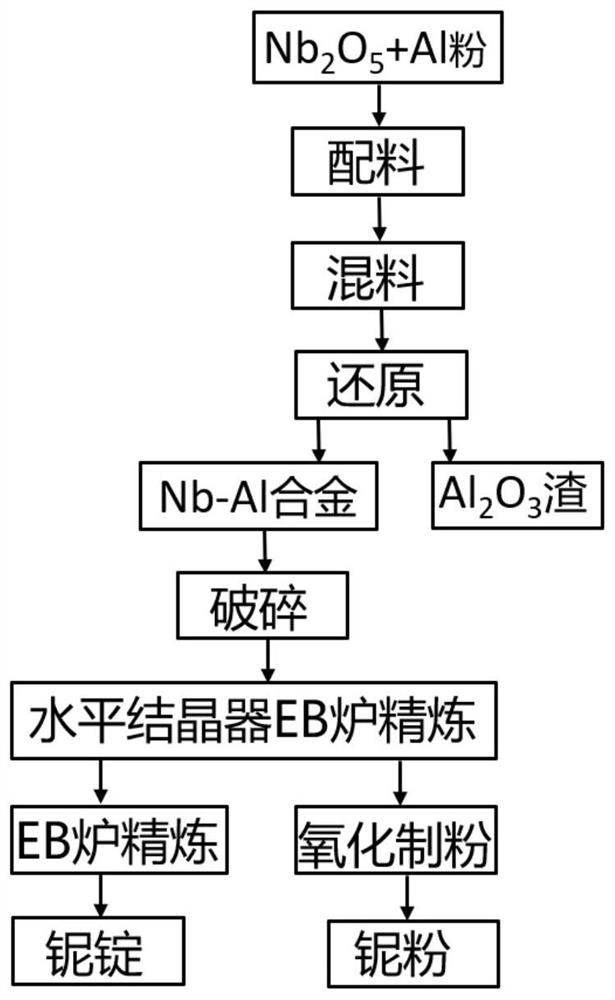

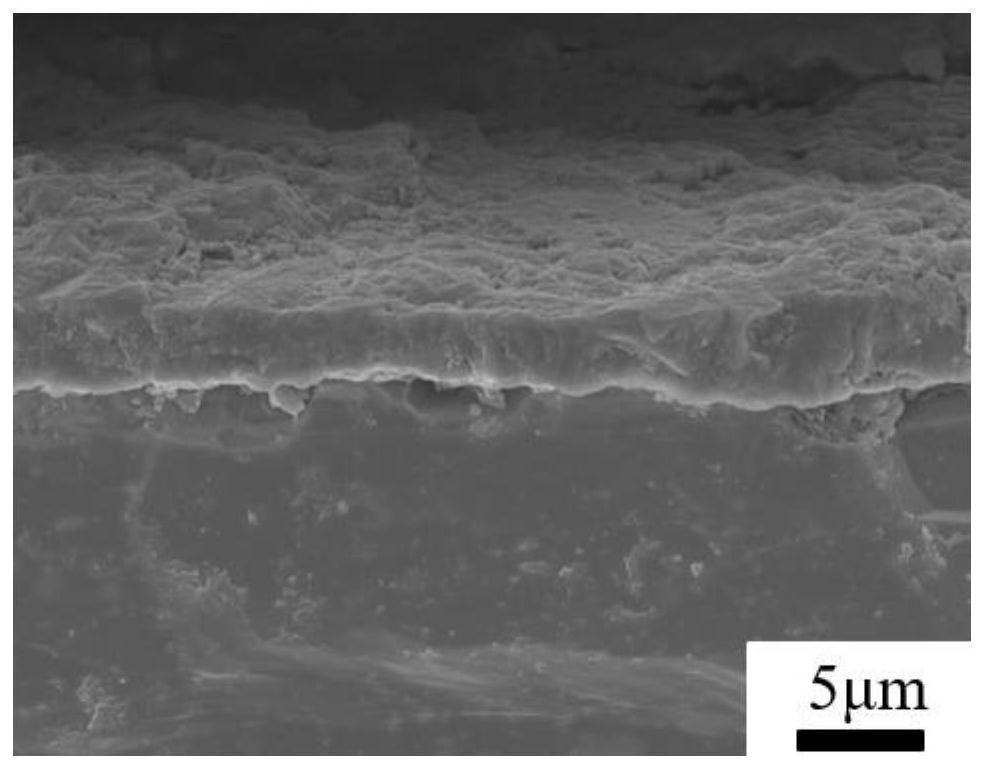

Protective film for corrosion resistance of metal niobium at high temperature and preparation method of protective film

ActiveCN113718193AImprove corrosion resistanceMelted completelyNuclear energy generationSolid state diffusion coatingInterfacial reactionLead bismuth

The invention discloses a protective film for corrosion resistance of metal niobium at a high temperature and a preparation method of the protective film. The preparation method comprises the following steps of sequentially carrying out vacuum melting, rolling and annealing treatment on a niobium bar, and then cutting the niobium bar into an experimental sample; melting a lead-bismuth alloy to obtain liquid lead bismuth; putting the treated experimental sample into the liquid lead bismuth, fixing the sample, and carrying out interface reaction and diffusion reaction on Nb in the experimental sample and oxygen dissolved in the liquid lead bismuth to generate a layer of NbO surface film at first; the NbO surface film further reacts with oxygen dissolved in the liquid lead bismuth to generate a layer of NbO2 protective film; and the experimental sample is taken out and placed on a stainless steel sheet, and metal niobium with the protective film is obtained after the experimental sample is cooled. The protective film lays a foundation for expanding the application of the refractory metal in the industry.

Owner:XI AN JIAOTONG UNIV

Magnesium alloy smelting protection solvent and preparation method thereof

The invention provides magnesium alloy smelting protection solvent and a preparation method thereof. The magnesium alloy smelting protection solvent comprises the following chemical components in parts by weight: 8-15 parts of barium carbonate, 12-15 parts of calcium sulfate, 12-17 parts of nanometer zirconium oxide, 12-15 parts of magnesium chloride, 12-20 parts of hydroxyapatite, 12-20 parts of magnesium silicate, and 1-5 parts of lithium chloride. The preparation method is to perform the mixing after the drying. The smelting protection solvent, provided by the invention, is molten to a liquid state in an environment of higher than 500 DEG C in the smelting process, and is spread on the surface of an alloy or molten magnesium to achieve an air isolating effect and to stop the magnesium oxidation so as to obtain excellent protection performance.

