Patents

Literature

52results about How to "Function as an air barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof coiled material with high flame retardance

InactiveCN106223549AImprove flame retardant performanceFunction as an air barrierRoof covering using flexible materialsProtective foundationGlass fiberPolymer modified

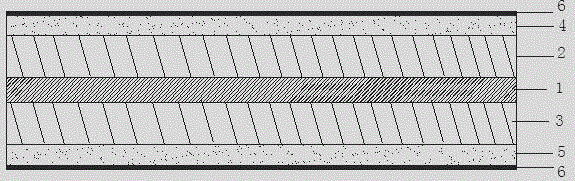

The invention provides a waterproof coiled material with high flame retardance and a preparation method. The waterproof coiled material comprises a glass fiber mat, wherein waterproof layers are arranged on the upper and lower surfaces of the glass fiber mat; flame retardant layers are arranged on the surfaces of the waterproof layers; the glass fiber mat is an alkali glass fiber mat; the waterproof layers are SBS modified asphalt layers; the flame retardant layers are graphene modified polyurethane coatings. The preparation method comprises the following steps: (1) preparation of SBS modified asphalt; (2) preparation of a polystyrene / graphene nanocomposite; (3) preparation of the waterproof material. The waterproof coiled material and the preparation method have the beneficial effects that by adopting the polystyrene / graphene nanocomposite layers as the flame retardant layers, the flame retardance of the polymer modified asphalt waterproof coiled material can be greatly improved, so the waterproof coiled material meets the requirements of the construction industry at present, and the waterproof coiled material is simple in preparation process and has higher application value.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

Magnesium and magnesium alloy composite protection fire-proof covering flux and its production method

InactiveCN1570162AGood flame retardant performanceImprove the protection effectFire retardantFluoride calcium

A magnesium and magnesium alloy composite protection fire-retardant covering flux and its manufacturing method are provided. The chemical components of the covering flux are as follows (by weight): 50% to 70% of magnesium chloride, 8% to 18% of potassium chloride, 7% to 16% of sodium chloride, 1% to 8% of calcium chloride,1% to 8% of calcium fluoride,1% to 7% of magnesia, 1% to 5% of fluxing medium cryolite, 0.5% to 6% of carbonate foaming agent, 0.5% to 4% of beryllide fire retardant. The flux provided by the invention has excellent flame retardant property.

Owner:SHANGHAI AIERSI LIGHT ALLOY

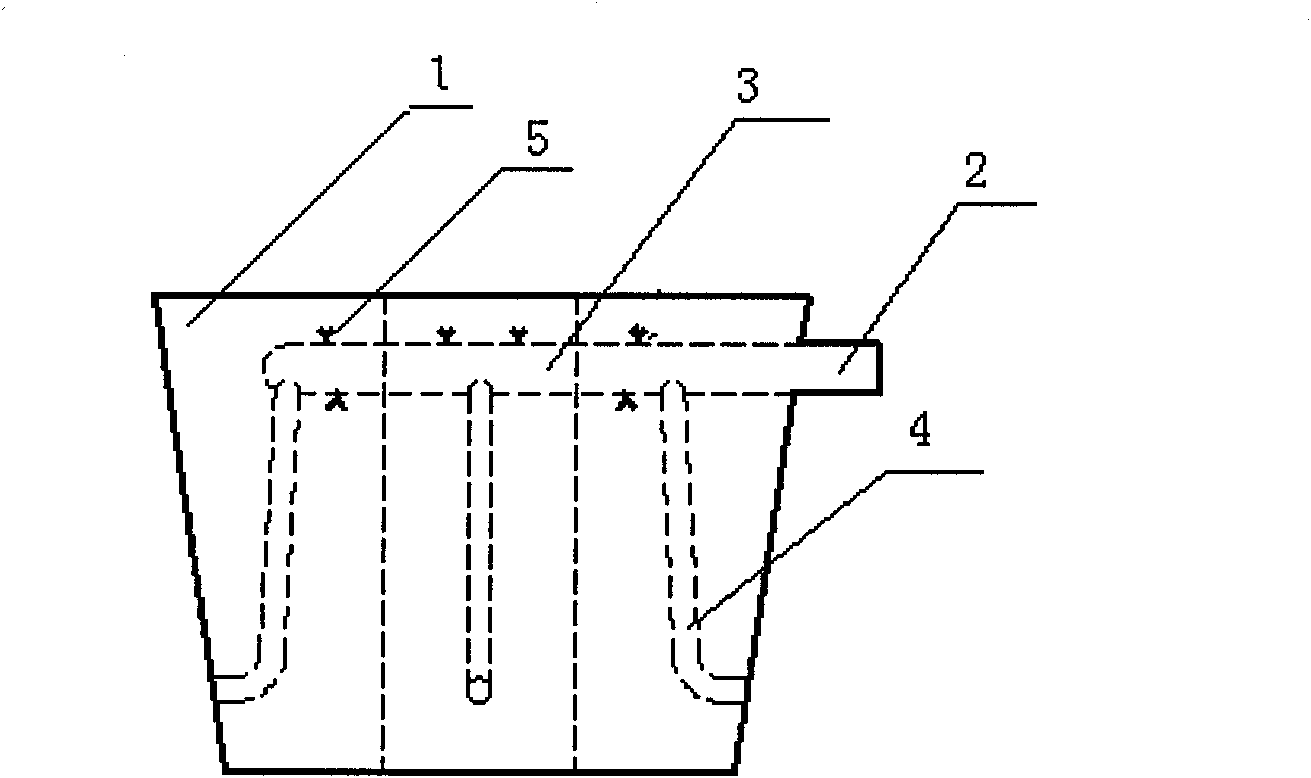

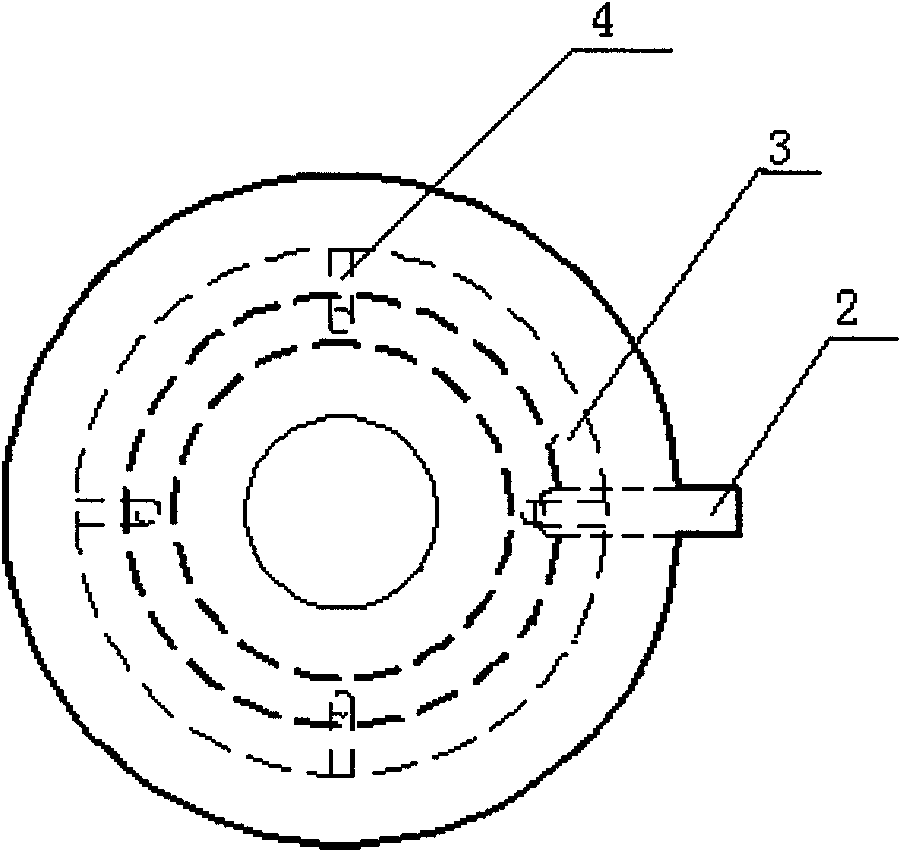

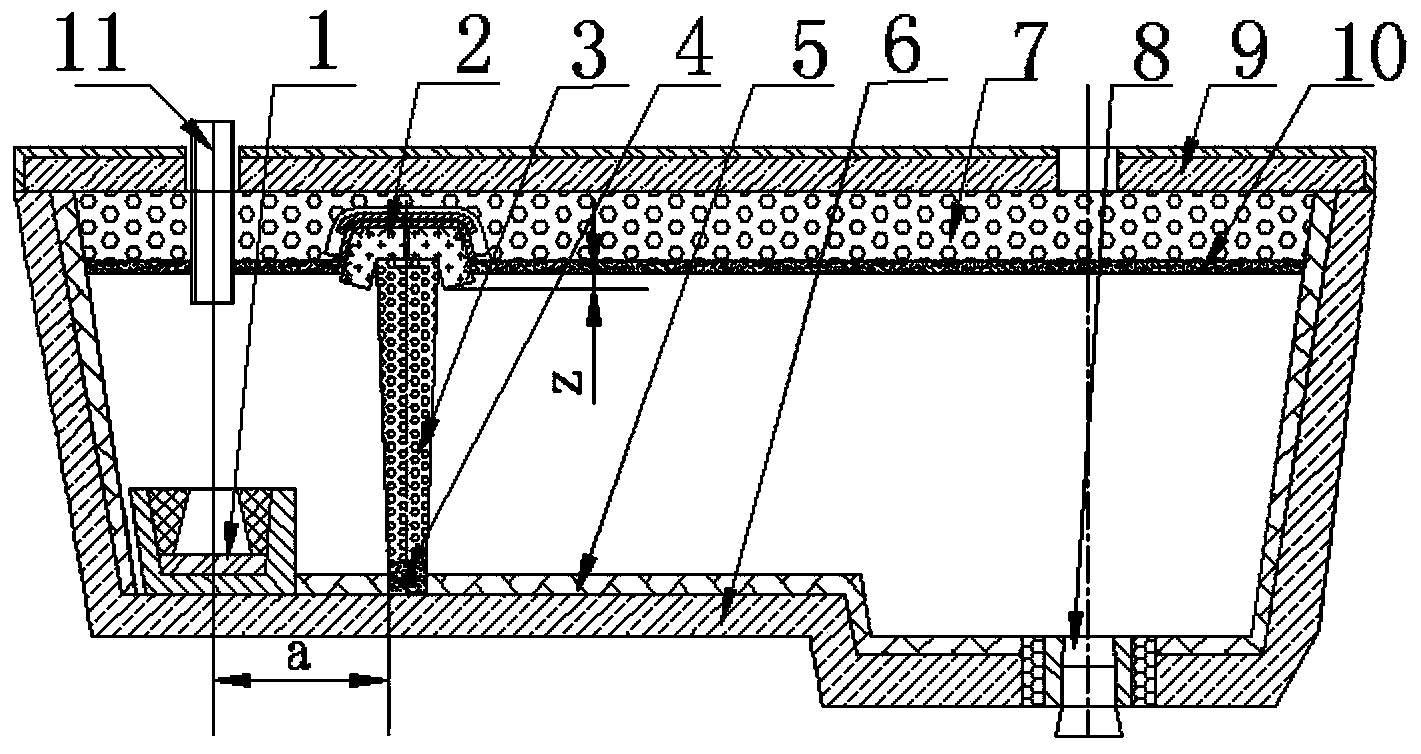

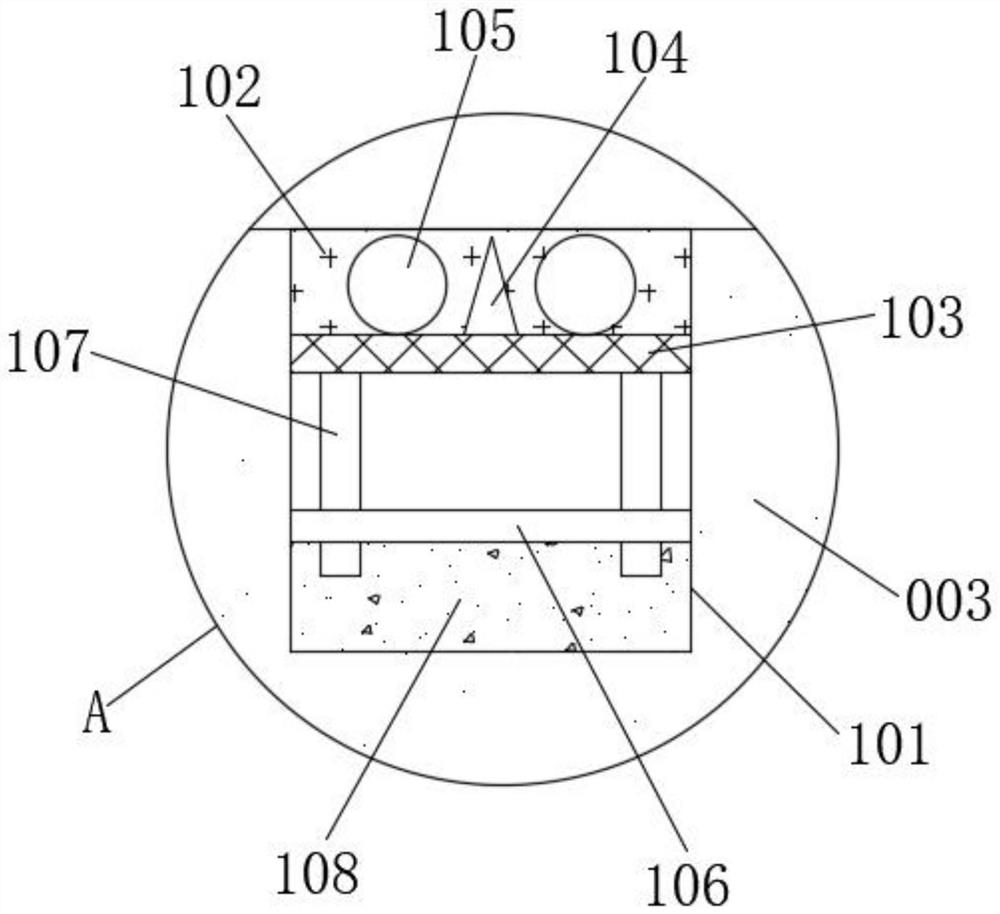

Water collecting type inflaming retarding garbage can

ActiveCN109132285AImprove the sealing effectImprove pumping effectRefuse receptaclesEngineeringSanitation

The invention belongs to the field of environment sanitation facilities, and particularly relates to a water collecting type inflaming retarding garbage can. The water collecting type inflaming retarding garbage can comprises a base, the upper end of the base is fixedly connected with a can body, a can cover is rotatably connected into the can body, a water storage cavity is formed in the base, anannular water collecting groove is formed in the upper end of the base, and communicates with the water storage cavity through multiple water conveying channels, multiple water sucking pipes are arranged on the side wall of the can body in a penetrating manner, the input ends of the water suction pipes are attached to the bottom face of the water storage cavity, the output ends of the water suction pipes are arranged on the inner side wall of the can body, multiple Z-shaped air exhaust channels are formed in the inner side wall of the can body, two ends of the Z-shaped air exhaust channels are arranged on the inner and outer side walls of the can body, an annular cavity is formed in the inner side wall of the can body, a piston ring is in sliding seal connection into the annular cavity, and the interior of seal space formed by the lower side wall of the piston ring and the annular cavity is filled with evaporation liquid. Collected rainwater is used for achieving fire extinguishing ofthe garbage can, and the garbage can is energy-saving, environment-friendly, high in speed and capable of avoiding large danger.

Owner:杭州杉芽科技有限公司

Method for preparing modified aliphatic ester plasticizer

InactiveCN101993783AImprove performanceImprove flame retardant performanceFatty acid chemical modificationPolyvinyl chlorideFatty acid methyl ester

The invention discloses a method for preparing a modified aliphatic ester plasticizer. Aliphatic methyl ester (or ethyl ester) is subjected to epoxidation reaction and then subjected to chlorine addition and chlorine substitution reaction, the tail gas is treated by adopting a secondary tail gas absorption device, and a calcium chloride byproduct (a water treatment agent) is manufactured. The method has the advantages that: the process is clean; and the modified aliphatic ester plasticizer has the properties of epoxy groups and chlorine ions, and has the properties of light resistance, heat resistance, stability and flame resistance as a plasticizer product. The product of the invention can be widely applied to polyvinyl chloride (PVC) tubes, profiles, PVC films and artificial leather polyurethane (PU) products with flame-resistant requirements, and plays a good role in resisting flame and plasticizing.

