Patents

Literature

140 results about "Shape deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

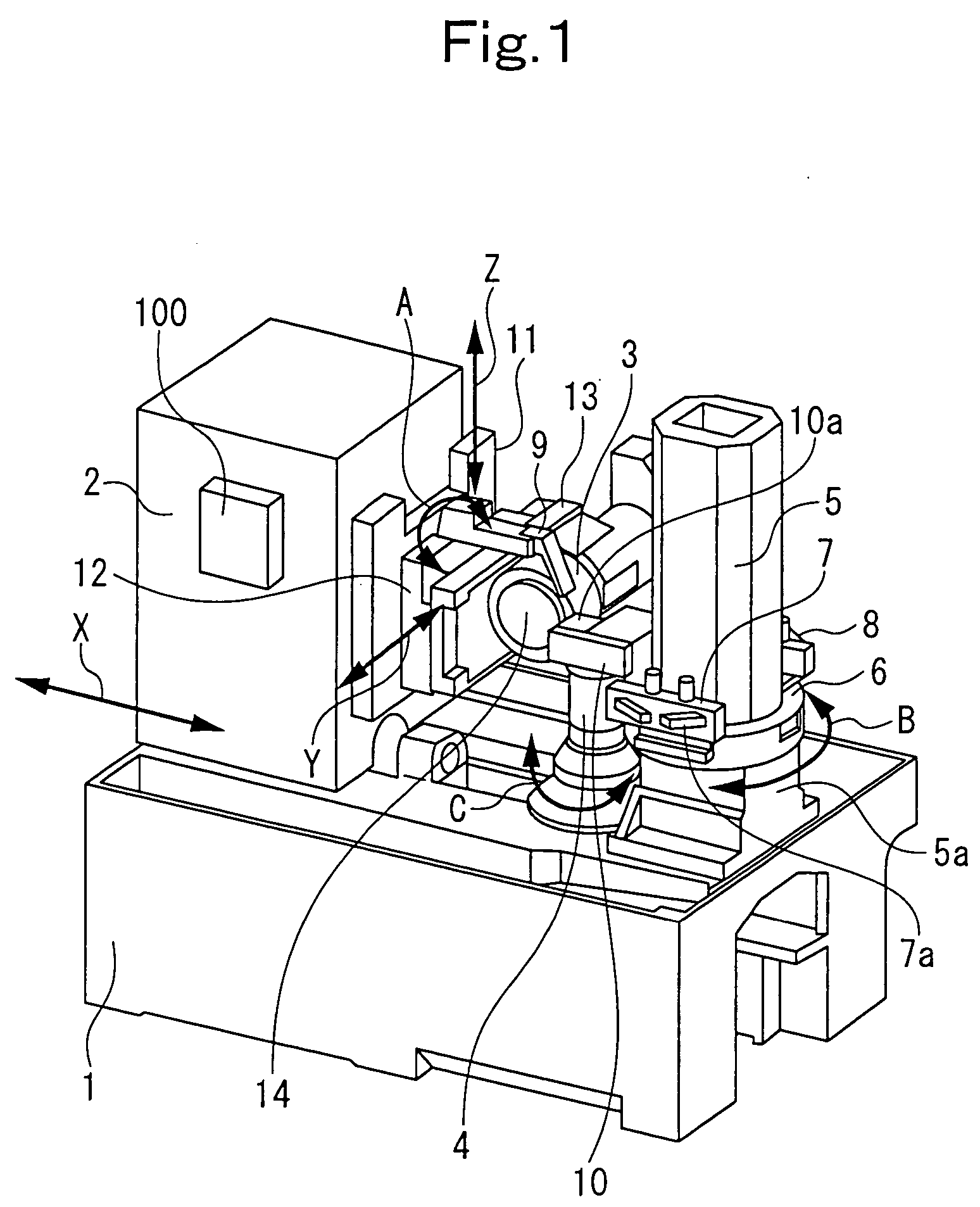

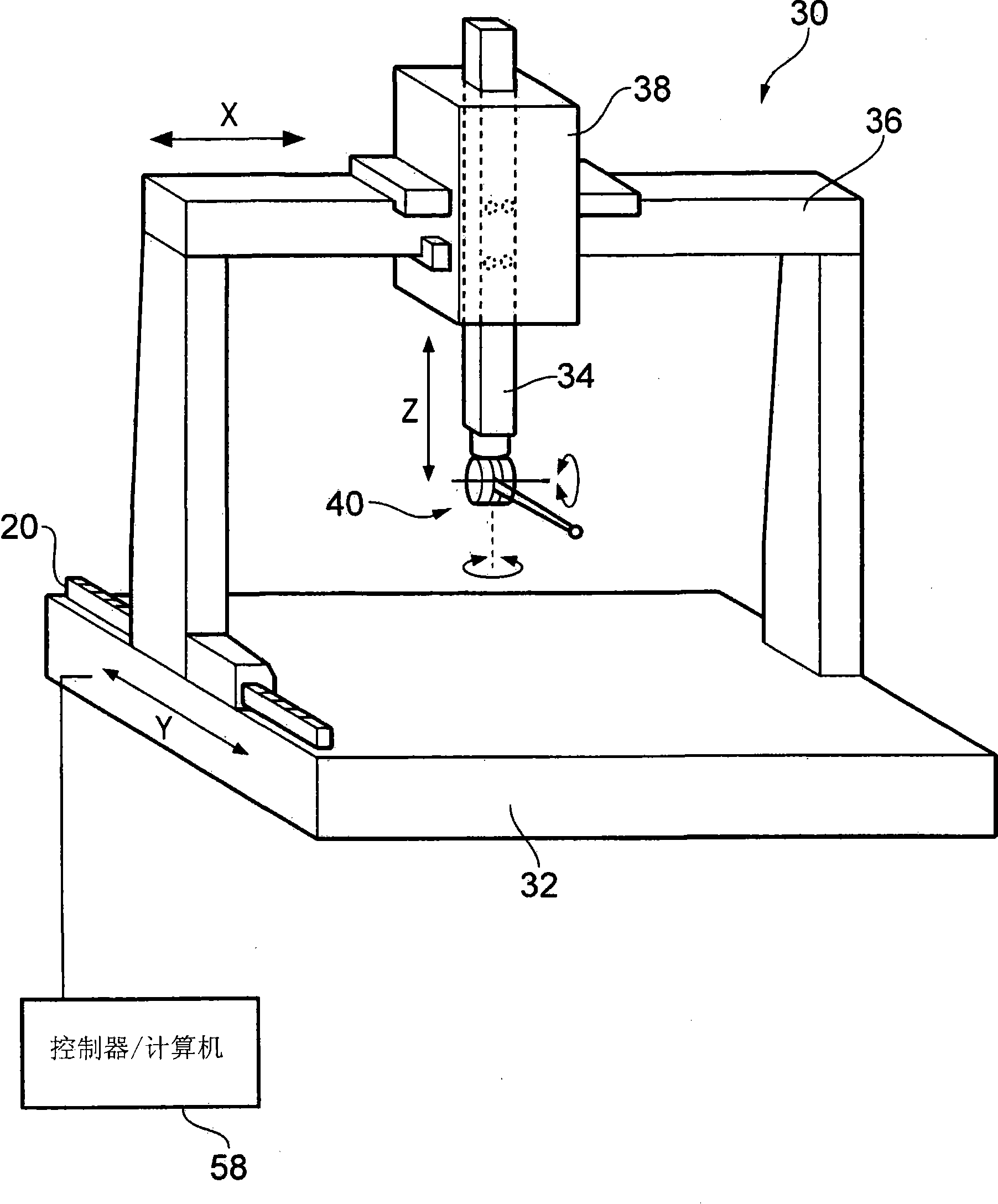

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

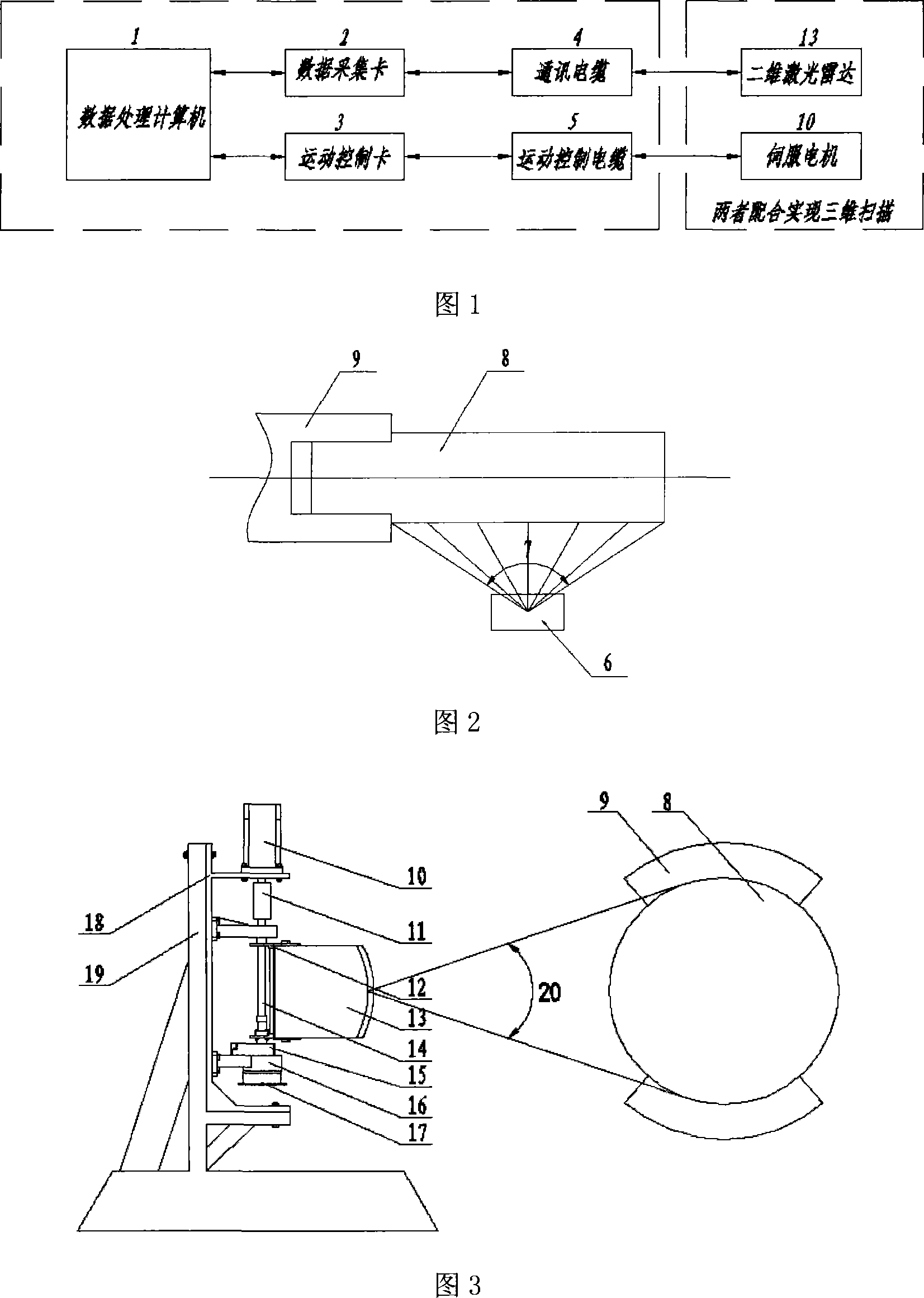

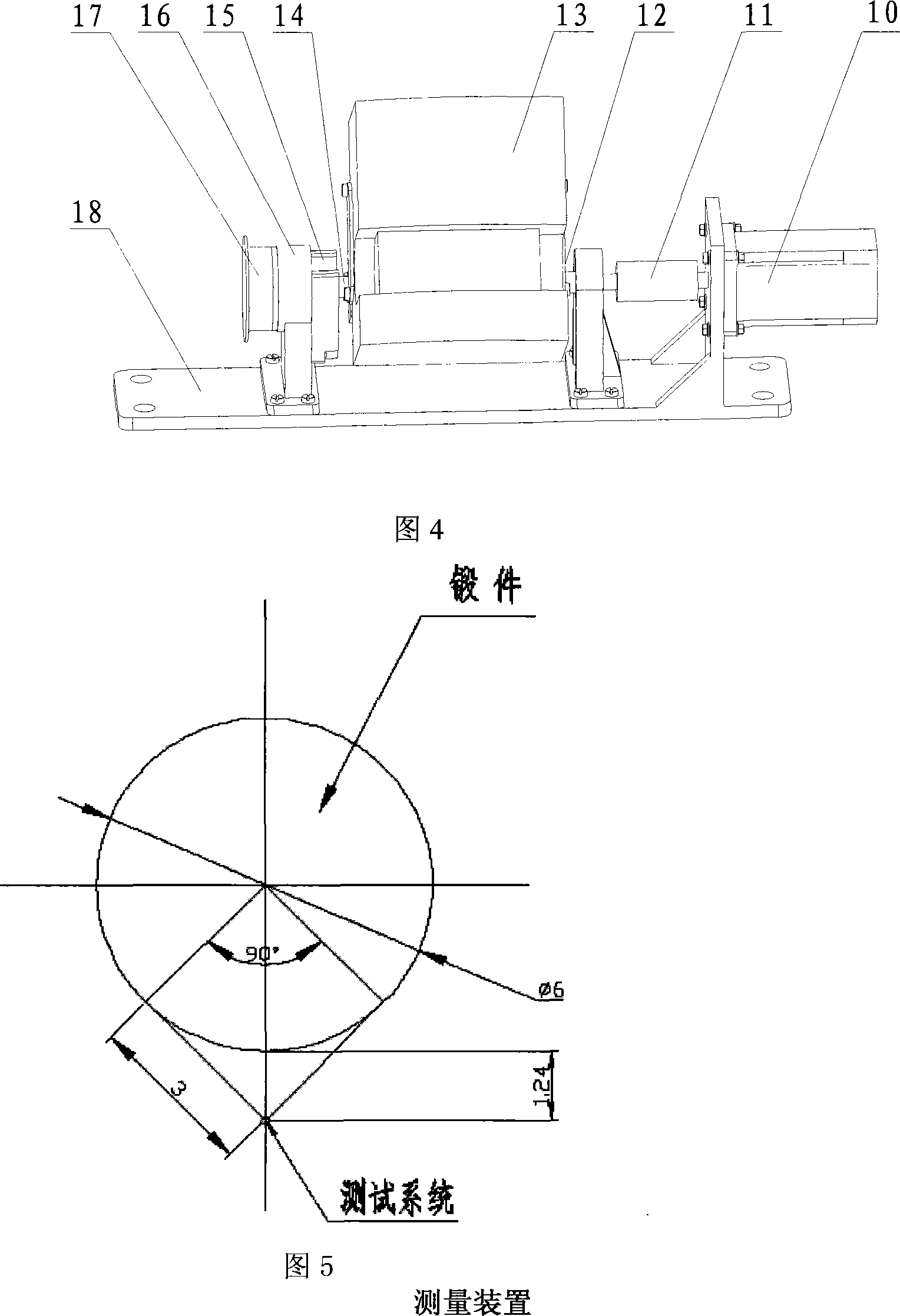

Large-scale forging laser radar on-line tri-dimensional measuring device and method

InactiveCN101187548AMeet the measurement requirementsHigh precisionUsing optical meansShape deviationData acquisition

The invention relates to a device and a method for on-line three-dimensional measuring of a laser radar of heavy forging in the measuring technical field, which comprises a two- dimensional laser radar, a servo-motor, a junction box, a rotary main shaft, a spacing and null point sensor, a bearing block which is provided with a bearing, a band brake apparatus, a back supporting stand of the laser radar, an L-shaped mounting bottom plate, a vertical mounting chassis, a movement-control card, a data collecting card, and a computer which is used for processing data. Firstly, the laser radar is positioned on the horizontal surface of a forging axial cord, then four surfaces of the forging are respectively scanned by the laser radar, the two-dimensional laser scanning radar is scanned in the surface which is vertical to an axial cord of the forging, the servo-motor drives the laser radar to rotate in the horizontal surface, thereby the three-dimensional scan of the forging is realized, finally, shape and parameter of the forging are gained through data process, and deviation of the shape of the forging is gained. The invention greatly increases accuracy and speed of identification, enlarges range of application, satisfies measuring requirement of a forging, and effectively increases measuring accuracy and efficiency of the forging.

Owner:SHANGHAI JIAO TONG UNIV

High-precision radial adjustable involute master of gear and adjusting method

ActiveCN104655080AHigh precisionImprove connection stiffnessMeasurement devicesMeasuring instrumentShape deviation

The invention discloses a high-precision radial adjustable involute master of gear and an adjusting method. One tooth face of four tooth faces is selected to be not precisely ground, has higher tooth profile shape deviation and is used for detecting a frequency response characteristic, a filtering effect and sensitivity of an instrument; another three tooth faces are precisely processed and have smaller tooth profile shape deviation, one precisely processed surface has certain tooth profile slope deviation and is used for detecting an amplification factor of the instrument, and other two tooth faces on opposite sides have tooth profile slope deviation which is approximate to zero and are used for representing the precision grade of the involute master of gear, transmitting involute parameter values and determining and correcting an indication error of an involute measurement instrument. The high-precision radial adjustable involute master of gear is simple in structure, convenient to adjust, high in connecting rigidity and reliable in connection with a master core shaft and high in precision, has a stable size, and can simultaneously meet demands for frequency response characteristic, filtering effect, sensitivity, amplification factor detection and instrument indication error correction of the involute measuring instrument.

