Flame retardant and antiflaming medium-density and high-density fiber panel containing flame retardant

A technology of flame retardant and expansion agent, which is applied in the fields of flame retardant, flame retardant, and high-density fiberboard. It can solve the problems of large amount of flame retardant and sizing agent, short service life, and high cost of flame retardant, and achieve flame retardant High efficiency, reduced release, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

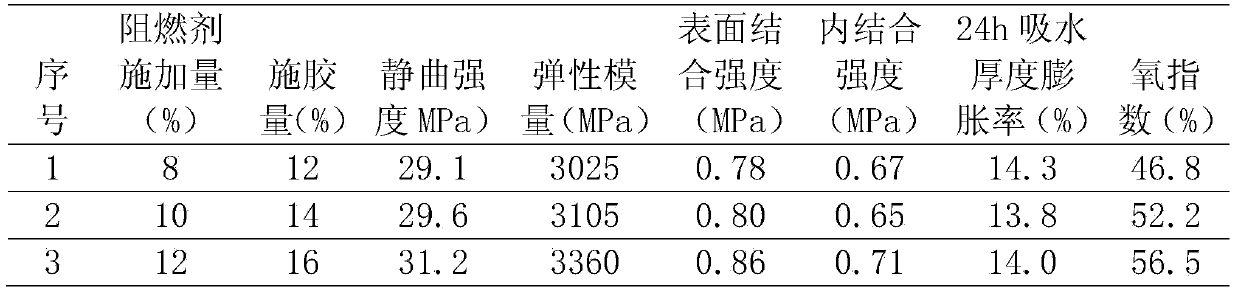

Embodiment 1

[0026] A flame retardant made from the following raw materials:

[0027] Type I ammonium polyphosphate 400g, expanded graphite 400g, zinc borate 50g.

[0028] The components are mixed evenly according to the proportion to make the flame retardant.

Embodiment 2

[0030] A flame retardant made from the following raw materials:

[0031] Type II ammonium polyphosphate 800g, expanded graphite 100g, melamine 50g, borax 200g.

[0032] The components are mixed evenly according to the proportion to make the flame retardant.

Embodiment 3

[0034] A flame retardant made from the following raw materials:

[0035] Type Ⅰ ammonium polyphosphate 400g, type Ⅱ ammonium polyphosphate 200g, expanded graphite 350g, boric acid 100g.

[0036] The components are mixed evenly according to the proportion to make the flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com