Owner:贵州航天风华精密设备有限公司

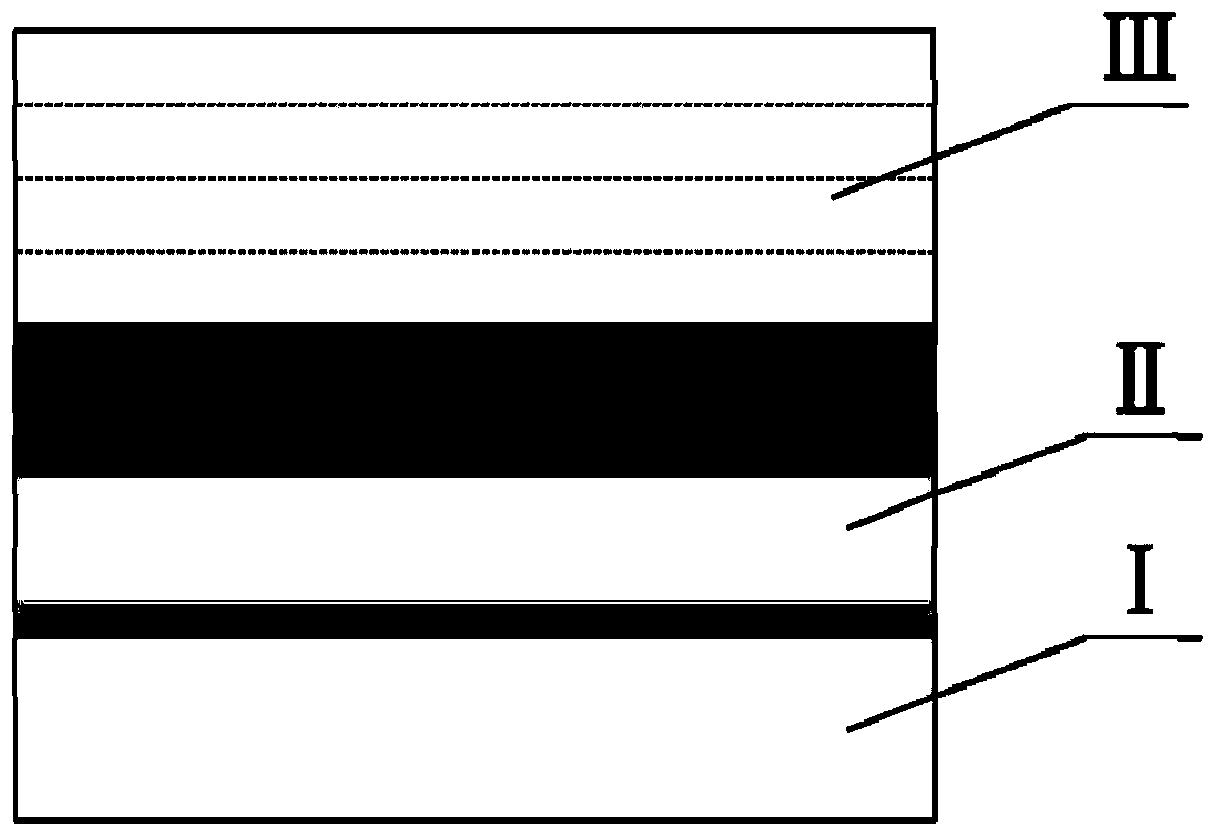

A kind of thermal shock-resistant high-temperature composite insulation layer and its preparation method

InactiveCN107142477BImprove high temperature insulation performanceImprove stabilityVacuum evaporation coatingSputtering coatingThin film sensorInsulation layer

The invention belongs to the technical field of thin film sensors, and provides a thermal shock-resistant high-temperature composite insulating layer and a preparation method thereof; the composite insulating layer includes a two-layer structure, which is Al from bottom to top 2 o 3 ~ Al‑O‑N gradient layer and microcrystalline Al 2 o 3 thin film insulating layer; the Al 2 o 3 ~The bottom layer of the Al‑O‑N gradient layer is Al 2 o 3 layer, the top layer is an amorphous Al-O-N film layer, and along the film growth direction, the content of N element increases. The composite film insulating layer of the present invention can form uniform and dense coverage on different parts such as the plane, bending, and folding of special-shaped precision components, effectively improve the uniformity and high-temperature insulation performance of the insulating layer, and effectively ensure the reliability of the film sensor under high temperature conditions and stability; at the same time, the solution method is used to prepare, and the sol-gel method can easily complete the coating of larger workpieces, which is beneficial to the realization of batch production; and the sol-gel method is low in cost and easy to operate. These factors make the present invention provide Composite insulating layer has a broader application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