Owner:DALIAN UNIV OF TECH

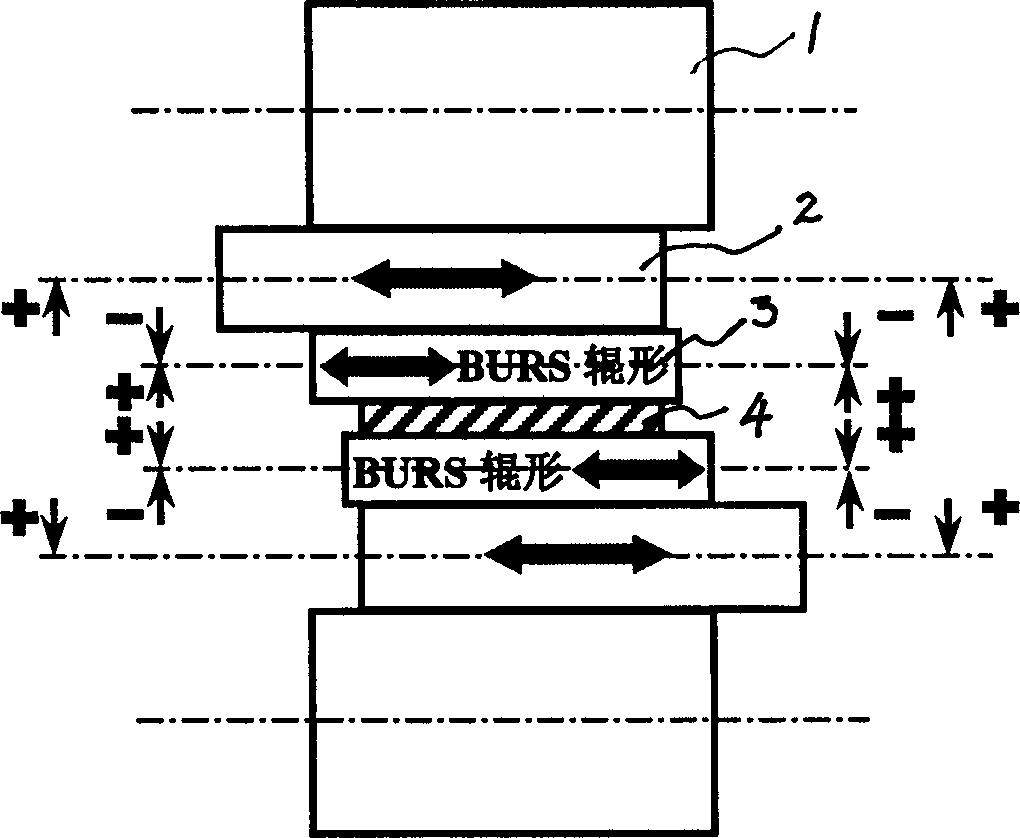

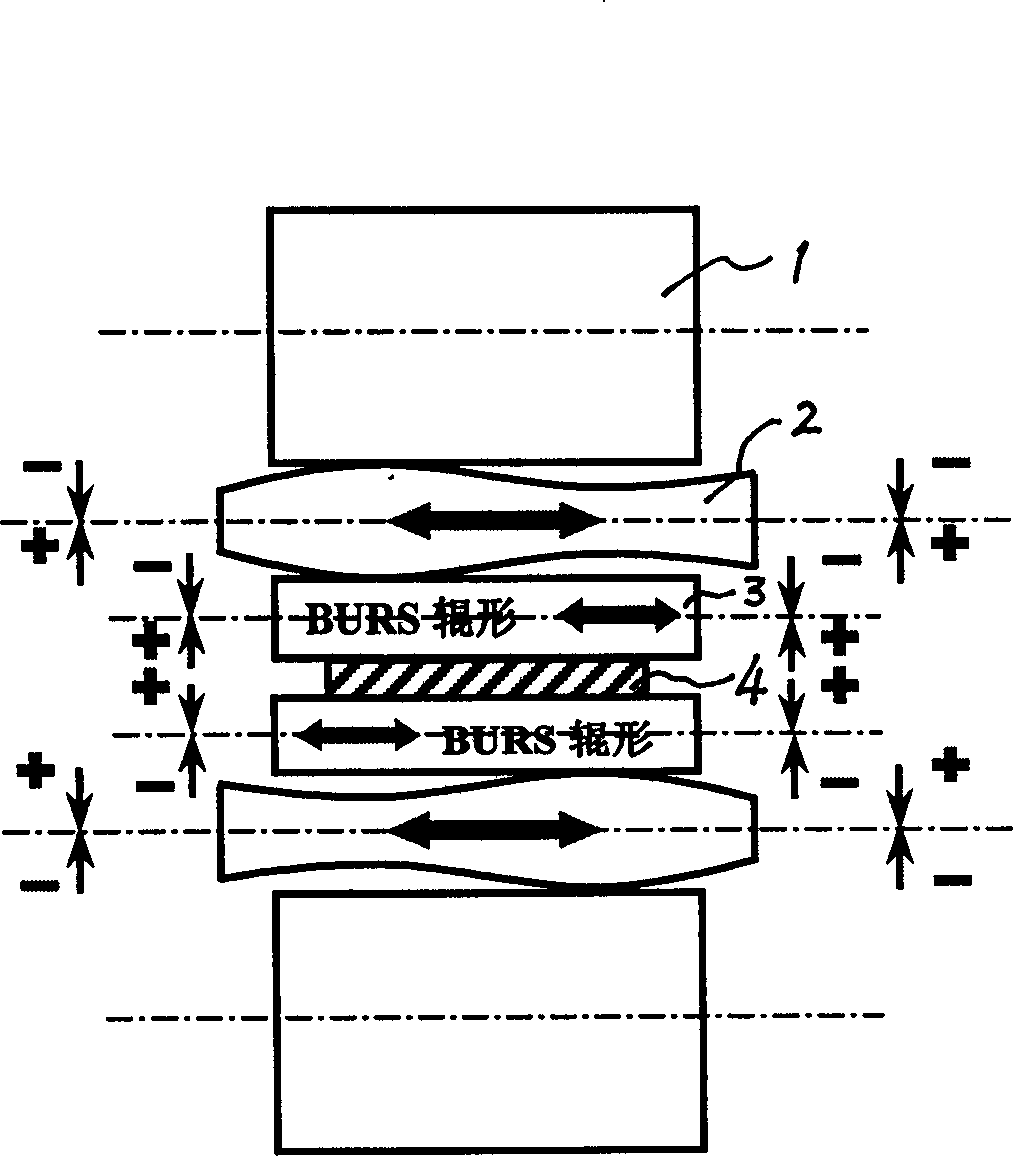

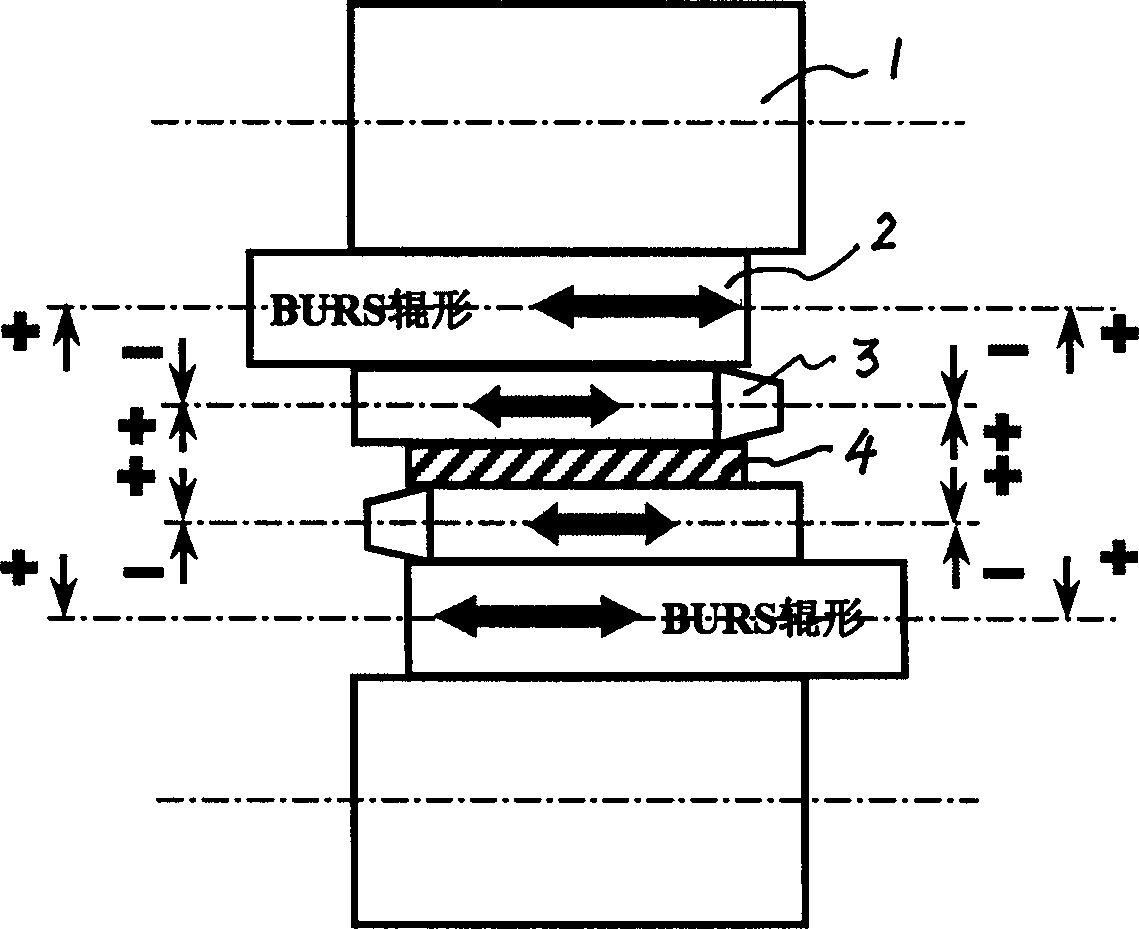

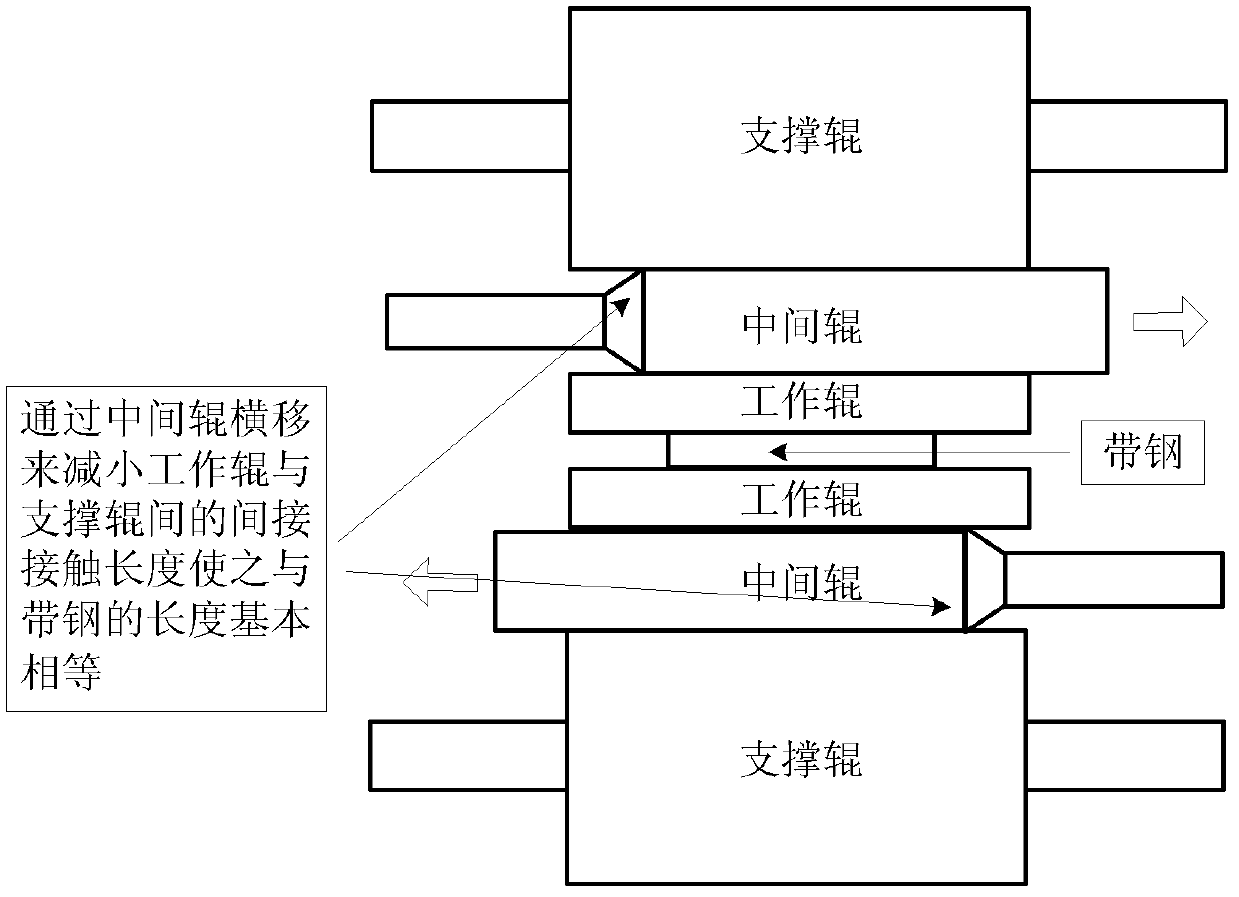

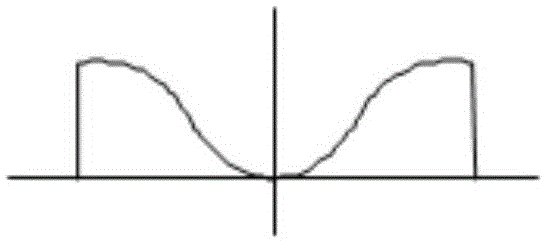

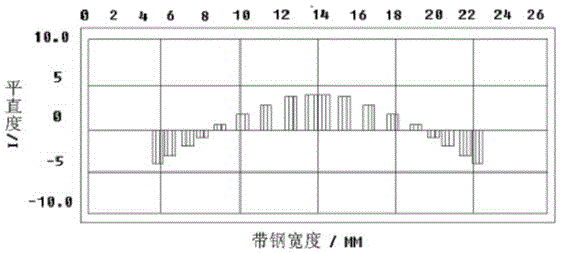

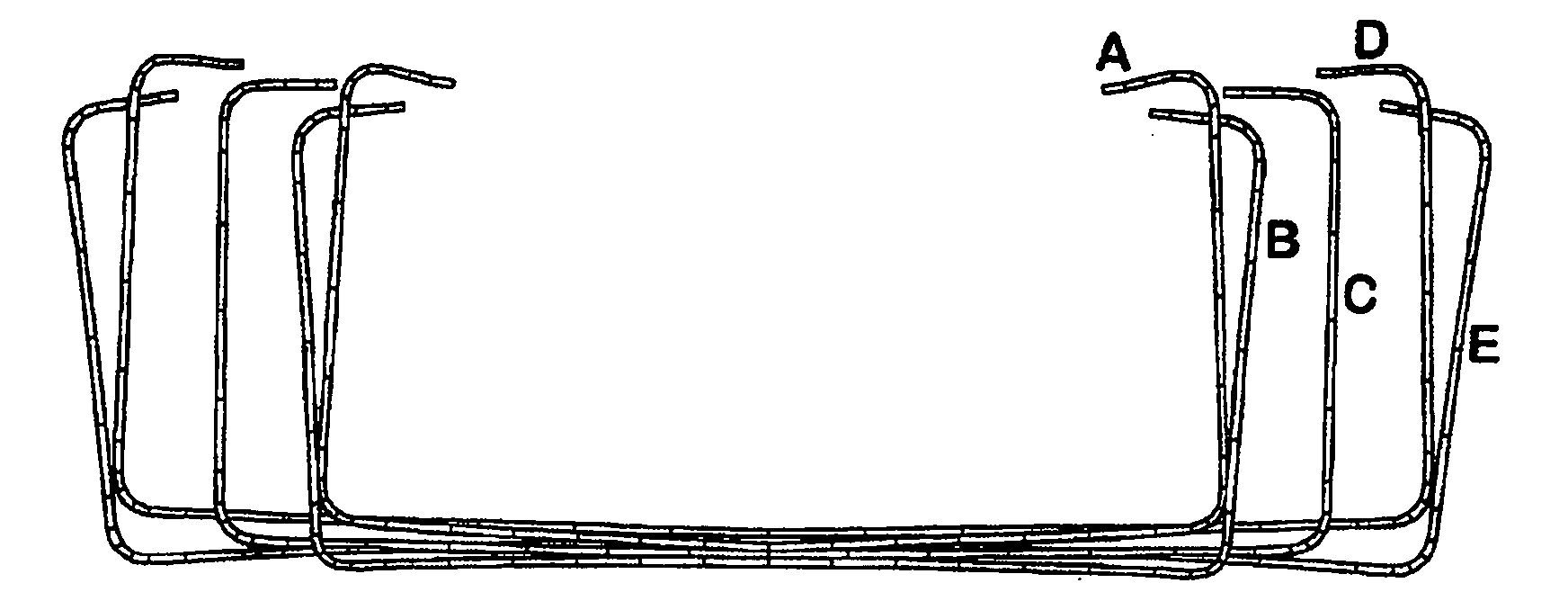

Rolling method for overcoming compound wave shape

A rolling method for overcoming the complex wave shape features that a rolling mill which has special pass configuration and contains at least 4 rollers (supporting roller and working rollers or intermediate rollers) and a plate shape control system are used. The plate shape controlling steps includes measuring plate shape data, processing to obtain plate shape signal, calculating plate shape deviation, and finding out the control signal of plate shape controller by polynomial fitting method or influence function method.

Owner:BAOSHAN IRON & STEEL CO LTD

Gear grinding machine

To correct the tooth profile error of a ground gear, the wheel angle of a threaded grinding wheel is modified by dressing the threaded grinding wheel by a dressing device. To correct the helix form deviation of a ground gear, namely, to modify the helix angle of the gear, synchronization between the moving motion in the Z-direction of the threaded grinding wheel and the rotary motion of a table for installation of the gear is adjusted. When the helix form deviation is corrected by adjustment of the synchronization, a tooth profile change inevitably occurs. In consideration of the tooth profile change, correction of the tooth profile error by dressing is made.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Self-mounting-reference equal-common-normal-line gear involute template

ActiveCN108061651AEasy to processEasy to testMachine gearing/transmission testingShape deviationInvolute

The invention belongs to the field of precise gear testing technology, and discloses a self-mounting-reference equal-common-normal-line gear involute template. The self-mounting-reference equal-common-normal-line involute template comprises a left tooth surface, a right tooth surface, an upper reference cylindrical surface, a lower reference cylindrical surface, an upper end surface, a lower end surface and a reference hole. The gear involute template satisfies a basic requirement for a grade-1 precise gear involute template in a gear involute template national standard. Furthermore the involutes of the left special-shaped tooth surface and the right special-shaped tooth surface of the template have a common normal line and a unified expanded basic circle arc. The self-mounting-reference equal-common-normal-line gear involute template facilitates subsequent ultra-precise processing and testing of the gear involute template. Furthermore, the self-mounting-reference is used for processing and measuring and is furthermore used as a magnitude transmission reference in use of the gear involute template. The measurement results of the structure tooth profile shape deviation ffalpha and atoth profile inclination deviation offset fHalpha are not closely related with the processing error and the mounting deviation error of a measuring core shaft in a use process, thereby ensuring highconvenience in use and high dimension stability in magnitude transmission.