Owner:浙江嘉澳环保科技股份有限公司

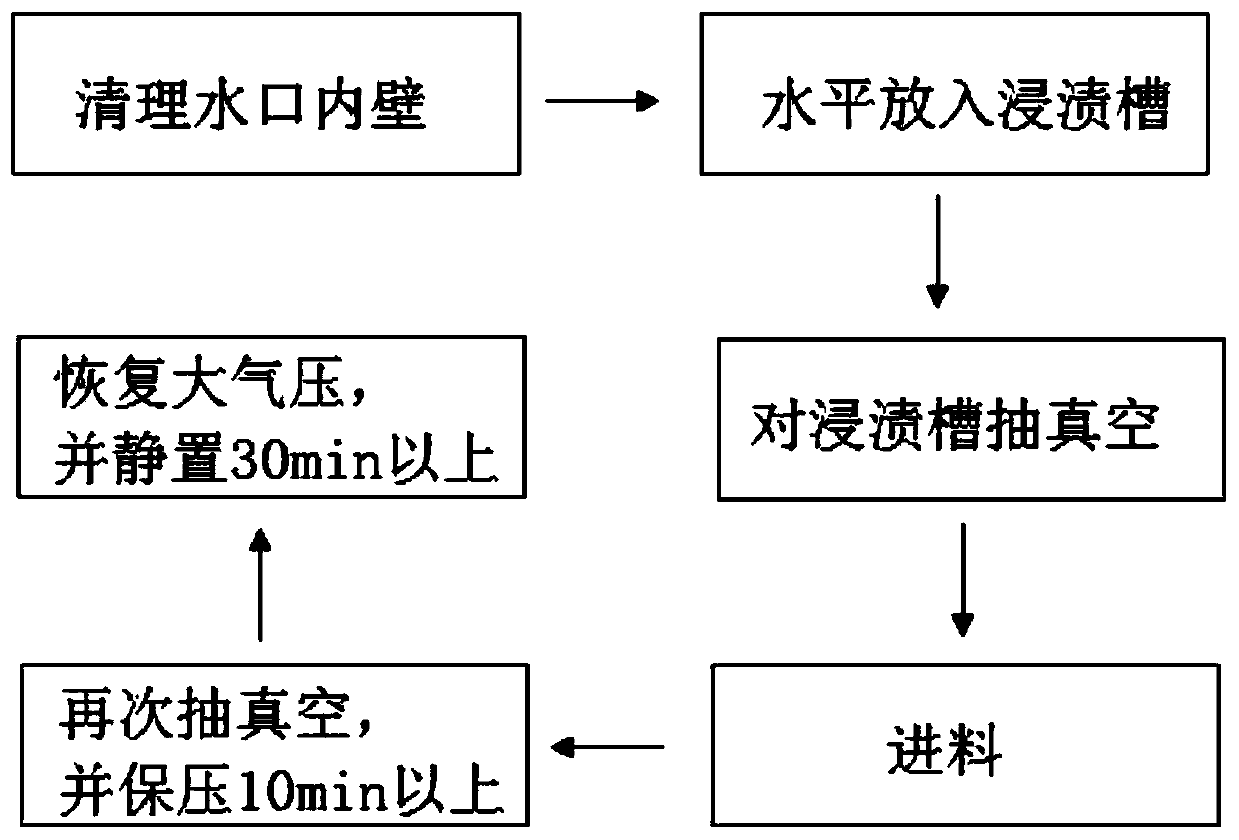

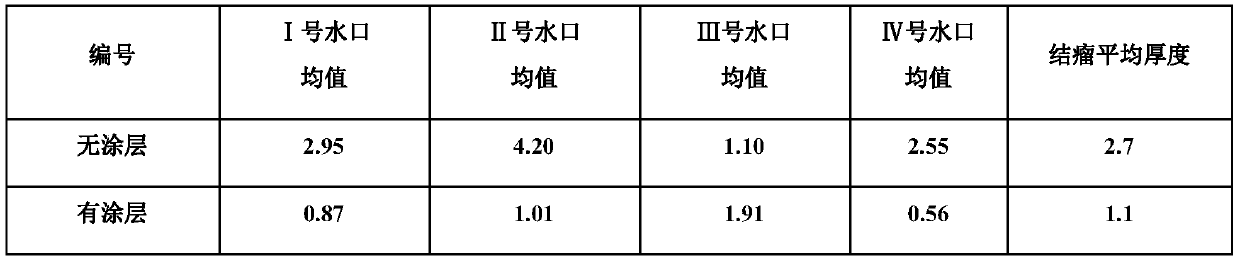

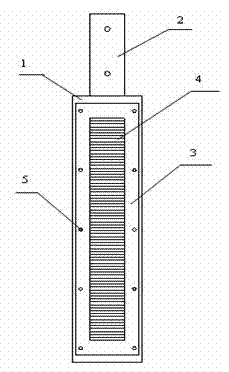

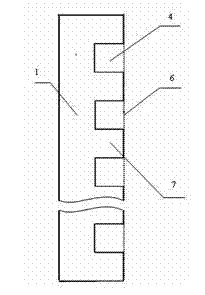

Coating material for preventing submersed nozzle from nodulation and preparation method thereof

ActiveCN110922214AGood adhesion performanceGood oxidation resistanceMelt-holding vesselsPhosphoric acidOxide

The invention discloses a coating material for preventing a submersed nozzle from nodulation and a preparation method thereof, and belongs to the technical field of coating materials of submersed nozzles. The coating material comprises the following components in parts by weight: 20-56 parts of mullite fine powder, 15-23 parts of corundum fine powder, 4-8 parts of Guangxi white mud, 7-18 parts ofactivated aluminum oxide micro powder, 5-8 parts of aluminum dihydrogen phosphate, 8-12 parts of a fluxing agent, 2-11 parts of an antioxidant and 0.3-2.0 parts of a dispersing agent. The invention aims to solve the problems that in the prior art, a submersed nozzle is easy to bake and oxidize, and nodules are generated to block the submersed nozzle. According to the coating material for preventing the submersed nozzle from nodulation and the preparation method thereof, the purposes of preventing the submersed nozzle from being baked and oxidized and preventing air from entering molten steel through the nozzle in the using process can be achieved, and the submersed nozzle is prevented from blocking caused by nodulation.

Owner:MAANSHAN IRON AND STEEL COMPANY

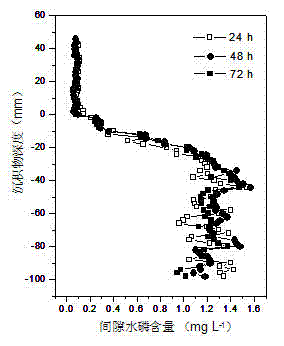

Device and method for acquiring and storing sediment pore water sample

ActiveCN102507262AIncrease vertical resolutionReduce the risk of oxidationWithdrawing sample devicesPreparing sample for investigationIonMembrane configuration

A device for acquiring and storing a sediment pore water sample comprises a main body and sampling grid chambers, wherein a group of horizontal grooves are distributed on the main body in a grid manner, a 0.45mum aperture permeation membrane is covered on the surface of the main body, the periphery of the permeation membrane is fixed by a frame on the main body, and the grooves are filled with water to form the sampling grid chambers with a length 10-30mm, a width 1mm, a volume 10-30muL and an interval 1.0mm. The device is vertically inserted into sediment and taken out when ion diffusion is balanced, and the pore water sample in the sampling grid chamber is cooled into ice and freezing-stored under the air isolation condition. After the device is taken out, defreezing is carried out at room temperature under the air isolation condition, and the permeation membrane is pierced to get the pore water sample sucked out from the sampling grid chamber for analysis. The inventive device and method have pore water collection vertical resolution 2mm and balance time 1-3 days in sediment, and the pore water sample can be stored in the device for at least three months.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

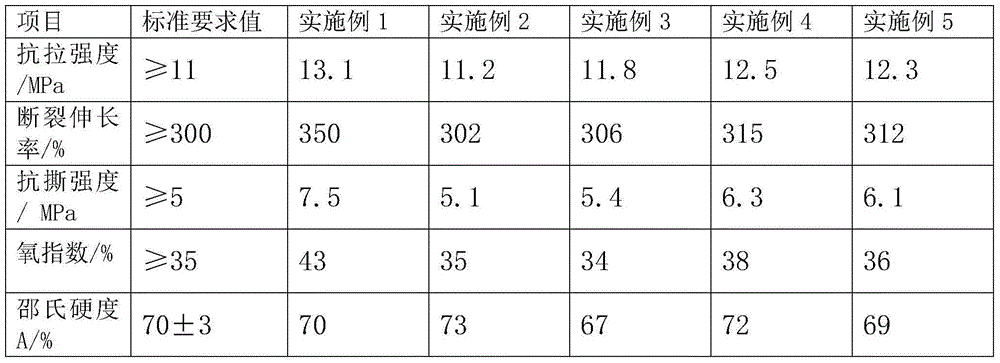

Building power cable rubber material, and preparation method thereof

The invention discloses a building power cable rubber material, and a preparation method thereof. According to the preparation method, silicone rubber and chlorinated polyethylene are subjected to plasticating so as to obtain plasticated rubber; zinc oxide, magnesium oxide, stearic acid, polyisobutylene, zinc methacrylate, and boric acid are added into the plasticated rubber, and an obtained mixture is subjected to first mixing so as to obtain a first mixed rubber compound; white carbon black and calcined clay are added into the first mixed rubber compound for second mixing so as to obtain a second mixed rubber compound; vulcanizing agent DCP, vulcanizing auxiliary agent TMPTMA, anti-aging agent RD, a coupling agent, Sb2O3, chlorinated paraffin, and Mg(OH)2 are added into the second mixed rubber compound for third mixing so as to obtain a third mixed rubber compound; the third mixed rubber compound is cooled so as to obtain the building power cable rubber material which possesses high strength and flame resistance.

Owner:合肥市再德高分子材料有限公司

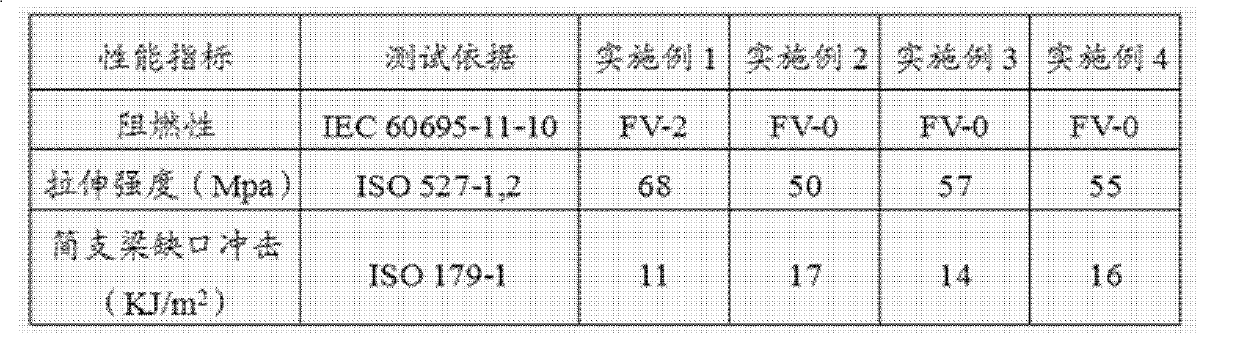

Flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

ActiveCN103374191ADilution concentrationFlame retardantChlorinated polyvinyl chlorideCombustible gas

The invention discloses a flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material which is prepared from the components in parts by weight: 40-80 parts of CPVC, 10-50 parts of ABS, 1-10 parts of a flame retardant and 1-8 parts of a processing agent. The invention further discloses a preparation method of the flame retardant CPVC-ABS alloy material. Compared with the prior art, CPVC in the alloy material disclosed by the invention combusts to generate HCl which can shield and dilute combustible gases. Antimonous oxide or (and) sodium antimonite in the initial combustion period is fused on the surface of the material to form a protective film to isolate air. In a high temperature state, antimonous oxide or (and) sodium antimonite is gasified to dilute oxygen concentration in air and is commonly used with CPVC to generate SbOCl and SbCl3, so as to have the flame retardant effect. The alloy material is less in use level and good in flame retardant effect.

Owner:滁州格美特科技有限公司

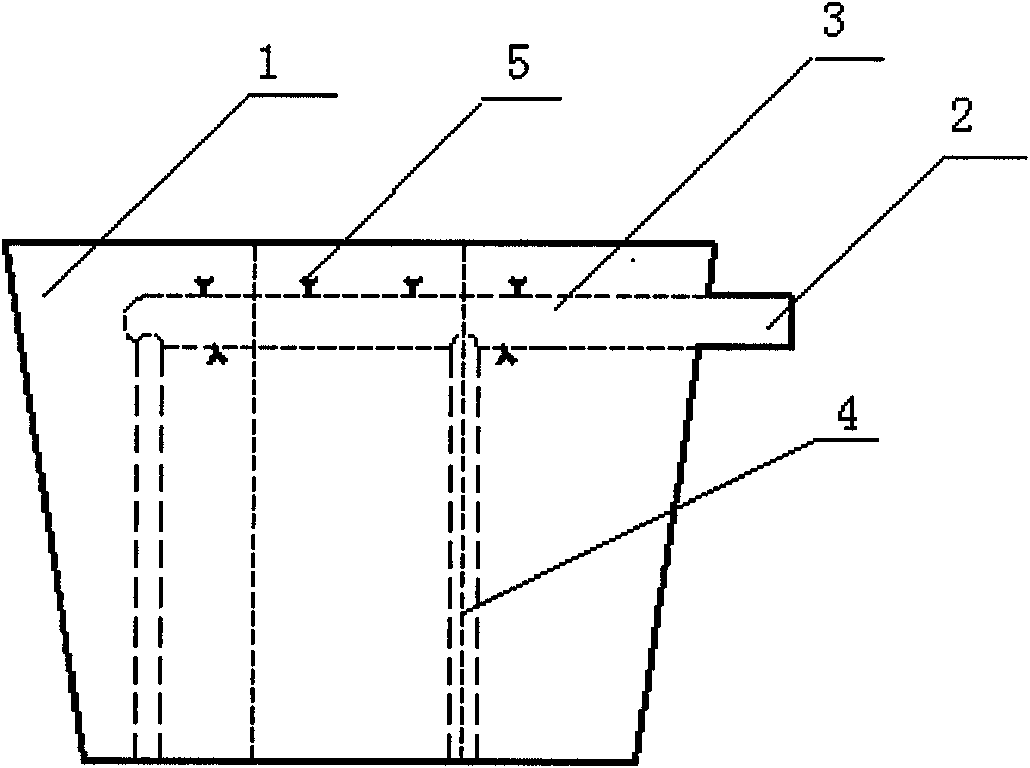

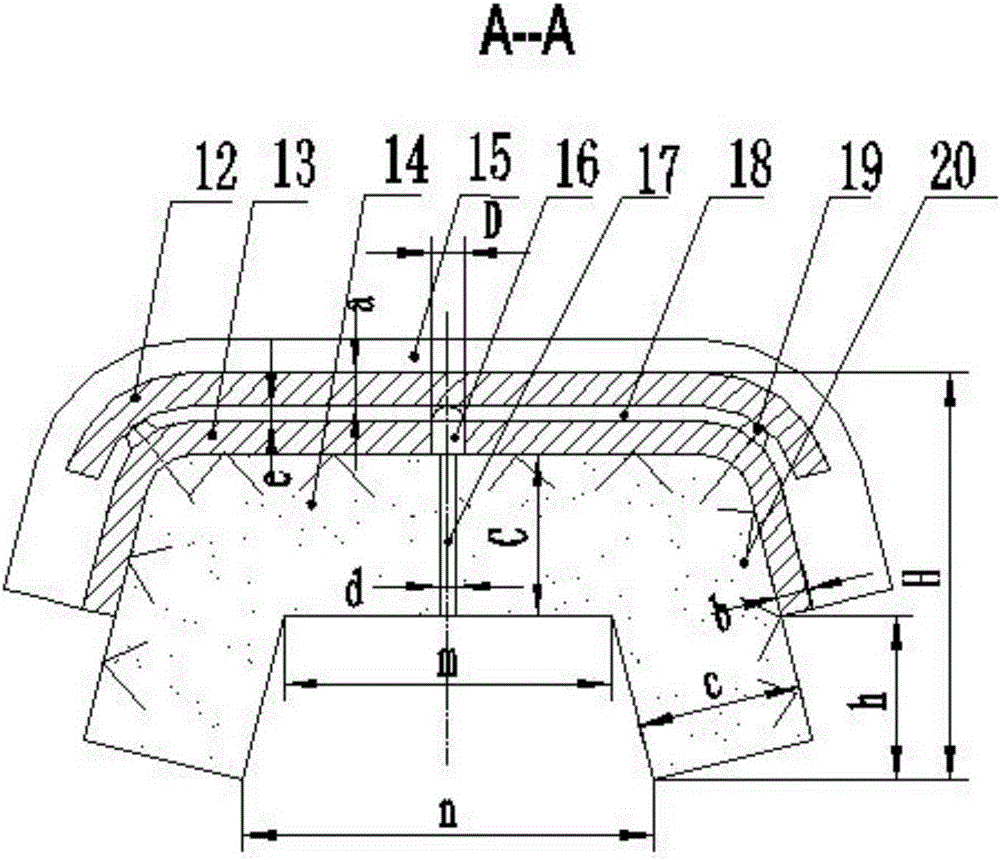

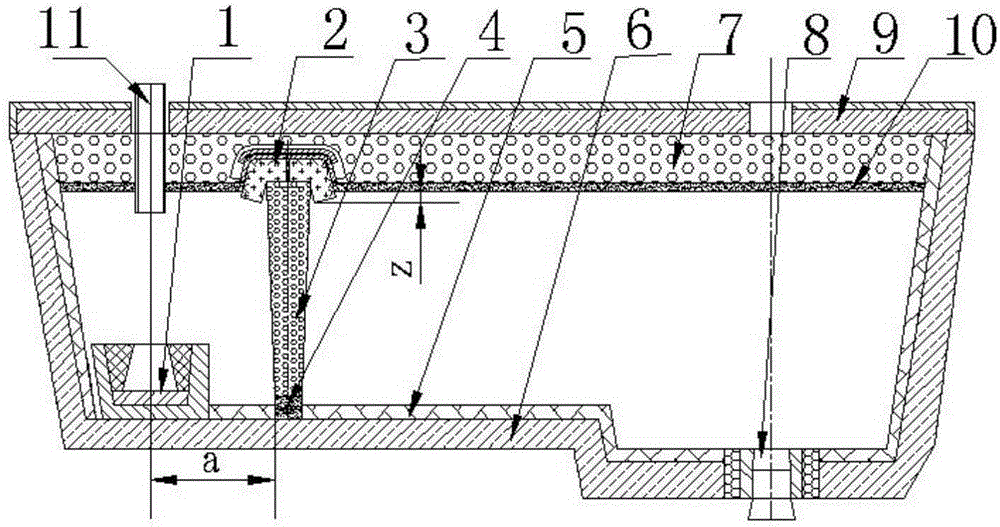

Argon-blowing prefabricated member for continuous casting tundish cover

InactiveCN102179491AImprove sealingGuaranteed metallurgical effectMelt-holding vesselsCooking & bakingMolten steel