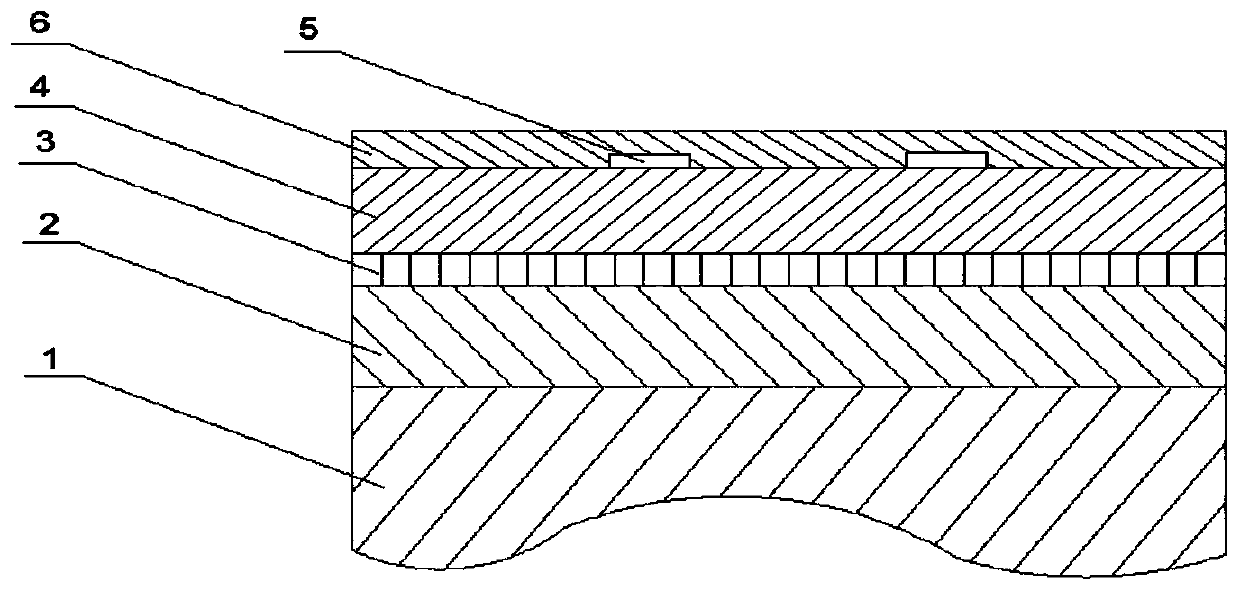

A kind of preparation method of copper electrode composite layer of thermistor

ActiveCN111587463BGood thermal stabilityInhibit copper diffusionVacuum evaporation coatingSputtering coatingOxidation resistantThermistor

A method for preparing a copper electrode composite layer of a thermistor. The ceramic substrate is washed and dried for use; the Ti powder is ball-milled to obtain Ti nano powder; the ceramic substrate is placed in a DC arc plasma evaporation device, vacuumed, vacuum degree is 10 ‑3 -10 ‑4 Mpa is filled with inert gas, and plasma sputtering treatment of Ti nano powder and Ti-Ni nano powder is respectively carried out in the inert gas reflux to obtain a semi-finished substrate; the semi-finished substrate is placed in an annealing device for annealing treatment, and after annealing, it will contain nano-aluminum The ion solution is coated on the surface of the semi-finished substrate to form a film, and after heat treatment, the copper electrode composite layer of the thermistor is obtained. The thermistor copper electrode composite layer prepared by the method has excellent electrical conductivity and anti-oxidation performance, and the method is simple, low in cost and convenient for industrialized production.

Owner:JIANGSU JINGWEI INTELLECTUAL PROPERTY OPERATION CO LTD

A protective film based on the corrosion resistance of metal niobium at high temperature and its preparation method

ActiveCN113718193BImprove corrosion resistanceMelted completelyNuclear energy generationSolid state diffusion coatingInterfacial reactionNiobium

Owner:XI AN JIAOTONG UNIV

A groove-type cable bridge and an anticorrosion process thereof

InactiveCN108988237AImprove stabilityAvoid generatingFireproof paintsElectrical apparatusEngineeringImpurity

The invention discloses a groove-type cable bridge, comprising a groove frame and a shield arranged on the groove frame, wherein the groove frame comprises the following components in percentage by mass: C: 0.15-0.19%, Cr:1.0-3.0%, Si:2-4%, Al:0.5-0.9%, Ti:0.2-0.5%, Cu:0.05-0.08%, B:0.05-0.08%, Sb:0.1-0.3%, Mo:0.2-0.35%, Zr:0.03-0.05%, Zn:0.5-0.8%, Nb:0.05-0.07%, Mn:0.45-0.48%, S:0.003-0.005%, P:0.005-0.007%, V: 0.01-0.03%, rare element: 0.15-0.18%, the rest is Fe and inevitable impurities; the invention also designs an anticorrosion process of the groove cable bridge, which has good anticorrosion performance and long service life.