Owner:金齿传动科技(大连)有限公司

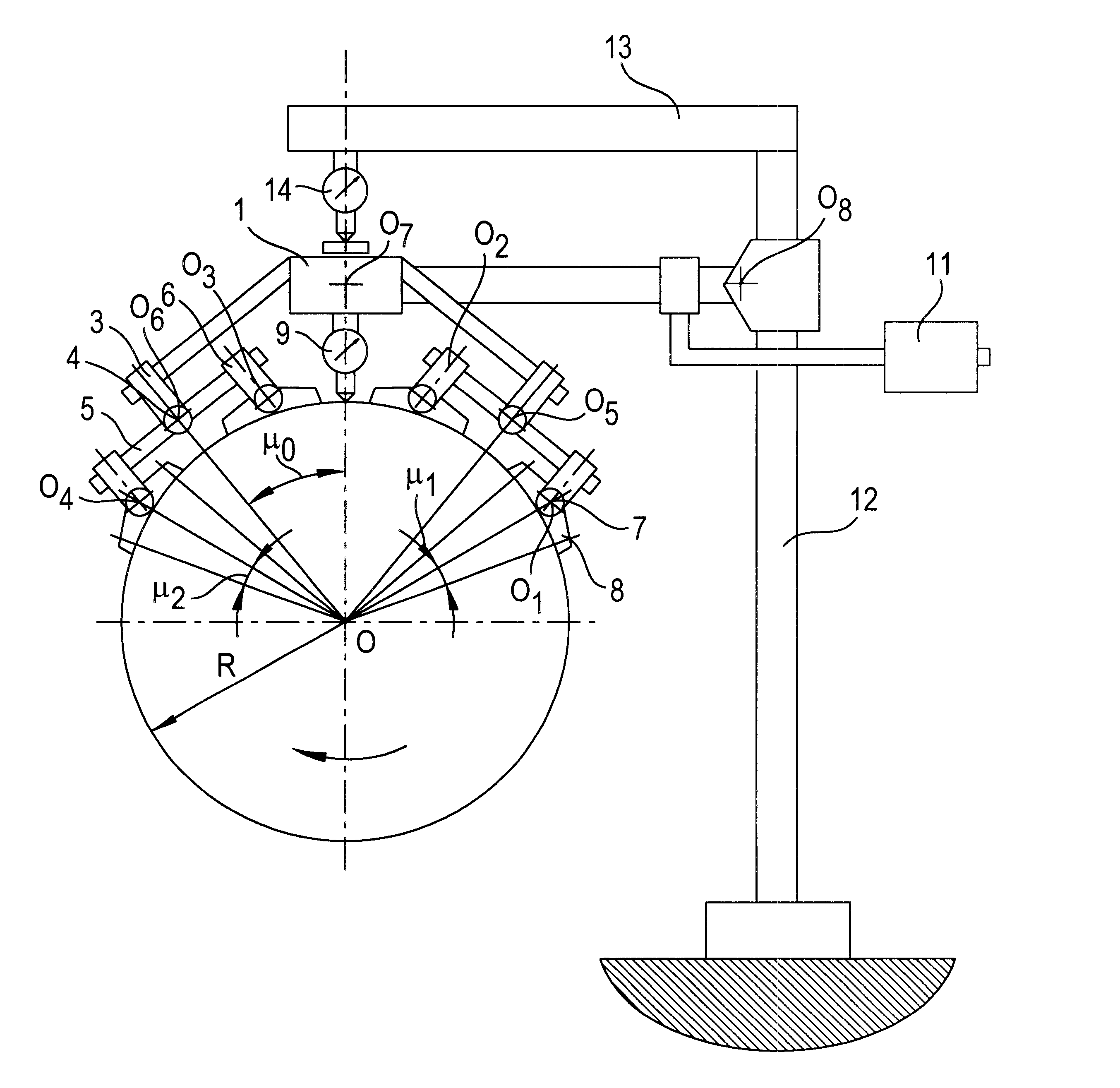

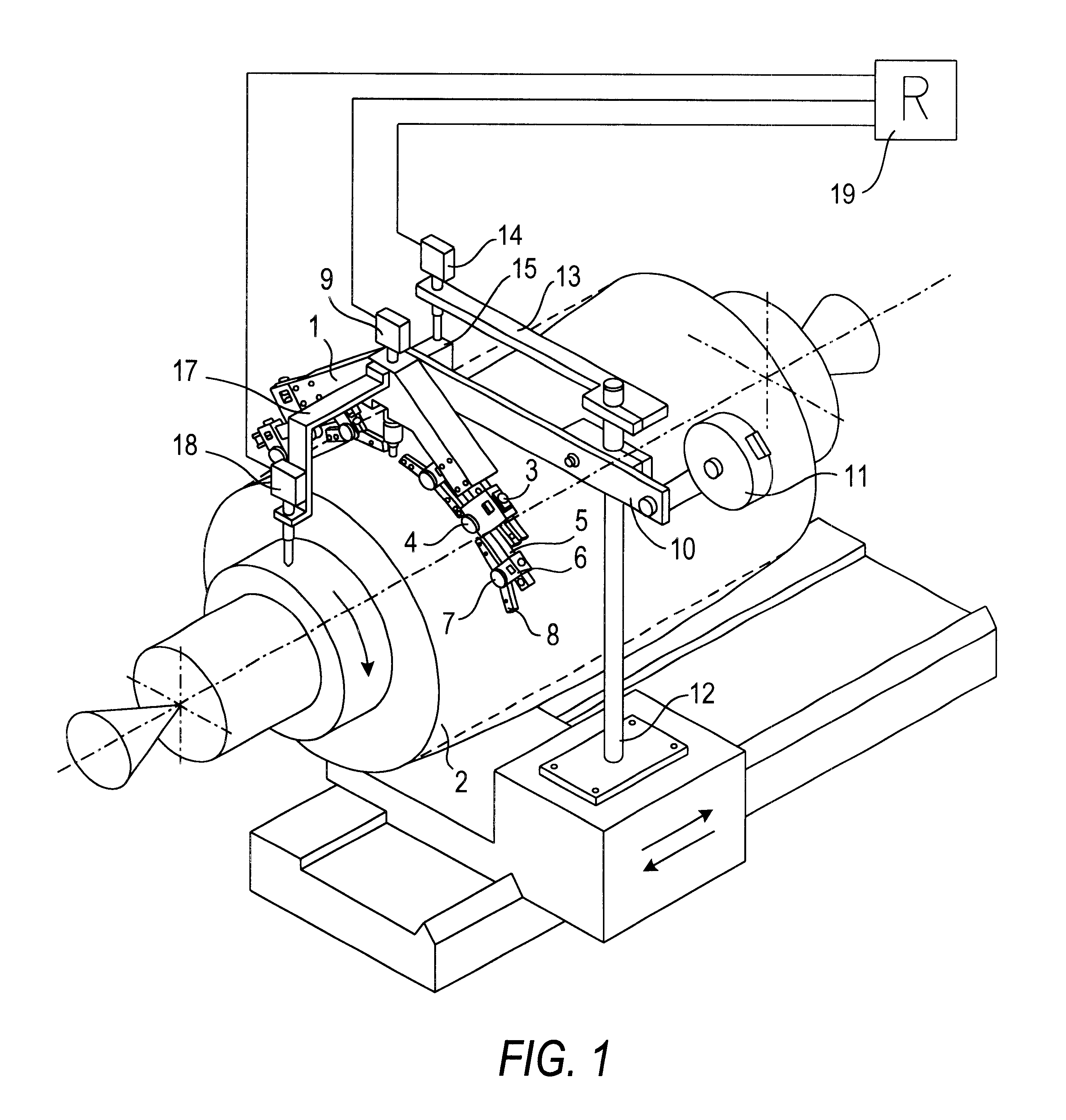

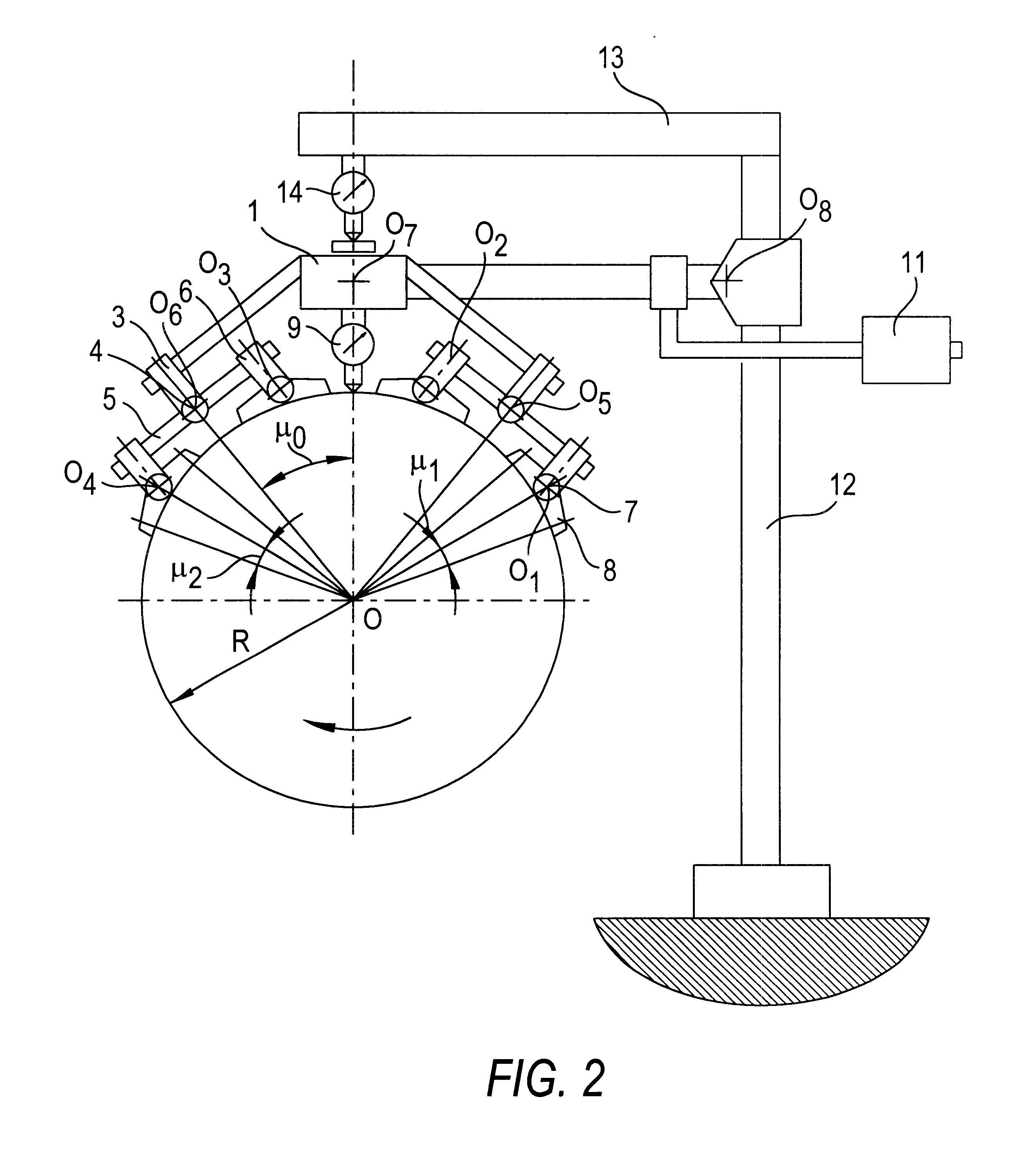

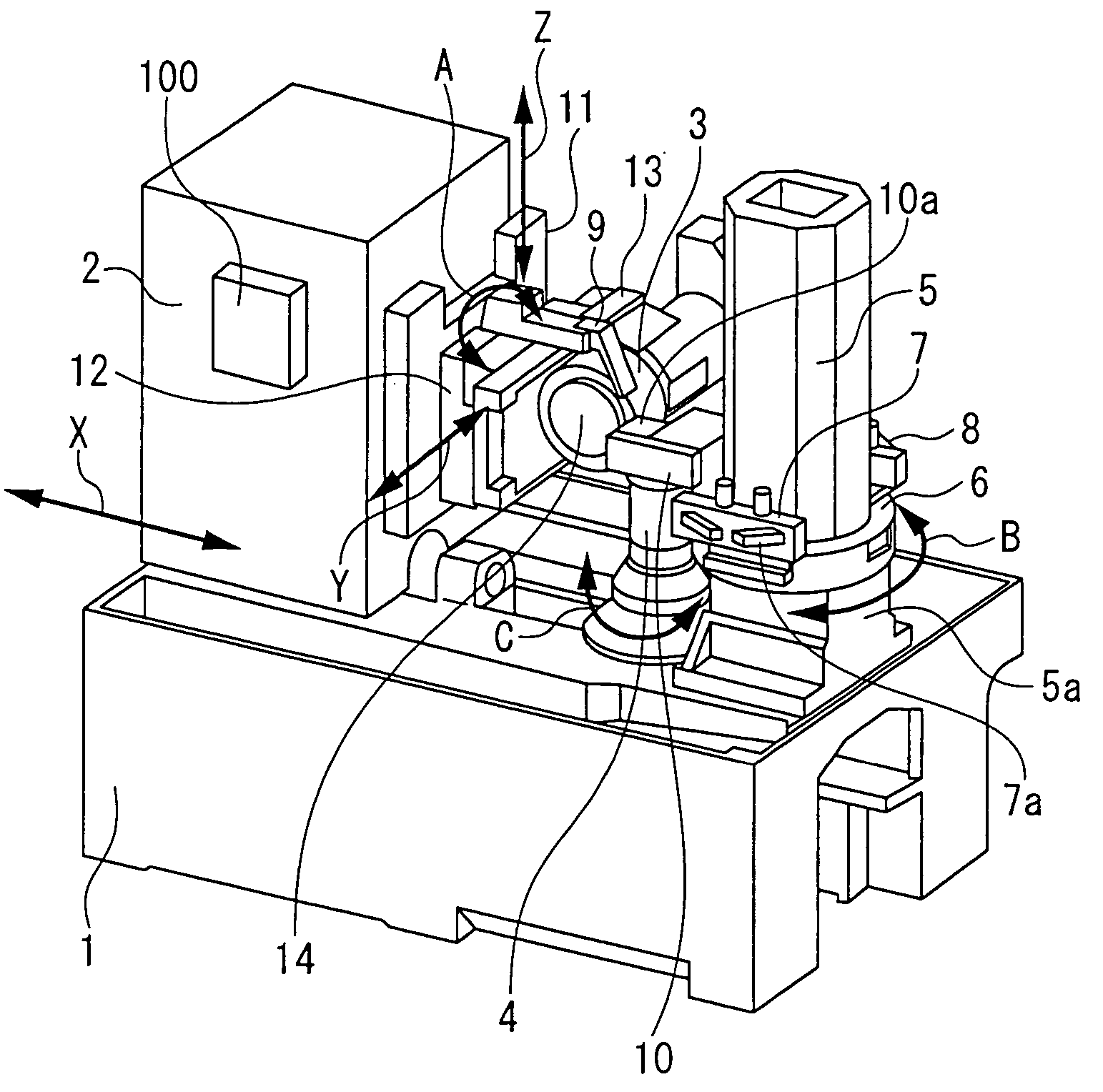

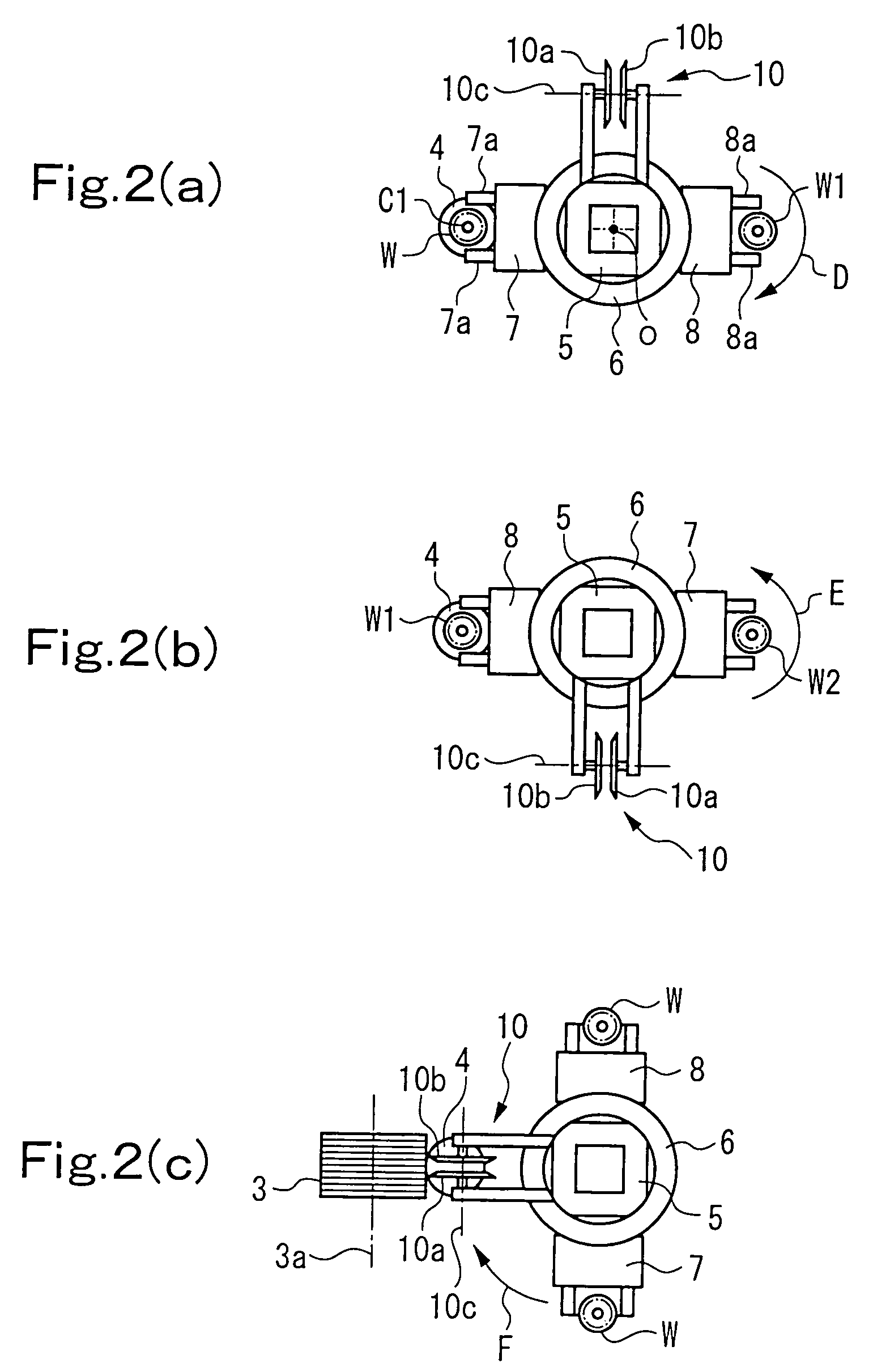

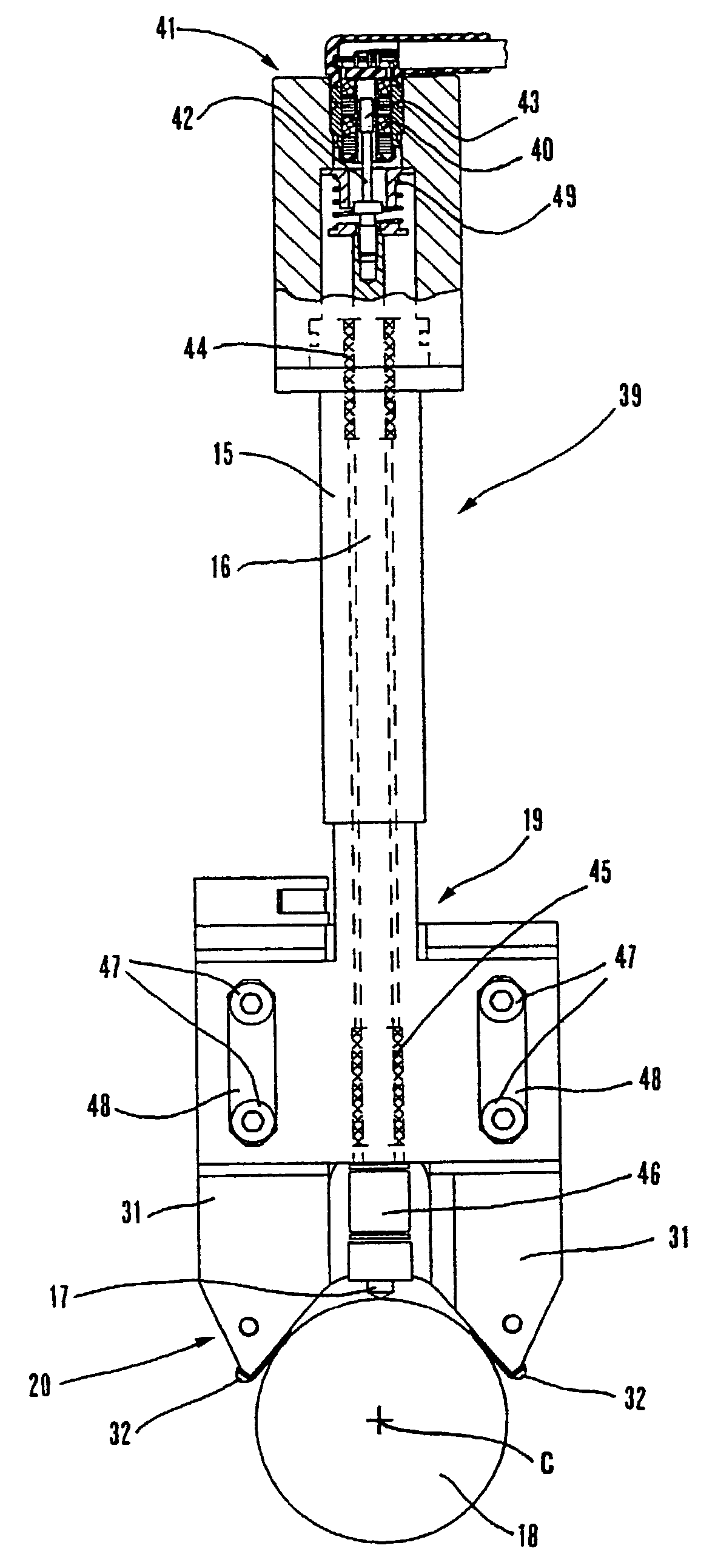

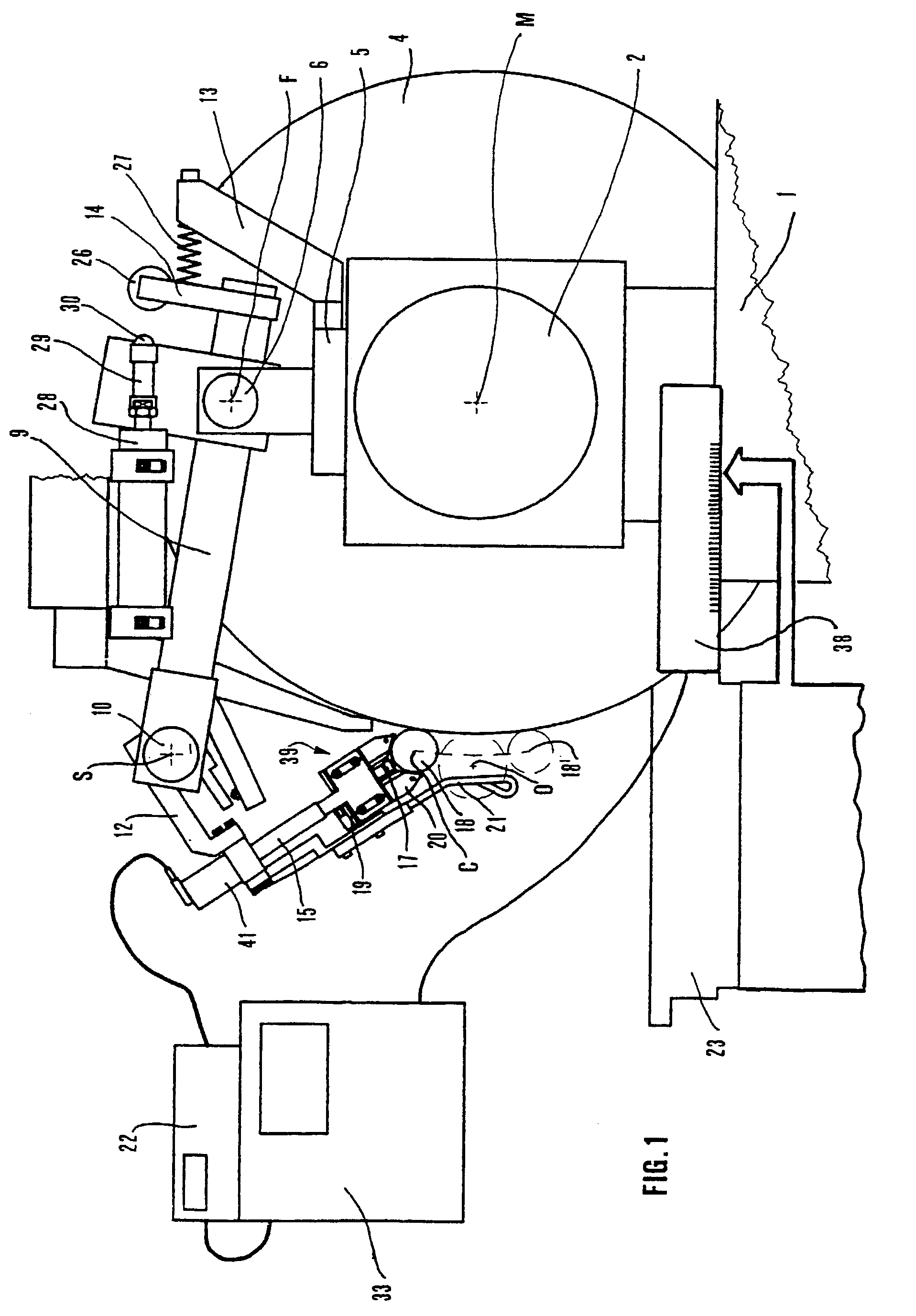

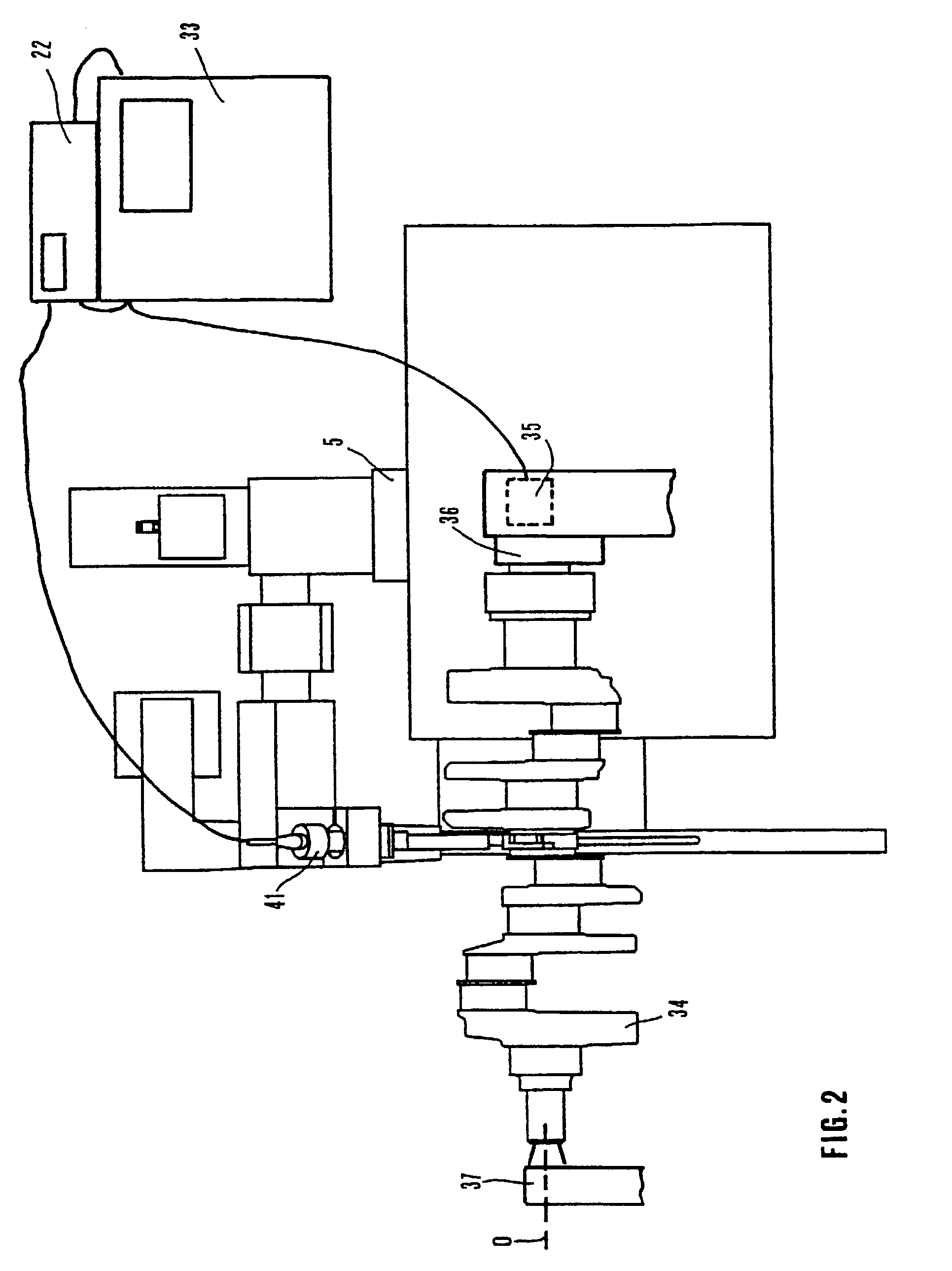

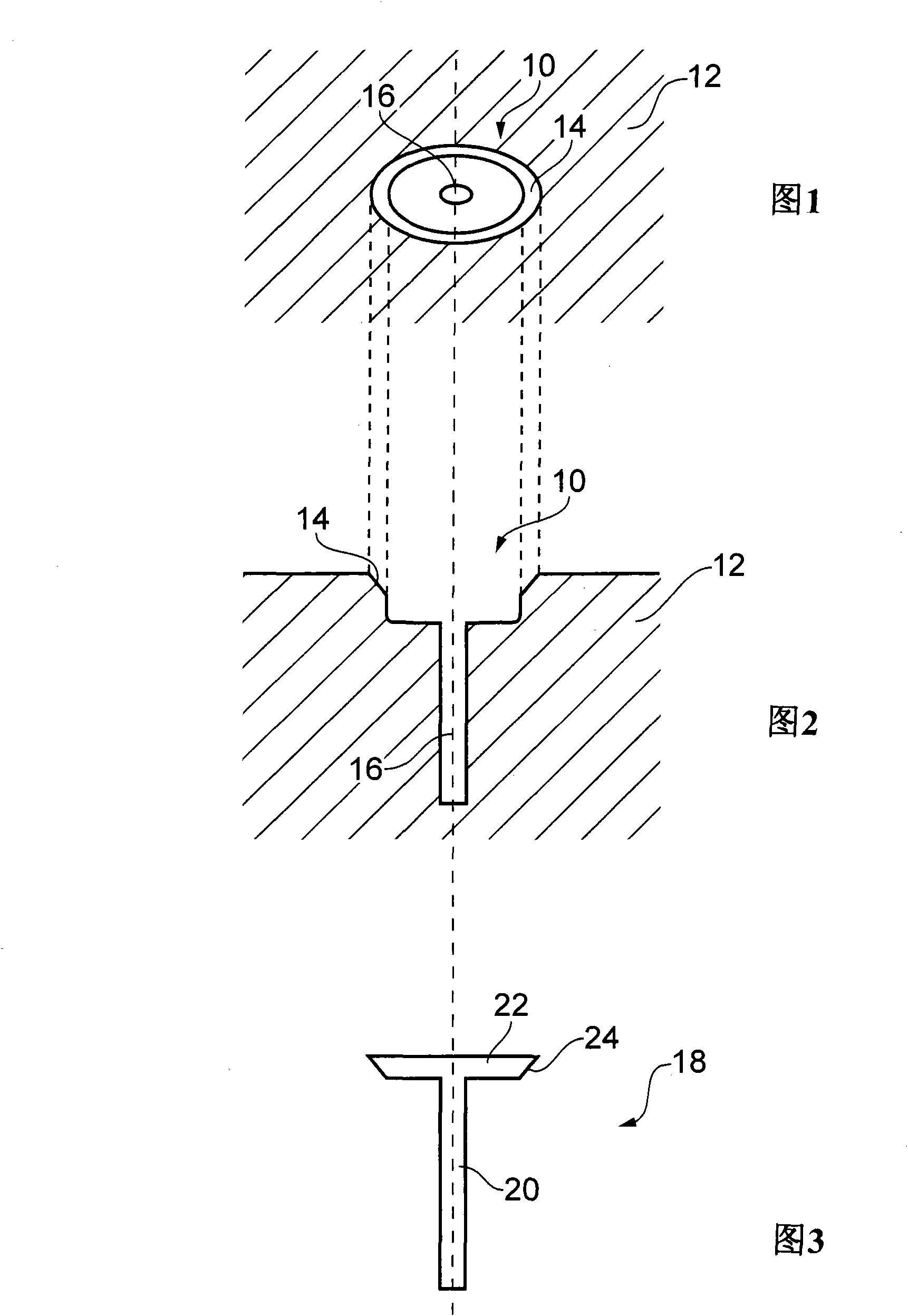

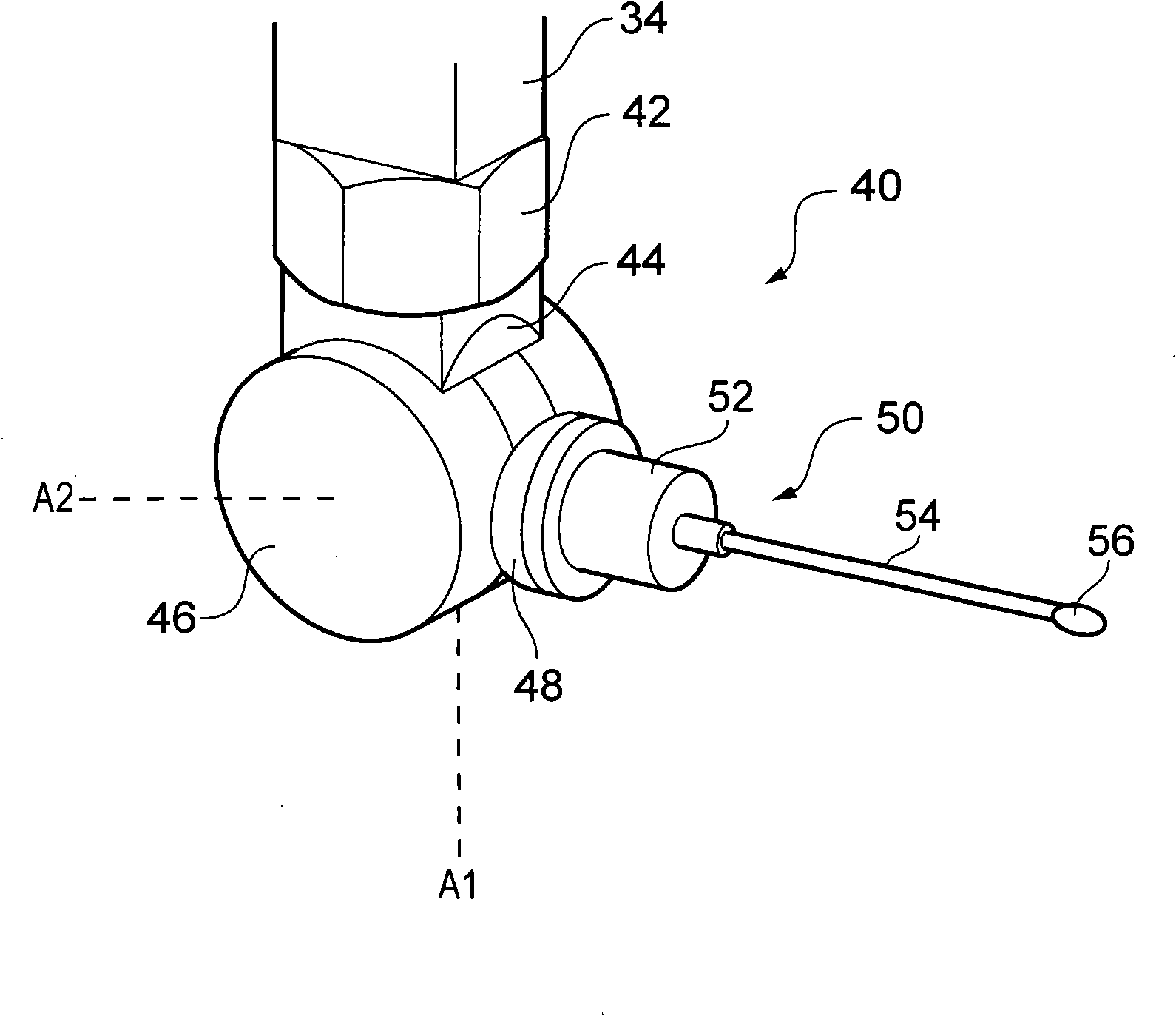

Apparatus and method to measure the dimensional and form deviation of crankpins at the place of grinding

InactiveUS7047658B2Walking sticksRevolution surface grinding machinesNumerical controlShape deviation

An apparatus and a relevant method for checking a crankpin (18) of a crankshaft (34) positioned on a numerical control grinding machine where it is worked includes a gauging head (39) with a Vee-shaped reference device (20) and a feeler (17), axially movable along a translation direction, that touches the crankpin surface, and an articulated support device (5,9,12) connected to the grinding-wheel slide (1), carrying the guaging head and allowing the reference device (20) to keep contact with the crankpin during its orbital motion around the main rotation axis (0) of the crankshaft. Rough values corresponding to a transducer (41) signals provided at predetermined angular positions of the crankshaft are stored and are processed also to compensate alterations caused both by contact between the sides of the Vee-shaped reference device and the surface of the crankpin to be checked, and by variations of the angular arrangement of the Vee-shaped reference device in the course of orbital rotations of the pin.

Owner:MARPOSS SPA

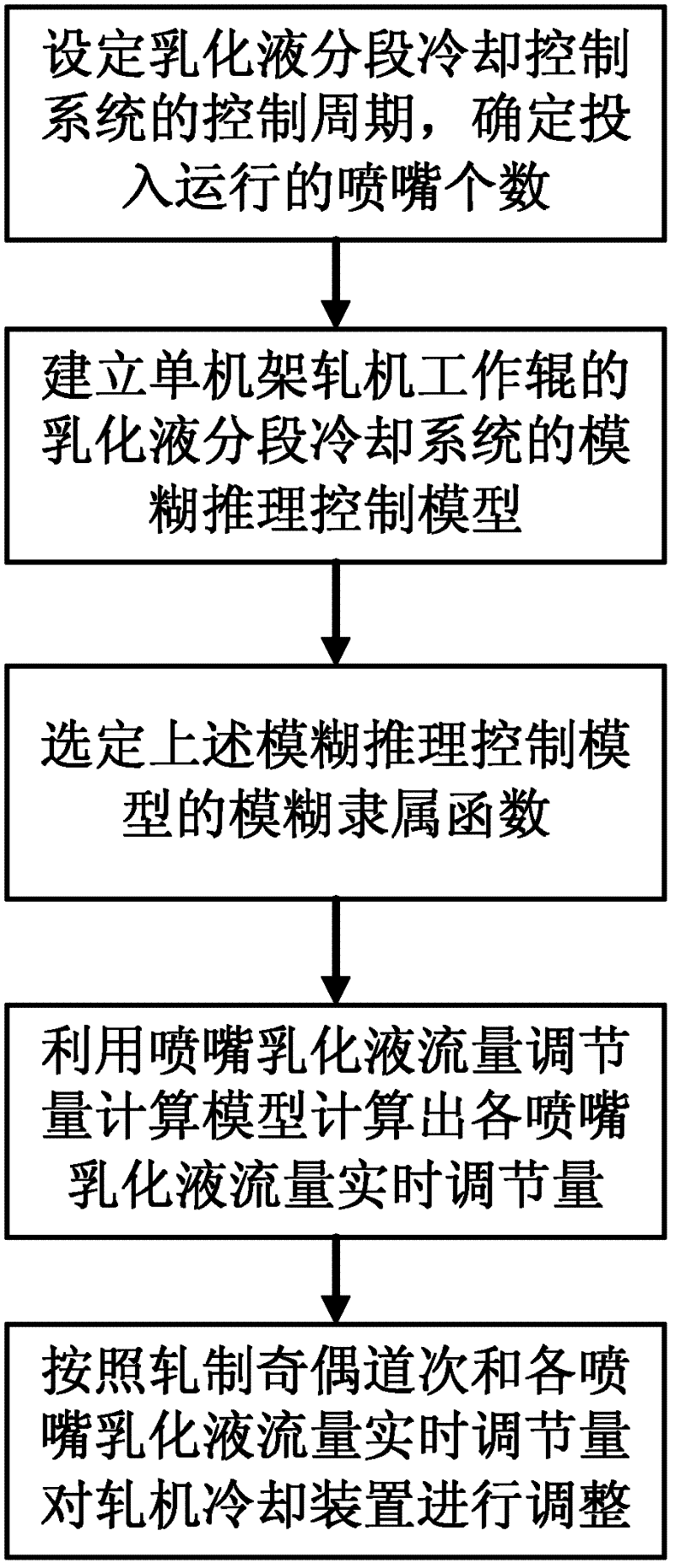

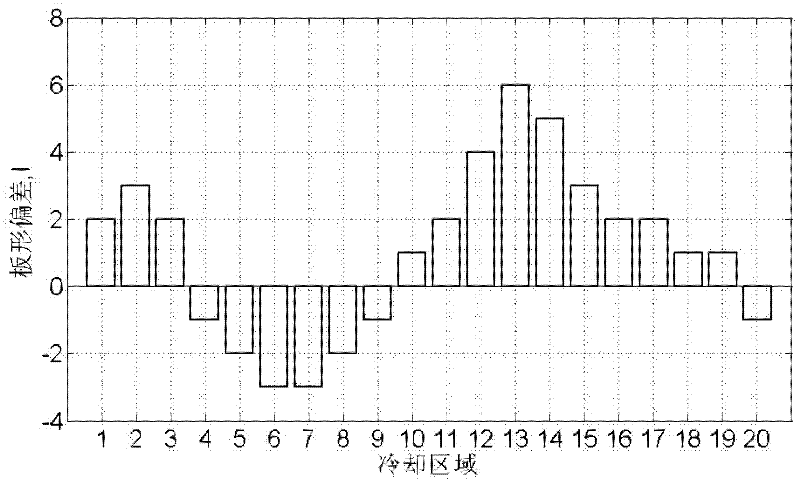

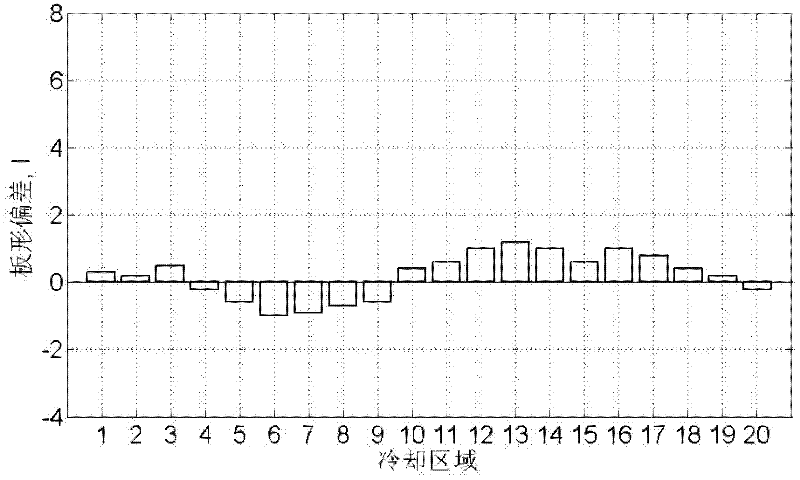

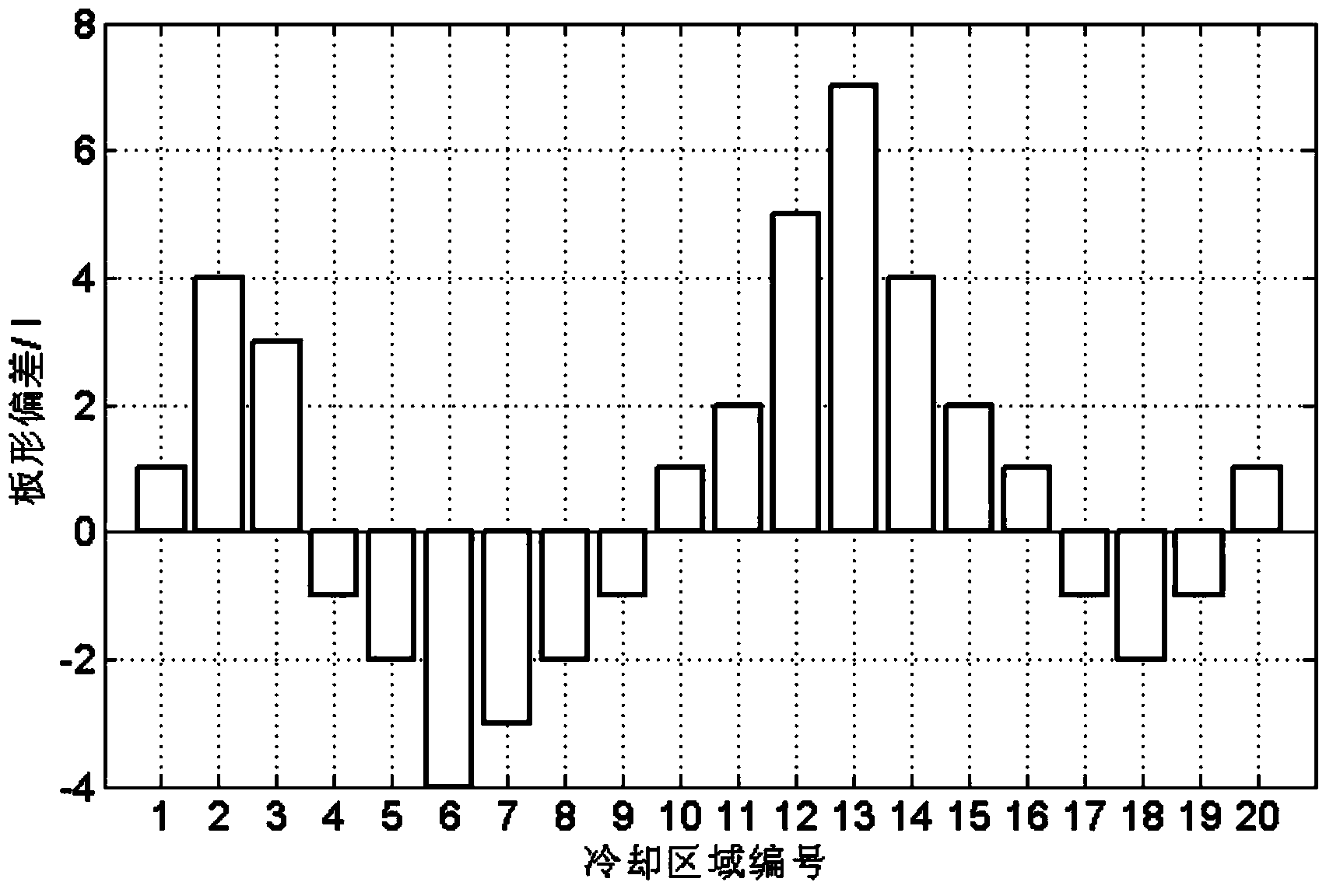

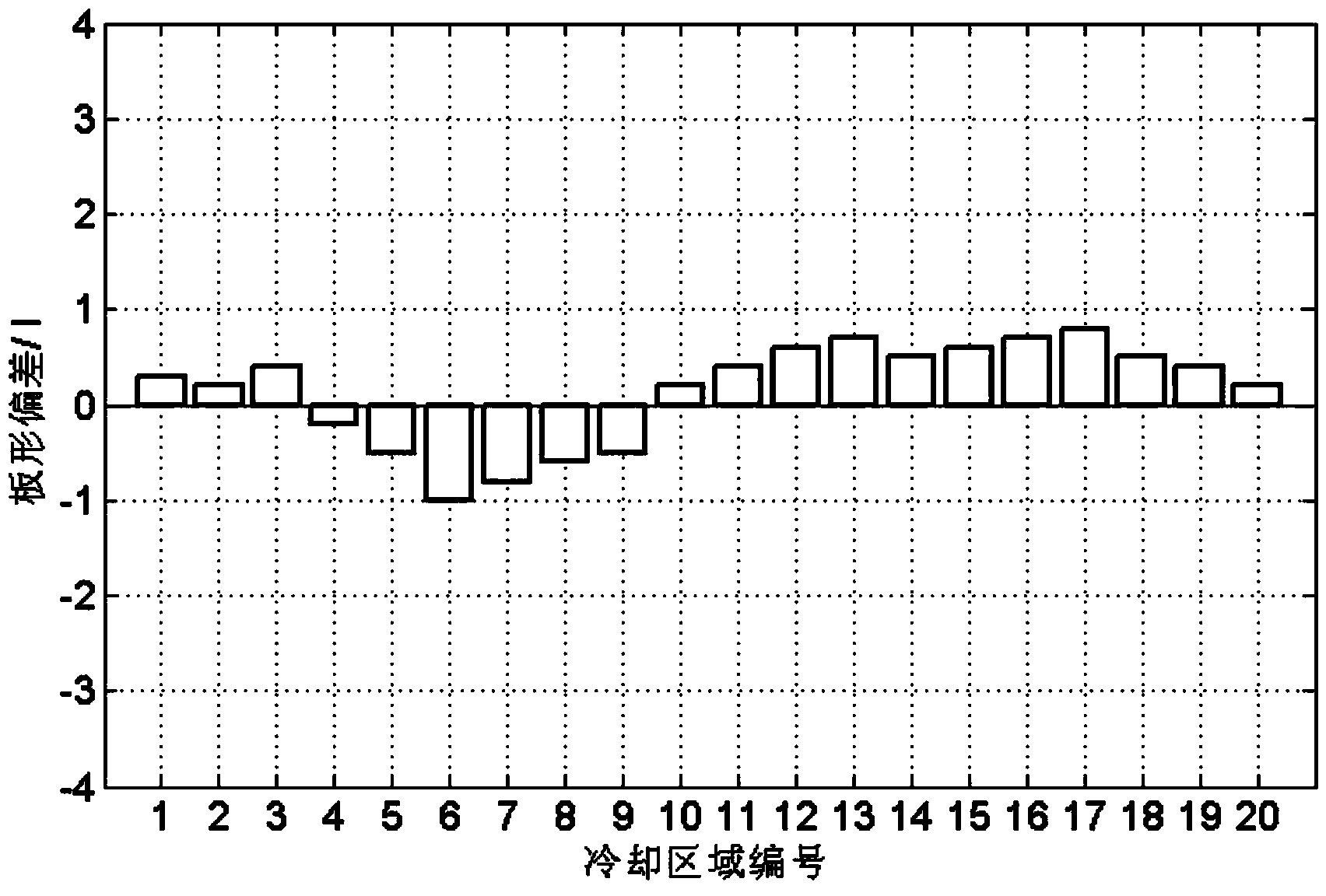

Sectional cooling control method for emulsion of working roller of single-frame rolling mill

InactiveCN102389902AOvercome technical problems that cannot be precisely controlledEliminate high order shape deviationRollsProfile control deviceTerra firmaEmulsion

The invention relates to a sectional cooling control method for an emulsion of a working roller of a single-frame rolling mill. Particularly, a fuzzy modeling method is used for establishing a quantitative relation among a plate-shape deviation, a previous regulating quantity of injected flow of the emulsion and a present regulating quantity of the injected flow of the emulsion, thereby realizinghigh-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill. The method provided by the invention overcomes the technical problem that precise control cannot be realized because a long-time hysteresis phenomenon exists in an emulsion injecting cooling action mechanism; high-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill is realized, thereby efficiently eliminating high plate-shape deviation of cold-rolling strip steel and promoting the quality of the plate shape of a cold-rolling strip steel product; the method is simple and practicable, fully meets a real-time demand of a sectional cooling control system and is characterized by effectiveness and practicability; and a firm foundation is established for high-precision plate-shape control of the cold-rolling strip steel.