The invention relates to an argon-blowing prefabricated member for a continuous casting tundish cover and belongs to the technical field of ferrous metallurgical equipment. Argon-blowing prefabricated members with difference sizes can be designed according to the size of a baking hole, a charging hole, a plug hole and the like of the tundish cover. The argon-blowing prefabricated member comprisesa prefabricated member body; the argon-blowing prefabricated member body has a shape of a cone of which the radius of the upper bottom is greater than that of the lower bottom, or the longitudinal section structure of the prefabricated member body is T-shaped. The prefabricated member body is hollow, an aeration pipeline is arranged in the prefabricated member body, and the prefabricated member body is provided with an aeration hole communicated with the aeration pipeline. The argon-blowing prefabricated member solves the problems that the peripheries of the baking hole and the plug hole are deformed and refractory materials fall off, and guarantee the cast-on can be performed smoothly; and the tightness of the tundish cover is improved, the reduction of the molten steel temperature is inhibited, the molten steel is prevented from being oxidized for secondary time, and meanwhile, the service life of the tundish cover can be prolonged.

Owner:LAIWU IRON & STEEL GRP

Waterproof anti-flaming photovoltaic coiled material and preparation method

InactiveCN108360759AImprove waterproof performanceImprove flame retardant performanceRoof covering using flexible materialsProtection layerPolyacrylamide

The invention discloses a waterproof anti-flaming photovoltaic coiled material. The photovoltaic coiled material sequentially comprises a transparent waterproof layer, a flexible photovoltaic module layer and a waterproof coiled material layer from top to bottom, and all layers are connected through grapheme modified epoxy adhesives. The transparent waterproof layer is a modified PE permeable film; the flexible photovoltaic module layer comprises a flexible thin film photovoltaic module, an ethylene-tetrafluoroethylene copolymer film layer and a graphene-silicone-modified polyacrylamide coating layer; and the waterproof coiled material layer sequentially comprises a reflecting film, a waterproof anti-flaming layer, a glass fiber mat layer and a self-adhered SBS modified asphalt layer fromtop to bottom, and the surface of the modified asphalt layer is provided with a PE protection layer. The waterproof anti-flaming photovoltaic coiled material is good in waterproof and anti-flaming performance, can fully realize the role of photovoltaic power generation, the production cost of the coiled material is low, the use is convenient, and the coiled material is suitable for popularizationand application.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

Flame-retardant graphene and polyurethane composite foam material and preparation method thereof

The invention relates to a flame-retardant graphene and polyurethane composite foam material. The material is prepared from, by mass, 10-30% of polyether polyol, 10-30% of polyester polyol, 40-50% ofisocyanate, 2-8% of a foaming agent, 0.5-5% of a foaming catalyst, 4-8% of a graphene-inorganic salt flame retardant and 1-4% of a foam stabilizer. The invention also discloses a preparation method ofthe material. The material of the invention has the advantages of good flame retarding effect, good mechanical properties, safety, non-toxicity, low cost and simple preparation process, and can meetlarge-batch production.

Owner:LANZHOU UNIVERSITY

Multi-segment combined nitrogen control method of high-strength microalloyed steel

InactiveCN106834610AExposure to NitrogenFunction as an air barrierManufacturing convertersSlagNitrogen

The invention discloses a multi-segment combined nitrogen control method of high-strength microalloyed steel. The multi-segment combined nitrogen control method comprises the following steps: a converter vanadium extracting process, a converter melting process, an LF (Ladle Furnace) refining process and a slab continuous casting protective casting process; the content of finished steel of the microalloyed steel is less than or equal to 0.005 percent. According to the multi-segment combined nitrogen control method disclosed by the invention, a slag layer with a certain thickness is formed on the surface of molten steel, so that a function of isolating air is obtained; a mode of firstly adding alloy materials with weak deoxidizing capacity and then adding alloy materials with strong deoxidizing capacity is adopted, so that the phenomenon of nitrogen increment caused by contact between the molten steel with the air due to a strong deoxidizing reaction in a steel ladle is prevented from happening; after tapping is ended, a steel ladle car can be driven to an argon blowing operation station, argon blowing and stirring can be carried out for 2 minutes, and the content of O in the molten steel is regulated to be less than or equal to 0.002 percent; the electric heating time is controlled through LF refining, calcium carbide is added in batches during a refining and heating process, so that furnace slag can be formed into good foam slag, the foam slag covers the surface of the molten steel to form a protective layer, and direct contact between the air and the molten steel is isolated. Through combined control of the processes, the microalloyed steel is finally obtained, and the content of N in the finished steel of the microalloyed steel is less than or equal to 0.005 percent.