Owner:江苏大印电子科技有限公司

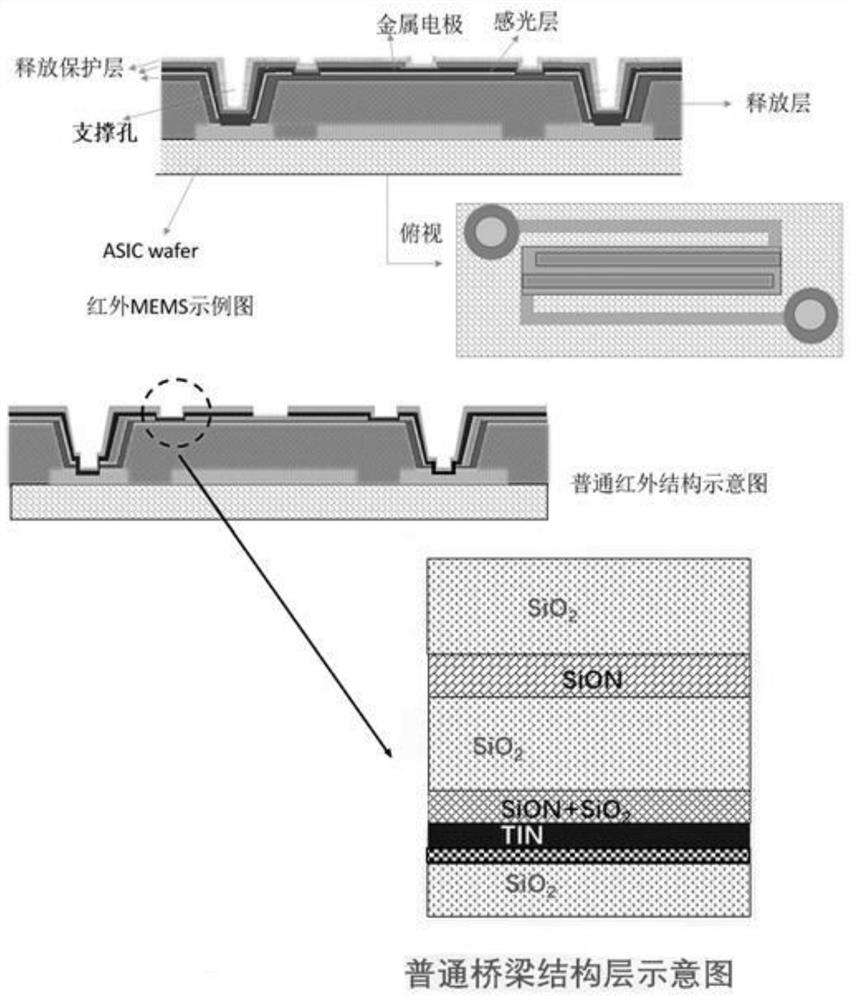

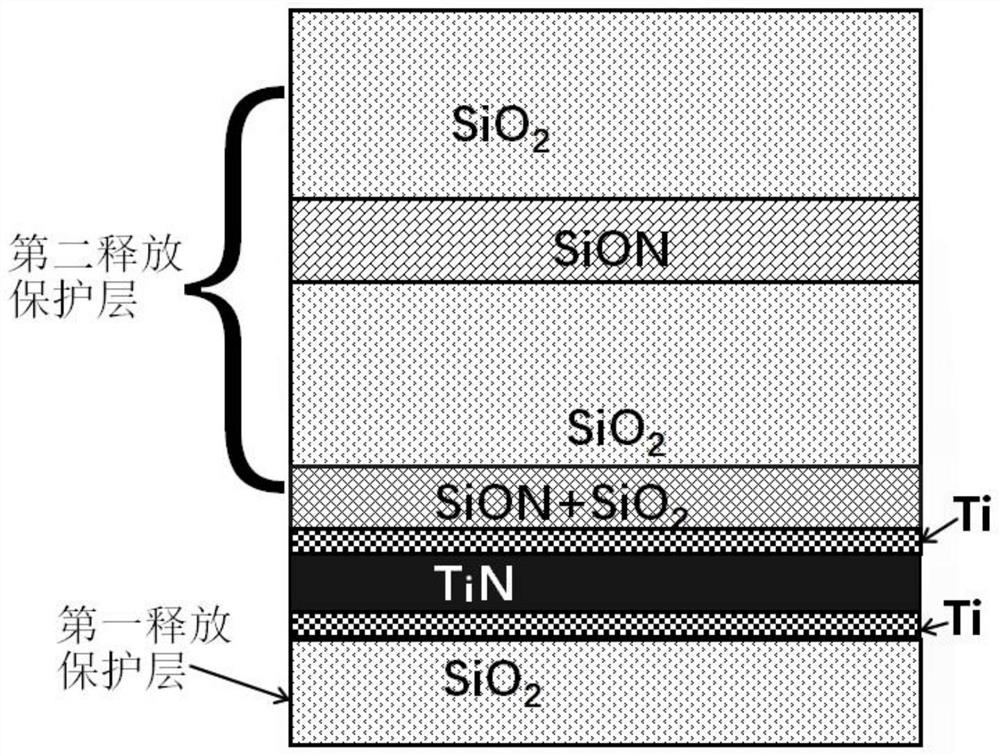

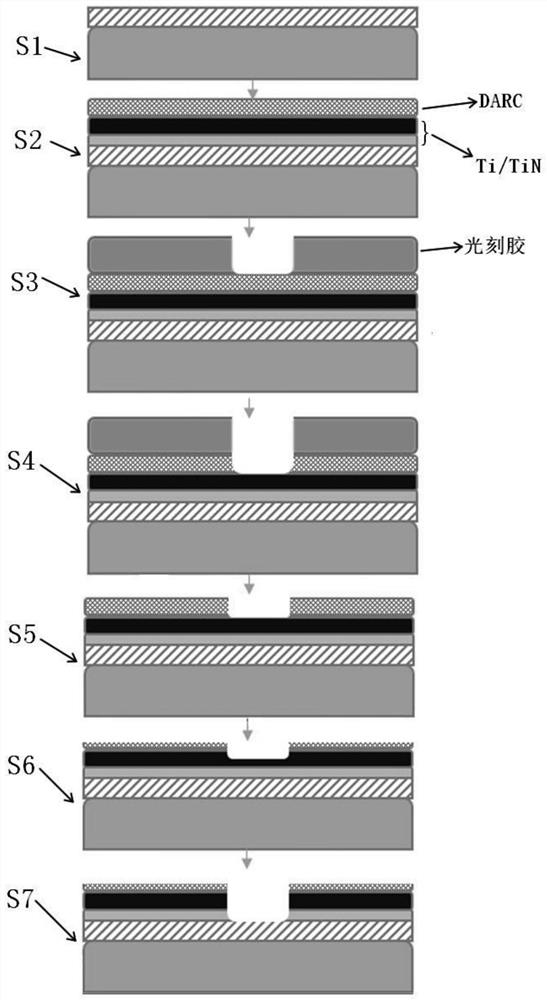

Infrared MEMS bridge column structure and process method

PendingCN112047294AOxidation barrierAvoid removalTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEtchingOxygen ions

The invention discloses an infrared MEMS bridge column structure and a forming method, and the structure employs a multilayer film composite structure which comprises a first release protection layer,a metal dielectric layer, and a second release protection layer. The first release protection layer is a silicon oxide layer; the second release protection layer is of a four-layer structure and sequentially comprises a silicon oxynitride and silicon oxide mixed layer, a silicon oxide layer, a silicon oxynitride layer and a silicon oxide layer from bottom to top; and the metal dielectric layer comprises three layers of structures, namely a Ti layer, a TiN layer and a Ti layer in sequence from bottom to top. According to the method, the metal Ti layer is added to the thin film layer when the metal dielectric layer is deposited, when the DARC is etched, the metal Ti layer can effectively prevent the TiN layer from being oxidized due to bombardment of oxygen ions during etching photoresist removal, subsequent wet etching is easier to remove completely, and residues are prevented.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method of graphene composite protective layer for prebaked carbon anode

The invention belongs to the field of carbon anode new materials for the electrolytic aluminium industry, and particularly relates to a preparation method of a graphene composite protective layer fora pre-baked carbon anode. The preparation method includes the steps of (1), adding graphene oxide in distilled water, stirring uniformly ultrasonically, adding phenolic resin with heating and stirring, performing redox reaction to obtain aqueous dispersion solution of graphene phenolic resin; (2) weighing a certain quantity of aqueous dispersion solution of graphene phenolic resin, sequentially adding graphite powder emulsion and nanometer aluminium oxide into the aqueous dispersion solution of graphene phenolic resin, and performing ultrasonic dispersion to obtain a graphene composite coating; (3), taking the graphene composite coating obtained the step (2), adding distilled water to dilute the graphene composite coating, covering the surface of the pre-baked carbon anode with the dilutedgraphene composite coating, and then drying naturally to obtain the graphene composite protective layer. The protective layer can effectively isolate oxidation action of air and carbon dioxide to carbon blocks; the carbon yield ratio in the air reactivity test is greater than 95%, and particularly the carbon yield ratio is greater than 96% after the CO2 reactivity test.