Owner:WISDRI ENG & RES INC LTD

Apparatus and method for surface measurement

A method of determining the dimensions and location of a surface feature, for example a valve seat. The surface of the feature is measured, for example using a spiral scan path with a tactile probe and the multiple data points acquired from the scan are used to create a digitized image. The digitized image is fitted to a nominal image (e.g. CAD data) of the surface feature. The deviation of the digitized image from the nominal image is used to determine at least one of the dimensions, location and form deviation of the surface feature.

Owner:RENISHAW PLC

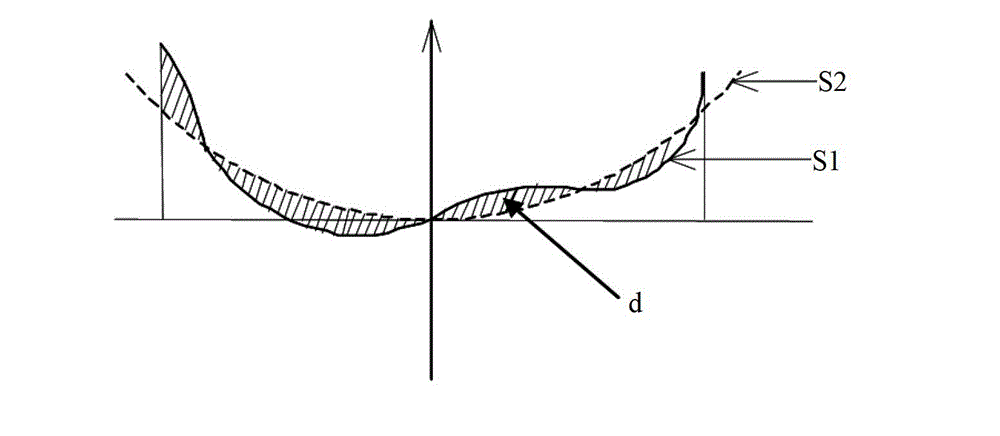

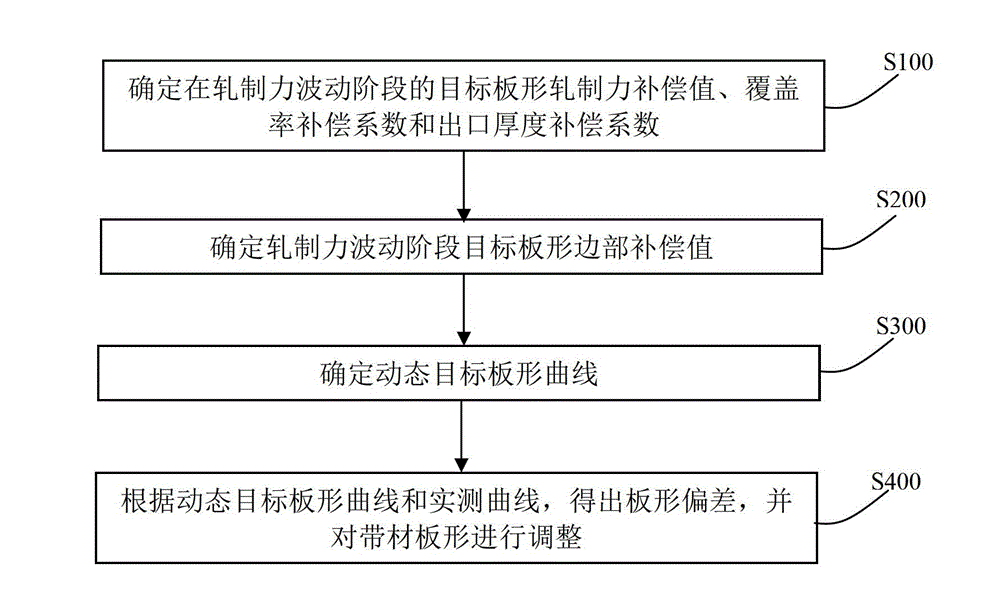

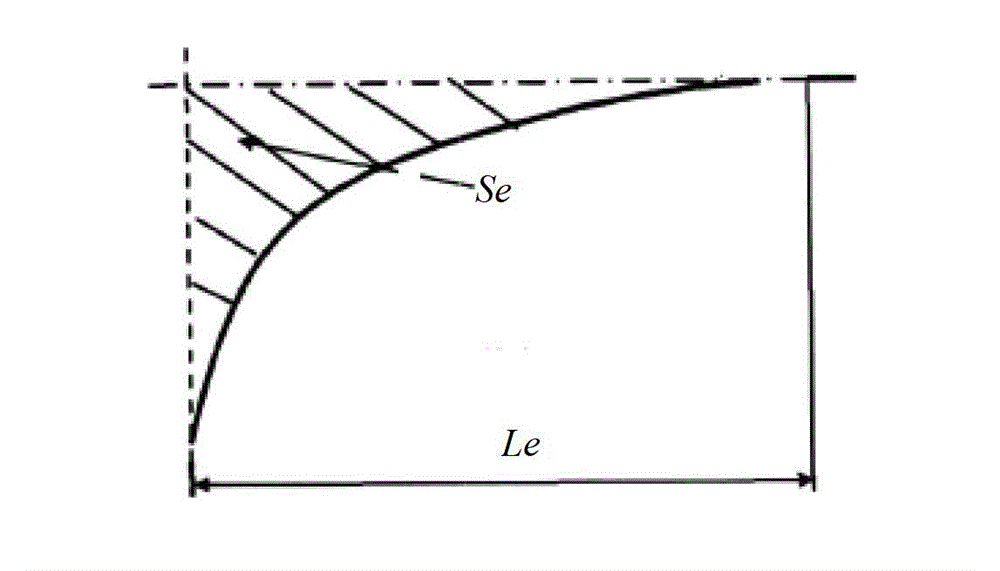

Target board shape setting method

ActiveCN104001730AImprove physical qualityHigh yieldProfile control deviceShape deviationEngineering

The invention discloses a target board shape setting method. The target board shape setting method comprises: step S100, confirming a target board shape rolling force compensation value, a coverage rate compensation factor and an outlet thickness compensation factor at a rolling force fluctuation stage; step S200, confirming a target board shape side portion compensation value at the rolling force fluctuation stage; step S300, confirming a dynamic target board shape curve; finally step S400, obtaining board shape deviation according to the dynamic target board shape curve and a measured curve and performing belt material board shape adjustment. The target board shape setting method can improve the board shape material object mass of belt material side portion at the rolling force fluctuation stage and ensures the rolling stability and decrease broken belt situation and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

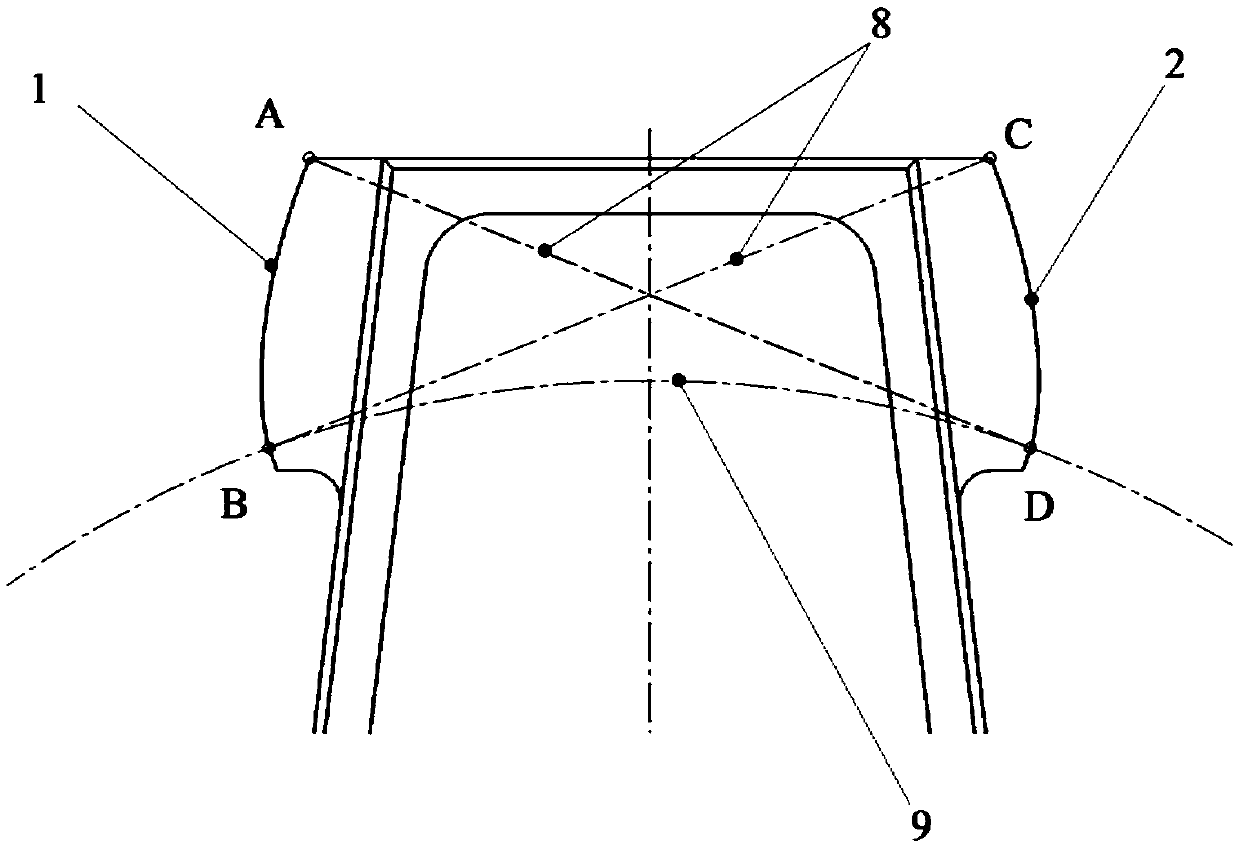

Method for measuring the shpericity of spherical profiles

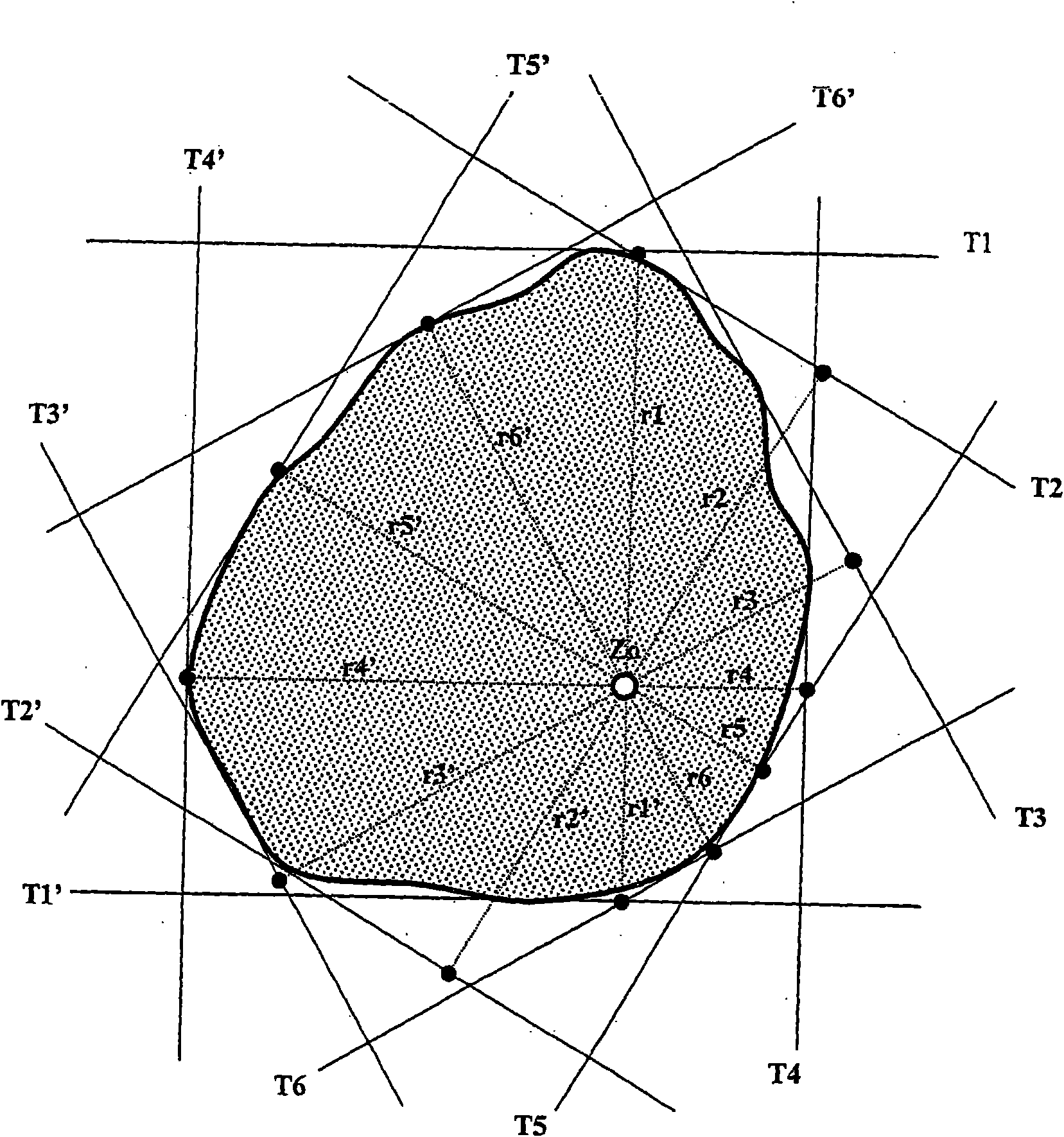

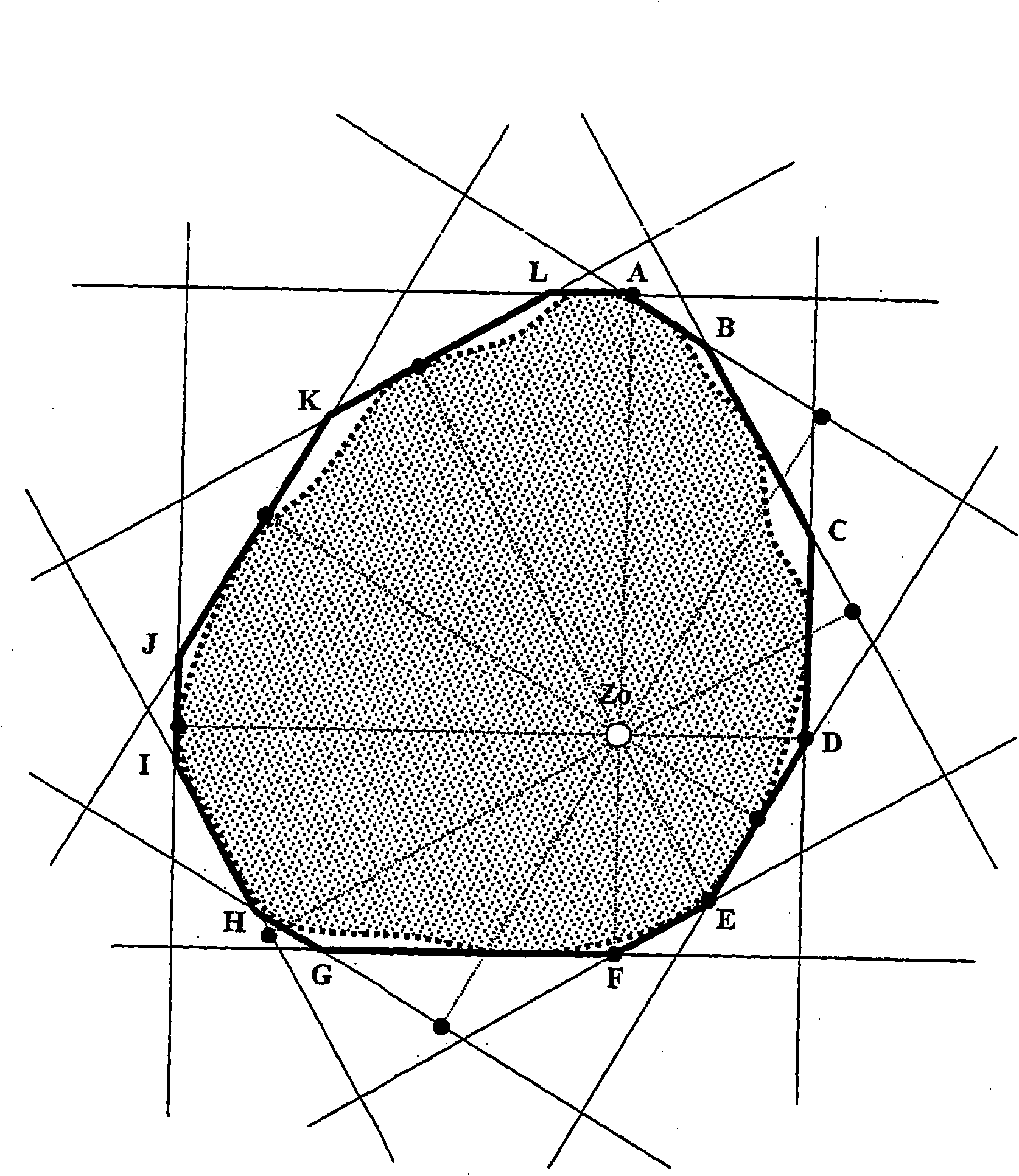

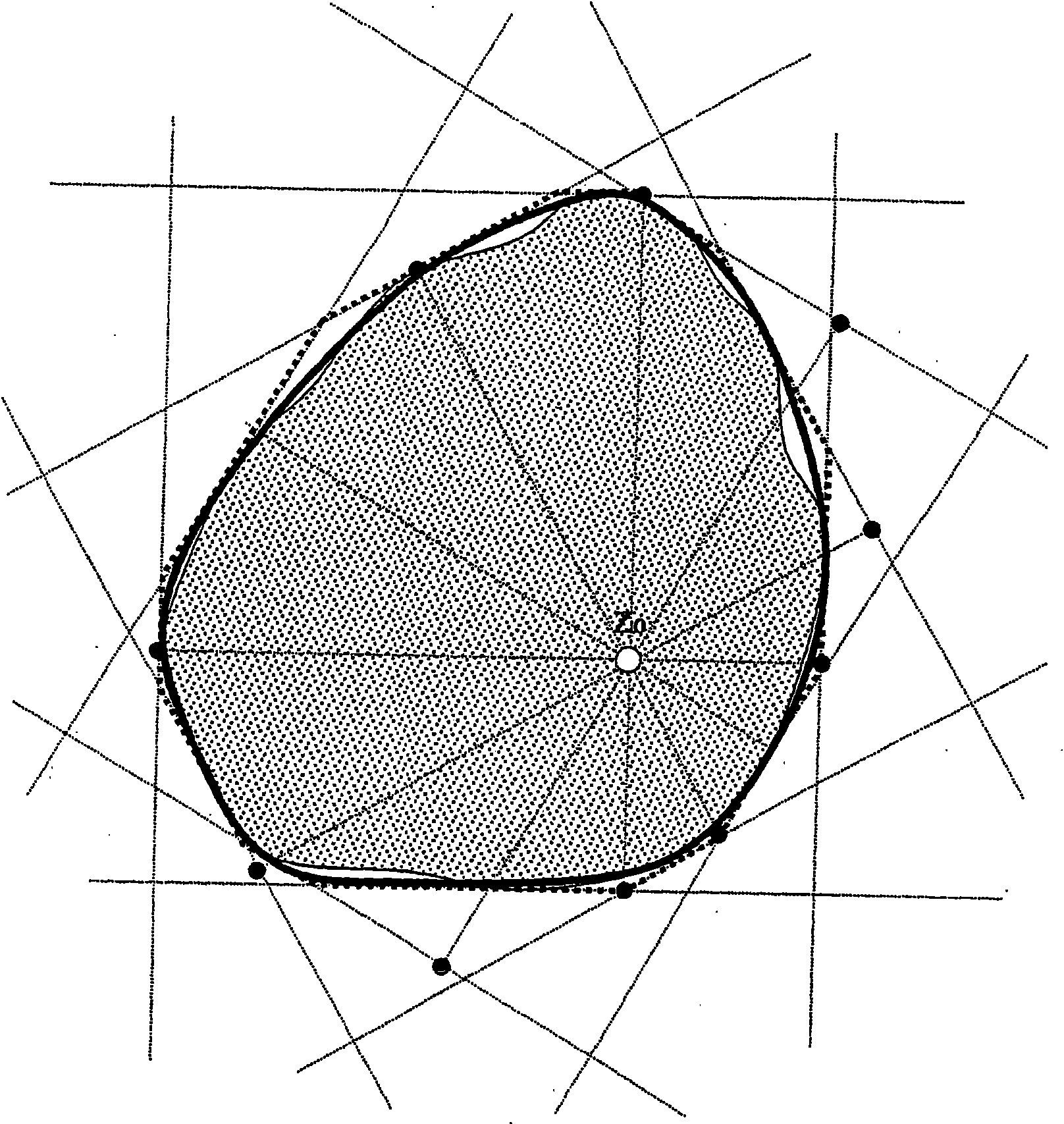

The invention relates to a method for measuring the sphericity or for measuring the shape deviation of spherical profiles in rolling trains that displace in the longitudinal direction thereof. According to the invention, at least three shadow edges that are adjacent to the spherical profile that is to be measured, that surrounds said spherical profile and that forms a polygon are produced and measured in a known manner, with the aid of a measuring device having at least two laser scanners that respectively comprise a light-sensitive sensor and a laser, and the corresponding tangents are calculated from said result. Said method is characterised in that a) prior to measurment, a centre (Z0) in the measuring field of the measuring device is calibrated and determined provided that said type ofcentre (Z0) has not already determined, b) perpendiculars (r1, - r6') from the centre (Z0) to the tangents (T1, bis T6' ) and also the distance from the centre (Z0) to the tangents (T1 - T6' ) is calculated, c) the corner points (A - K) of the polygon surrounding the spherical profile are calculated, a contour is determined, d) a reference circuit is determined in relation to the contour such that i) the quadratic shape deviation of the contour reaches a minimum in relation to said reference circuit, ii) said reference circuit represents the smallest possible circuit that adapts to the contour, iii) said reference circuit representing the largest possible circuit that adapts to the contour, or iv) the reference circuit together with an additional circuit that is concentric to the reference circuit surrounds the contour at a minimal radial distance, e) the diameter (Dref) of the reference circuit is calculated and the reference centre (Zp) is determined from the position in the cavitythat represents the centre point of the reference circuit and f) at least two vectors are calculated from said reference centre (Zp) to the contour and the ovality is determined from said data.

Owner:ZUMBACH ELECTRONICS

Cold-rolled plate shape control method based on optimization algorithm

InactiveCN102489525AFully meet the process setting requirementsMeet process setting requirementsProfile control deviceControl systemShape deviation

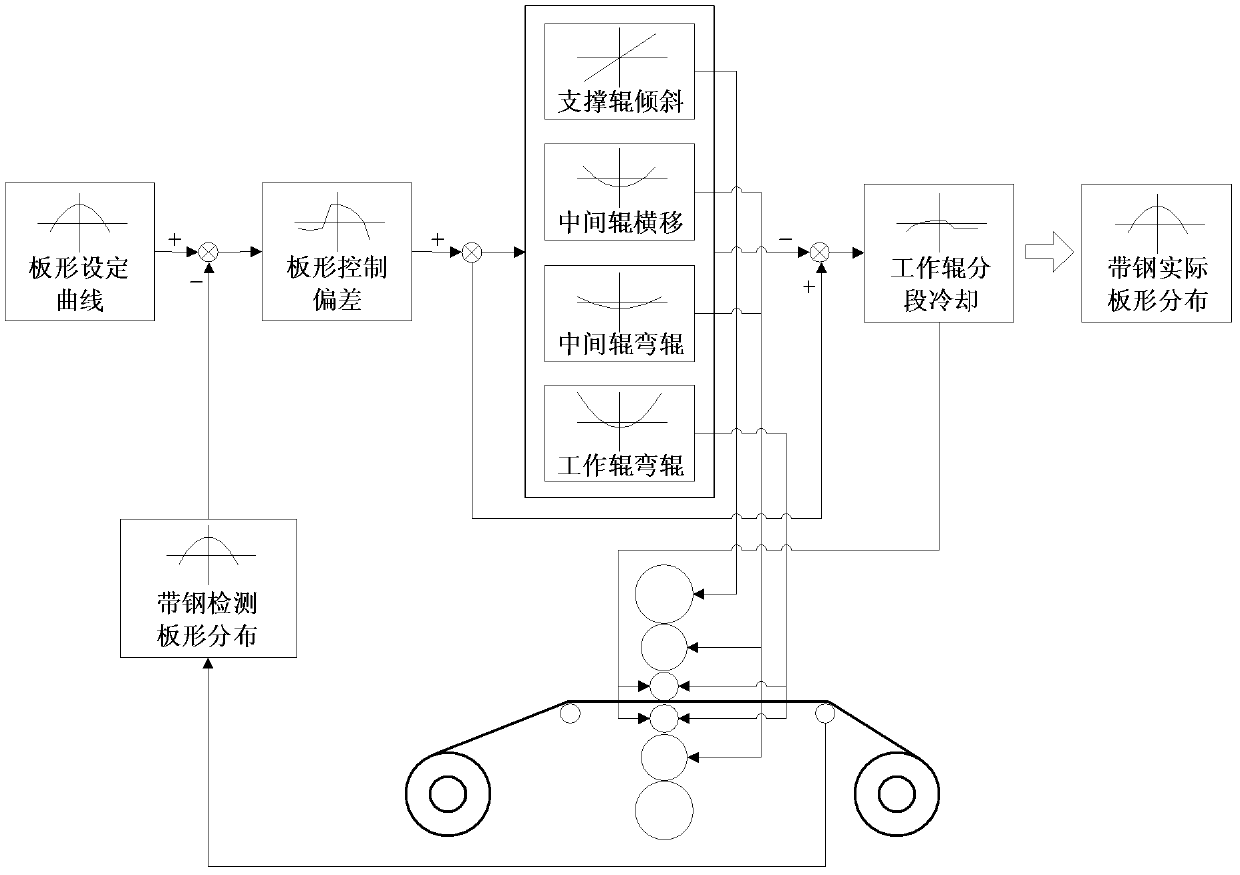

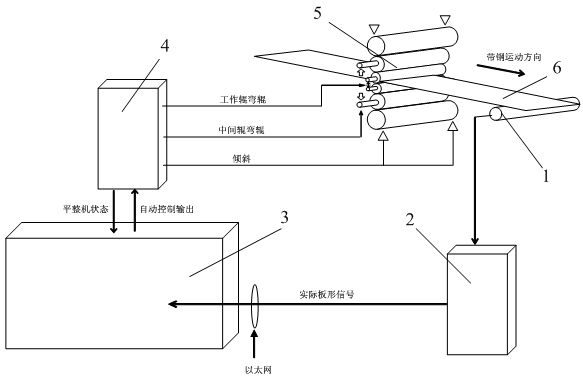

The invention relates to a cold-rolled plate shape control method based on an optimization algorithm. The cold-rolled plate shape control method based on the optimization algorithm is characterized by comprising the following steps of: sequencing each plate shape adjusting mechanism in an L1-level base automated central processing unit (CPU) according to the sequence of a supporting roller inclining mechanism, an intermediate roller bending mechanism, a working roller bending mechanism and an intermediate roller transversely moving mechanism; invoking a formula (2) and a formula (3) derived from an evaluation function F for each plate shape adjusting mechanism to calculate the action adjusting value of each plate shape adjusting mechanism; and after calculation is finished, transmitting all the action adjusting values to each plate shape adjusting mechanism by using the CPU to control the plate shape so as to eliminate the plate shape deviation of each plate shape adjusting mechanism. By the cold-rolled plate shape control method based on the optimization algorithm, the key problems in the conventional cold-rolled plate shape control system can be solved, and the method can be directly applied to the plate shape control procedure of the L1-level base automated CPU, so that the advantage in the aspect of improving the calculation precision on the action adjusting quantity of the plate shape control mechanism is exerted completely.