Owner:HEBEI IRON AND STEEL

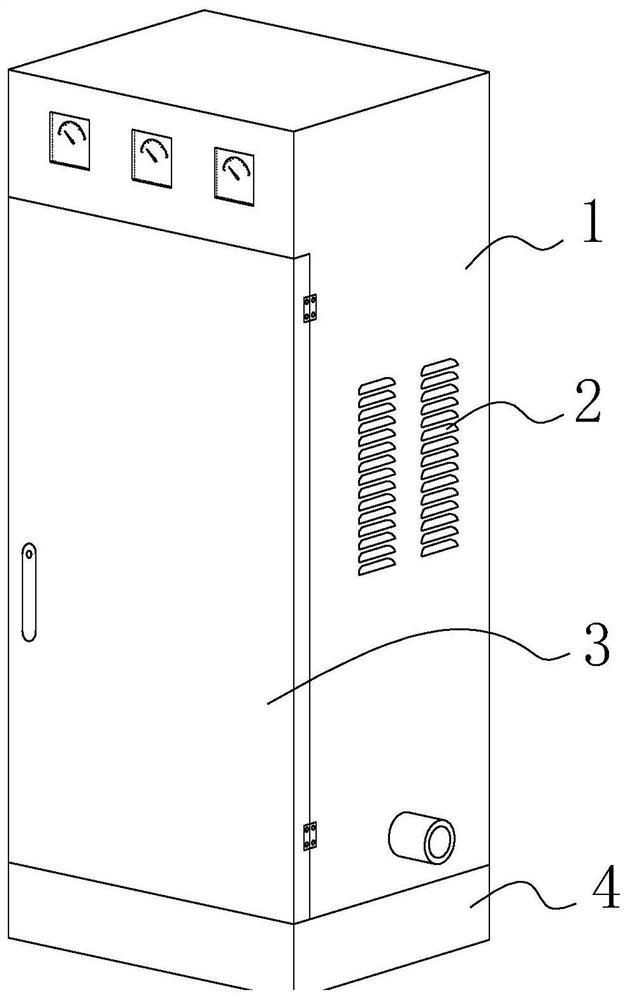

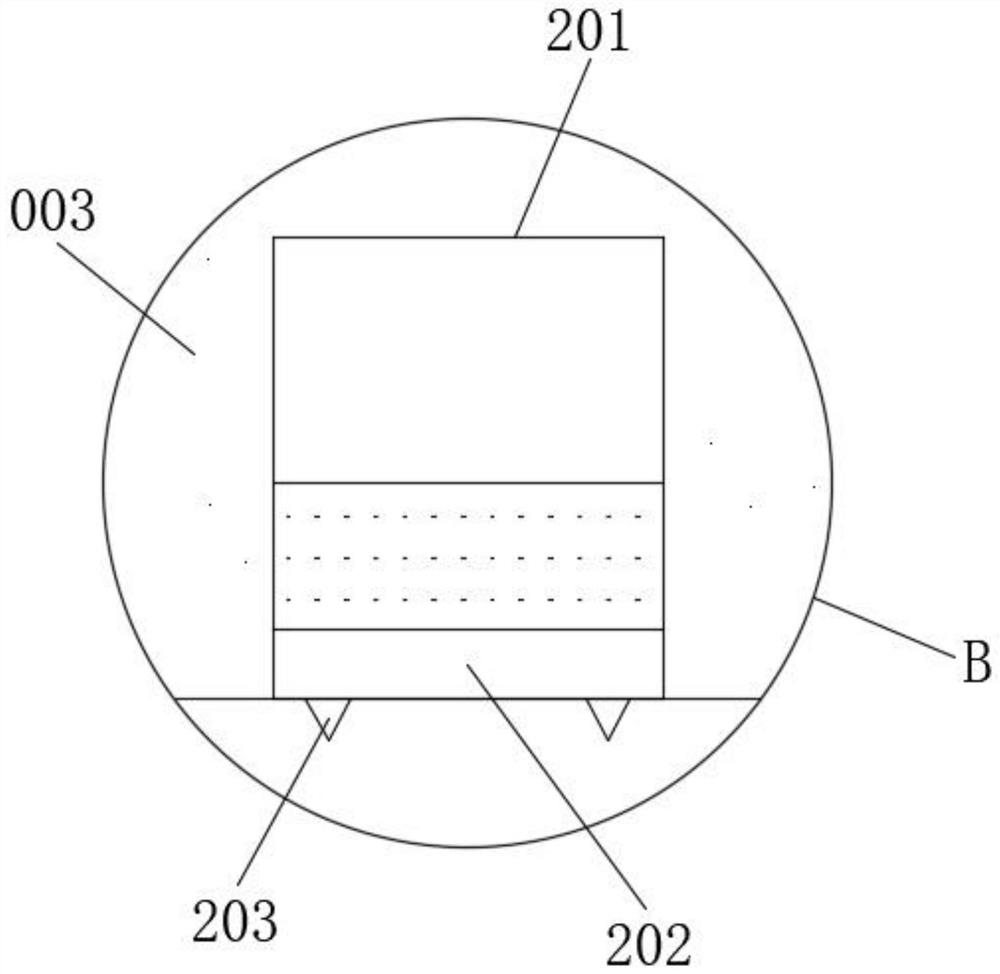

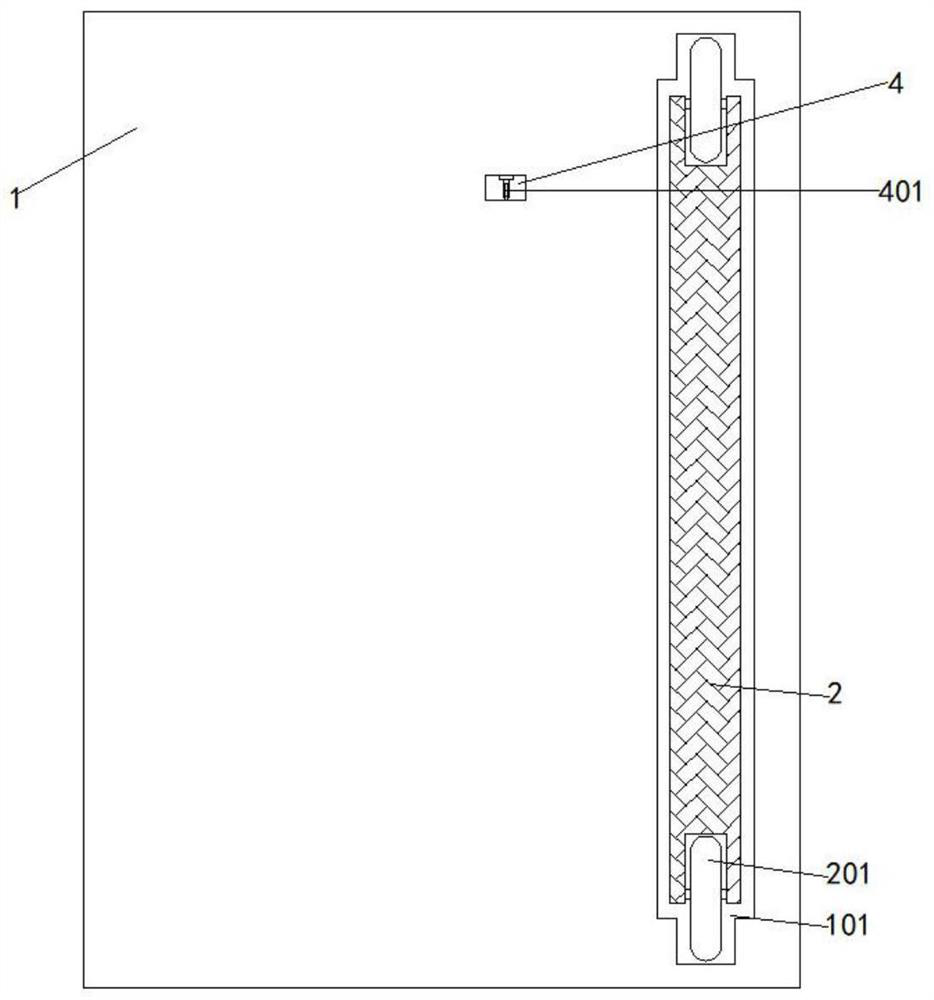

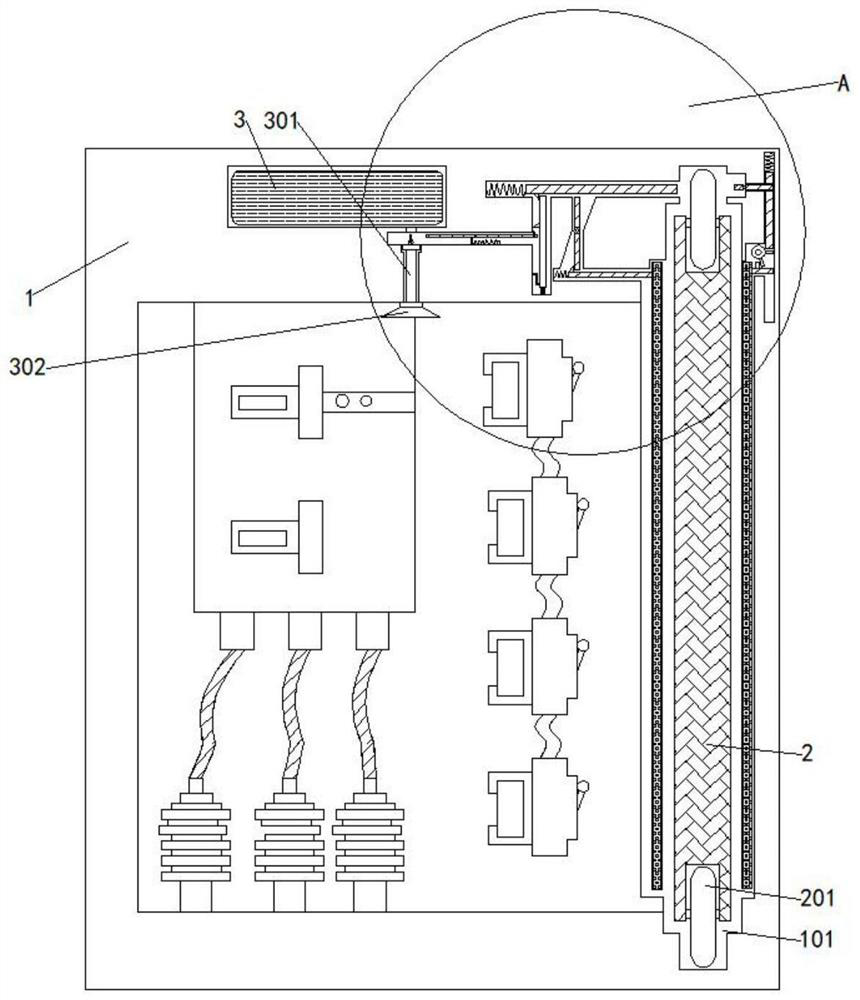

Power distribution cabinet with flame-proof function

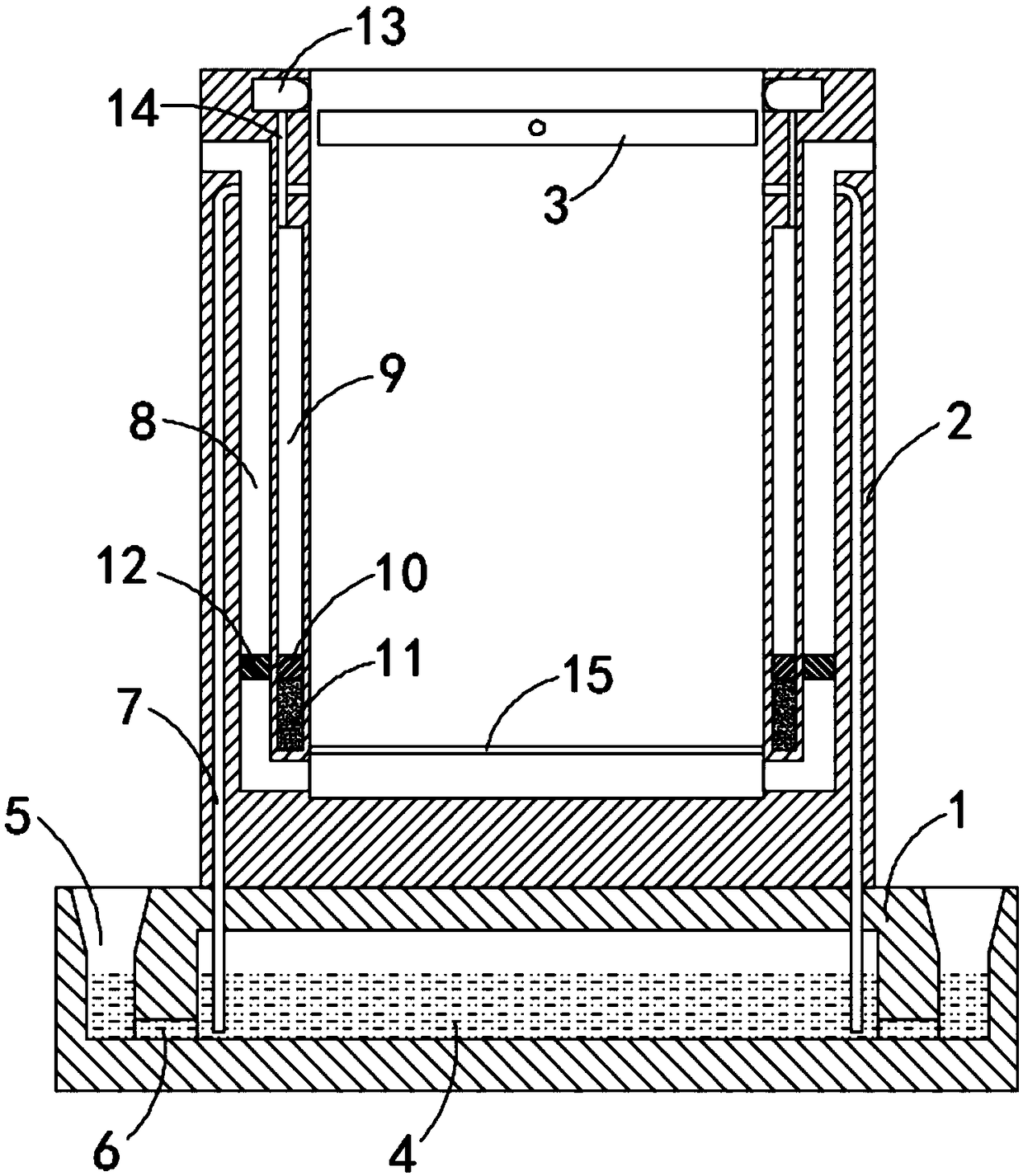

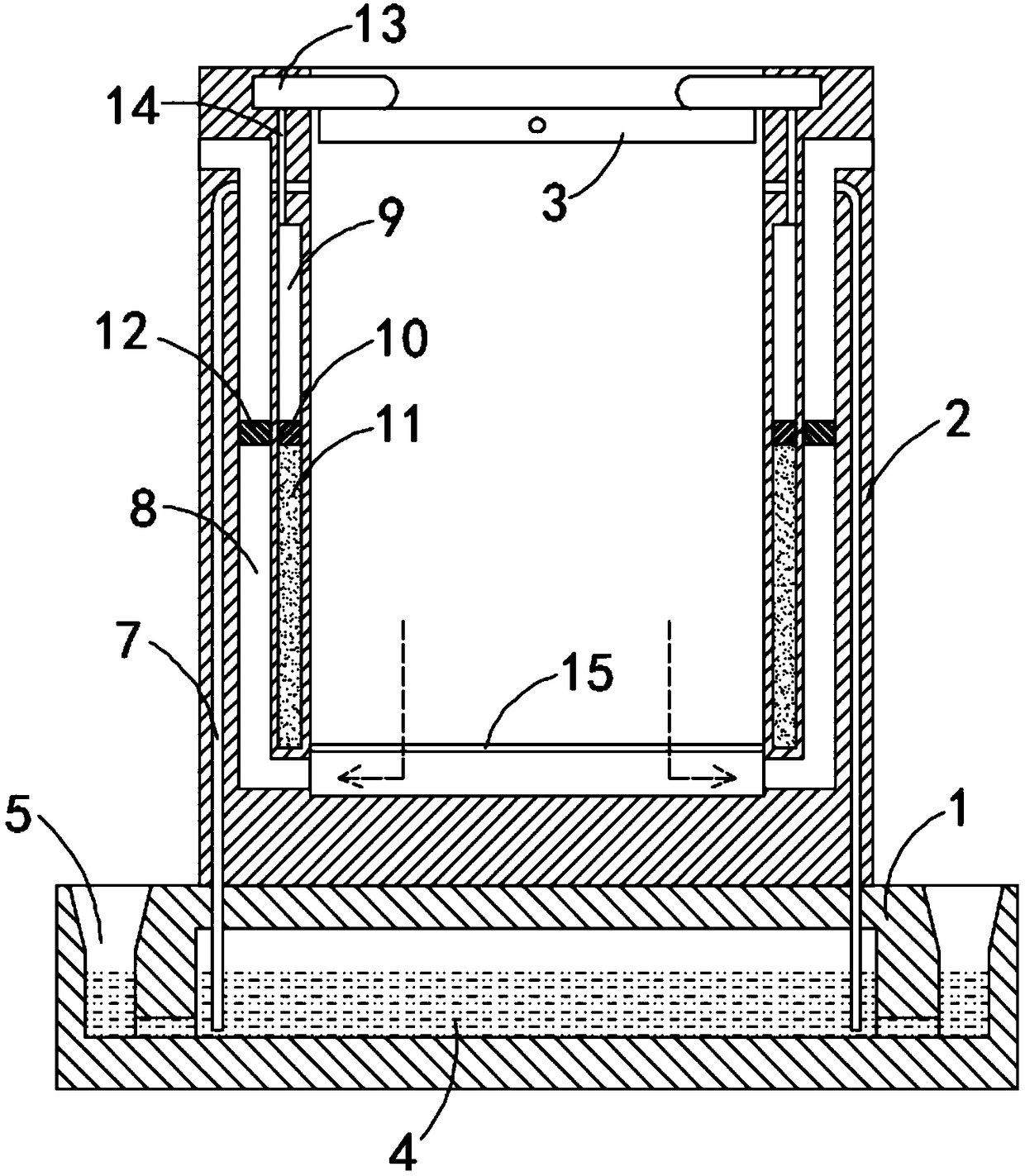

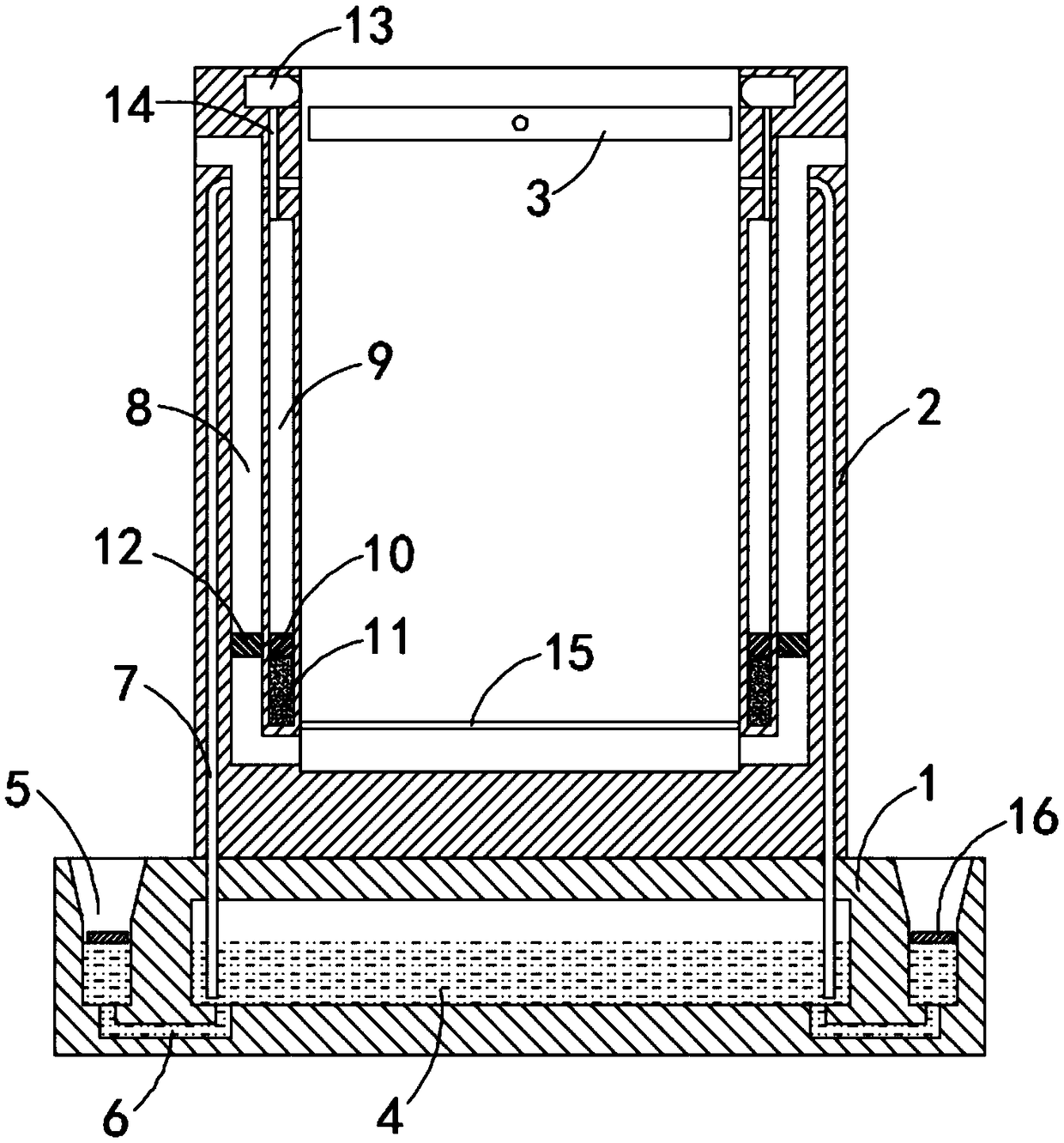

ActiveCN112928619AFunction as an air barrierReduce lossesSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention relates to the technical field of power distribution cabinets, in particular to a power distribution cabinet with a flame-proof function, which comprises a cabinet body, a base fixed at the bottom of the cabinet body and a cabinet door hinged with the cabinet body, a plurality of heat dissipation holes are uniformly formed in one side surface of the cabinet body, and flame-retardant plates for blocking the heat dissipation holes are arranged on the inner sides of the heat dissipation holes. Vertically-arranged L-shaped guide rails are arranged on the two sides of the flame-retardant plates correspondingly, limiting assemblies used for limiting the positions of the flame-retardant plates are arranged on the upper sides of the L-shaped guide rails, positioning assemblies used for limiting the positions of the flame-retardant plates are installed on the lower portions of the back faces of the two L-shaped guide rails, and a horizontally-arranged supporting plate is fixedly connected to the lower ends of the L-shaped guide rails; an inert gas tank is arranged on the lower side of the supporting plate, and a sealing assembly is installed in the middle of the upper surface of the inert gas tank, and compared with the prior art, the cabinet has the following advantages that the effect of isolating air is achieved, and external air is prevented from continuously entering the space formed by the cabinet body and the cabinet door.