Owner:SUNSTONE DEV

A kind of preparation method of refractory metal molybdenum protective film resistant to liquid lead and bismuth corrosion

ActiveCN111020552BOxidation barrierIsolated contactMetallic material coating processesCrucibleLiquid state

Owner:XI AN JIAOTONG UNIV

Metallized film for rail transit locomotive and processing technology thereof

InactiveCN107331510BOxidation barrierReduce capacityThin/thick film capacitorStacked capacitorsSelf-healingEvaporation

The invention relates to a metalized film used for a rail transit locomotive and a processing technology thereof. The processing technology comprises the steps of insulation basal film pretreatment, primary evaporation for preparing an aluminum coated layer, insulation basal film secondary treatment and performing secondary evaporation on the aluminum coated layer for composite preparing a tin coated layer. Oxidation of the aluminum coated layer can be effectively prevented by the tin coated layer, and sharp declining of the capacity of the capacitor does not occur in working under the AC high voltage and high current. The subsequent capacity of the capacitor does not influenced even insulation defects exist on the insulation basal film; and continuous breakdown of the multilayer insulation basal film does not occur in case of self-healing so that the phenomenon of large-area burning can be avoided. Therefore, the capacitor prepared by coiling of the metalized film can be massively applied to the rail transit locomotive to act as the energy storage component.

Owner:宋仁祥

Silicon carbide-based composite foam ceramics with multi-layer pore-reinforcement structure and preparation method thereof

The invention discloses a silicon carbide-based composite foamed ceramic of a multilayer hole rib structure and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing silicon carbide, micro alumina powder, silicon powder, ammonium lignosulfonate, polycarboxylate and water so as to prepare slurry I; uniformly mixing micro alumina powder, a silicon source polycarboxylate and water so as to prepare slurry II; then dipping polyurethane sponge in the slurry I, and successively carrying out extruding or slurry centrifugation, drying and heat preservation at 600 to 850 DEG C for 0.5 to 3 h so as to obtain a presintered body of silicon carbide foamed ceramic; subjecting the presintered body of silicon carbide foamed ceramic to vacuum dipping in the slurry II and successively carrying out slurry centrifugation and drying so as to obtain a green body of silicon carbide-based composite foamed ceramic; and carrying out heat preservation at 1300 to 1500 DEG C in an air atmosphere for 2 to 4 h so as to prepare the silicon carbide-based composite foamed ceramic of the multilayer hole rib structure. The preparation method has the characteristics of simple process and low cost; and the prepared silicon carbide-based composite foamed ceramic of the multilayer hole rib structure has high mechanical strength, good thermal shock resistance and excellent high-temperature anti-oxidation performance.

Owner:WUHAN UNIV OF SCI & TECH

Energy-saving safe support system applied to solar heat power generation

InactiveCN108864890AImprove stabilityReduce harmEnergy inputAnti-corrosive paintsRare-earth elementCross-link

The invention discloses an energy-saving safe support system applied to solar heat power generation. The support system is used for supporting a fused salt pipeline and comprises a main frame and heatinsulation blocks, wherein the heat insulation blocks are distributed on the main frame; a protection layer is also arranged on the main frame and is prepared from the following components in parts by mass: 15-20 parts of organosilicone-modified epoxy resin, 10-15 parts of alcohol-soluble acrylate resin, 15-18 parts of ATO powder, 1-3 parts of potassium hexatitanate whisker, 2-4 parts of compoundferrotitanium powder, 10-12 parts of alcohol, 6-8 parts of sepiolite, 3-5 parts of glass powder, 5-10 parts of a dispersant, 5-8 parts of a leveling agent, 6-8 parts of a defoaming agent, 5-7 parts of a thickening agent, 1-2 parts of an ultraviolet absorbent, 1-3 parts of a cross-linking agent and 0.02-0.04 part of rare-earth element. The support system is simple and compact in structure, low incost and long in service life, and has excellent heat insulation performance and corrosion resistance.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

An anti-oxidation treatment process for steel structure materials before heat treatment

ActiveCN110773721BAccelerated corrosionImprove wear resistanceMolten spray coatingSurface roughnessOxidation resistant

The invention discloses an anti-oxidation treatment technology before steel structure material heat treatment. The anti-oxidation treatment technology specifically comprises the following steps of (1)steel structure material pretreatment, (2) steel structure material roughening treatment, and (3) steel structure material surface spraying treatment. According to the anti-oxidation treatment technology, by processing a steel structure material, on the premise that the strength of the steel structure material meets the industrial requirement, the grain size of the steel structure material is increased as much as possible, the surface height of the steel structure material is made to be different, and accordingly, the surface roughness of the steel structure material is improved; then, spraying powder is sprayed onto the surface of the steel structure material, an anti-oxidation coating is formed, oxygen is stopped from scattering into the steel structure material, and the situation thatthe steel structure material oxidizes in the heat treatment process, and oxide scale is generated is effectively prevented; and in addition, the corrosion resistance and the abrasion resistance of thesteel structure material can be improved through the coating subjected to heat treatment, influence on direct using or follow-up machining of workpieces is avoided, and the wide application prospectis achieved.