Owner:WISDRI WUHAN AUTOMATION

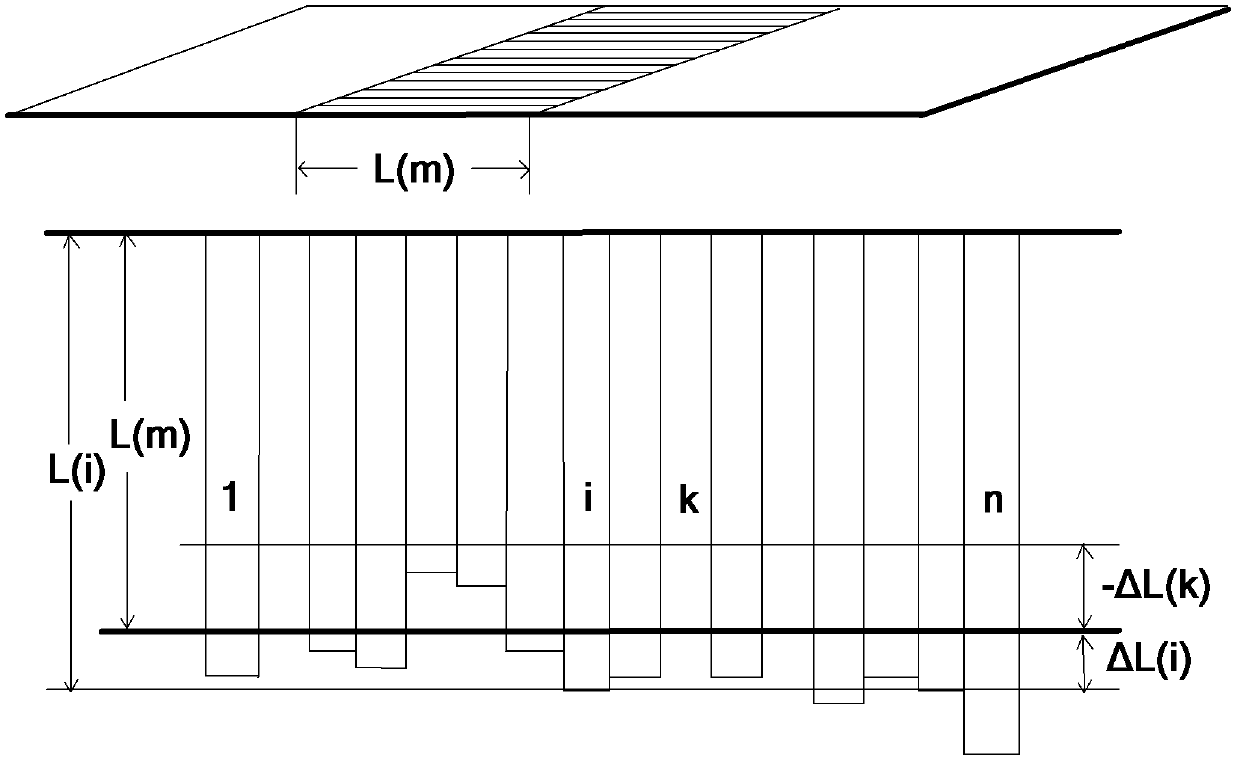

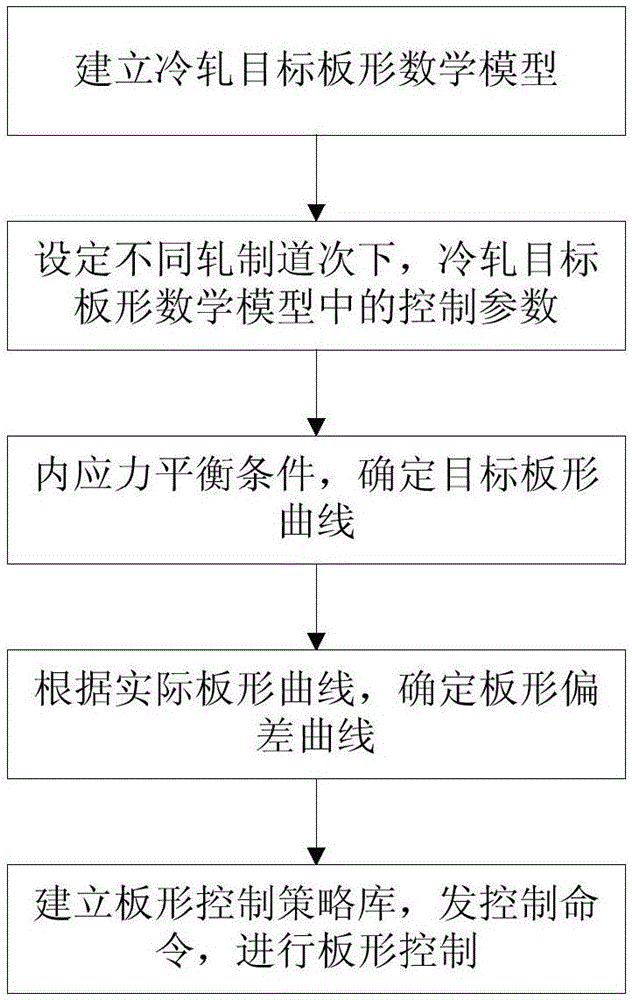

Strip shape control method based on target strip shape settings of cold-rolled strip steel

ActiveCN106475420AImprove calculation accuracyQuality is easy to controlProfile control deviceMathematical modelShape deviation

The invention discloses a strip shape control method based on target strip shape settings of cold-rolled strip steel. The control method includes the steps of establishing a mathematical model of cold rolling target strip shapes; setting control parameters of the mathematical model of the cold rolling target strip shapes in different rolling passes according to different rolling technology requirements of different rolling passes; determining a target strip shape curve; obtaining a strip shape deviation curve by measuring actual strip shape curves of each pass in real time; and establishing a strip shape control strategy database according to the strip shape deviation curve, sending control commands and carrying out strip shape control. According to the control method, the product quality can be improved, the production efficiency can be improved, the rolling stability can be improved, and the problems that existing control modes do not adapt to settings of high-temperature rolling target strip shapes of thin strip steel, fine setting and controlling cannot be realized according to target strip shapes of a machine frame or passes and the control quality of strip shapes of the thin strip steel is poor can be solved.

Owner:BAOSHAN IRON & STEEL CO LTD

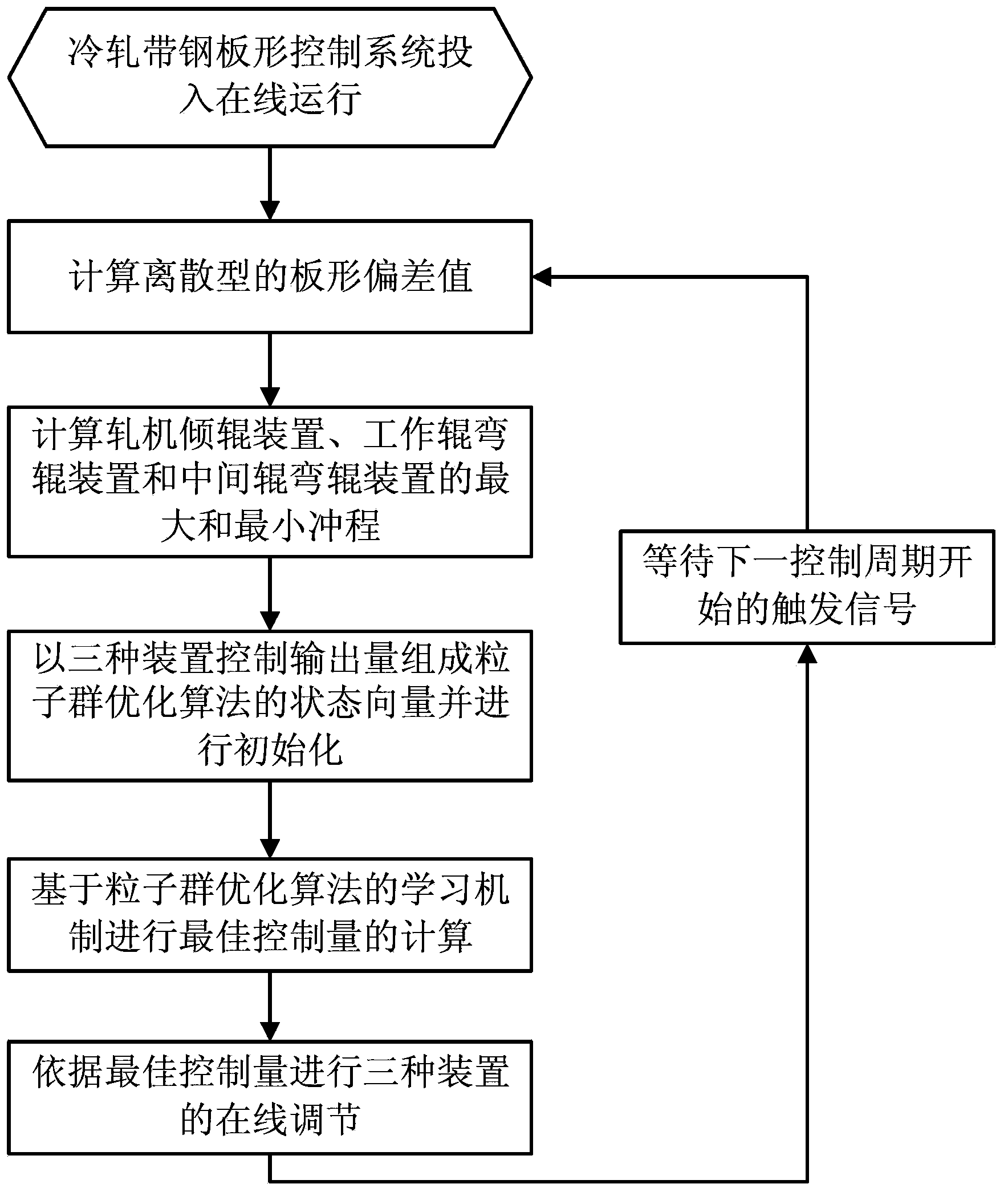

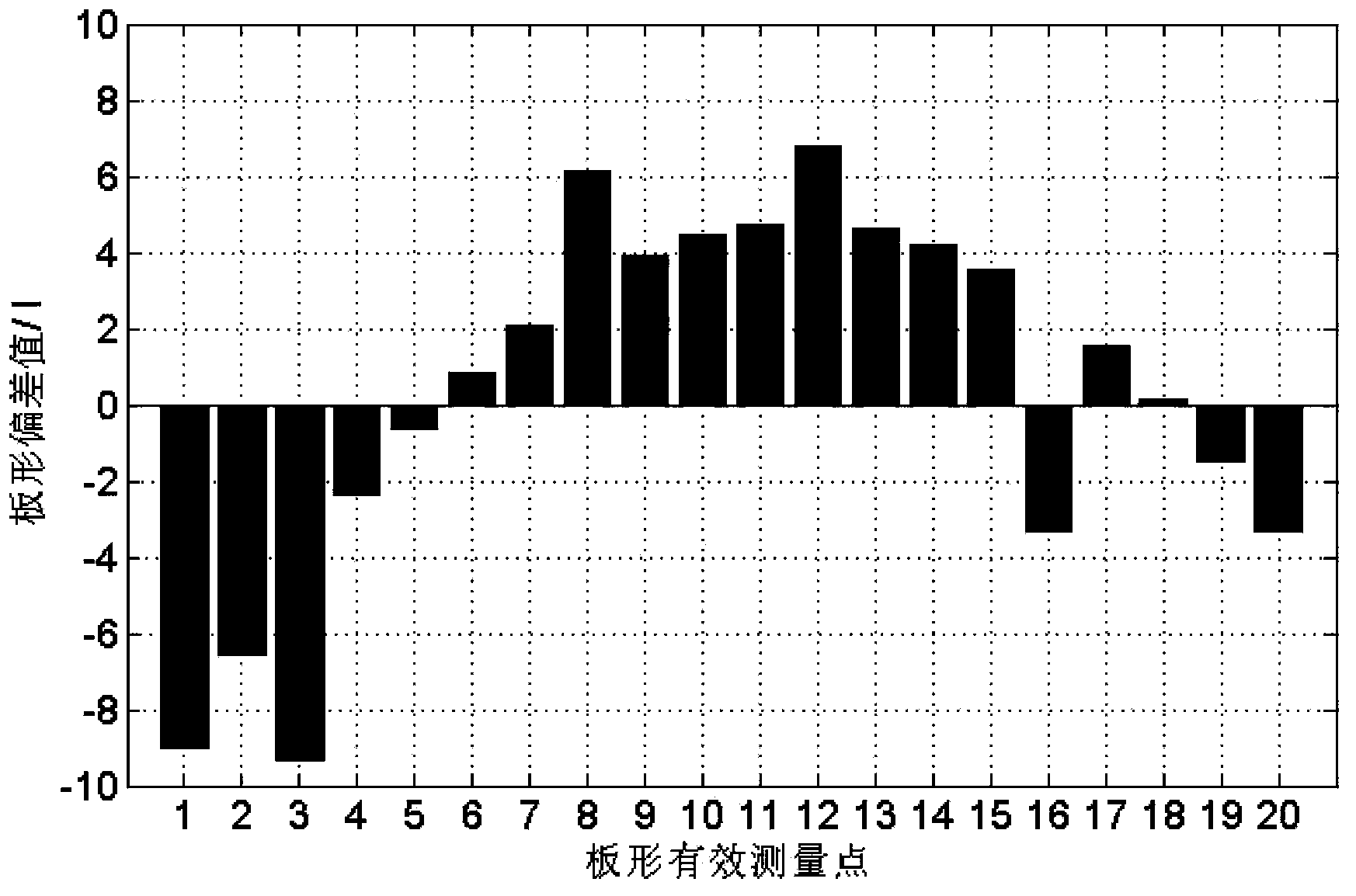

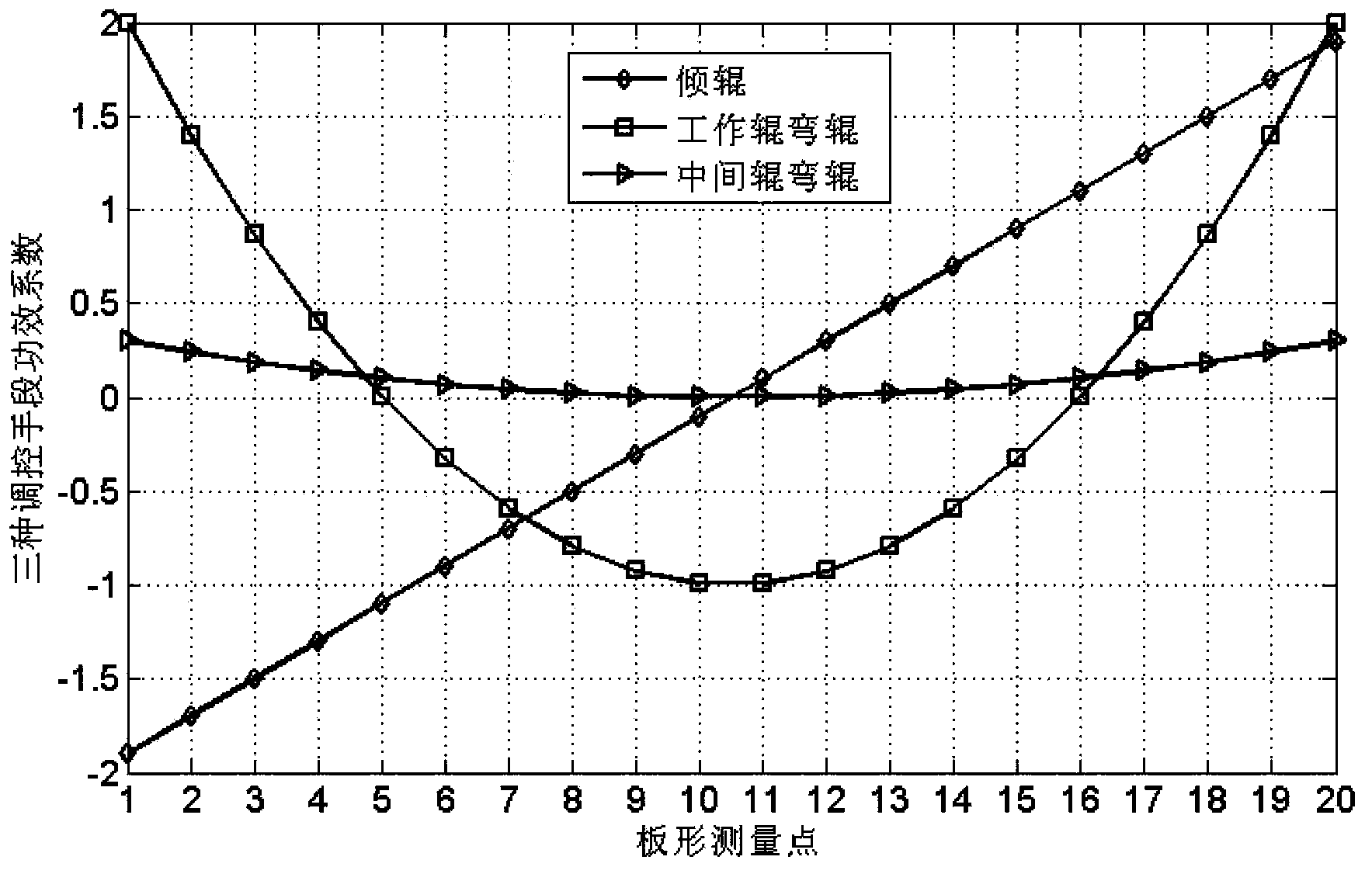

Method for controlling strip shape of cold-rolled strip steel

ActiveCN103394521AAvoid saturationSmall amount of calculationProfile control deviceShape deviationControl system

The invention provides a method for controlling the strip shape of cold-rolled strip steel. The method for controlling the strip shape of the cold-rolled strip steel comprises the steps of receiving target strip shape distribution signals and actual strip shape distribution signals, and calculating discrete type strip shape deviation values; receiving real-time position signals of a roll pouring device, a working roller bending device and a middle roller bending device of a rolling mill, and calculating the maximum movement stroke and the minimum movement stroke can be achieved by each transmission device of the rolling mill in a current control cycle; forming state vectors of a particle swarm optimization algorithm through the control output quantity of the roller pouring device, the control output quantity of the working roller bending device and the control output quantity of the middle roller bending device of the rolling mill, and generating N1 sets of state vector initial population particles of the particle swarm optimization algorithm and an index evaluation function in a particle swarm optimization learning process; calculating the optimal control output quantity of the roller pouring device, the optimal control output quantity of the working roller bending device and the optimal control output quantity of the middle roller bending device, and transmitting the optimal control output quantities to a basic automation grade PLC of a strip shape control system to complete on-line adjustment. The method for controlling the strip shape of the cold-rolled strip steel fundamentally eradicates the possibility of the occurrence of the phenomenon of saturation of an actuator in the control process of the strip shape of the cold-rolled strip.

Owner:WISDRI ENG & RES INC LTD

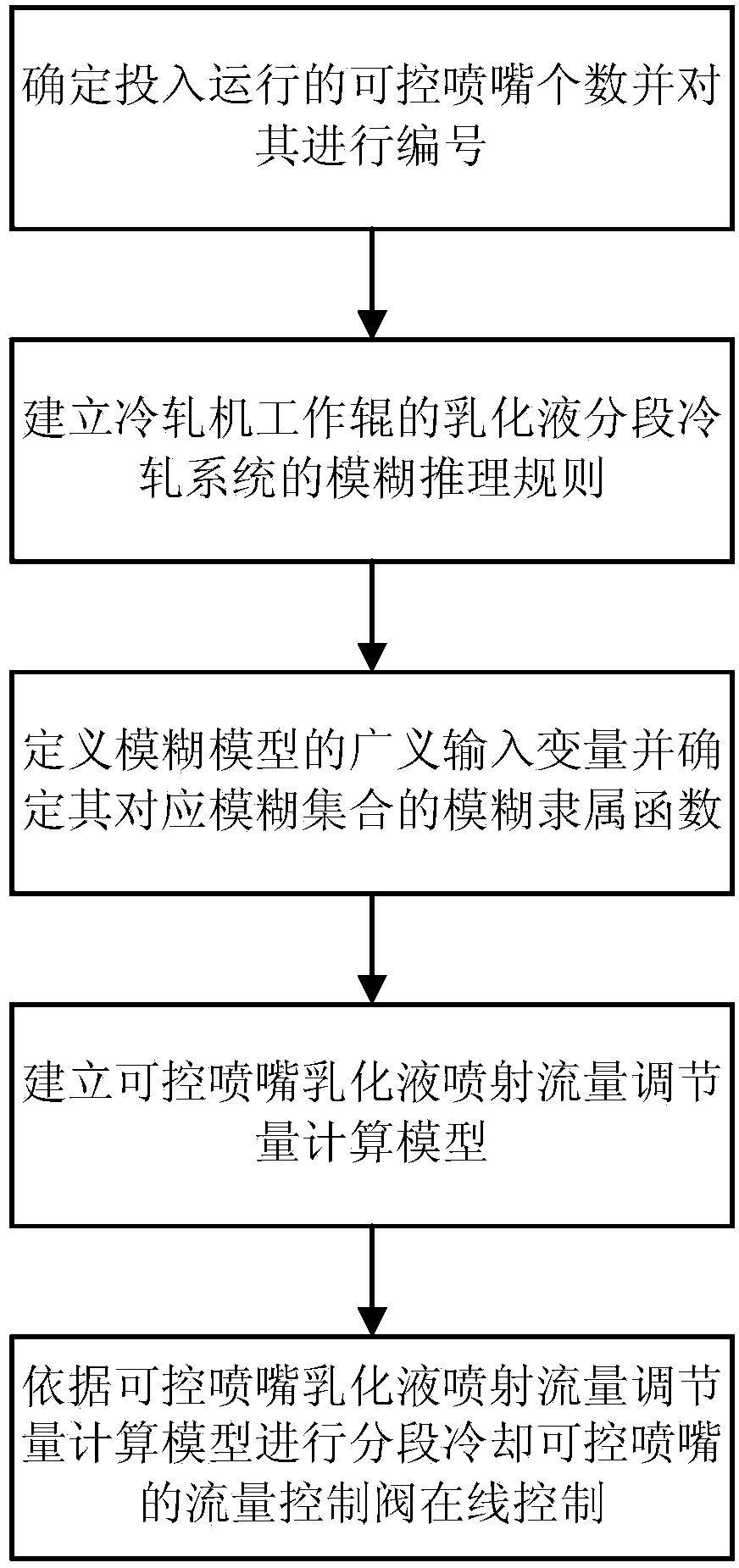

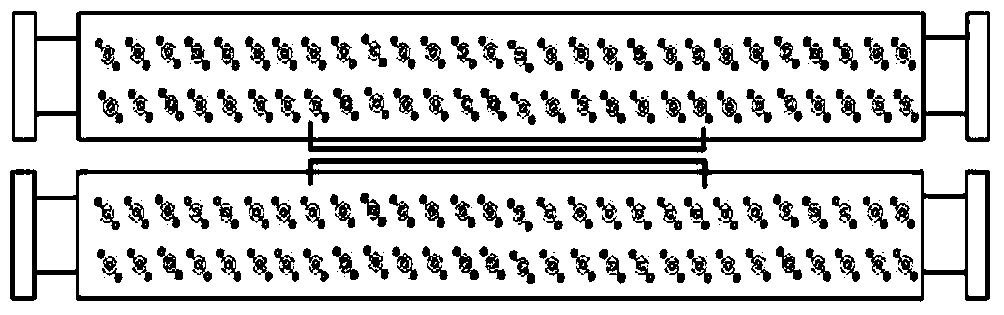

FHM-based (fuzzy hyperbolic model-based) cold-rolling mill working roll emulsion sectional cooling control method

ActiveCN103406370APrecise online controlSolve the cooling effectTemperature control deviceRollsEmulsionWork roll

The invention provides an FHM-based cold-rolling mill working roll emulsion sectional cooling control method. The method comprises determining the amount of nozzles covering strip steel and sequentially numbering the controllable nozzles; establishing fuzzy inference rules of an FHM-based cold-rolling mill working roll emulsion sectional cooling system; defining generalized input variables for the fuzzy inference rules and obtaining the fuzzy membership functions of fuzzy sets corresponding to the generalized input variables; by means of the obtained fuzzy inference rules, the obtained generalized input variables and the obtained fuzzy membership functions of the fuzzy sets, calculating out the spraying flow adjusting amount of an i-th nozzle at a current time to obtain an emulsion spraying flow adjusting amount calculation model of a controllable nozzle to achieve the flow control valve online control of the sectional cooling controllable nozzle. According to the FHM-based cold-rolling mill working roll emulsion sectional cooling control method, by establishing the physical relationship between plate shape deviation and the emulsion spraying flow adjusting amount of the controllable nozzle at the current time, the emulsion spraying flow adjusting amount calculation model of the controllable nozzle can be obtained and meanwhile the precise online control of cold-rolling mill working roll emulsion sectional cooling can be achieved.

Owner:WISDRI ENG & RES INC LTD

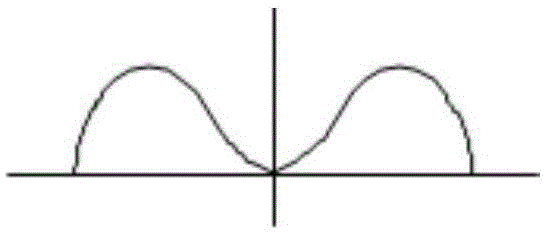

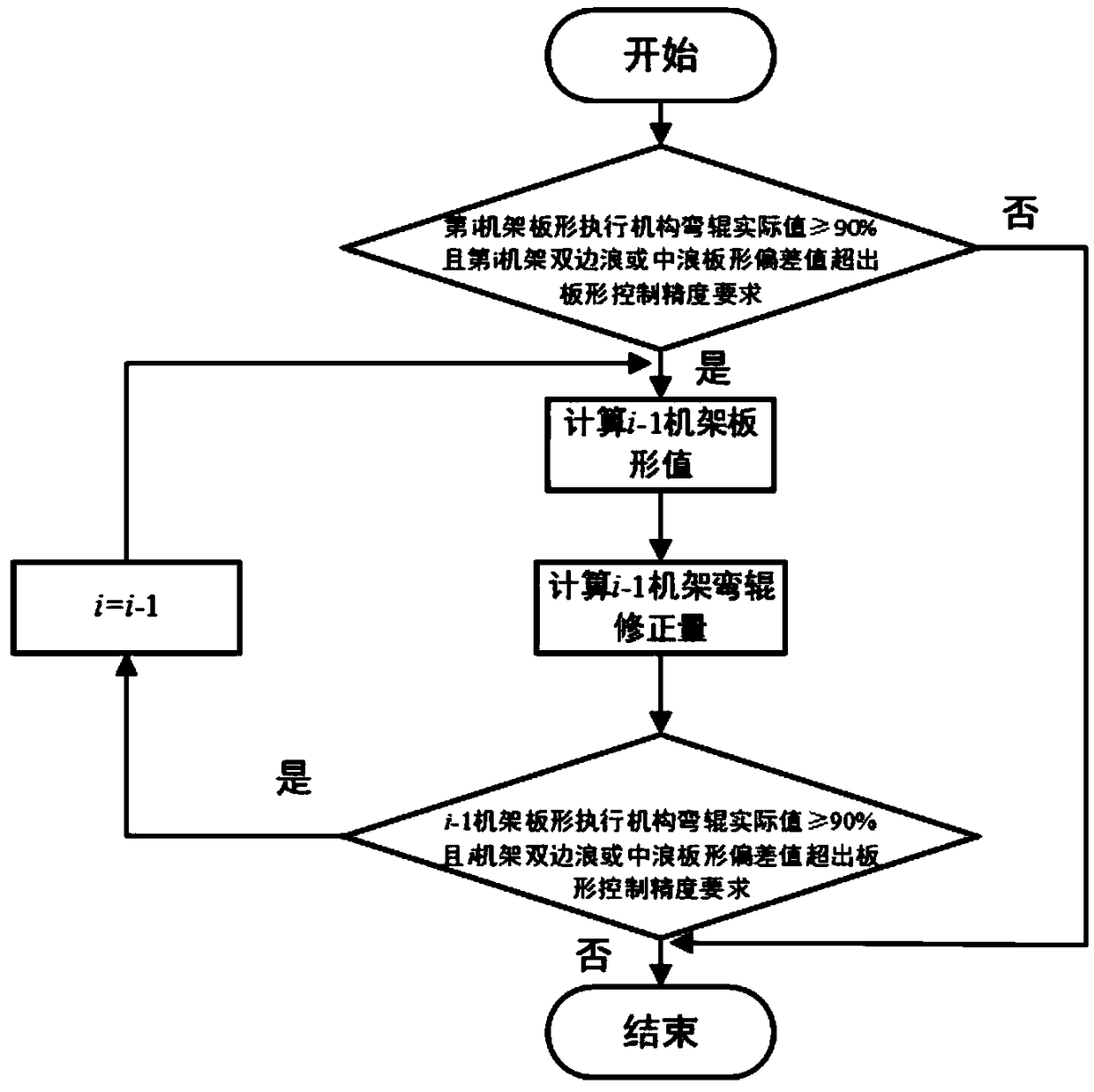

Method for controlling shapes of double-side wave and medium wave plate of five-stand cold continuous rolling high-strength steel plate belt

ActiveCN109226280AImprove calculation accuracyHigh precisionProfile control deviceSheet steelWork roll

