A tool for detecting interference phenomenon in the assembly of a hollow blade cooling duct and a manufacturing method

A technology for cooling ducts and testing tools, which is used in measuring devices, engine testing, and machine/structural component testing. , the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

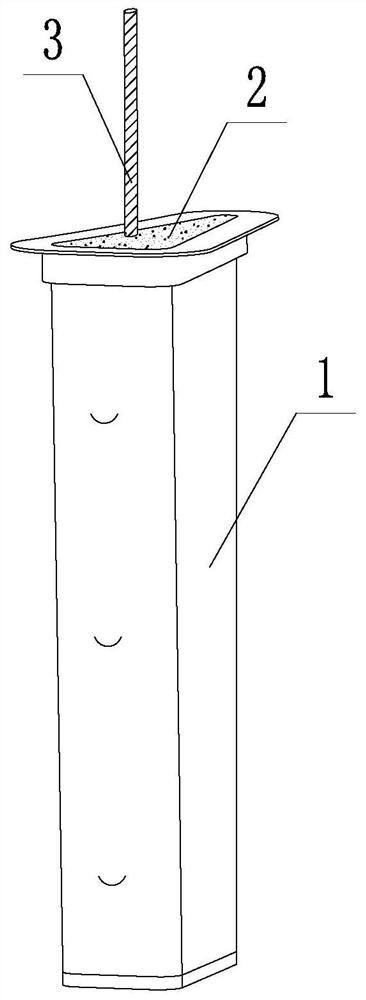

[0021] Such as figure 1 As shown, a hollow blade cooling duct assembly interference detection tool includes a cooling duct finished product 1, a duct lumen support body 2 and a handle 3; the inner cavity of the cooling duct finished product 1 is completely filled by the duct lumen support body 2 One end of the handle 3 is fixed in the support body 2 of the catheter lumen, and the other end of the handle 3 extends to the outside of the finished cooling catheter 1 .

[0022] The manufacturing method of the hollow blade cooling duct assembly interference phenomenon detection tool includes the following steps:

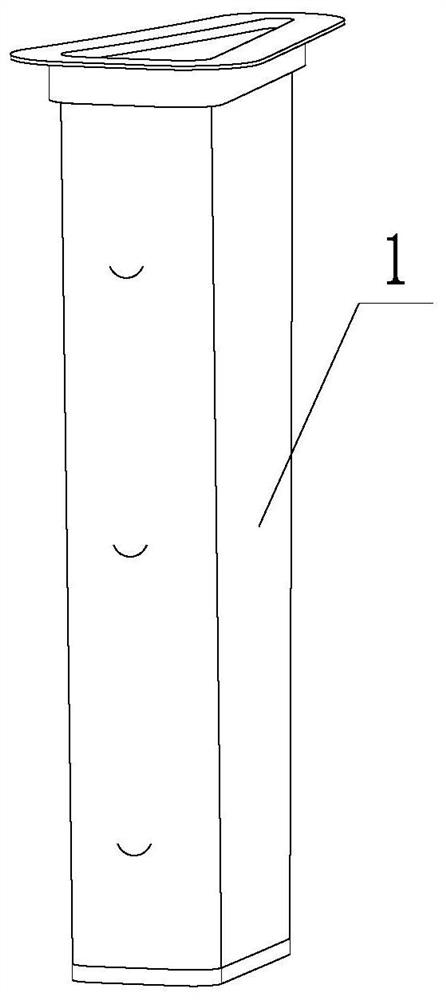

[0023] Step 1: Select a cooling duct product 1, such as figure 2 shown;

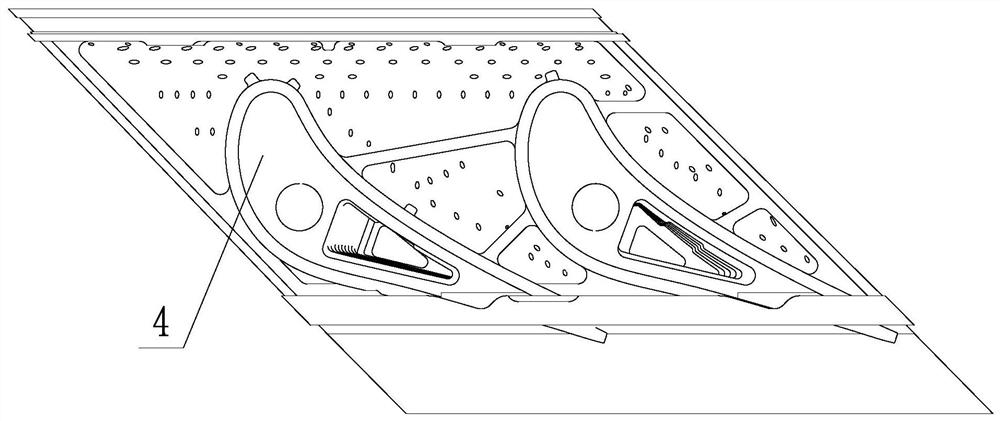

[0024] Step 2: Select the catheter lumen support body 2 used to fill the inner cavity of the finished product 1 of the cooling catheter. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com