Owner:MAANSHAN SANCHUAN MACHINERY MFG CO LTD

A processing method for inhibiting browning of dried fruit slices

ActiveCN105248626BOxidation barrierEasy to controlFood processingFruits/vegetable preservation by coatingDrug biological activityPre cooling

The invention discloses a processing method for inhibiting browning of dried fruit slices. The processing method comprises the following steps: raw material pretreatment, plant colloid embedding, liquid nitrogen pre-cooling, low-temperature mixed gas quick freezing, low-temperature vacuum lyophilization, heat pump drying and packaging. According to the processing method, the shortcomings of the existing dried fruit slice processing method and the quality defect of a product are overcome; the processing time is further shortened, the energy consumption is reduced, the production efficiency is improved, browning of the dried fruit slices is effectively inhibited, the drying quality is high, the color, the fragrance, the shape, the biological activity and the nutritional components of the dried fruit slices are retained to the maximum extent, and the preservation time is long.

Owner:HANSHAN NORMAL UNIV +1

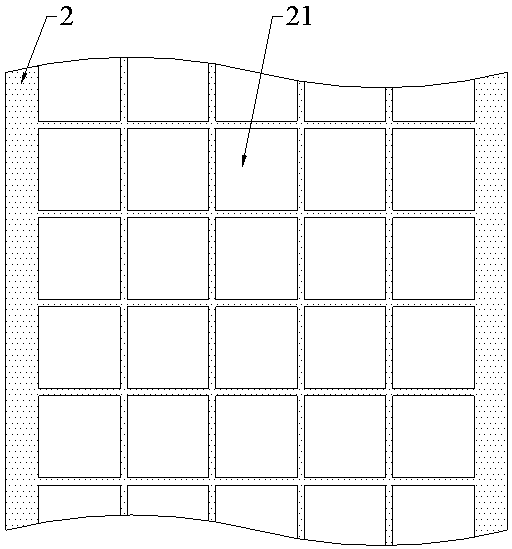

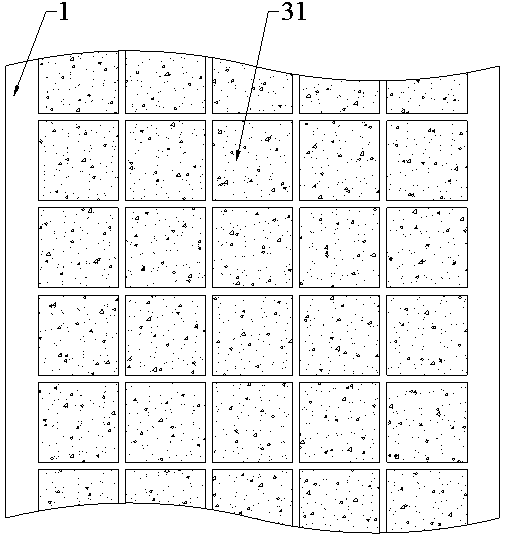

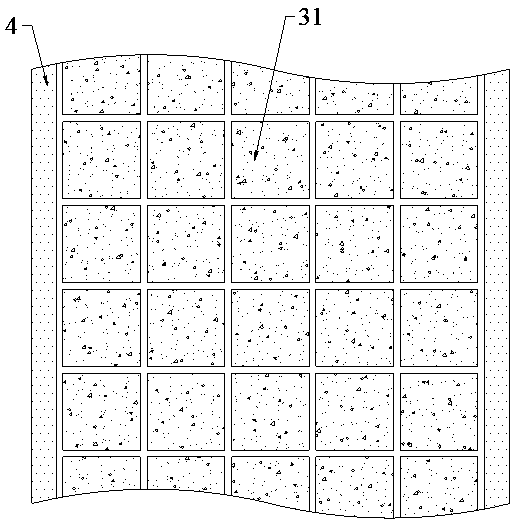

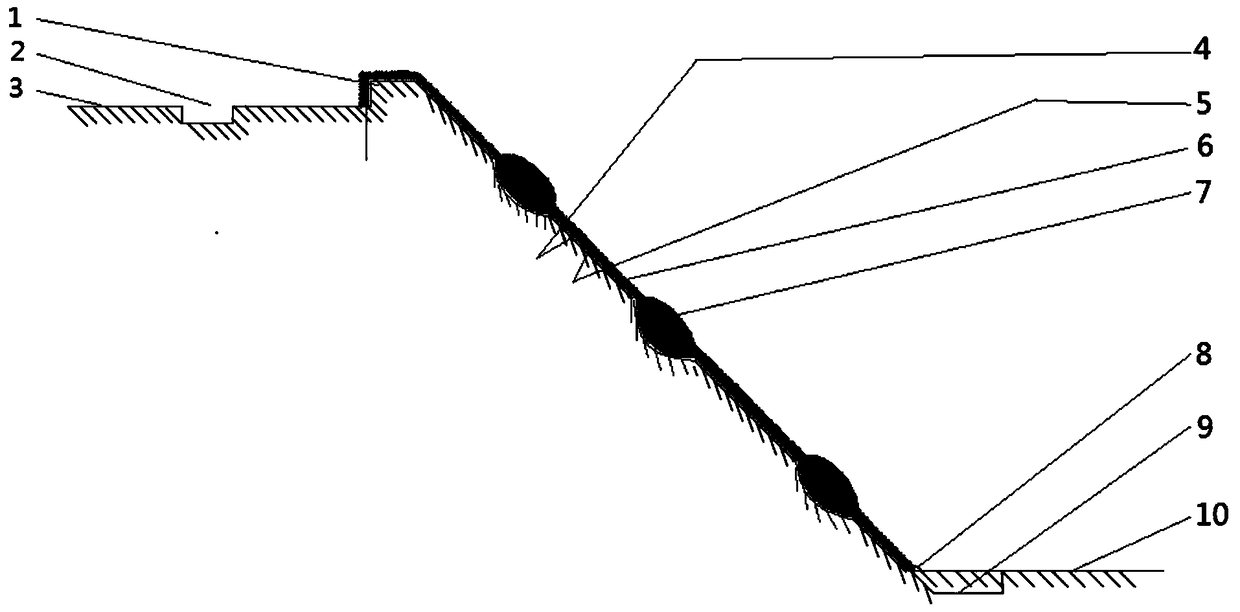

Slope protection structure and construction method of sea cucumber culture pond

InactiveCN105265372BSimple layingLow costPisciculture and aquariaFresh water organismFreshwater discharge