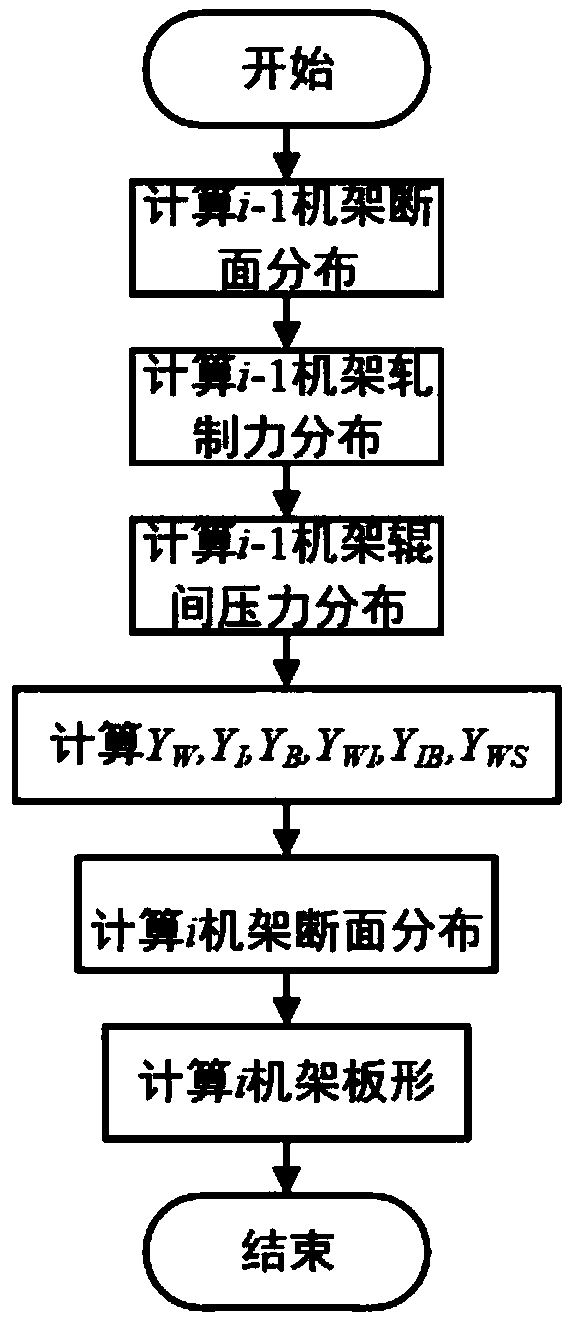

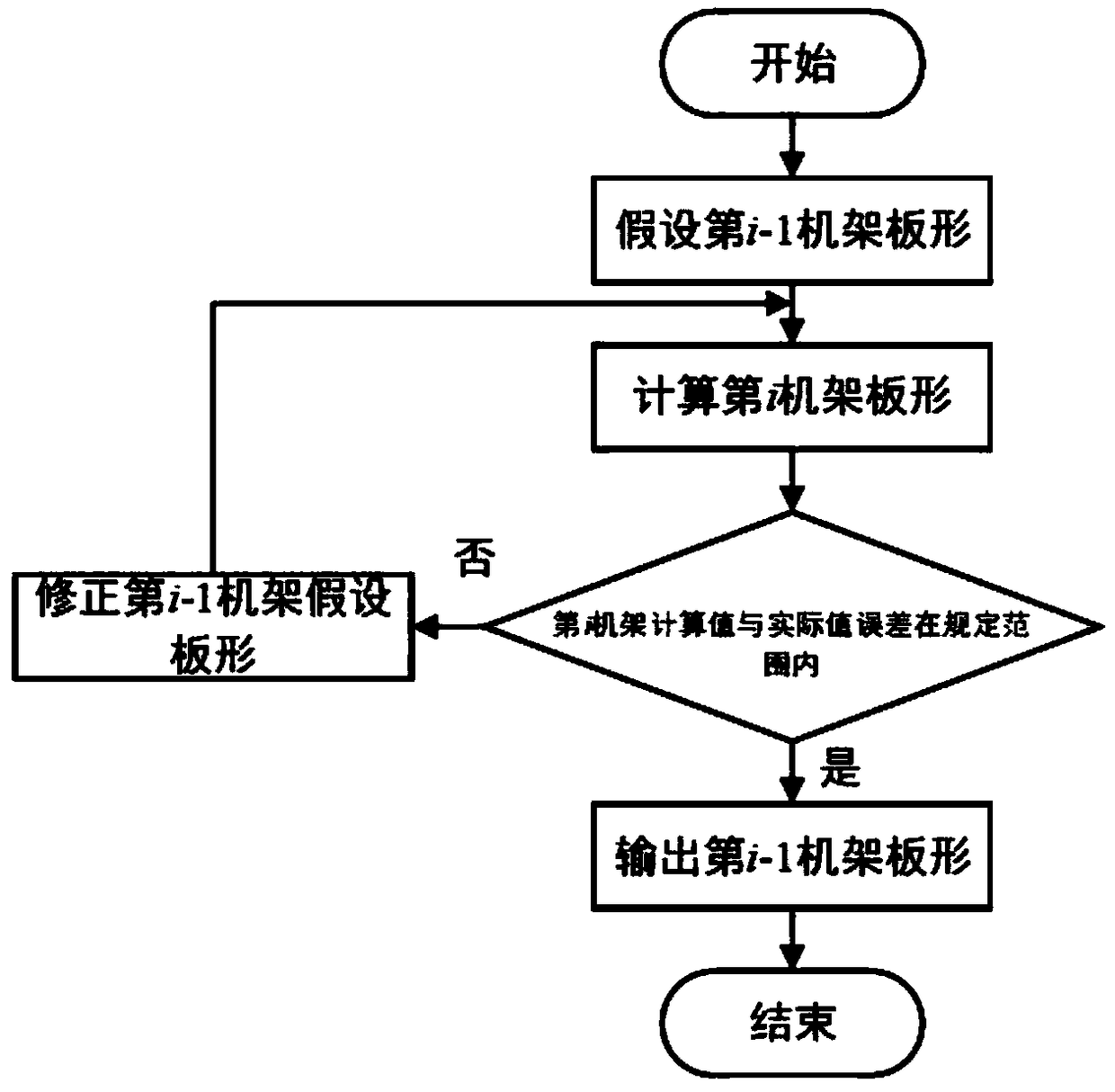

The invention provides a method for controlling the shapes of a double-side wave and medium wave plate of a five-stand cold continuous rolling high-strength steel plate belt, and relates to the technical field of shape control of cold continuous rolling steel plate belts. The method comprises the following steps of: firstly, giving a precondition for controlling the shapes of the double-side waveand medium wave plate by using the method; secondly, setting an end frame as an i-1th stand; and calculating the shape value of the double-side wave or medium wave plate of an outlet of the i-th stand, comparing the calculated shape value of the double-side wave or medium wave plate of the outlet of the i-1th stand with a measured value, repeatedly carrying out the calculation until the calculatedvalue meets the quality requirement of the finished product plate shape; calculate a correction value of a roll bending force between a working roller and middle roller of the i-1th stand, if the correction value of the roll bending force does not meet the requirement, calculating a correction value of a roll bending force of between a working roll and middle roll of the i-2th stand; until the shape deviation of the double-side wave or medium wave plate at the outlet of the i-1th stand reaches the quality requirement of the finished product shape. According to the control method, the controlprecision of the shape of the double-side wave or medium wave plate of the front stand is improved, the regulation and control pressure of the last stand is reduced, and the plate shape quality of theproduct is improved.

Owner:NORTHEASTERN UNIV

Method for automatically controlling plate shape of continuous annealing leveling mill based on stability index

ActiveCN102371278AStable rolling processImprove shape qualityProfile control deviceAutomatic controlStability index

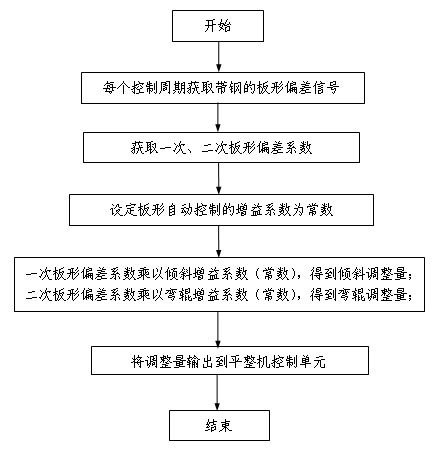

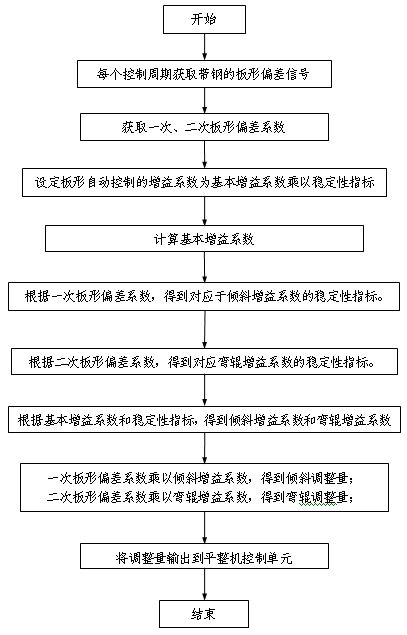

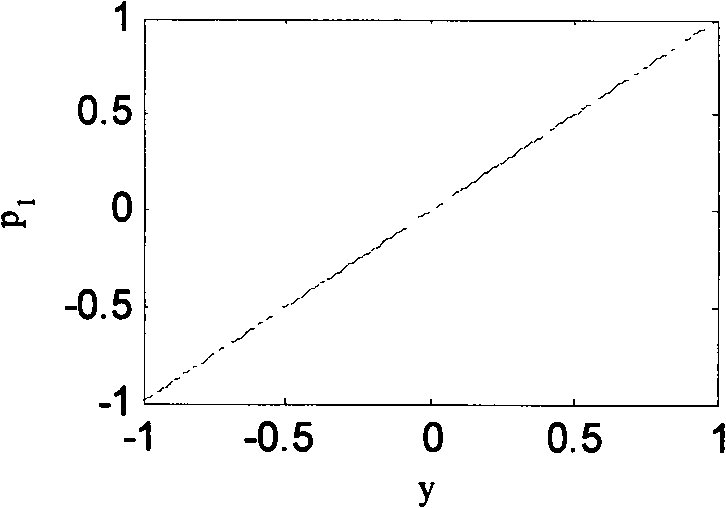

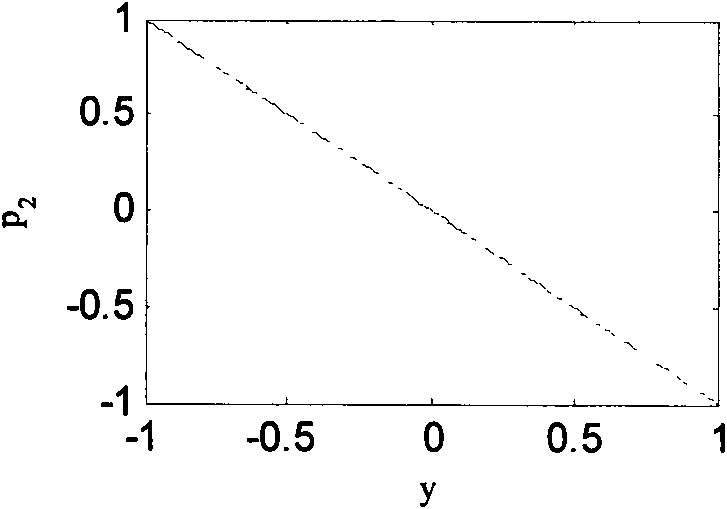

The invention relates to the field of slab band cold rolling post-treatment, in particular to a method for automatically controlling a plate shape of a continuous annealing leveling mill. A method for automatically controlling a plate shape of a continuous annealing leveling mill based on a stability index is characterized in that the method comprises the following steps of measuring data of an actually measured plate shape with a plate shape measuring roll, obtaining primary and secondary plate shape deviation coefficients alpha 1 and alpha 2; obtaining the basic parameters of a continuous annealing leveling mill through a test; firstly calculating the obtained basic gain coefficient and a stability index, and then calculating the gain coefficient, and finally multiplying the gain coefficient with the plate shape deviation coefficients, obtaining the adjustment quantity of a plate shape executive mechanism of the continuous annealing leveling mill. With the adoption of the method provided by the invention, the gain coefficient is optimized on-line with the change of the plate shape deviation; the stability index is defined in a certain value range, so that the rolling stability of the continuous annealing leveling mill can be ensured and the plate shape quality of the band steel can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

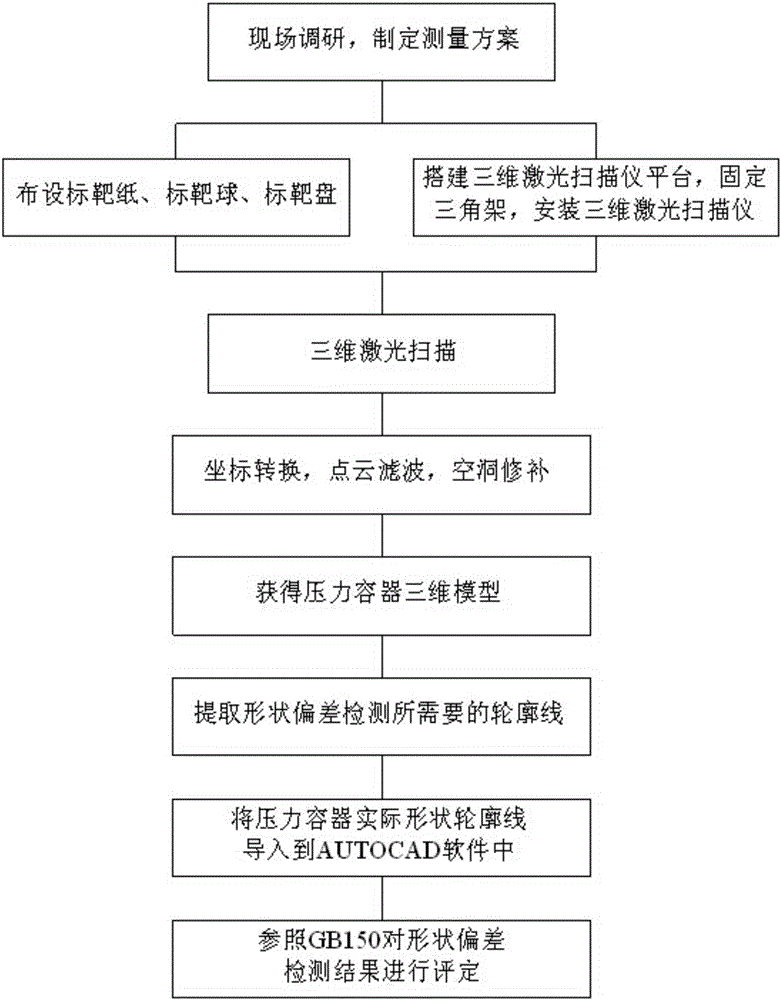

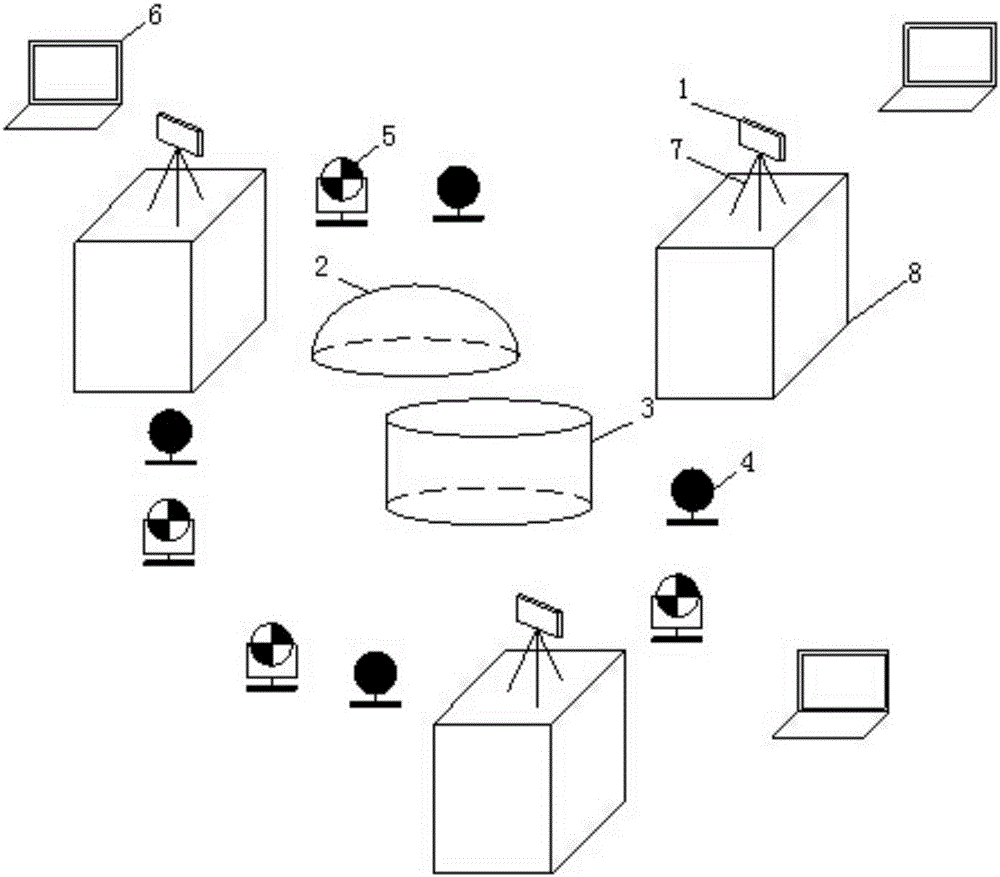

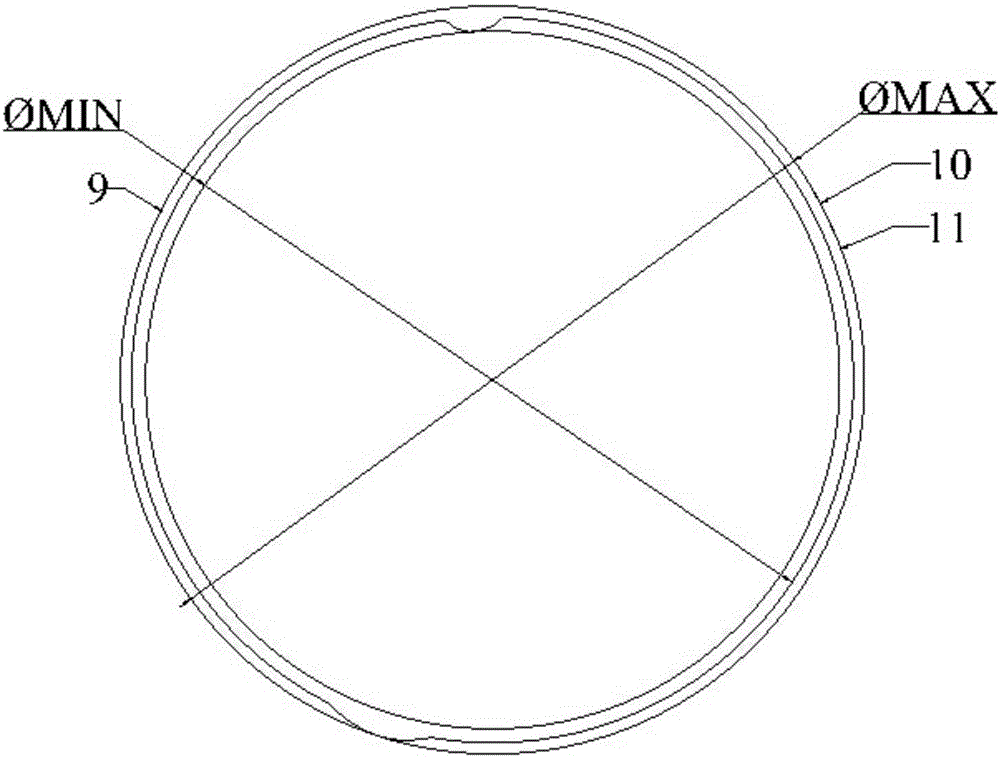

Pressure container shape deviation detection method based on three-dimensional laser scanning

ActiveCN105865368AAccurate measurementQuick measurementUsing optical meansPoint cloudShape deviation

The invention relates to shape deviation detection and provides a pressure container shape deviation detection method based on three-dimensional laser scanning. The pressure container shape deviation detection method based on three-dimensional laser scanning includes the steps that three-dimensional laser scanning devices are distributed around a pressure container; three-dimensional laser scanning is conducted on the pressure container to obtain the quantity of point cloud data; the point cloud data is processed to obtain a three-dimensional model composed of triangular patches; an outline required by shape deviation detection is extracted from the three-dimensional model; the extracted outline is compared with a designed shape outline to evaluate a shape deviation detection result. The method can be used for accurately, quickly and comprehensively measuring shape deviation of an oval end socket in a non-contact mode. The method is high in collection point location density, high in measurement accuracy, high in measurement speed, capable of saving labor time, low in labor intensity and capable of conveniently achieving automatic measurement, and accordingly the shape deviation of the pressure container can be accurately and quickly measured.

Owner:ZHEJIANG UNIV

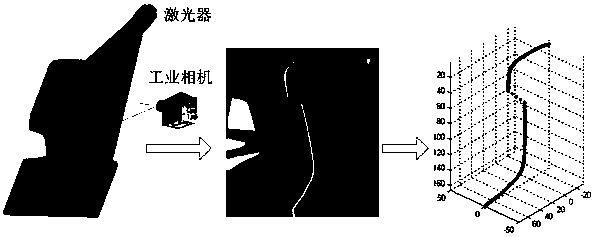

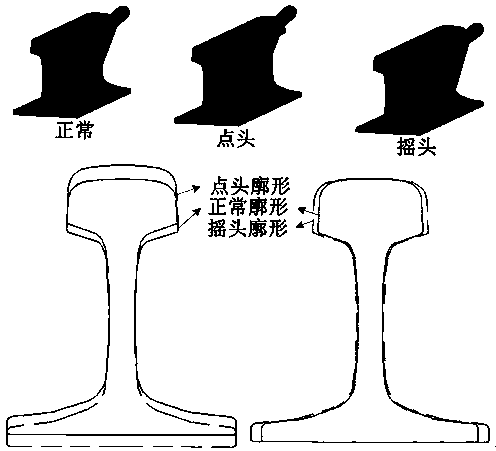

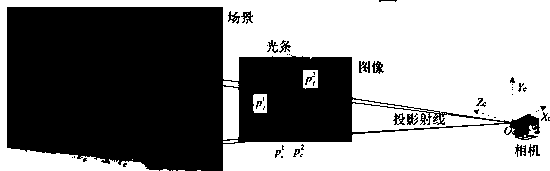

Multi-line structured light self-calibration method and system for rail profile dynamic detection

ActiveCN108955576ARealize self-calibrationAchieve correctionUsing optical meansRail profileShape deviation

The invention discloses a multi-line structured light self-calibration method and system for rail profile dynamic detection. The method comprises the following steps: obtaining the feature points on multi-line structured light strips from the scene image of a rail according to an angle extraction algorithm; establishing the three-dimensional profile of the rail according to the feature points andthe geometrical shape of rail through combination with the structured light visual model; obtaining the projection profile according to the three-dimensional profile of the rail; and quantifying the size and shape deviation of the projection profile and the standard profile in three non-abrasion areas of the rail jaw, the inner side of the rail head and the rail bottom by using the curve similarity measurement method; and iteratively optimizing the plane parameters of the multiline structured light according to the quantified deviation so as to realize self-calibration of the multiline structured light. According to the scheme, the problem that the structured light cannot be calibrated automatically and quickly online by relying on the calibration template can be solved so that the robustness of measurement profile reconstruction and auxiliary plane construction can be improved and correction of the distorted rail profile caused by multi-degree-of-freedom vibration can be facilitated.

Owner:湖南东映碳材料科技股份有限公司

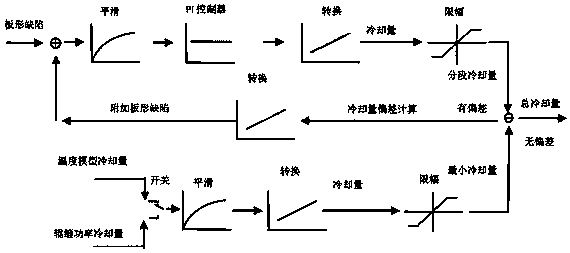

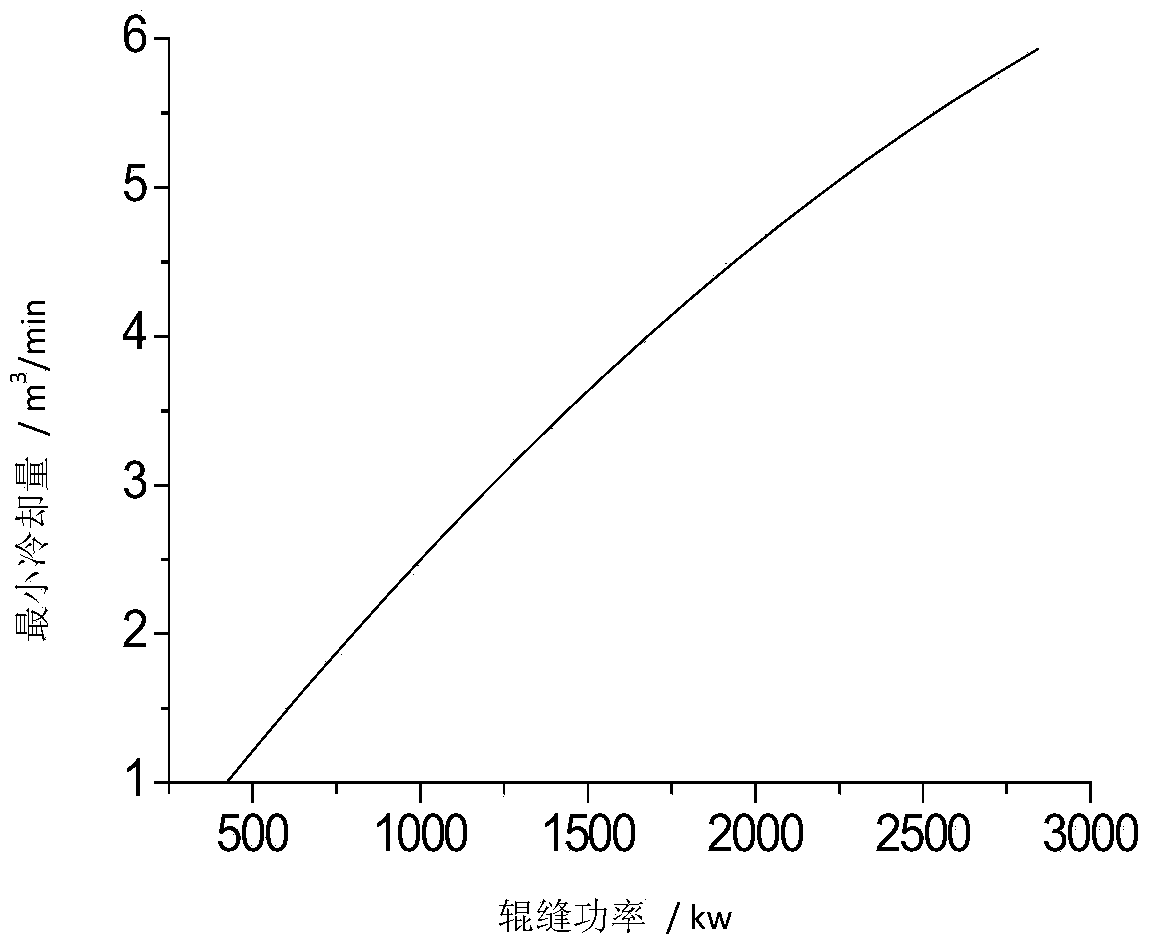

Optimal control method of cold-rolling mill process cooling system

ActiveCN103861875ARealize combinatorial optimization controlQuality is easy to controlTemperature control deviceEmulsionShape deviation

The invention discloses an optimal control method of a cold-rolling mill process cooling system. The method includes: calculation of rolling process cooling flow; calculation of stage-by-stage cooling shape control flow; and combination optimal control of basic cooling and stage-by-stage cooling. The invention puts forward calculation models which are respectively needed by cooling control for the cold-rolling mill process and stage-by-stage cooling control for shapes. Corresponding additional shape deviation is worked out according to emulsion cooling flow deviation and used for compensating the technological requirements of the basic cooling function and the stage-by-stage cooling function for shape control on the jetting of different emulsion flows in the process of cold rolling. Consequently, the optimal control of cooling flow in the two different technological functions is realized, the combination optimal control between basic cooling for the cold rolling process and stage-by-stage cooling for shapes is realized, and under the premise of ensuring cooling flow needed by stable rolling, the good control of strip shape quality is realized.

Owner:北京邦信天硕工程技术有限公司

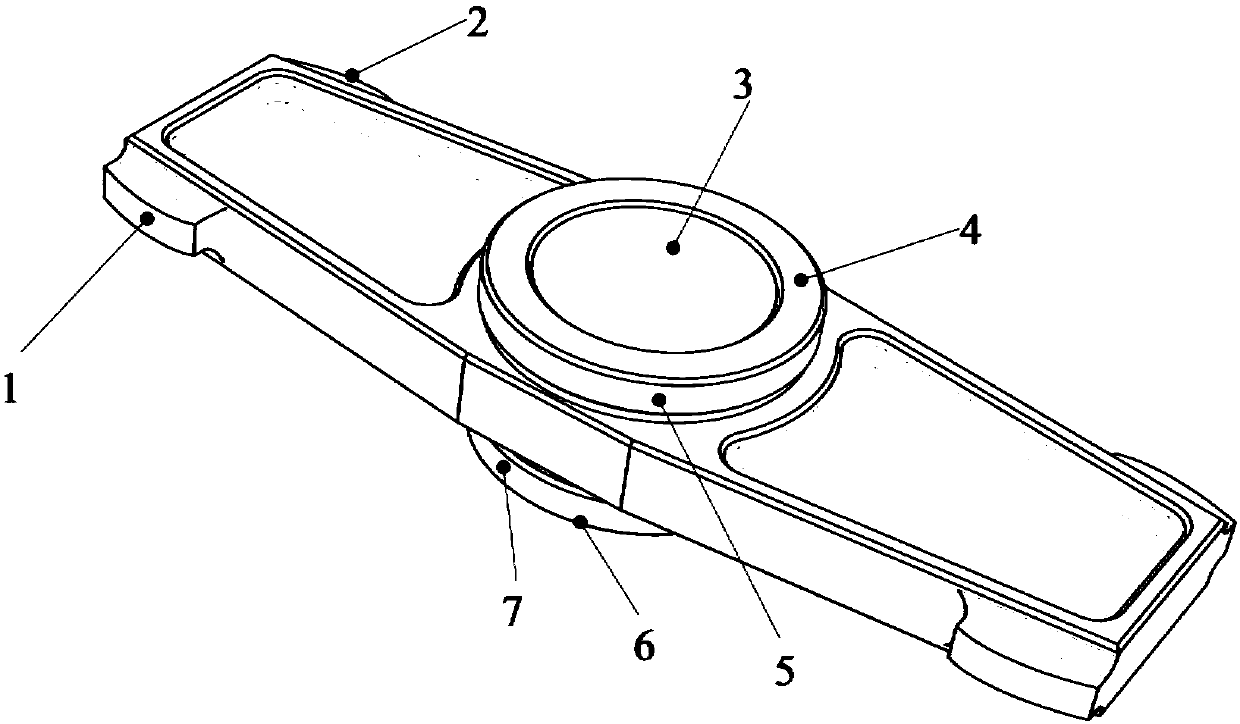

Checking device of shape deviation of large-diameter seal head

InactiveCN103335583ASimple structureEasy to useMechanical counters/curvatures measurementsShape deviationEngineering

The invention discloses a checking device of a shape deviation of a large-diameter seal head. The device comprises a frame, a slide block and a ruler, wherein a 0 point is arranged in the center of the frame; scale distances are marked on the two sides of the frame and marked from the bottom end of the ruler; the slide block is mounted on the frame, and slidingly matched and connected with the frame; the ruler is mounted on the slide block, and movably matched and connected with the slide block; and the ruler and the frame are decussated. The device is simple and reasonable in structure and convenient to use, can verify the shape deviation of the large-diameter seal head, can accurately measure actual distances from various points on the internal surface of the seal head to the end face of a straight section of the seal head, provides a length adjustment basis for an adapter tube on the seal head, and ensures that equipment with a mixing device cannot be affected by the seal head.