Owner:胜利油田胜利电器有限责任公司

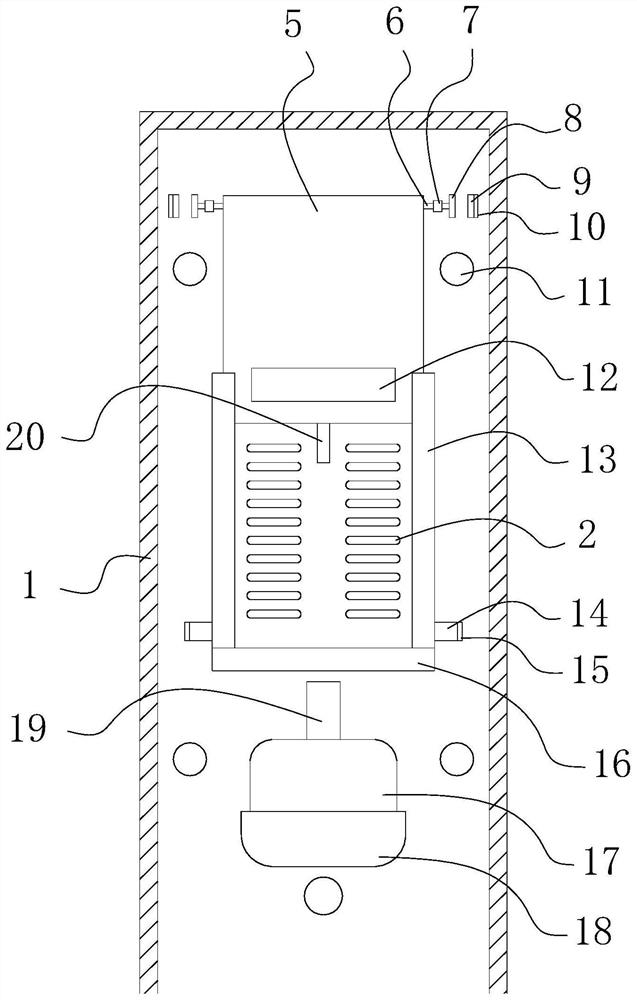

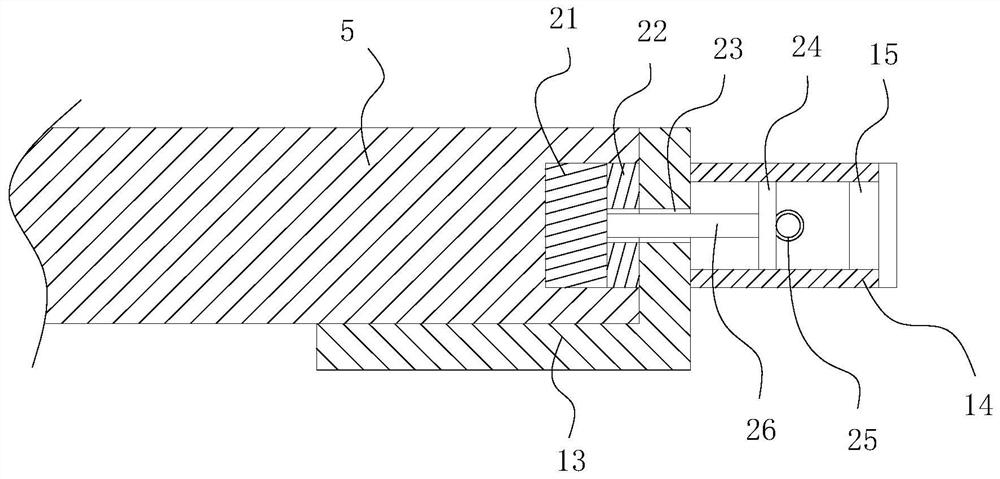

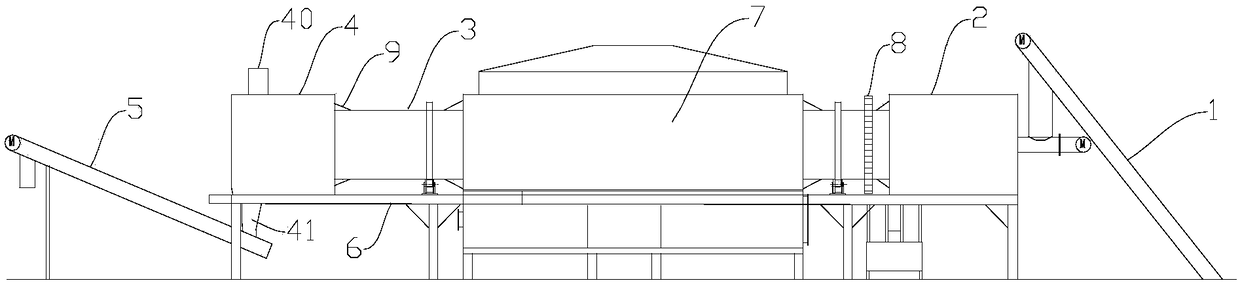

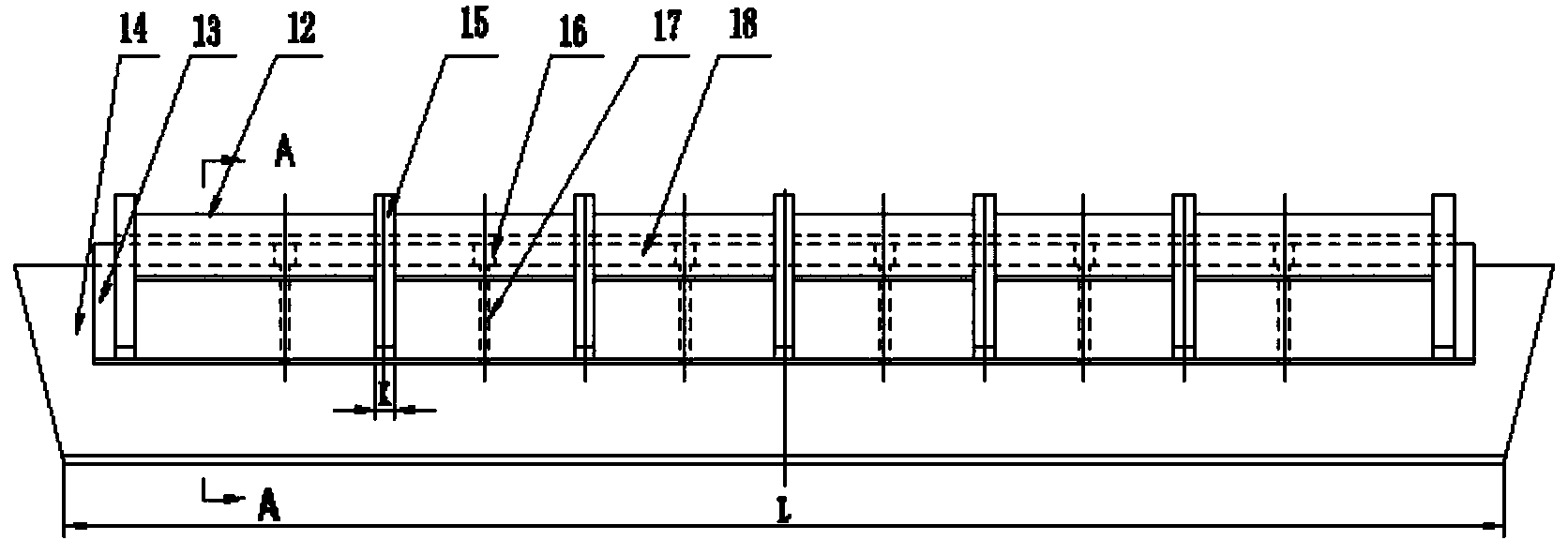

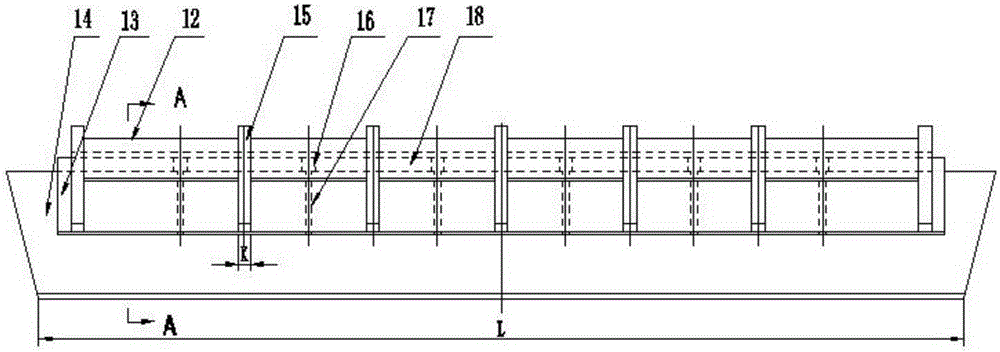

Sealing pyrolyzing furnace achieving continuous feeding and discharging

PendingCN108441241ALower oxygen partial pressureSmooth pyrolysisProductsReagentsCombustion chamberContinuous feeding

The invention relates to a sealing pyrolyzing furnace achieving continuous feeding and discharging. The furnace comprises a screw feeder, a feeding bin, a pyrolyzing furnace cylinder, a discharging bin and a screw discharge bin which are sequentially connected in the material conveying direction, the feeding bin and the discharge bin are fixedly arranged on a rack, the pyrolyzing furnace cylinderis supported on the upper portion of the rack through multiple rollers, the outer wall of the pyrolyzing furnace cylinder is sleeved with a gear ring, the rack is provided with a driving mechanism driving the pyrolyzing furnace cylinder to rotate along the central axis through the gear ring, one end of the pyrolyzing furnace is communicated with the feeding bin, the other end of the pyrolyzing furnace is communicated with the discharge bin, a heating pyrolyzing mechanism is arranged in the middle of the pyrolyzing furnace and comprises a combustion chamber located on the lower portion and a pyrolyzing chamber located on the upper portion, openings allowing the pyrolyzing furnace to penetrate through are formed in the left side and the right side of the pyrolyzing chamber, and elastic sealing structures preventing air leakage are arranged on the joints of the pyrolyzing furnace cylinder and the feeding bin, the discharge bin and the pyrolyzing chamber. The sealing pyrolyzing furnace hasthe advantages that the structure is reasonable, continuous feeding and discharging can be achieved, the sealing effect is good, the safety is good, and the pyrolyzing efficiency is high.

Owner:湖北春阳环保装备有限公司

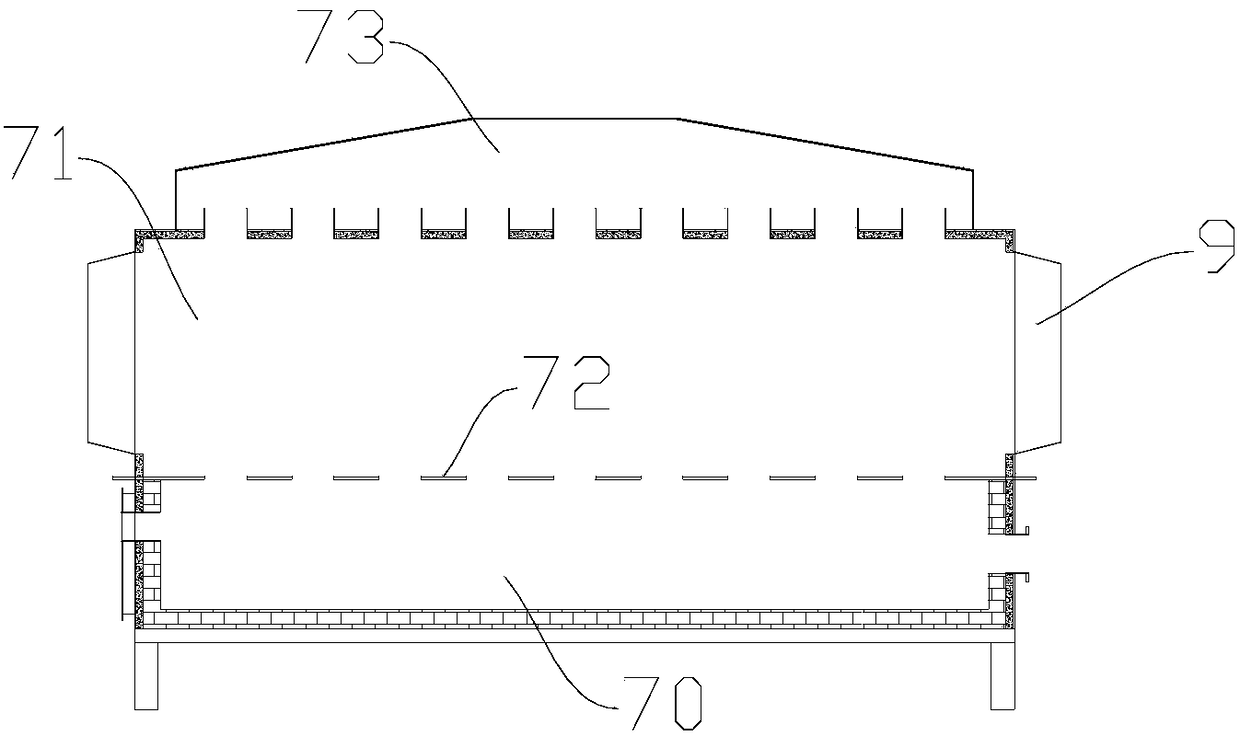

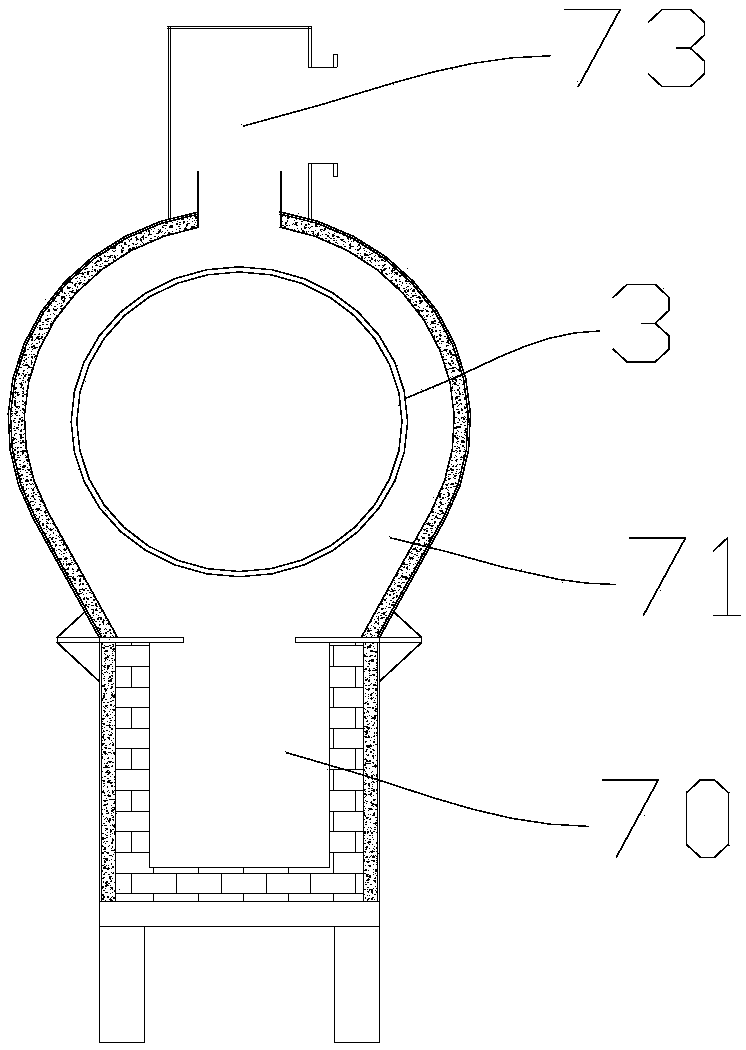

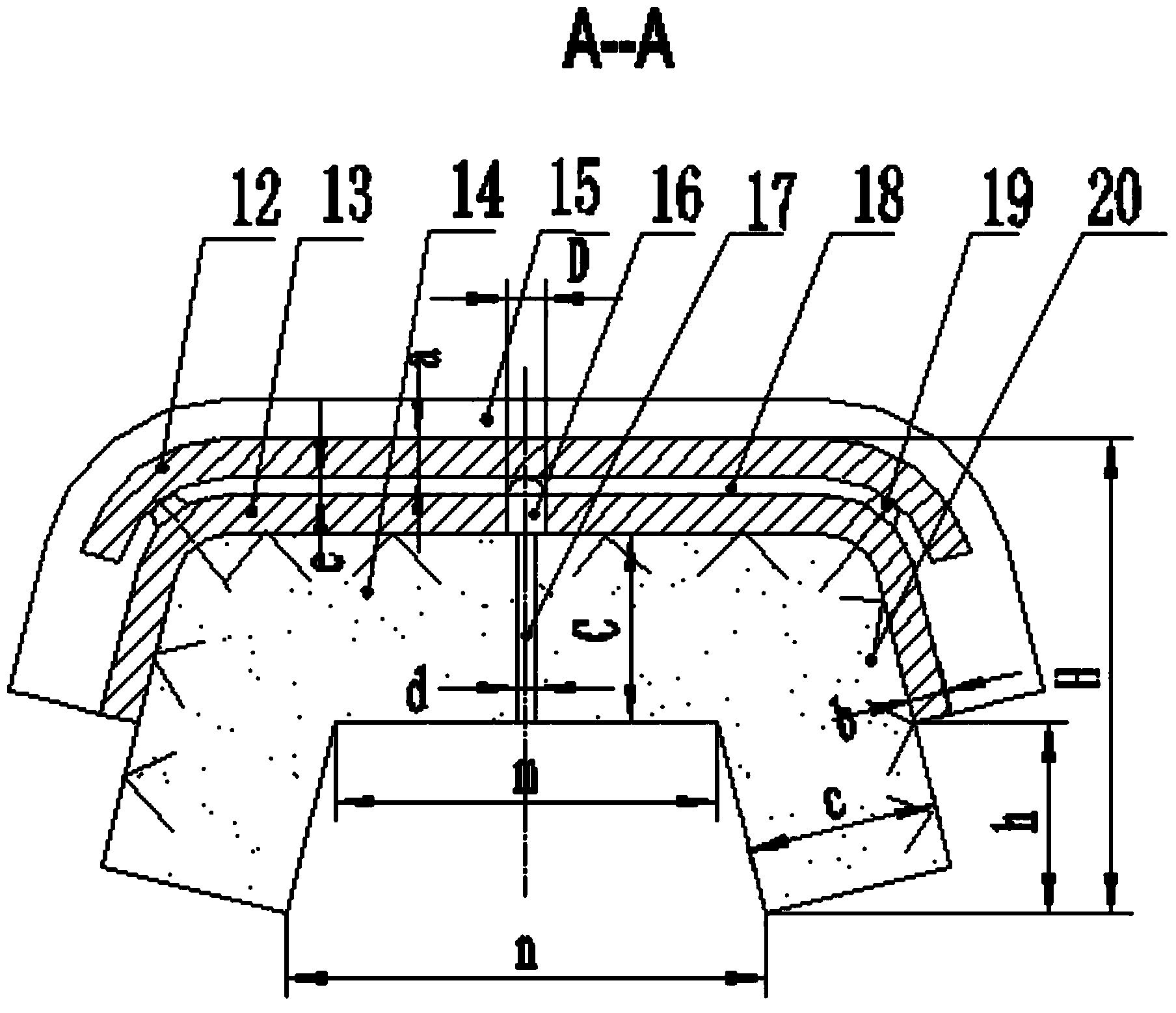

Refining cover for continuous casting tundish and manufacturing method of refining cover

The invention relates to a refining cover for a continuous casting tundish and a manufacturing method of the refining cover. The refining cover comprises an outer arc plate, an inner arc plate and a dipping cover. A circulation seam is reserved between the outer arc plate and the inner arc plate, and communicated with a gap between a tundish cover and a steel slag layer inside the tundish. Air exhaust holes penetrating through the dipping cover are formed in the dipping cover, through holes opposite to the air exhaust holes are formed in the inner arc plate, the air exhaust holes are communicated with the circulation seam through the through holes, argon is blown in through air curtain ventilation bricks, an air curtain barrier with the large continuous intensity is formed between the air curtain ventilation bricks and the dipping cover, the inclusions are captured and are adsorbed and removed by the steel slag layer, the argon breaks through the steel slag layer below the dipping cover to move upwards continuously and enters the circulation seam through the air exhaust holes and the through holes, the argon enters the position above the steel slag layer of the tundish through the circulation seam, and argon seal is formed in the space between the steel slag layer inside the tundish and the tundish cover. The steel slag face is protected, secondary oxidation of liquid steel is avoided, the 0.5 level of the four kinds of inclusions in LHG2 steel reaches more than 90%, and the cleanliness of the liquid steel is greatly improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Photovoltaic cable having electromagnetic shielding effect and preparation method

InactiveCN107274975AImprove electromagnetic shielding performanceReduce electromagnetic radiationCommunication cablesInsulated cablesCopper wireWear resistant

The invention discloses a photovoltaic cable with electromagnetic shielding effect and a preparation method thereof. The photovoltaic cable includes a wire core formed by twisting a plurality of tinned copper wires and a protective layer covering the wire core. The protective layer is from the inside to the outside. It is an electromagnetic shielding layer, an insulating protective layer and a wear-resistant and waterproof layer in sequence; the preparation method includes: firstly preparing the electromagnetic shielding layer material and the wear-resistant and waterproof layer material; Extrude the 180°C halogen-free flame-retardant photovoltaic cable irradiated insulating material onto the electromagnetic shielding layer, and carry out irradiation cross-linking to form an insulating protective layer; evenly coat the surface of the insulating protective layer with a wear-resistant and waterproof layer, dry, That is, the photovoltaic cable is obtained. The photovoltaic cable of the present invention not only has good electromagnetic shielding effect, but also has good flame retardancy and water resistance, greatly improves the service life of the photovoltaic cable, and has good application value and prospect.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

A refining cover for continuous casting tundish and its preparation method

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Magnesium and magnesium alloy composite protection fire-proof covering flux and its production method

A magnesium and magnesium alloy composite protective flame-retardant covering flux and a production method thereof, the chemical components of the flux range in mass percent: 50-70% magnesium chloride, 8-18% potassium chloride, 7-16% sodium chloride, 1 -8% calcium chloride, 1-8% calcium fluoride, 1-7% magnesium oxide, 1-5% slagging agent cryolite, 0.5-6% carbonate foaming agent, 0.5-4% beryllium compound flame retardant. The flux of the present invention has a variety of composite protective and flame-retardant functions during use. The beryllium oxide protective film formed by the beryllium compound sprinkled on the surface of the melt makes the magnesium alloy have good flame-retardant performance, which obviously improves the protective effect and does not As a result, the alloy grains are coarse and the mechanical properties of the alloy are reduced. The inert gas generated during the use of the flux that does not react with magnesium covers the magnesium liquid, which further enhances the protective effect. The cryolite added to the flux is beneficial to improve the flux. Slag ability, and improve the physical properties of the flux.