The invention provides a slope protection structure of a sea cucumber culturing pond and a construction method thereof, wherein the slope protection structure and the construction method belong to the field of aquaculture. The slope protection structure comprises a freshwater discharging trench, a slope upper edge, a slope surface, fixed pendants and a slope lower trough. The freshwater discharging trough is arranged at the central part in a pond dam and forms an independent ditch along the longitudinal direction of the pond dam. The slope upper edge extends along the dam body and is forms a ridge-shaped member above the pond dam. The slope upper edge is connected with the upper end of the slope surface of the pond. The lower end of the slope surface of the pond is connected with the bottom of the pond. An included angle is formed between the slope surface of the pond and the bottom surface of the pond. The lower end of the slope surface extends to the portion below the bottom surface of the pond along the slope surface, thereby forming the slope lower trough of a recessed structure. The portion above the slope lower trough is compressed by soil at the bottom of the pond. Fixed pendants are arranged on the slope surface in a laying manner. The materials of the slope protection are characterized in that a canvas layer is laid in a manner of clinging to the ground and a cement mortar is laid above the canvas through high-pressure injection. The slope protection structure has advantages of simple laying, low cost, long service life and easy popularization.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI +1

Protective solvent for magnesium alloy smelting and preparation method thereof

The invention provides magnesium alloy smelting protection solvent and a preparation method thereof. The magnesium alloy smelting protection solvent comprises the following chemical components in parts by weight: 8-15 parts of barium carbonate, 12-15 parts of calcium sulfate, 12-17 parts of nanometer zirconium oxide, 12-15 parts of magnesium chloride, 12-20 parts of hydroxyapatite, 12-20 parts of magnesium silicate, and 1-5 parts of lithium chloride. The preparation method is to perform the mixing after the drying. The smelting protection solvent, provided by the invention, is molten to a liquid state in an environment of higher than 500 DEG C in the smelting process, and is spread on the surface of an alloy or molten magnesium to achieve an air isolating effect and to stop the magnesium oxidation so as to obtain excellent protection performance.

Owner:贵州航天风华精密设备有限公司

Atomic oxygen resistant molybdenum disulfide-based organic or inorganic hybrid lubricating coating and preparation method

ActiveCN105153927BImprove wear resistanceOxidation barrierPretreated surfacesAnti-corrosive paintsLubricationCold welding

The invention provides an atomic oxygen disulfide-resistant molybdenum disulfide-based organic or inorganic hybrid lubricating coating and a preparation method thereof. Composed of oxidation modifier, dispersant, mixed solvent and modified silica sol. The present invention can overcome the problem that the adhesive and lubricant of MoS2 solid lubricating coating bonded by polyamide-imide for space are easily oxidized by atomic oxygen, and is especially suitable for the moving parts of aircraft in the space low-orbit environment, such as gears, screw-nuts, Surface lubrication and anti-cold welding treatment of friction pairs such as shaft-shaft sleeves and slideways.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