Owner:NANJING DUBLE METAL EQUIP ENG

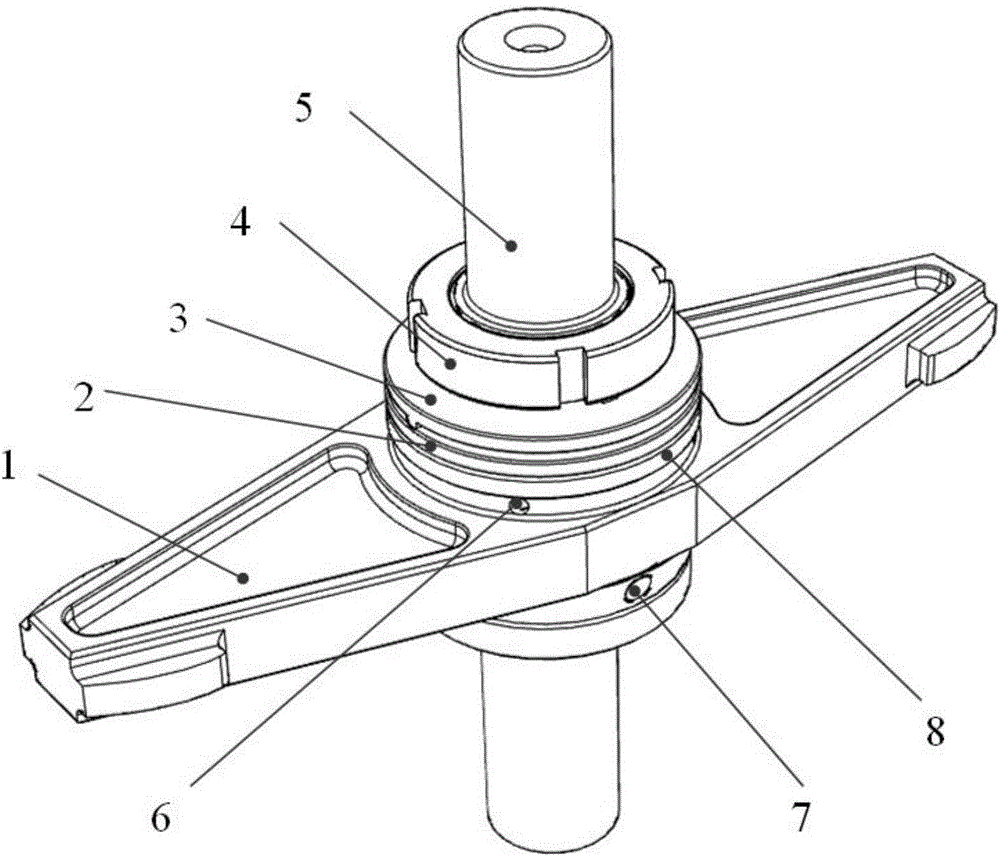

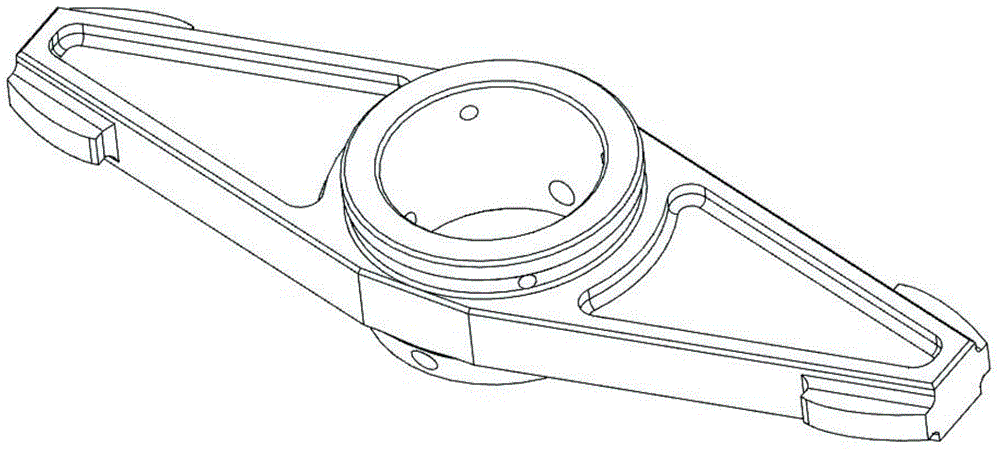

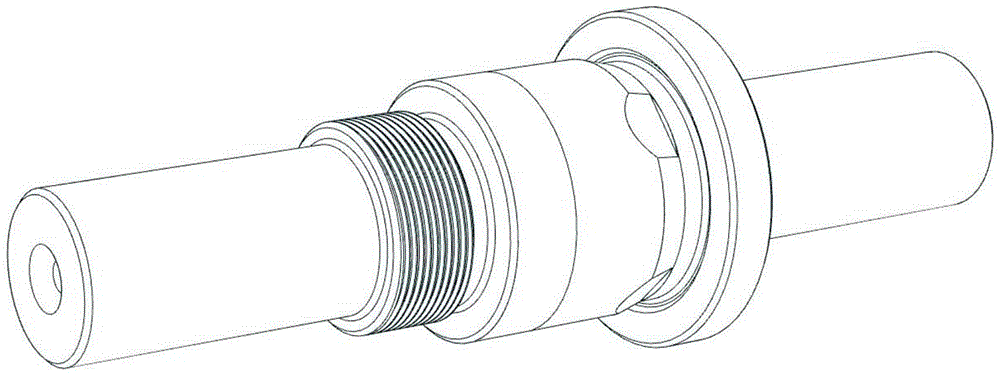

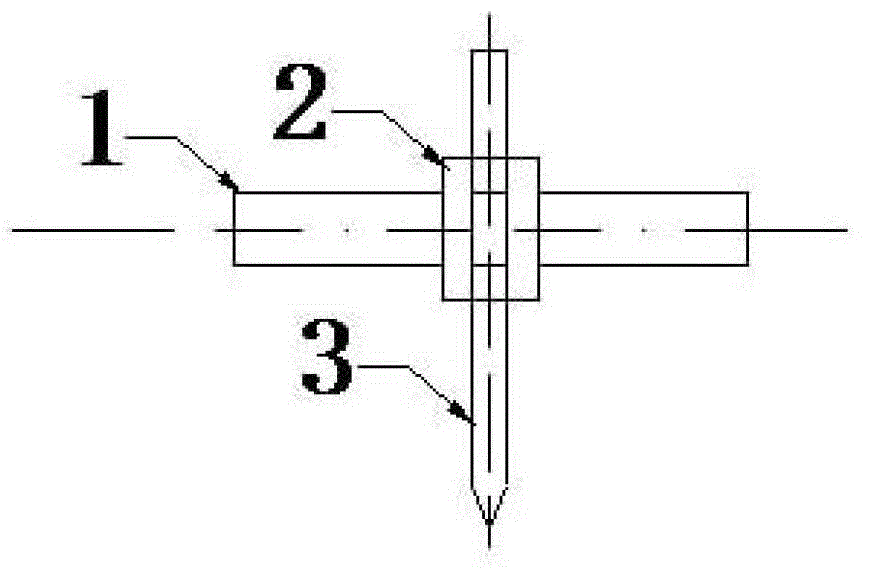

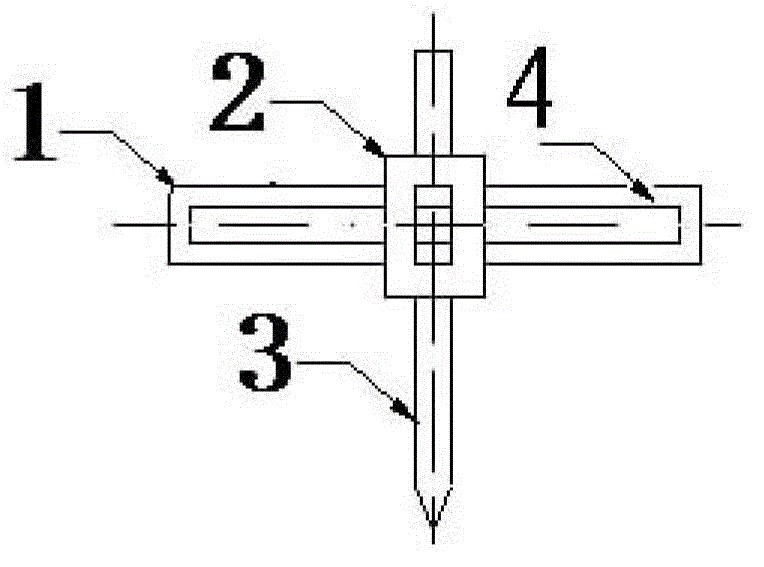

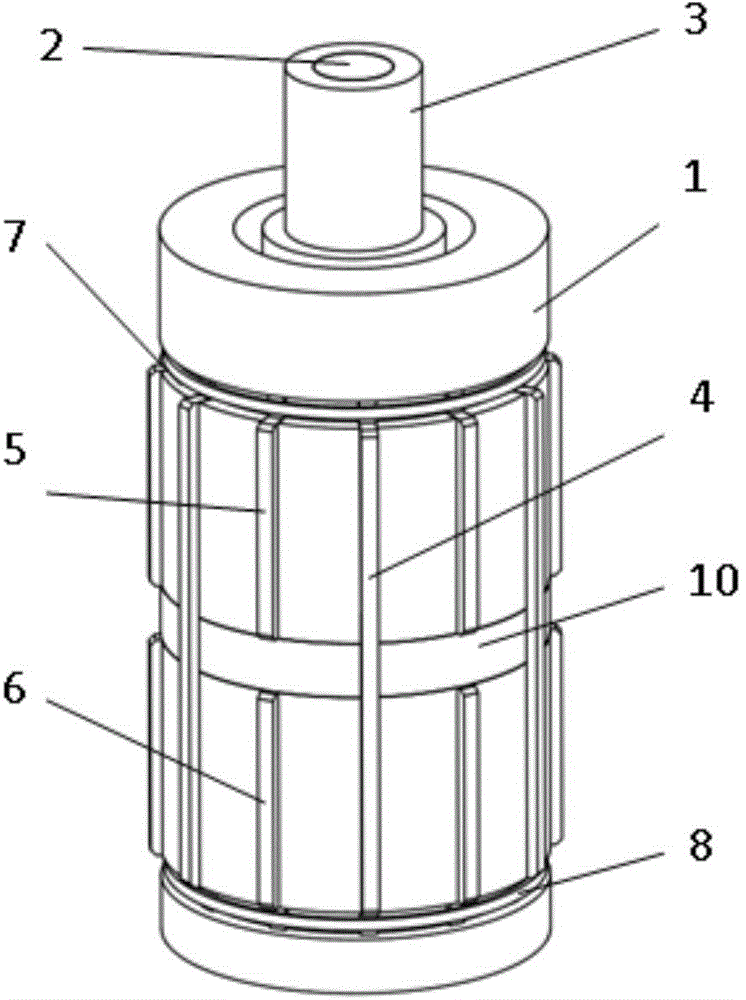

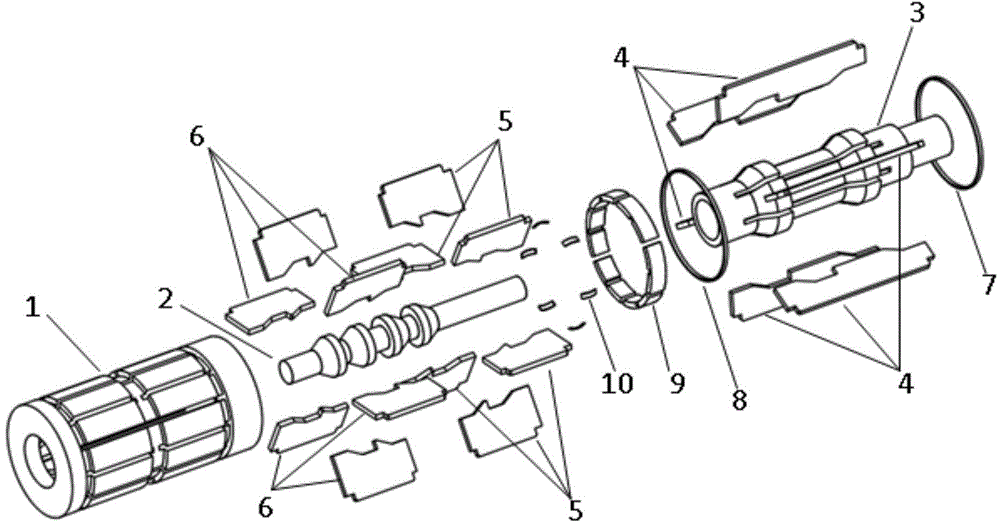

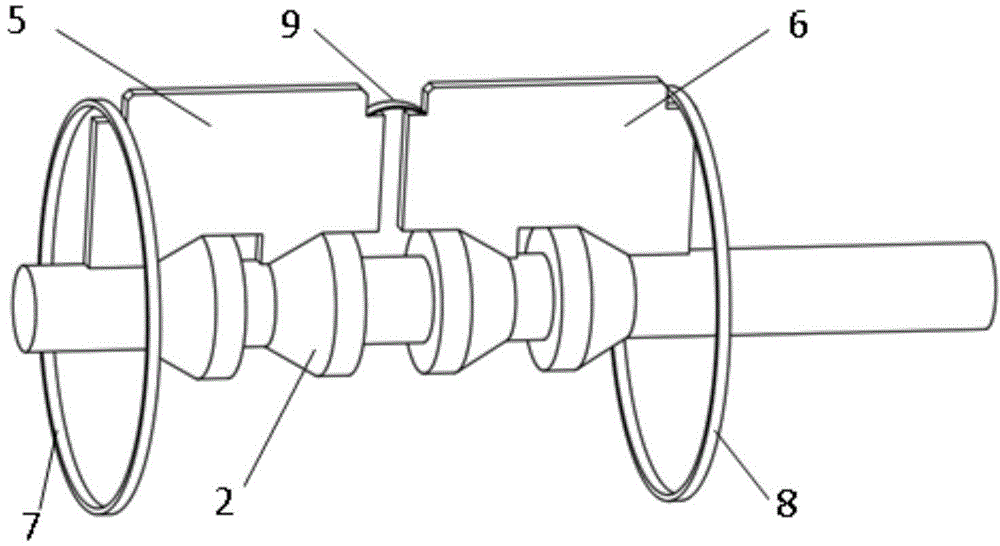

Sectional feeding honing head device with shape deviation compensation function

ActiveCN104400613ANo need to change the running trackSimplify movementGrinding drivesHoning toolsReciprocating motionShape deviation

The invention relates to a sectional feeding honing head device with a shape deviation compensation function. The sectional feeding honing head device with the shape deviation compensation function comprises a main body, an inner spindle, an outer spindle, a main oilstone seat, an upper compensation oilstone seat and a lower compensation oilstone seat, wherein the inner spindle is installed in a hole of the outer spindle, the outer spindle is installed in a center hole of the main body, the main oilstone seat is installed in a main oilstone groove of the main body, the upper compensation oilstone seat and the lower compensation oilstone seat are installed in compensation oilstone grooves of the main body, the edges of the two ends of the main oilstone seat are respectively pressed by a retraction spring ring, the edges of the outer sides of the upper compensation oilstone seat and the lower compensation oilstone seat are respectively pressed by a retraction spring ring, the edges of the inner sides of the upper compensation oilstone seat and the lower compensation oilstone seat are pressed by retraction leaf springs, the upper compensation oilstone seat and the lower compensation oilstone seat are fixed by compensation oilstone fixing blocks, and a main oilstone and compensation oil stones are respectively installed on the corresponding oilstone seats. The sectional feeding honing head device with the shape deviation compensation function has the advantages that since the device itself has the shape deviation compensation function, under the situation that the back-and-forth movement trajectory of the honing head is unchanged, the shape deviation which occurs during machining can be compensated in real time and the shape accuracy of the honed inner bore can be guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

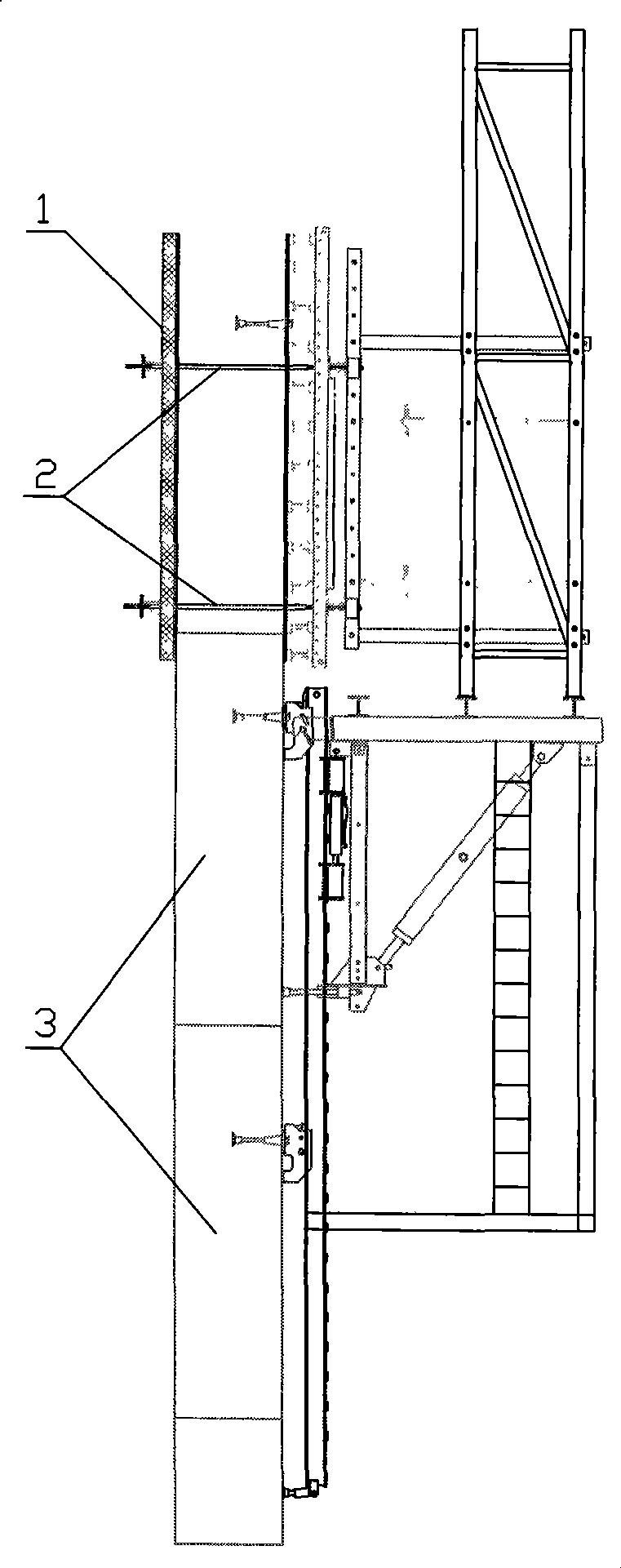

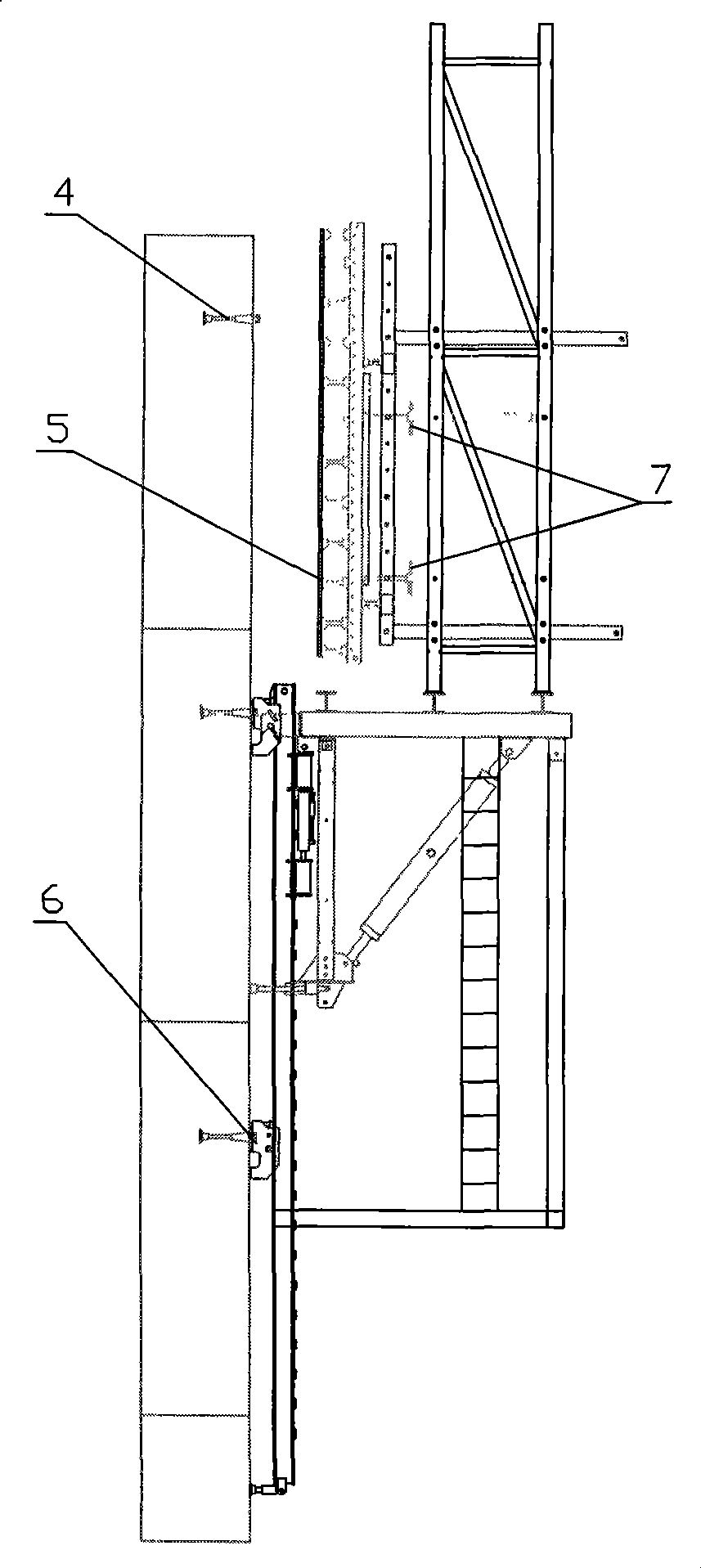

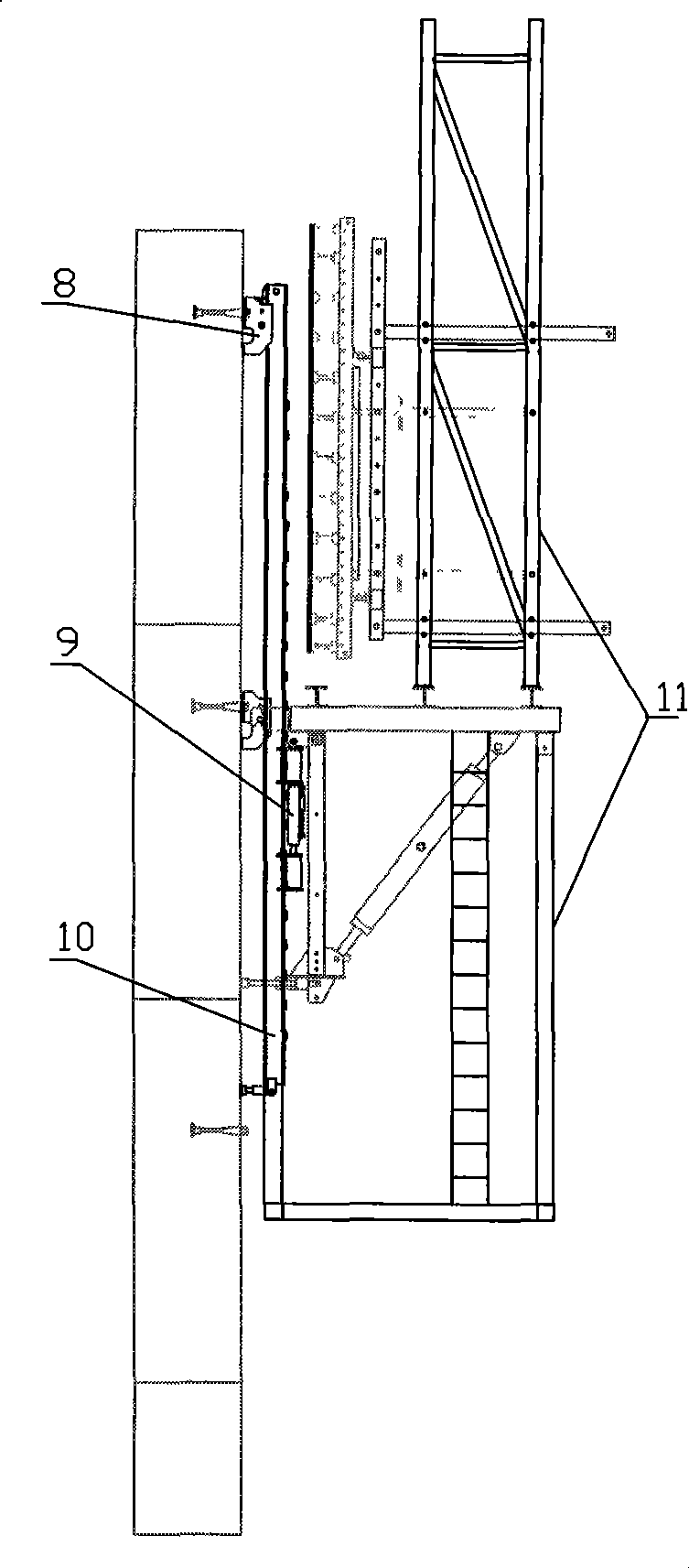

External inclined type concrete arch rib construction method and hydraulic self-creeping formwork equipment

InactiveCN101413248AThe deviation value of the three-dimensional coordinates of the structure is smallAccurate structure sizeForms/shuttering/falseworksBridge erection/assemblyShape deviationCantilever

The invention applies to the field of bridge construction, and provides a method for constructing camber-type concrete arch ribs, as well as a hydraulic self-ascending mold device. The method is to utilize the hydraulic self-ascending mold device for construction by adopting a self-ascending mold segmented cantilever casting mode. A rail and a template of the self-ascending mold device are both in the shape of a straight line or straight surface, or are both in the shape of a curve or a curved surface. The method constructs the camber-type concrete arch ribs by adopting the self-ascending mold segmented cantilever casting mode, wherein the guide rail and the template of the self-ascending mold device can be in the shape of a curve or a curved surface; as the template and a bracket of the device can be repeatedly used during the construction of the arch ribs, steel used for the template and the bracket can not be wasted; in addition, the method can greatly improve construction efficiency, shortens construction period, and realizes that a cast concrete arch rib is small in the deviation value of structural three-dimensional coordinate, accurate in structure size, smooth in line shape and clear in edge angle, and achieves the high-precision requirements on line shape deviation.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

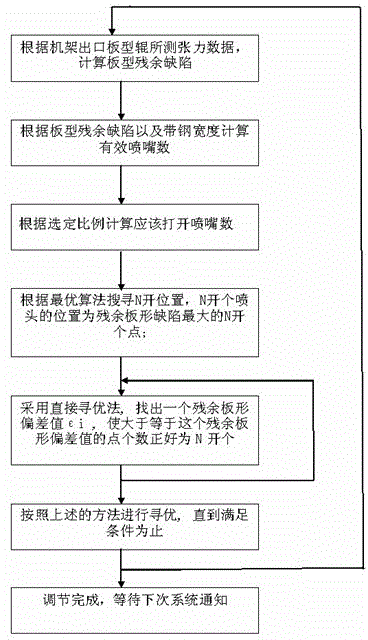

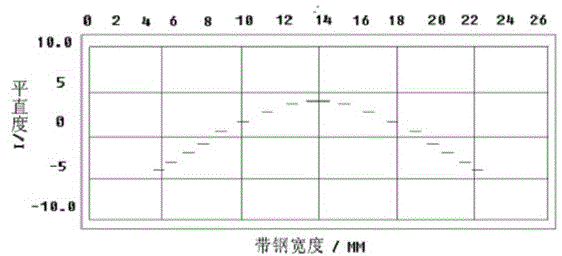

Emulsion fine cooling system control method and control device

ActiveCN104874614AReduce resistanceAvoid damageTemperature control deviceWork cooling devicesEmulsionShape deviation

The invention relates to an emulsion fine cooling system control method. The emulsion fine cooling system control method is characterized by comprising the following steps that the plate-shaped residual defect is calculated in dependence on steel strip contact tension data detected by a frame outlet plate-shaped roller; 2) the valid nozzle number is calculated in dependence on the plate-shaped residual defect and the steel strip width, N (valid)=B / 52, wherein B is the steel strip width (mm), and the distance between any two adjacent nozzles is 52mm; 3) the number N (open) of nozzles which need to be opened is calculated in dependence on a selected proportion, N (open) = N (valid)*K1, K1 is the selected open proportion, and is generally selected to be 50%, and the K1 can be reset as needed; 4) the positions of the N (open) nozzles are searched in dependence on the optimal algorithm, the positions of the N (open) nozzles are N (open) points where the plate-shaped residual defect is maximal; 5) through a direct optimum seeking method, a residual plate-shaped deviation value [epsilon]I is found out, and the number of points which are smaller than or equal to the residual plate-shaped deviation value is just equal to N (open); and 6) the optimum seeking is carried out through the above way until the condition is satisfied.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