Owner:SHANGHAI AIERSI LIGHT ALLOY

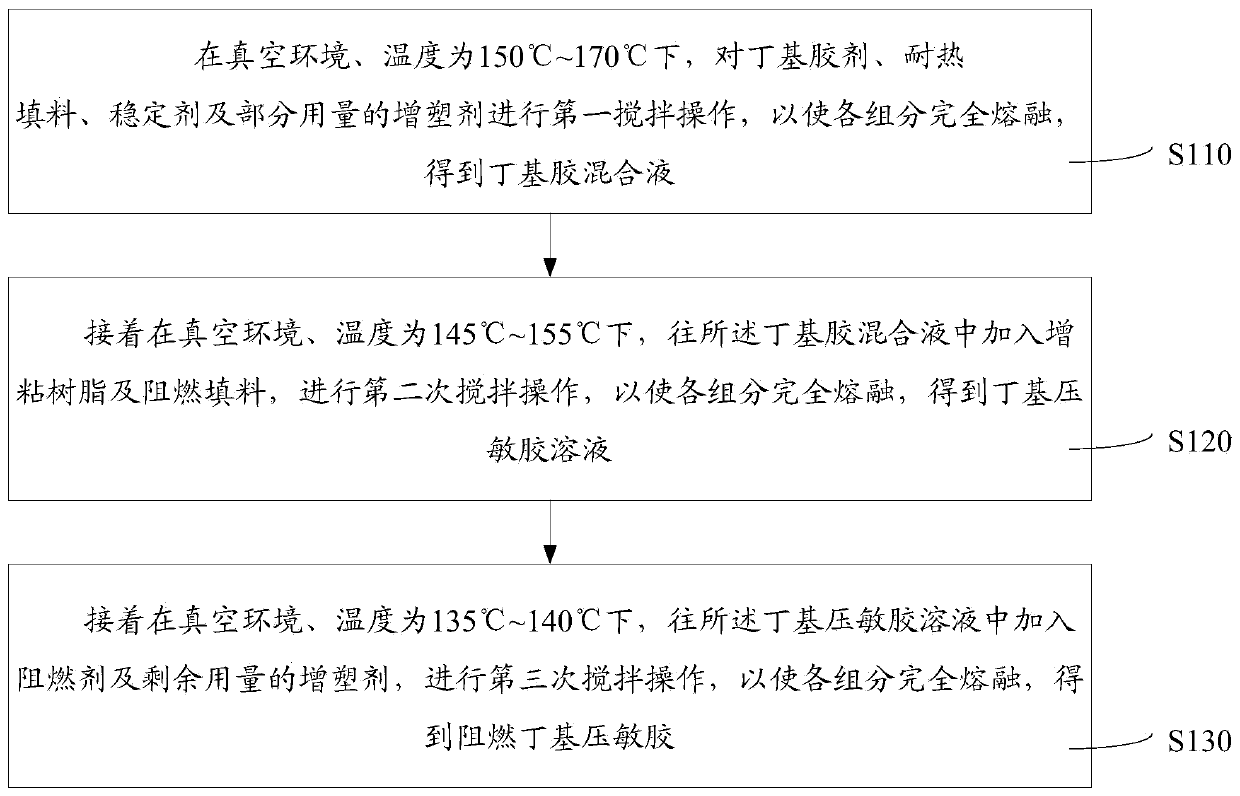

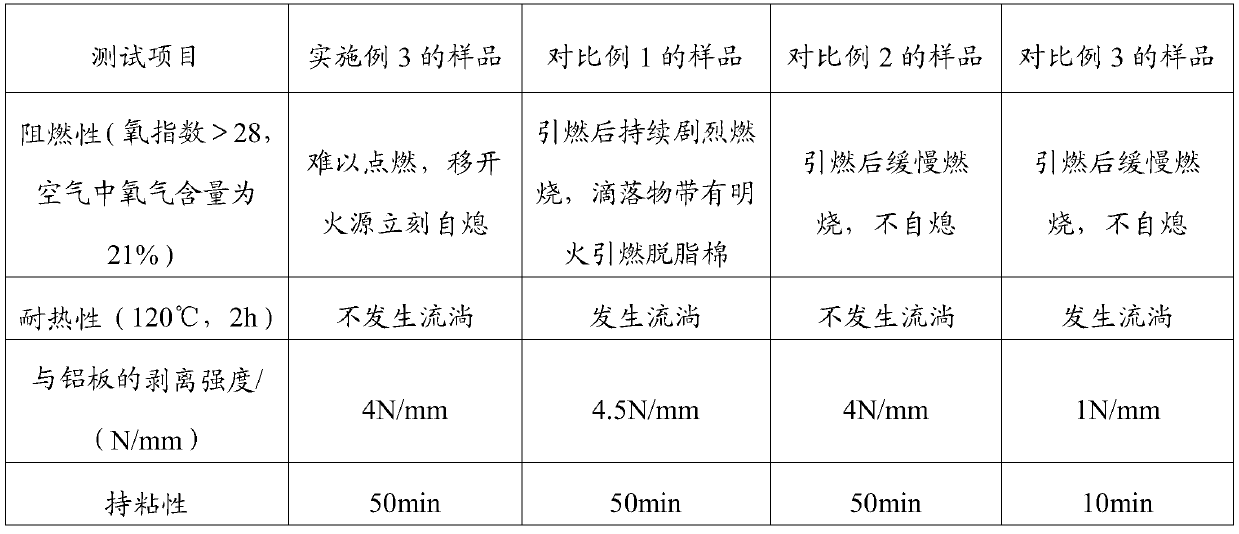

Flame retardant butyl pressure sensitive adhesive

ActiveCN110295020AIncrease stickinessReduce hardnessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMolecular networkWater vapor

The invention relates to the field of pressure-sensitive adhesives and discloses a flame-retardant butyl pressure-sensitive adhesive, which comprises the following components in parts by mass: 20-35 parts of a plasticizer, 20-25 parts of butyl rubber, 3-10 parts of a heat-resistant filler, 6-20 parts of a flame-retardant filler, 5-15 parts of a flame retardant, 1-5 parts of a stabilizer and 20-30parts of tackifying resin. The heat-resistant filler is uniformly embedded in the molecular network of the butyl rubber, thereby improving the cohesive energy of the butyl rubber and reducing the deformation and sliding of the molecular network of the butyl rubber under the action of high temperature, and further improving the heat resistance of the flame-retardant butyl pressure-sensitive adhesive. The flame-retardant filler and the flame retardant are synergistically flame-retardant, wherein the flame-retardant filler may decompose to generate water vapor during combustion to reduce the surface temperature of a combustion substance and isolate part of oxygen, thus playing a flame-retardant role; the flame retardant can capture free radical OH<-> in the flame when burning to restrain theflame, and is also attached to the surface of the flame retardant butyl pressure-sensitive adhesive to isolate the air.

Owner:HUIZHOU NENGHUI CHEM CO LTD

Weather-resistant and antibacterial steel surface coating material and preparation method thereof

InactiveCN104673043AHigh temperature resistantCorrosion resistanceFireproof paintsAntifouling/underwater paintsSodium bicarbonatePolylysine

The invention discloses a weather-resistant and antibacterial steel surface coating material and a preparation method thereof. The weather-resistant and antibacterial steel surface coating material is prepared from the following components in parts by weight: 25-39 parts of polyacrylamide, 8-14 parts of vinyl versatate, 0.5-1.2 parts of polylysine, 0.05-0.08 part of dibutyltin maleate, 0.8-1 part of sodium bicarbonate, 0.01-0.2 part of antioxygen, 11-17 parts of propylene glycol monomethyl ether and 100-110 parts of water. The invention further provides the preparation method of the weather-resistant and antibacterial steel surface coating material. The weather-resistant and antibacterial steel surface coating material prepared by the invention can be widely applied to the surfaces of household electrical appliances, instruments, meters, air purification equipment and water purification equipment.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

Photovoltaic coating for improving solar energy conversion and preparation method

InactiveCN108456488AGood waterproofGood scratch resistanceAntifouling/underwater paintsPaints with biocidesSilicone resinPolymerization catalysts

The invention discloses a photovoltaic coating for improving solar energy conversion and a preparation method thereof. The coating is prepared from acrylic modified silicone resin, silica sol, polyethylene terephthalate, graphene, butyl titanate , nano titanium dioxide, nano silicon dioxide, single crystal silicon, photopolymerization catalyst, polyisocyanate, modified attapulgite clay, metal nanoparticles and antifoaming agent. The above components are reacted and uniformly mixed according to a certain ratio, and the photovoltaic coating is obtained. The coating not only has better waterproofperformance, aging resistance and electrical conductivity, but also can effectively improve the conversion of solar energy into electric energy, and provides a good application prospect for the development of solar photovoltaic materials.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

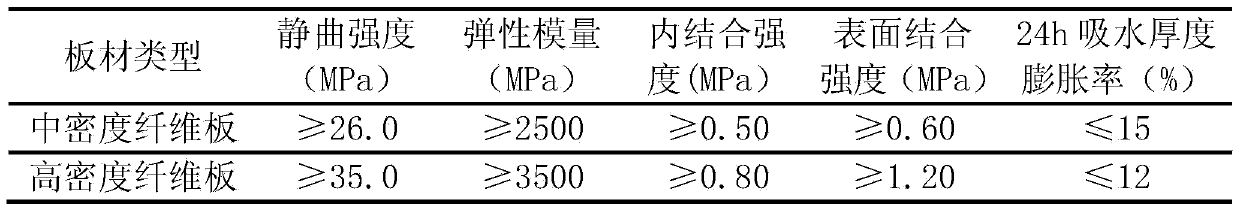

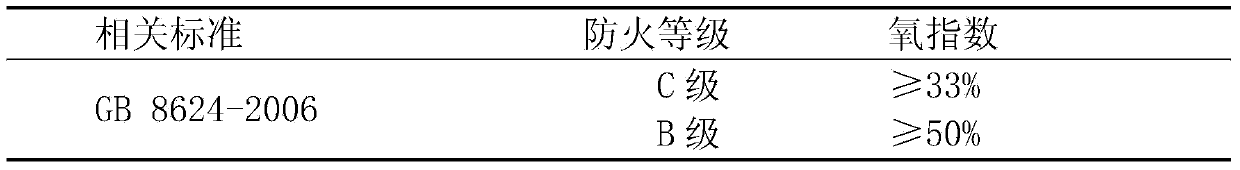

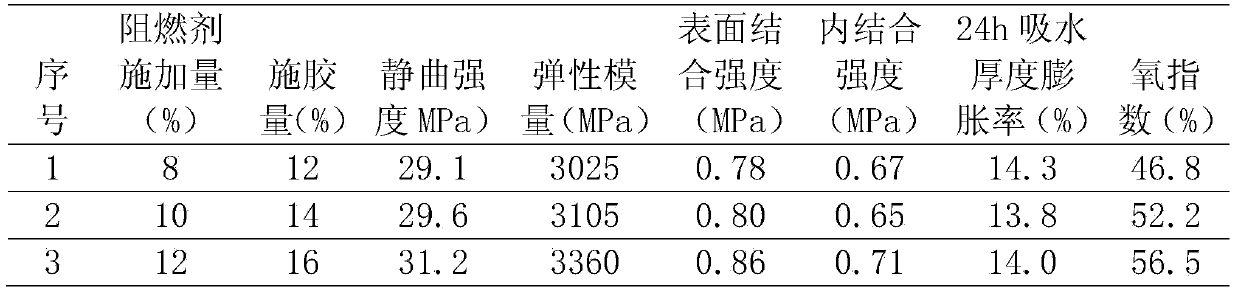

Flame retardant and antiflaming medium-density and high-density fiber panel containing flame retardant

InactiveCN103993527AOvercome costsOvercoming Flame RetardancyFibreboardInorganic compound additionBorideFiber

The invention discloses a flame retardant and an antiflaming medium-density and high-density fiber panel containing the flame retardant. The flame retardant comprises, by weight, 40-90 parts of ammonium polyphosphate, 5-50 parts of expanding agents and 5-20 parts of boride. The flame retardant is in a powder shape, is efficient expansibility flame retardant and has the advantages of being good in thermal stability, high in flame retardant efficient and low in cost. When the antiflaming medium-density and high-density fiber panel is made, the flame retardant can be directly applied to a fiber conveying pipeline and is uniformly mixed with suspended fibers in the pipeline through the action of air flow, original production procedures are seldom changed, and the problems that an existing antiflaming medium-density and high-density fiber panel is high in cost, the flame retardant addition quantity is large, energy consumption is large during drying and moisture absorption of the fiber panel is high are solved.

Owner:蒋启荣

Ceramic tile for exterior wall decoration with self-repairing joint

The invention discloses a ceramic tile for exterior wall decoration with a self-repairing joint, and belongs to the technical field of ceramic tile self-repairing. After cement at the joint of two ceramic tiles falls off, a sealing protection block is exposed in the air, the sealing protection block made of calcium hydroxide can react with carbon dioxide in the air to generate calcium carbonate and water, a vertical steel needle and a mud storage balloon are gradually leaked, the generated water is guided into bottom filler under the water guiding effect of a water guiding core, a sliding supporting net, the vertical steel needle and the mud storage balloon can move towards a sunken groove of the other ceramic tile, the vertical steel needle punctures a sealing leakage-proof film, an inverted steel needle punctures the mud storage balloon, then bonding powder in the mud storage balloon and clear water in the sunken groove are mixed, the two ceramic tiles are bonded again, and thereforethe joint of the two ceramic tiles is automatically repaired, the ceramic tiles are effectively prevented from falling off, convenience is greatly improved, and meanwhile safety performance is remarkably improved.