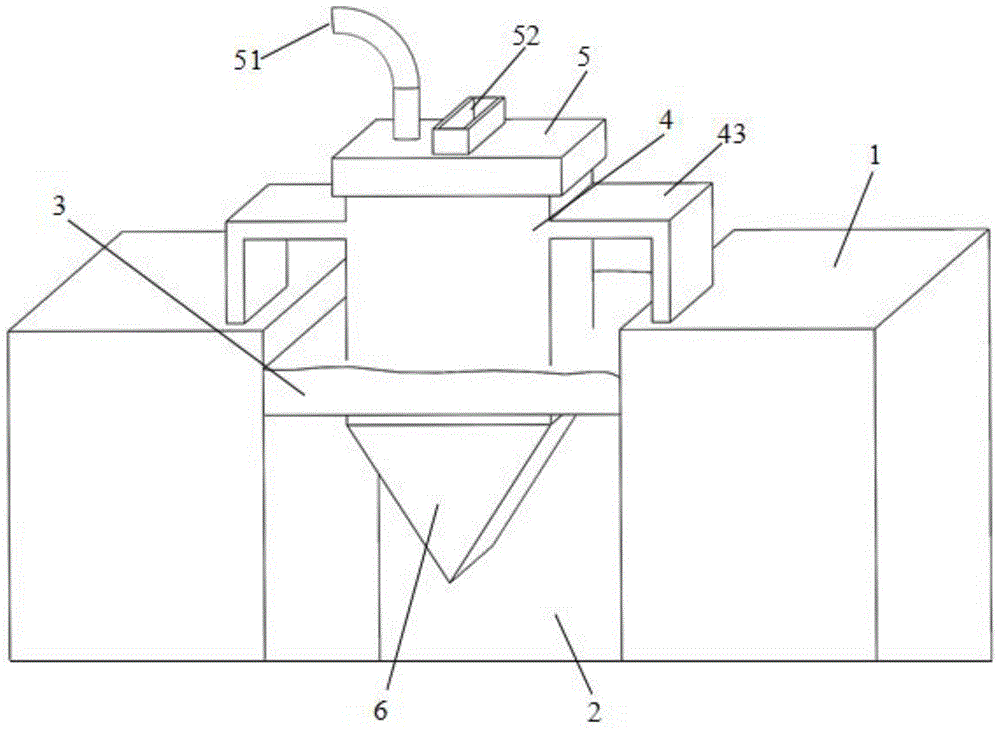

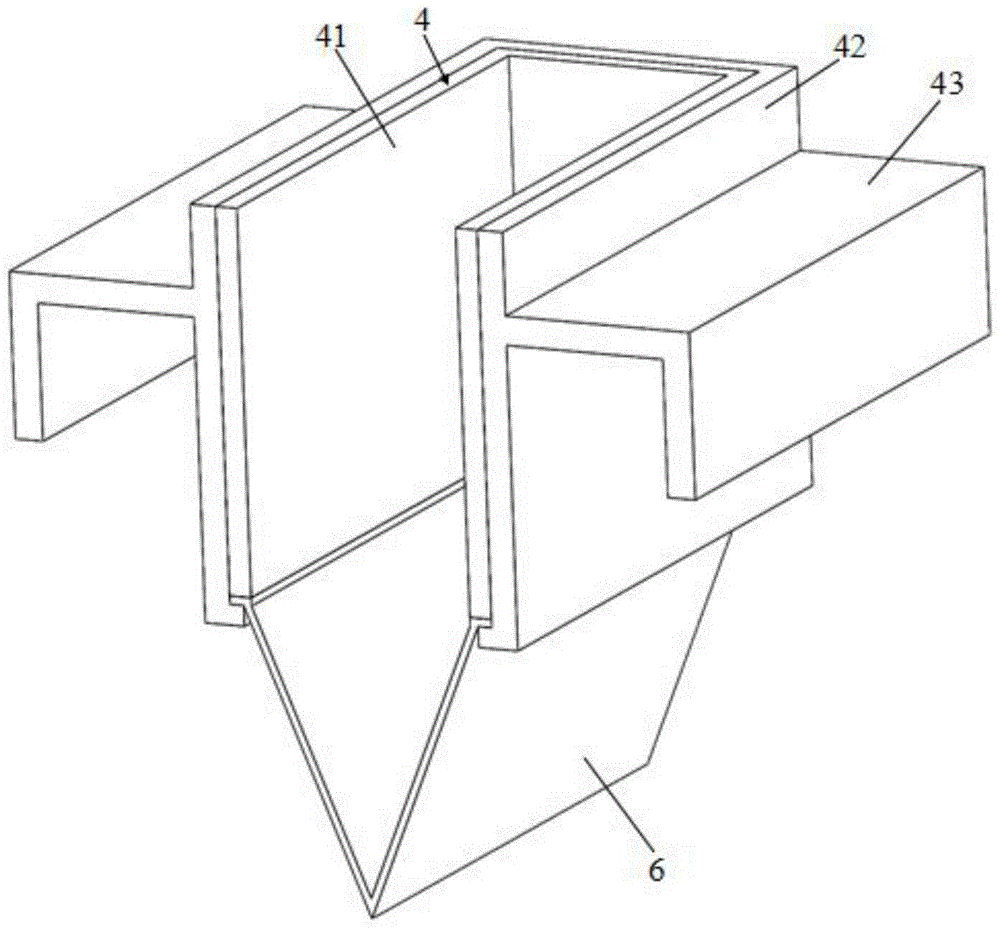

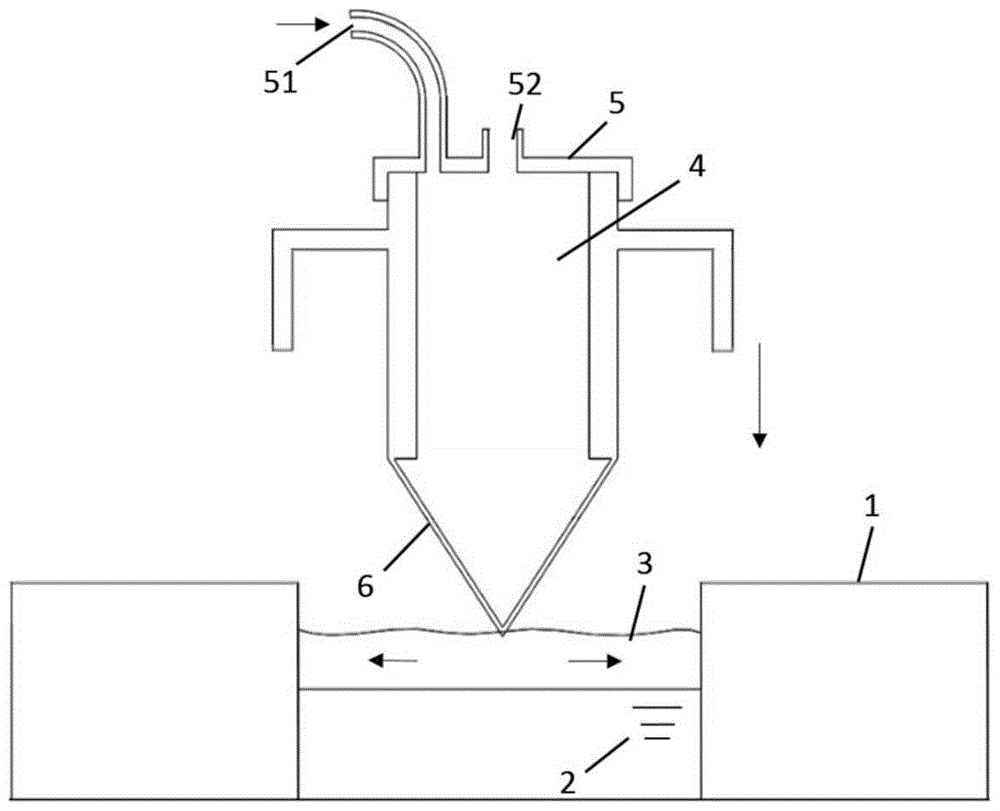

A kind of slagging device and method for feeding steel belt of gas shielded continuous casting crystallizer

A slag discharge device and method for a steel feeding belt in a gas-protected continuous casting mold, used in a continuous casting mold. There is molten steel in the crystallizer, and there is protective slag on the top surface of the molten steel. The slag discharge device includes a hollow cover body , the top of the cover body is provided with an upper cover, and the upper cover is provided with a feed port and an air inlet. The feed port is for feeding the steel strip, and the air inlet is for inert gas to enter. The lower end of the cover body enters the molten steel, and the lower end of the cover body enters the molten steel. The bottom is connected with a steel slag discharging piece. The steel slag discharging piece displaces the protective slag and enters the molten steel. The size of the steel slag discharging piece gradually decreases from top to bottom. Inert gas enters from the air inlet and is discharged from the pores of the feed port to protect the molten steel from oxidation. At the same time, when the slag discharge device extends into the crystallizer, the steel slag discharge parts with a narrow lower part and a wide upper part remove the protective slag. Displace it so that the cover body is partially immersed in the molten steel to prevent the protective slag from entering the cover body. Therefore, when the steel strip is inserted into the molten steel, it will not touch the protective slag and prevent the protective slag from entering the molten steel.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com