Double-station reciprocating rotary type injection stretch blow hollow forming machine

A reciprocating rotation, injection-stretch-blow technology, applied in the field of double-station reciprocating-rotation injection-stretch-blow blow molding machines, can solve the problems of complex operation process, huge machine, inconvenient operation, etc., and reduce the number of matching and mold costs. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

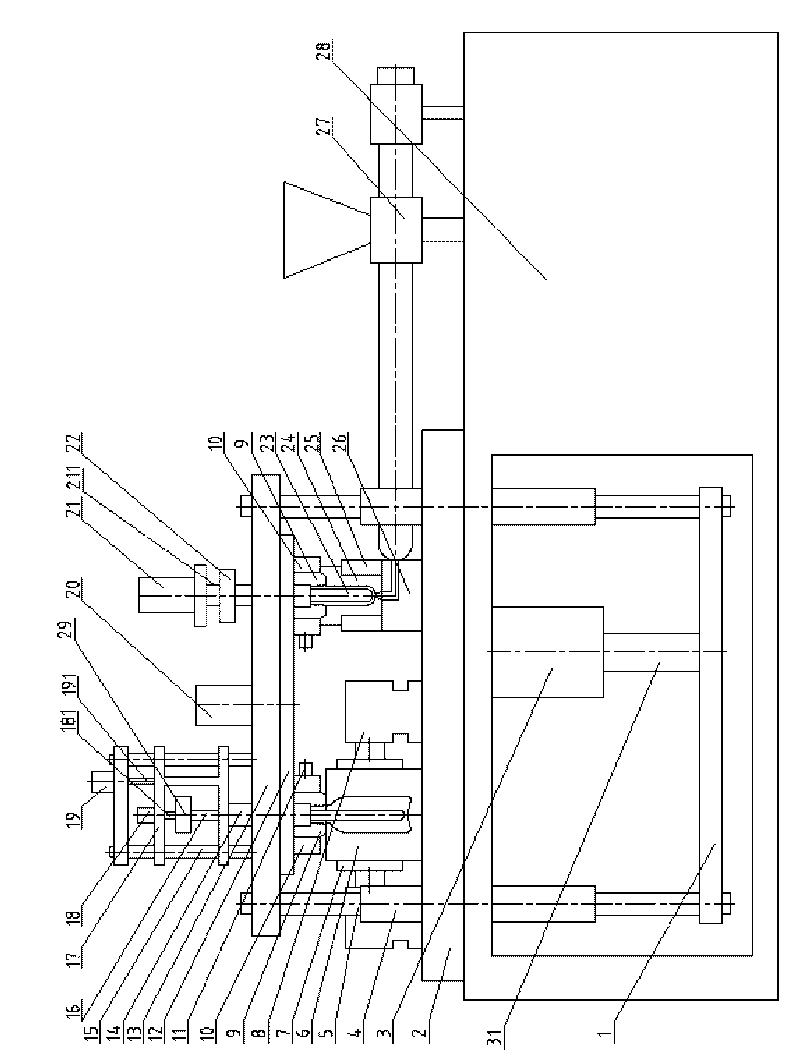

[0035]A double-station reciprocating rotary injection-stretch-blow molding machine includes two parts: a main machine and a mold. The main machine part includes a frame 28, a worktable panel 2 fixed horizontally on the frame 28, and placed The injection system 27 placed horizontally on the frame 28, the injection molding clamping system arranged perpendicular to the workbench panel 2, the blow molding mold clamping system placed horizontally on the workbench panel 2 and the stretching device arranged vertically;

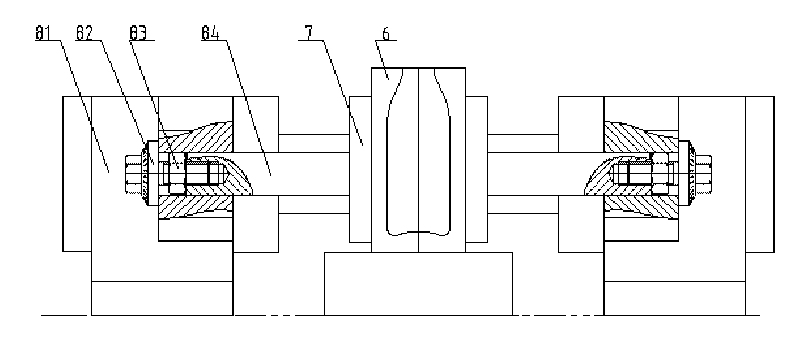

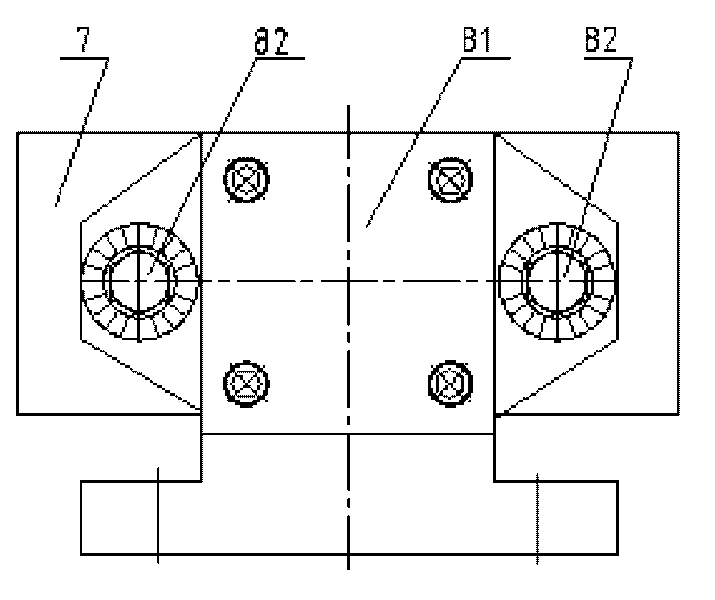

[0036] The injection molding clamping system includes an upper template 13, a workbench panel 2, a lower template 1, a clamping cylinder 3, a guide post 5, a rotary drive mechanism 20, a rotating disc 12 and a core pulling cylinder 21, and the workbench panel 2 is fixed horizontally On the frame 28, the lower formwork 1 is connected with the upper formwork 13 through four guide pillars 5 vertically passing through the workbench panel, the clamping oil cylinder 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com