Owner:邓秀美

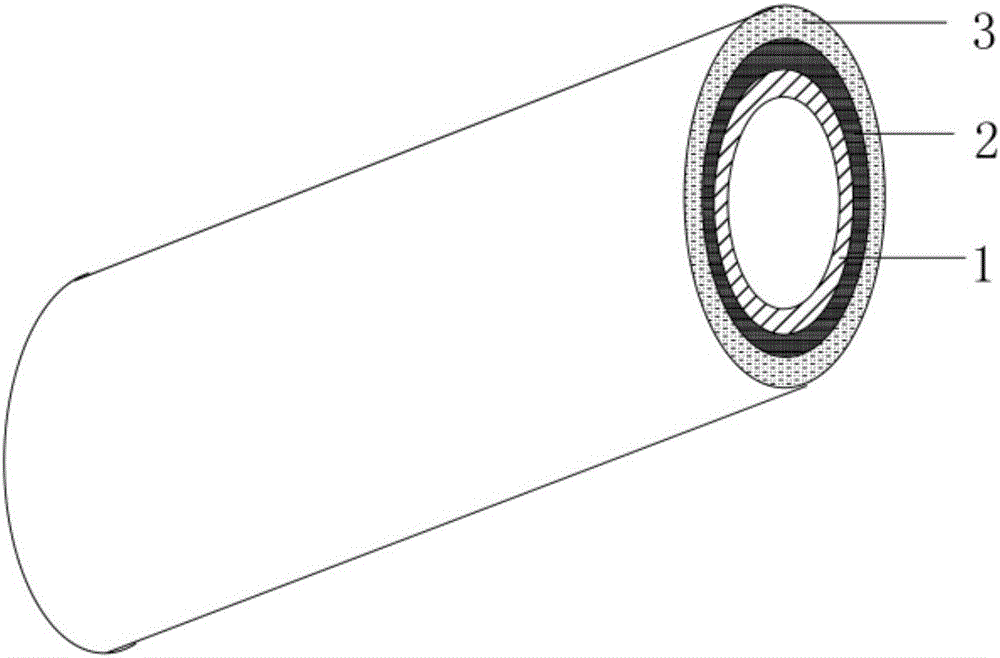

Highly flame-retardant waterproof wire and preparation method

InactiveCN106847393AImprove the safety of useAvoid fireClimate change adaptationInsulated cablesPolyolefinGraphene nanocomposites

The invention discloses a high flame-retardant waterproof wire and a preparation method thereof, belonging to the technical field of wires and cables. The high flame-retardant waterproof wire includes a wire body, an electrostatic shielding layer, and a flame-retardant protective layer from the inside to the outside. The electrostatic shielding layer is a polyethylene terephthalate / graphene nanocomposite material layer. The flame-retardant protective layer is a graphene-modified polyurethane coating, and the wire body is a highly flame-retardant polyolefin wire. The preparation method includes: (1) preparing highly flame-retardant polyolefin wires; (2) coating polyethylene terephthalate / graphene nanocomposite on the surface after cooling the prepared highly flame-retardant polyolefin wires The material is dried; (3) the surface of the wire in step (2) is coated with a graphene-modified polyurethane coating, and dried. The electric wire of the present invention has good flame-retardant effect and excellent waterproof performance, and improves the use safety of the electric wire. The preparation method has simple process, mild conditions and good application prospect.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

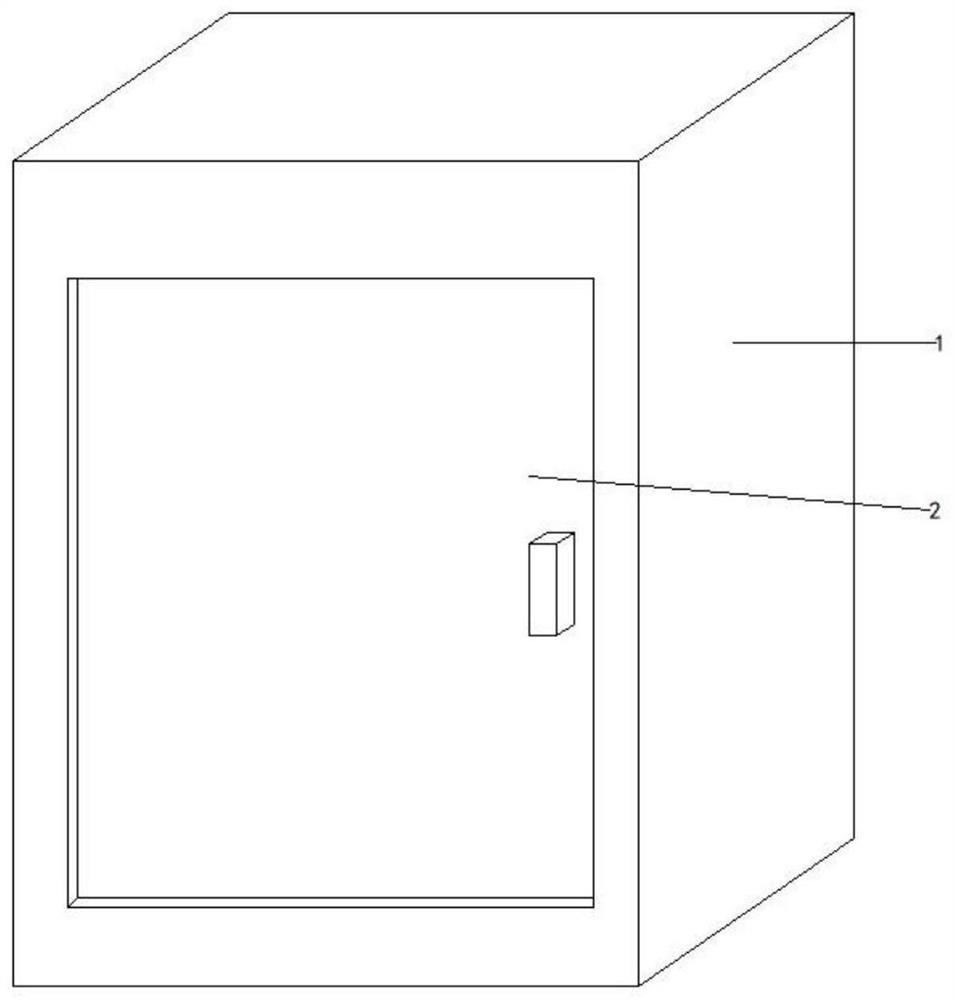

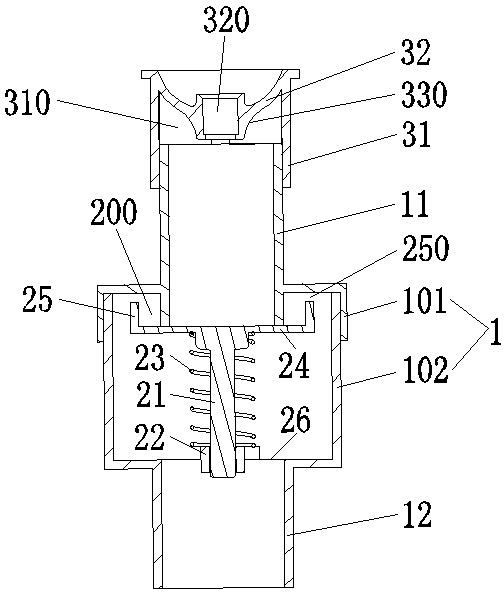

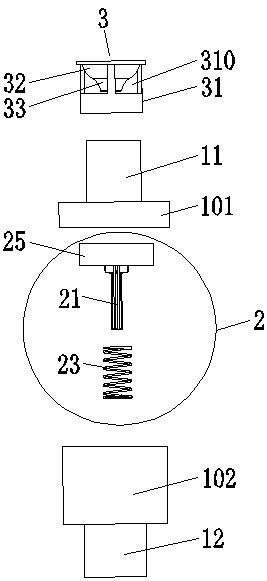

Power distribution cabinet door with high-temperature self-locking function

PendingCN114336343AImprove securityAvoid enteringWing fastenersSubstation/switching arrangement casingsEngineeringIndustrial engineering

The invention provides a power distribution cabinet door with a high-temperature self-locking function, which comprises a power distribution cabinet, sliding grooves, a cabinet door and pulleys, the sliding grooves are formed in the upper part and the lower part of one side in the power distribution cabinet, the cabinet door is slidably arranged between the two sliding grooves through the pulleys, and a self-locking structure and a sealing structure are respectively arranged in the power distribution cabinet. The self-locking structure comprises a groove A, a glass tube, a sliding block A, a triangular clamping block A, a groove C, a clamping block and a triangular clamping block C. The groove A is formed in one side of the power distribution cabinet in a hollow mode, the glass tube is fixedly installed at the bottom of the groove A, and the sliding block A is connected into the groove A through a spring. Through arrangement of a groove A, a glass tube, a sliding block A, a triangular clamping block A, a groove C, a clamping block and a triangular clamping block C, the glass tube can be heated and broken when a fire disaster occurs outside, so that a series of linkage reactions occur, the clamping block extends out to block a pulley at a cabinet door, flame cannot enter the power distribution cabinet to damage the power distribution cabinet, and the safety is improved.

Owner:张宝兴

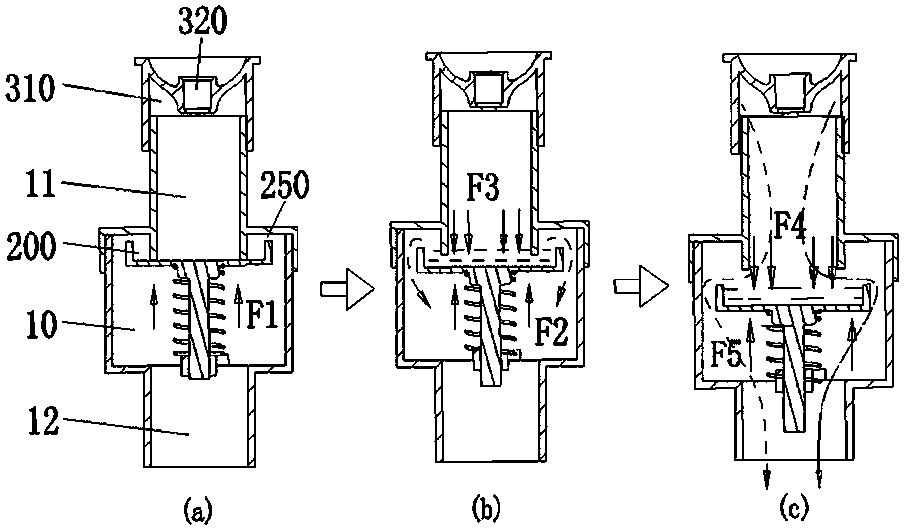

Overflow device for improving overflow capacity and accelerating drainage of drainage valve

PendingCN111188390AIncrease speedAccelerates the effect of insulating airFlushing devicesDrainage tubesCheck valve

The present invention relates to an overflow device capable of improving the overflow capacity and accelerating the drainage speed of a drainage valve. The overflow device comprises a shell and a check valve, a cavity is formed in the shell, and a water inlet pipe and a drainage pipe which are communicated with the cavity are fixedly connected at the top and the bottom of the shell respectively. The check valve comprises a valve rod, a valve sleeve, an elastic body, a supporting plate and an annular water baffle, the valve sleeve is fixed to the lower portion in the cavity, and the bottom of the valve rod is installed in the valve sleeve and can move up and down. The supporting plate is fixed to the top of the valve rod, and the valve rod sleeves the elastic body and abuts against the supporting plate. The annular water baffle is fixedly arranged at the top of the supporting plate, an overflow port is formed at the top of the annular water baffle, and a water seal area is defined between the annular water baffle and the supporting plate. The bottom end of the water inlet pipe extends into the water seal area, and the bottom face of the water inlet pipe is attached to the upper surface of the supporting plate in a sealed mode. The overflow device can be independently installed to achieve the overflow function and can also be installed on the drainage valve, so that the outside air cannot enter a drainage outlet of the drainage valve, and the drainage speed of the drainage valve is increased.

Owner:GULI (XIAMEN) TECH CO LTD

Preparation method of flame-retardant modified polyester fabric

InactiveCN113430813AHigh densityFunction as an air barrierHeat resistant fibresPolyesterPolymer science

The invention provides a preparation method of a flame-retardant modified polyester fabric. The preparation method comprises the following steps of S1, modifying a polyester fabric; S2, preparing low-molecular-weight open-loop sodium hyaluronate; S3, preparing a modification solution: preparing a silk peptide solution and a sodium hyaluronate mixed solution, then adding citric acid and sodium hypophosphite, and performing uniform mixing; S4, padding and finishing the fabric: adding the modified polyester fabric prepared in the step S1 into the modification solution, and carrying out padding and baking treatment; and S5, performing flame-retardant modification of the fabric: dipping the fabric treated in the step S4 in a CaCl2 solution for constant-temperature water bath treatment, performing baking, putting the treated fabric in a SbCl3 solution for constant-temperature water bath treatment, taking out the fabric from the solution, and performing baking to obtain the flame-retardant modified polyester fabric. A preparation method of a phosphorus-containing flame-retardant fabric in the prior art is improved, and the flame-retardant modified polyester fabric is obtained through a composite modification method.

Owner:吴江市腾旭纺织厂

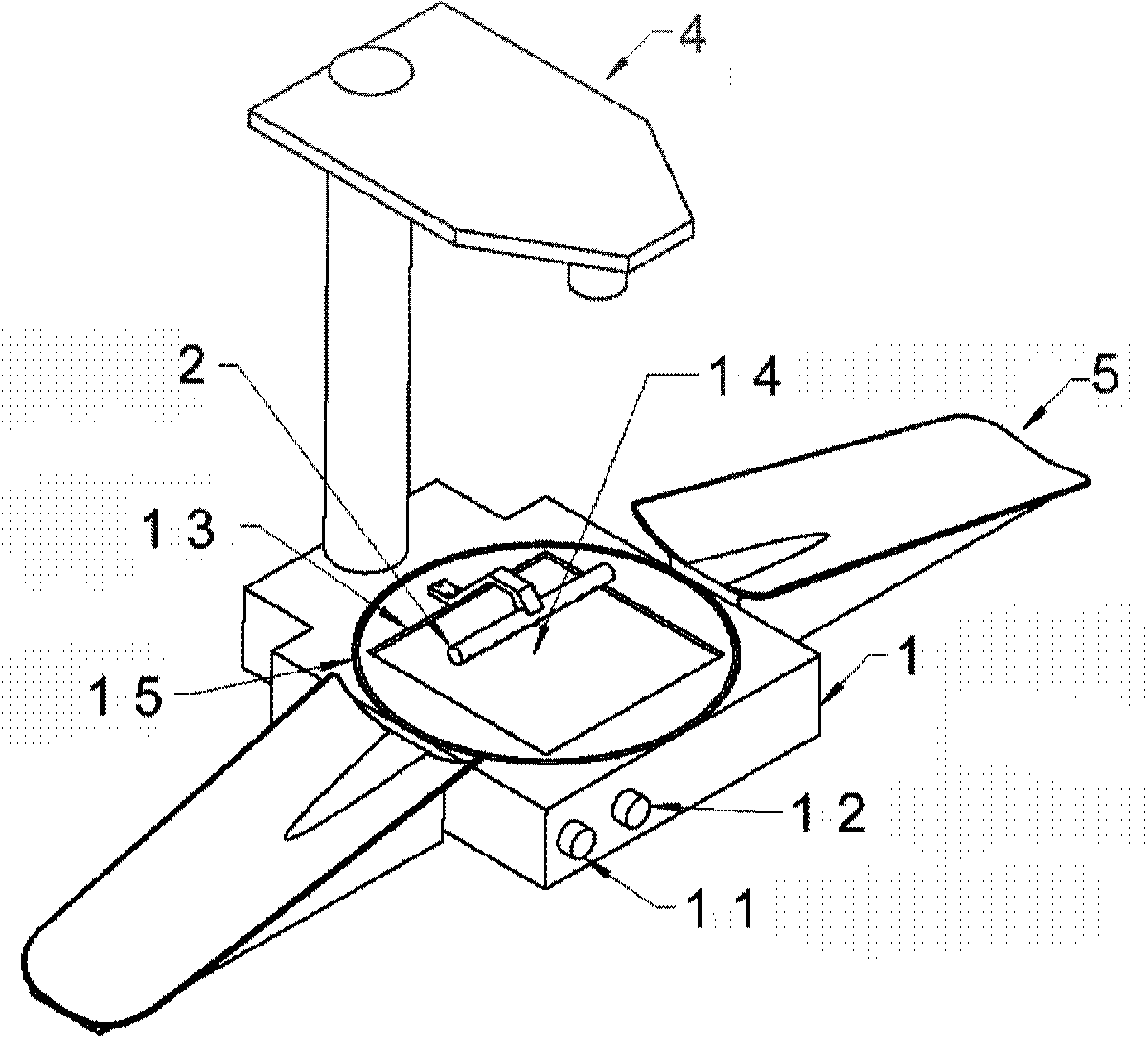

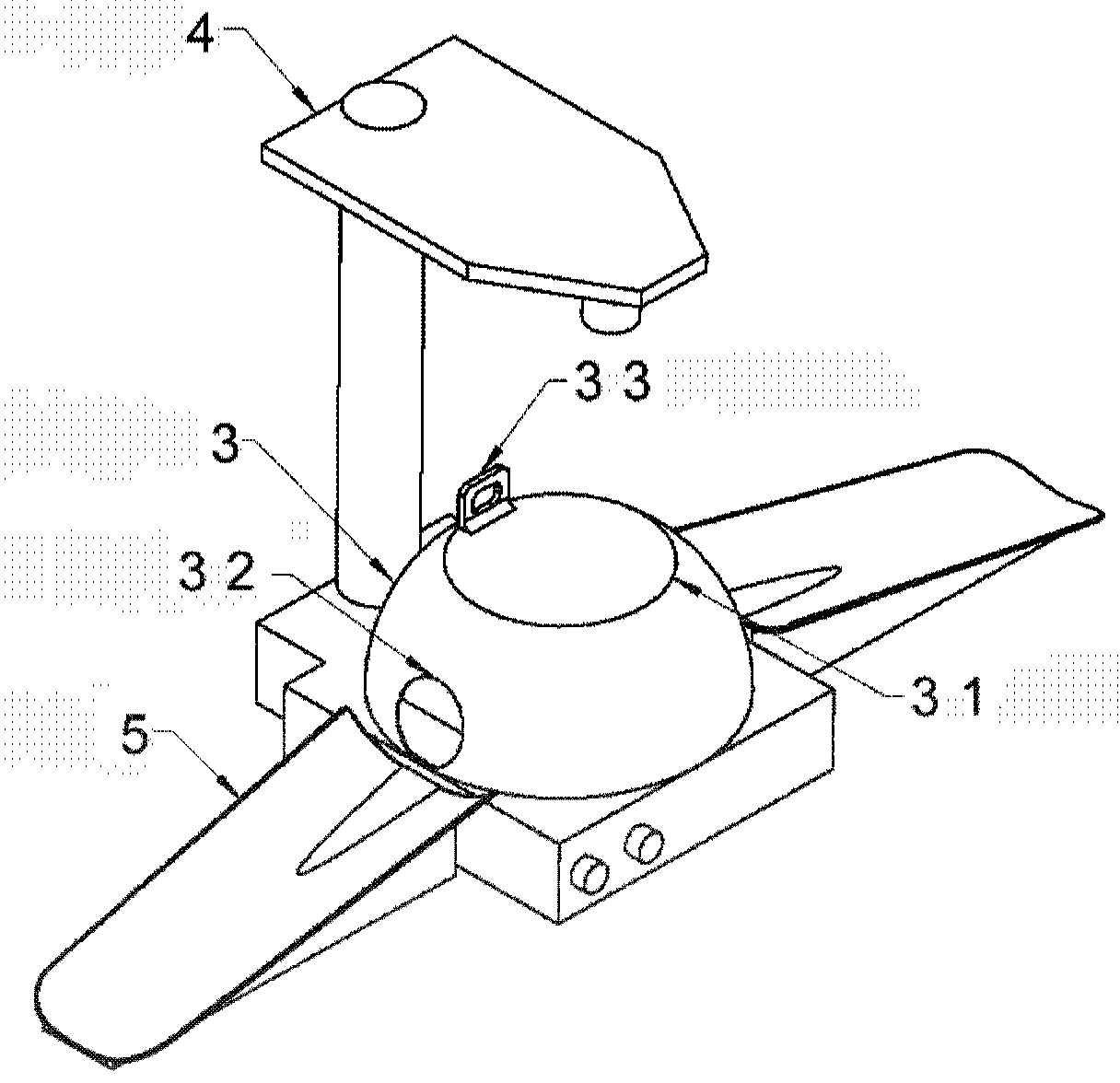

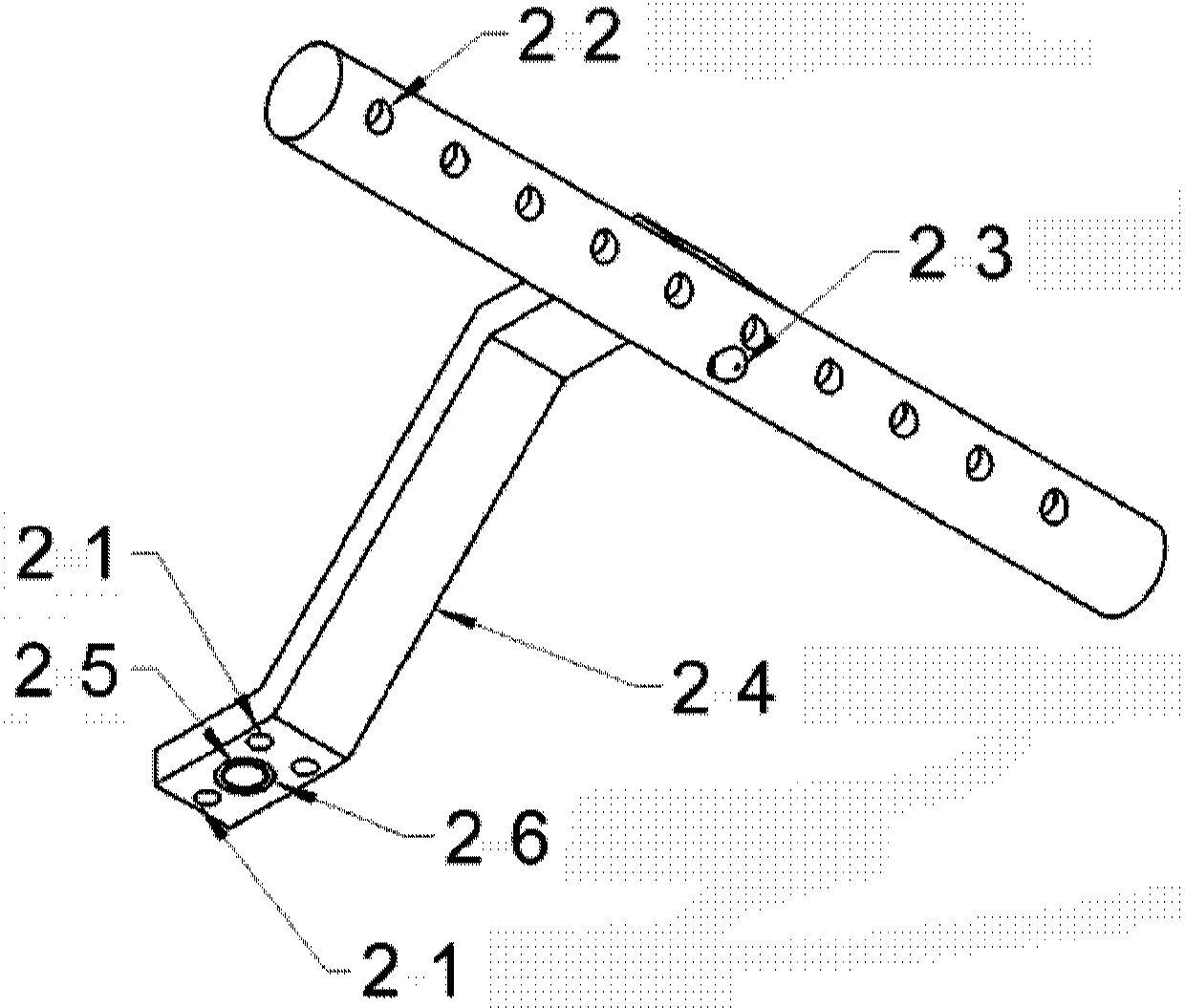

Eutectic soldering device and application thereof

ActiveCN110773832ATo achieve the protective effectPrevent oxidationSolid-state devicesSemiconductor/solid-state device manufacturingSpray nozzleShielding gas

The invention provides a eutectic soldering device and application thereof. The eutectic soldering device includes a heating stage, a gas spray nozzle and a support frame, wherein a eutectic working zone is arranged on the upper surface of the heating stage; the gas spray nozzle is arranged above the eutectic working zone, and gas vents are formed in the gas spray nozzle, face to the eutectic working zone, and are used for blowing a shielding gas to the eutectic working zone; the support frame is arranged between the gas spray nozzle and the heating stage, and is used for fixedly connecting the gas spray nozzle with the heating stage; wherein a through cavity is formed inside the support frame, and is communicated with the gas spray nozzle, so as to form a route for conveying the shieldinggas to the gas spray nozzle. According to the invention, the design that the heating stage is equipped with the gas spray nozzle is provided, so that the eutectic working zone is blown to achieve theeffect of gas shielding, and oxidation of welding flux caused by contact with air is avoided; and the eutectic soldering device is applicable to eutectic soldering of small-scale chips, and the production cost is reduced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Magnesium alloy smelting protection solvent and preparation method thereof

The invention provides magnesium alloy smelting protection solvent and a preparation method thereof. The magnesium alloy smelting protection solvent comprises the following chemical components in parts by weight: 8-15 parts of barium carbonate, 12-15 parts of calcium sulfate, 12-17 parts of nanometer zirconium oxide, 12-15 parts of magnesium chloride, 12-20 parts of hydroxyapatite, 12-20 parts of magnesium silicate, and 1-5 parts of lithium chloride. The preparation method is to perform the mixing after the drying. The smelting protection solvent, provided by the invention, is molten to a liquid state in an environment of higher than 500 DEG C in the smelting process, and is spread on the surface of an alloy or molten magnesium to achieve an air isolating effect and to stop the magnesium oxidation so as to obtain excellent protection performance.

Owner:贵州航天风华精密设备有限公司

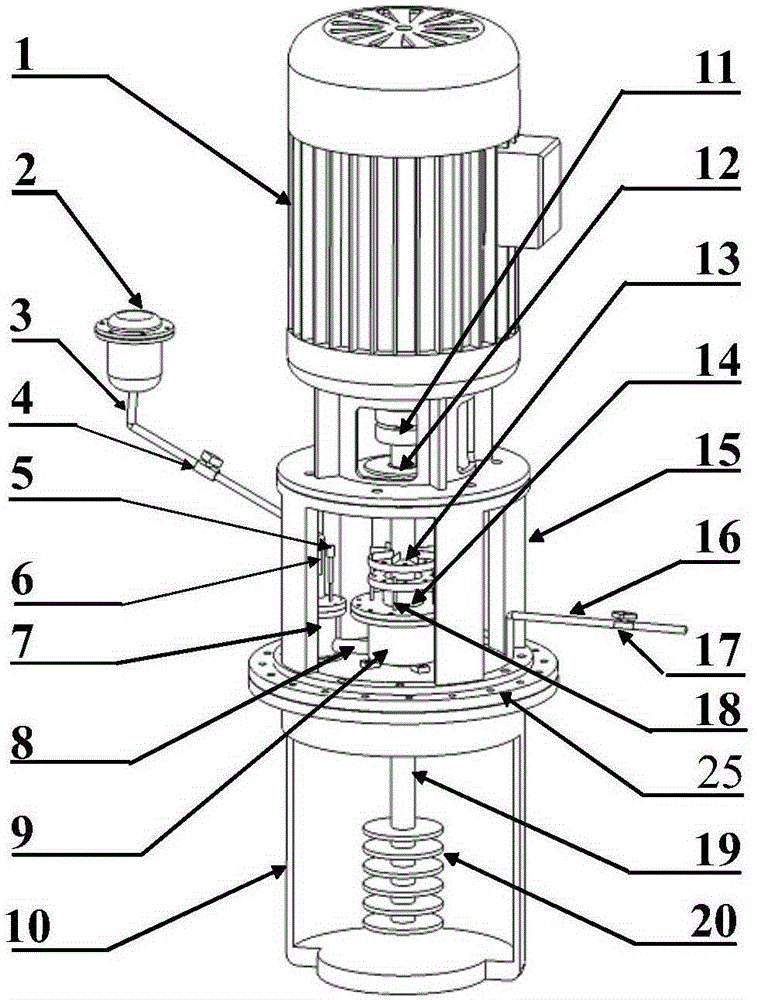

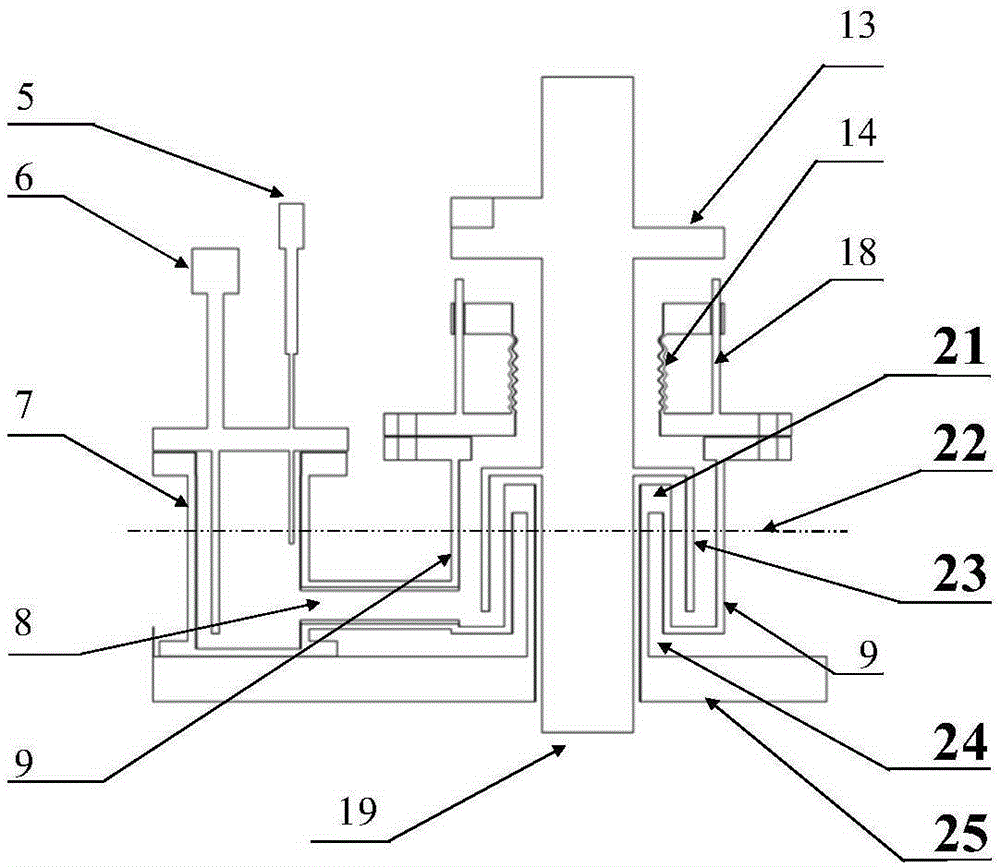

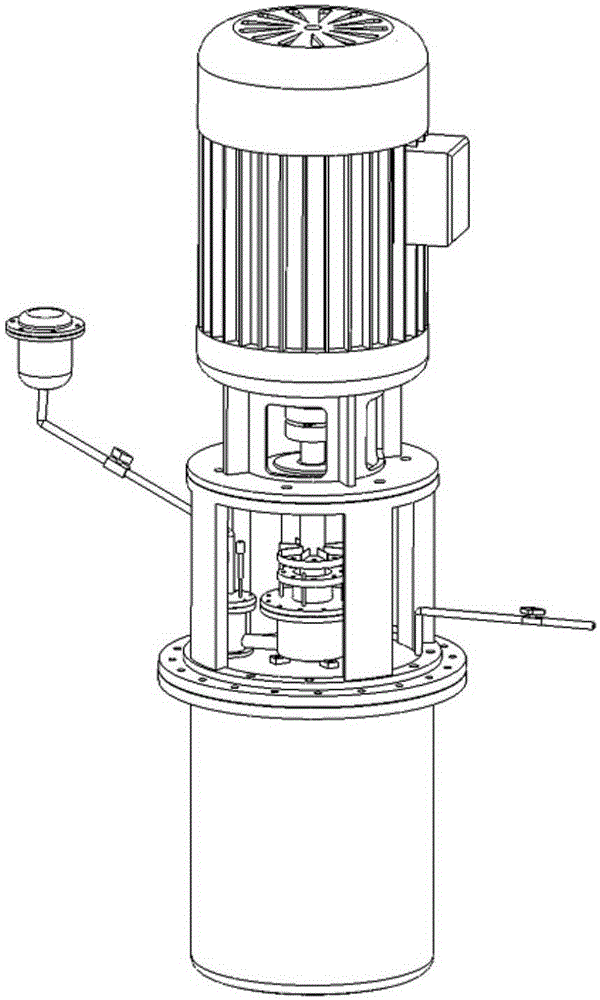

A bell type sealed liquid heavy metal rotating device

ActiveCN103398941BSimple structural designImprove securityWeather/light/corrosion resistanceIndustrial equipmentMolten salt

The invention discloses a bell jar seal liquid heavy metal rotating device which flexibly utilizes a bell jar principle to replace the conventional easy-to-wear mechanical seal, packing seal and a rotating mode driven by a high-temperature demagnetizing electrode magnet rotor, can achieve long-time running under a condition that a shaft seal system is not worn, prevents air due to the fact that equipment is run in a long-term high-temperature environment and subjected to shaft seal wear from entering a polluted experimental area, and avoids changing the shaft seal system regularly. The device comprises a fused salt thawing box, a liquid collecting box, a variable-frequency motor, a bell jar, a support and a shaft sample experimental section, and is simple in structure and easy to operate. The device is in a unique bell shaft seal structure, is provided with the rotating speed-adjustable variable-frequency motor, combines an auxiliary heating and warm-keeping system, and is matched with the replaceable sample experimental section, so that the device can carry out corrosion mechanism researches of structural materials in different speed fields and temperature fields. In addition, the device can be widely applied to the field of industrial equipment corrosion tests and fundamental scientific research projects, and has important scientific research values and engineering application values.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com