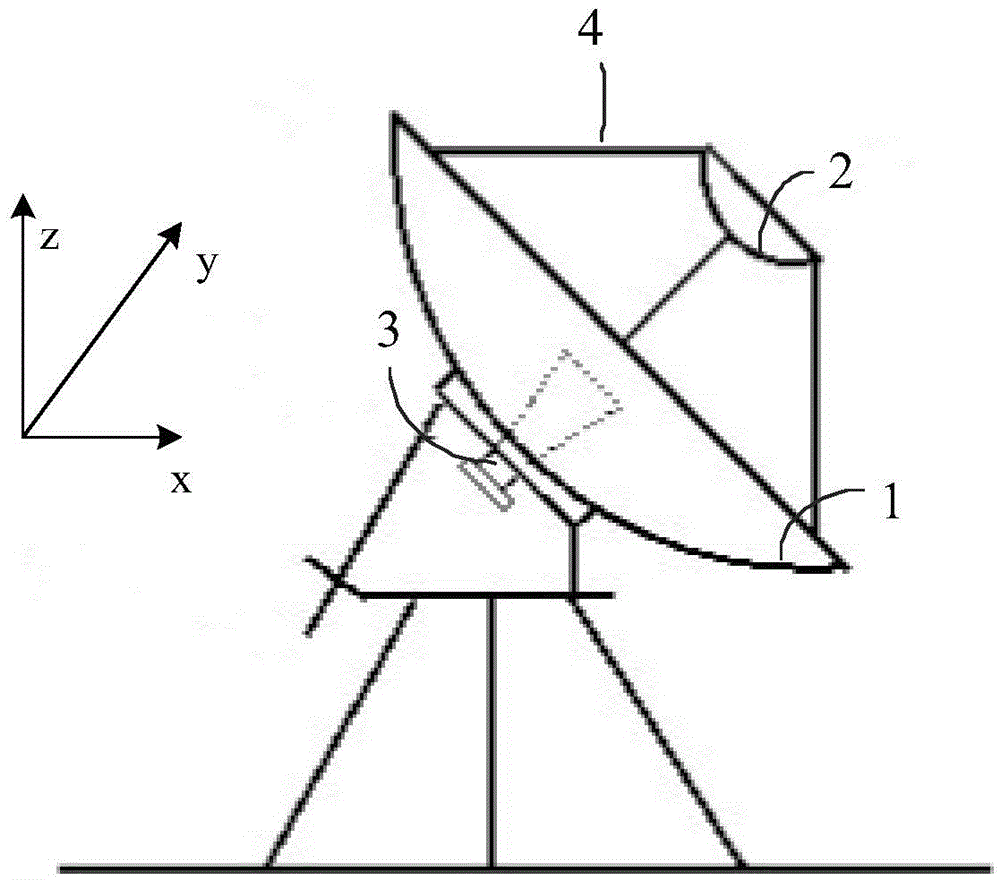

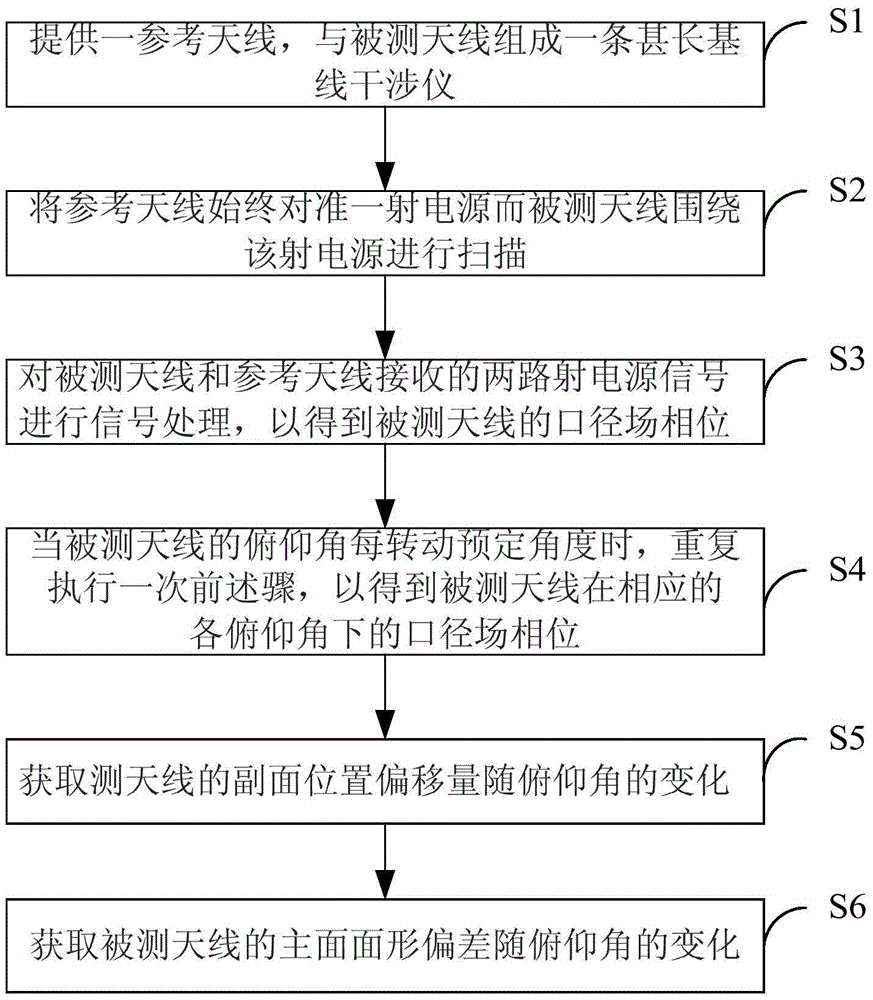

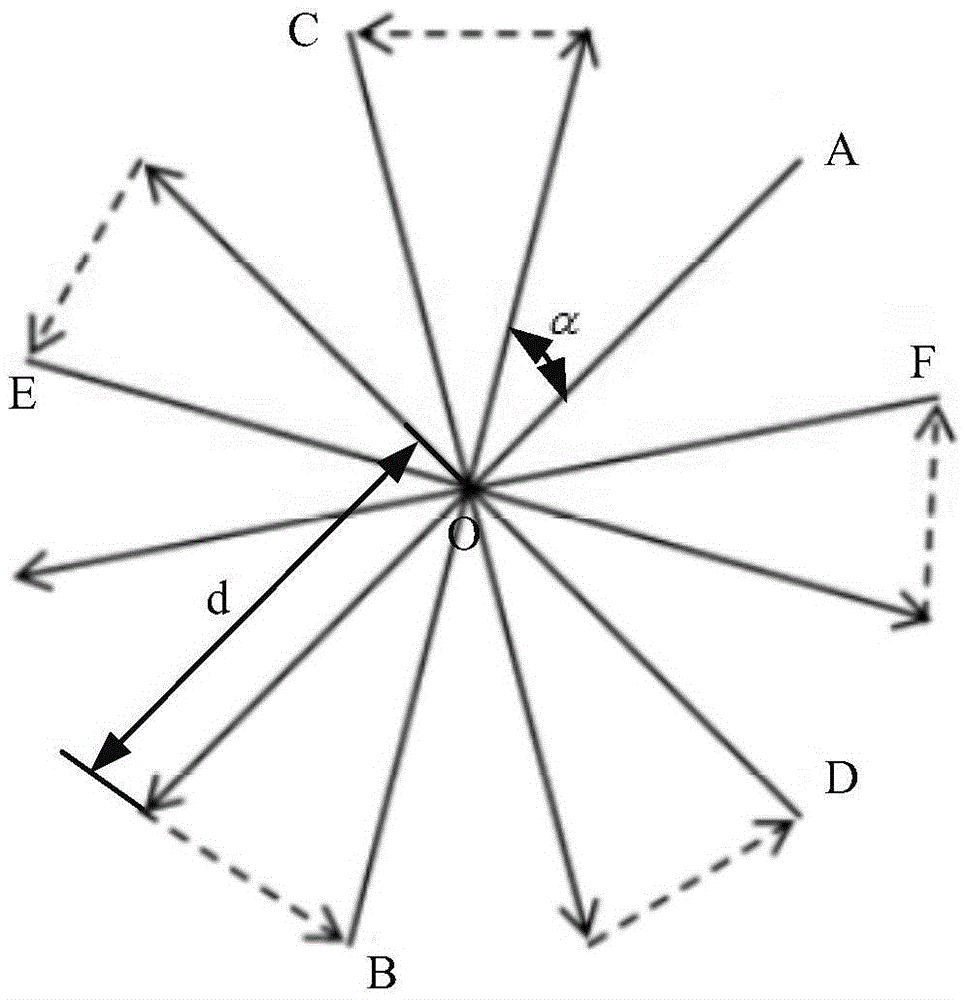

Method for measuring gravity deformation of large parabolic antenna

ActiveCN105627977ARealize gravity deformation measurementAngle measurementReference antennaShape deviation

The invention provides a method for measuring gravity deformation of a large parabolic antenna. The method comprises the following steps that a reference antenna is provided, and a very long baseline interferometer is formed by the reference antenna and a measured antenna; the reference antenna is enabled to be constantly aligned with a radio source and the measured antenna performs scanning around the radio source so that the reference antenna and the measured antenna are enabled to respectively receive radio source signals transmitted by the radio source; signal processing is performed on the two paths of radio source signals received by the measured antenna and the reference antenna so as to obtain the aperture field phase of the measured antenna; when the pitch angle of the measured antenna rotates for a preset angle each time, the aforementioned steps are performed repeatedly so as to obtain the aperture field phase of the measured antenna under the corresponding pitch angle, and the aperture field phase is the aperture field phase corresponding to primary side precision; the change of secondary side position offset of the measured antenna along with the pitch angle is obtained; and the change of primary side shape deviation of the measured antenna along with the pitch angle is obtained. The change of primary side shape deviation and secondary side position offset of the antenna along with the pitch angle of the antenna can be accurately measured.

Owner:SHANGHAI ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

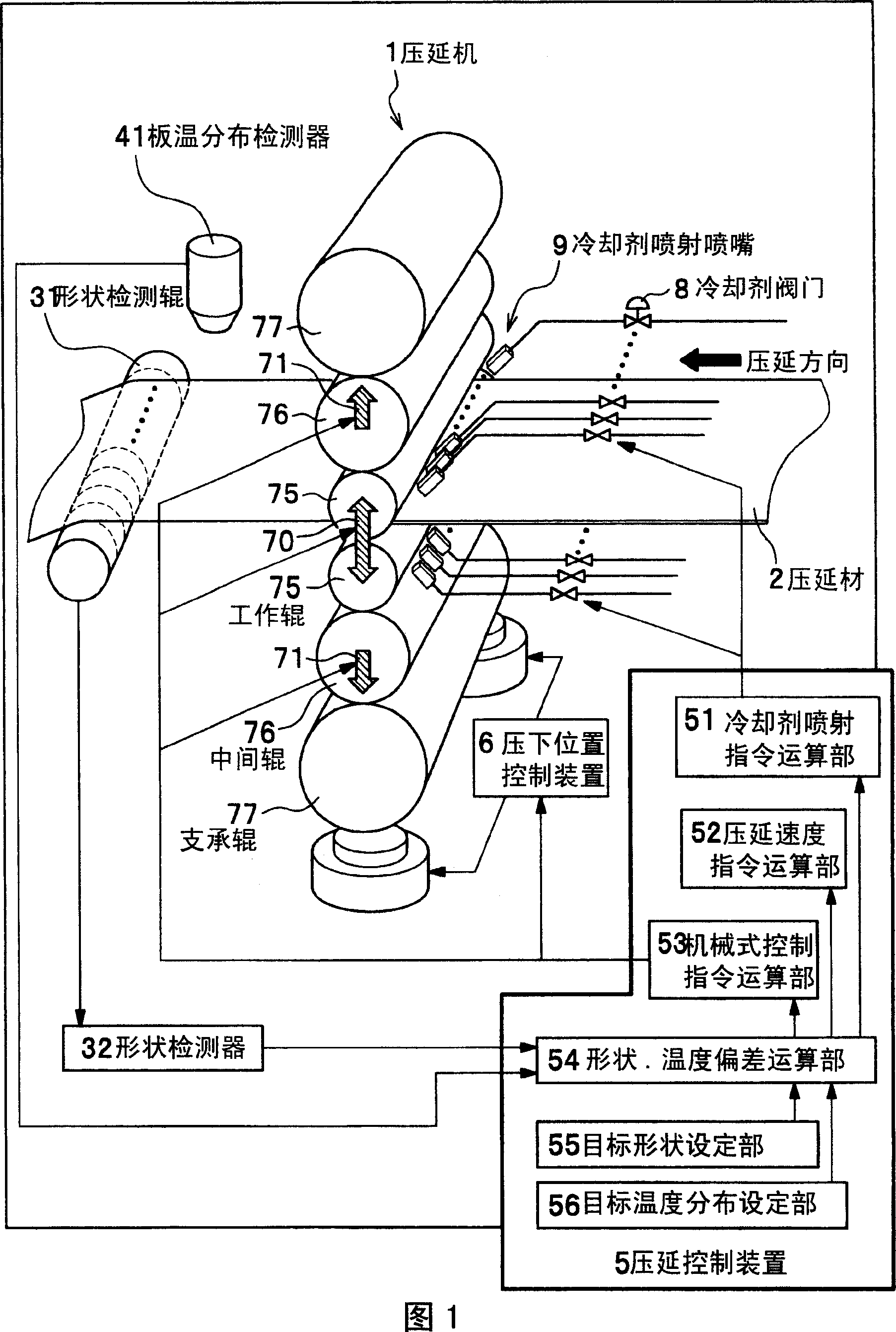

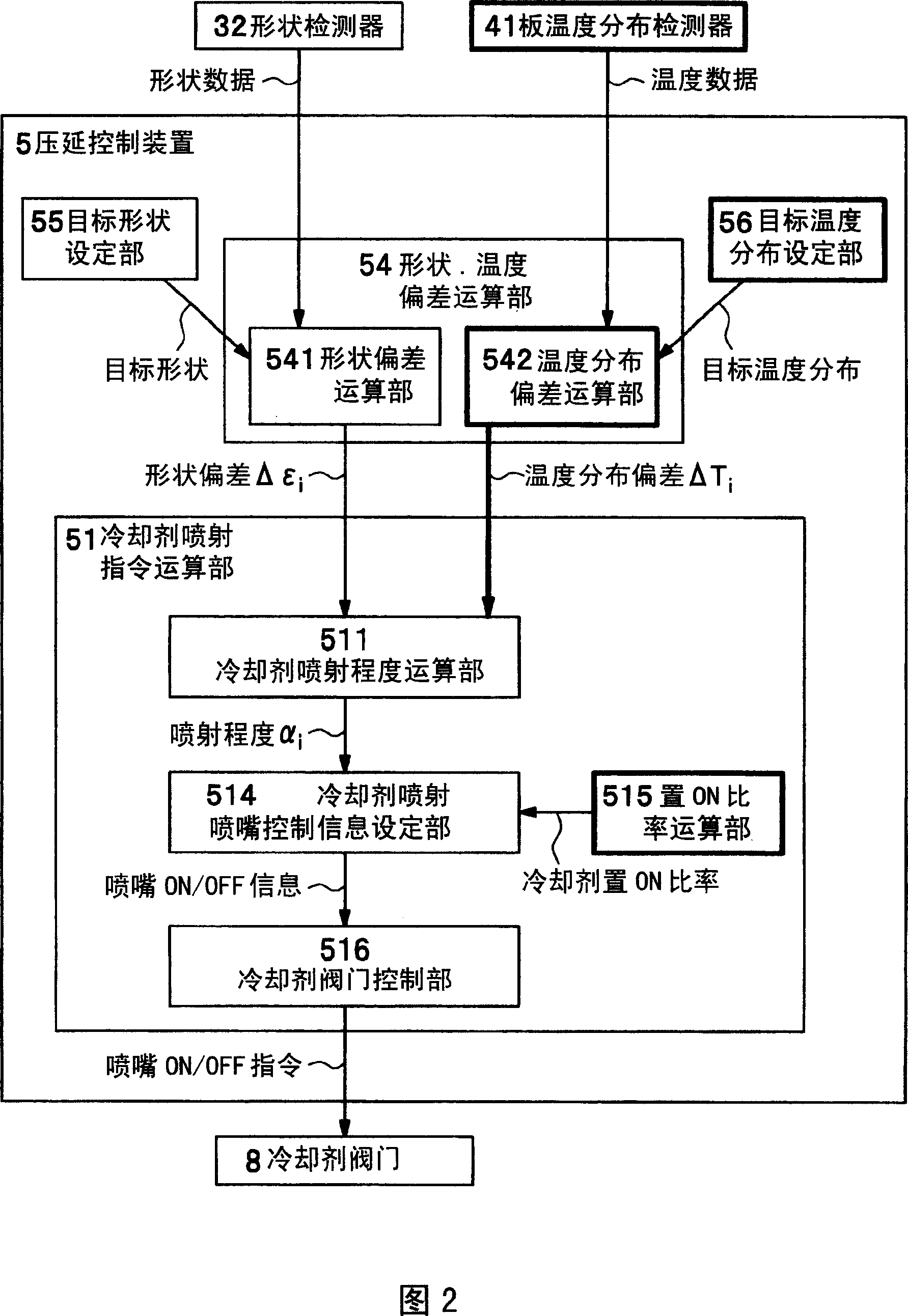

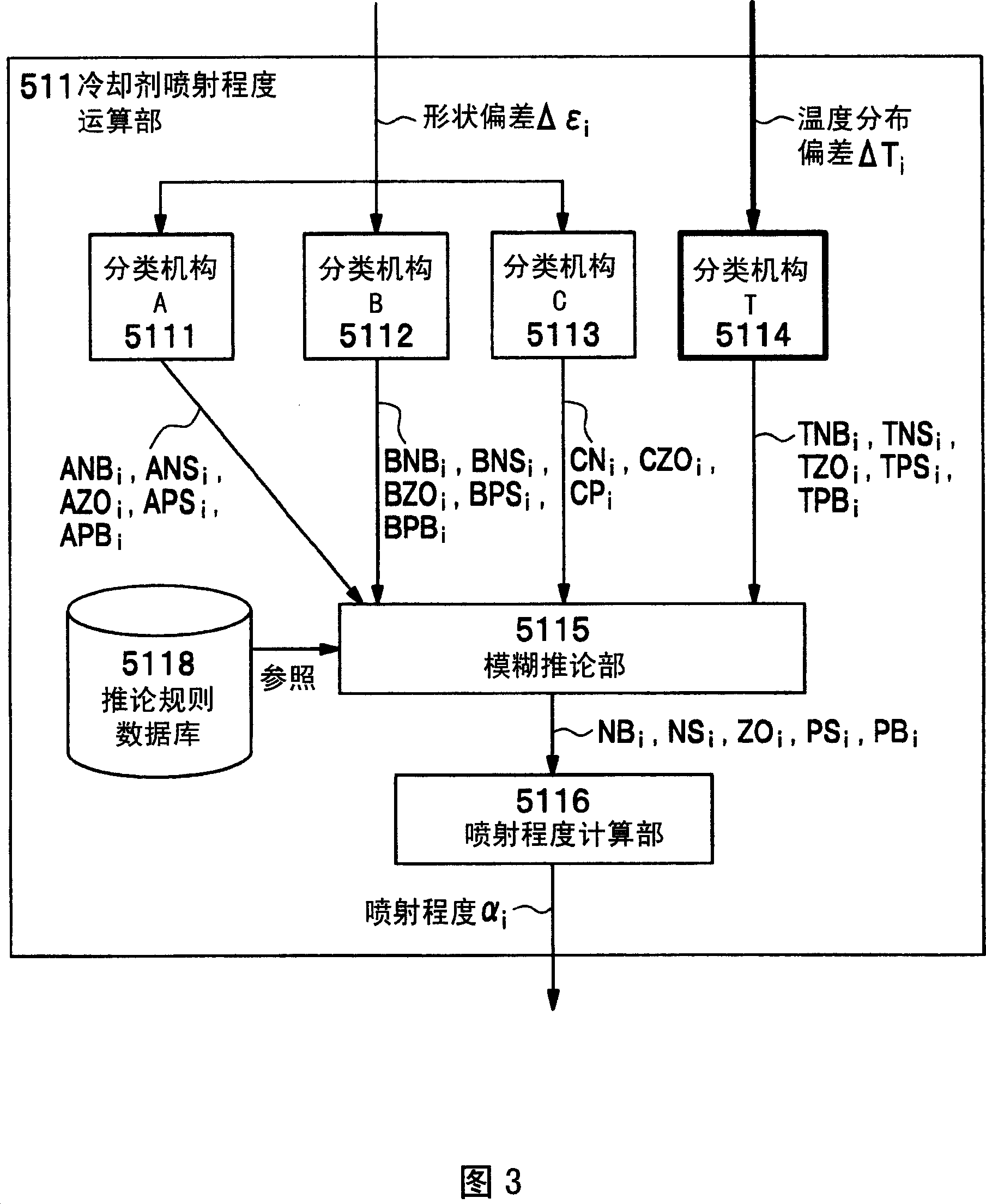

Rolling control device and rolling control method

ActiveCN1927483AQuality improvementTemperature control deviceMeasuring devicesShape deviationEngineering

The invention is to improve magnetic characteristics and shape quality by simultaneously controlling both of strip temperature and temperature distribution in a width direction of a rolling material and strip shape of the rolling material. A coolant jet command computation unit (51) calculates a widthwise deviation of shape of the rolling material (2) detected by a shape detector (32), and widthwise deviation of temperature distribution of the rolling material detected by a strip temperature distribution detector (41) and obtains a widthwise distribution of coolant jetting level which is a necessary level for coolant jetted from a coolant jet nozzles (9). Then, based on the obtained widthwise distribution of coolant jetting level, control information for the coolant jetting nozzle (9) to jet the coolant is set up, and based on the control information set up, an ON / OFF command for coolant jetting is issued to coolant valves (8).

Owner:HITACHI LTD

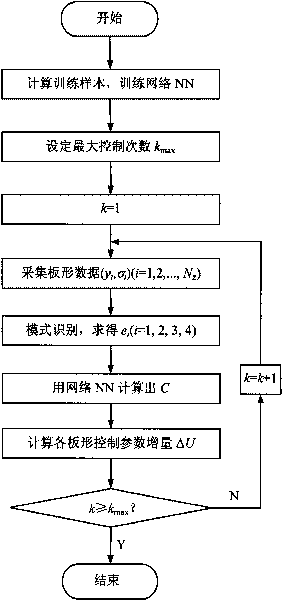

Tertiary panel-shape closed-loop control method

The invention relates to a tertiary panel-shape closed-loop control method, comprising the following steps: (a) panel-shape data (yi, Sigmai) are collected, wherein the i is equal to 1, 2,..., Nz, the Nz is the number of the measure points, and Sigmai is the panel-shape deviation at the yi of the coordinate; (b) the model of collected panel-shape data (yi, Sigmai) is identified with the tertiary panel-shape identification method to obtain the panel-shape characteristic parameter ei, wherein i is equal to 1, 2, 3 and 4; (c) a panel-shape adjustment influence coefficient matrix is established to rapidly calculate a network NN, and an influence coefficient matrix C is calculated with the network NN according to the current rolling state; and (d) the increment DeltaU of each panel-shape control parameter is calculated according to the panel-shape characteristic parameter ei identified in the step (b) and the influence coefficient matrix C calculated in the step (c) to control the panel-shape. The invention provides a simple, practical and displayed panel-shape control calculation method according to the panel-shape identification and the panel-shape control calculation through considering the tertiary panel-shape during the identification of the model of the panel-shape, and the panel-shape control calculation method is suitable for on-line control.

Owner:YANSHAN UNIV

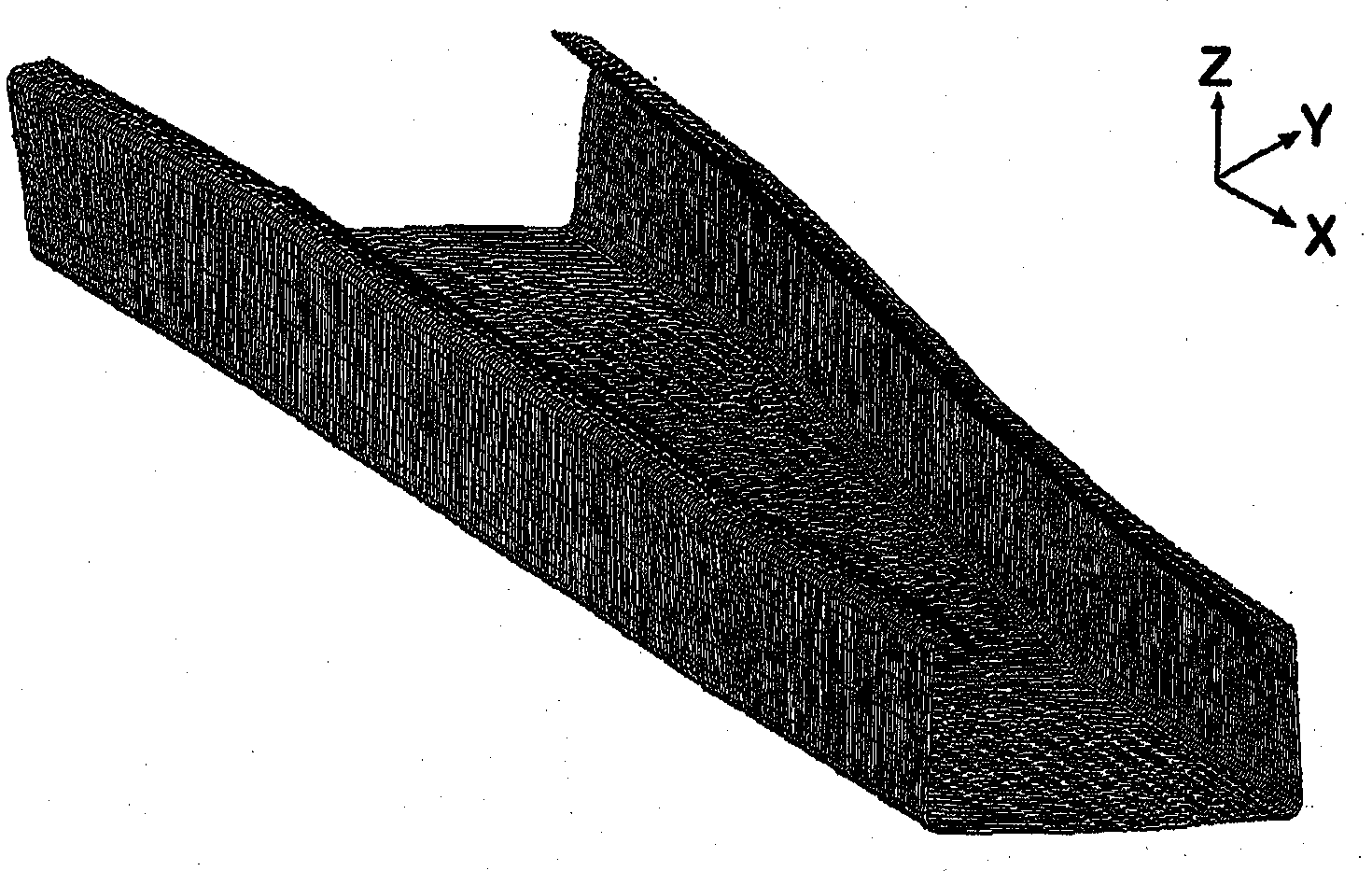

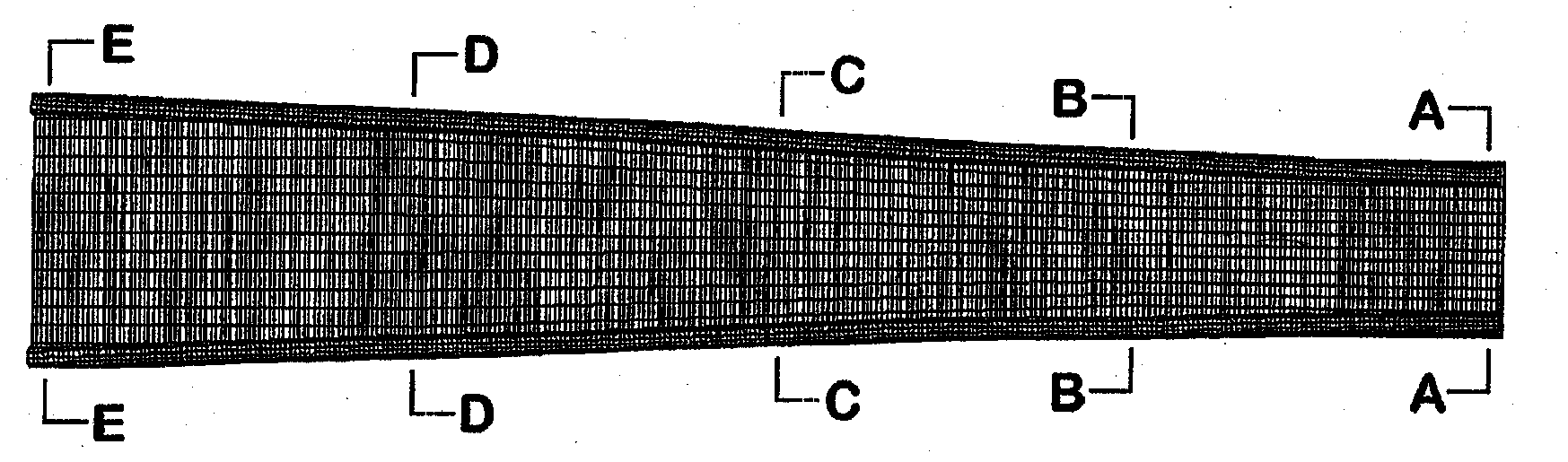

System for cold roll profiling profiles having variable cross-sections

InactiveCN102170979ASimple structureReduce in quantityMetal rolling arrangementsMetal stripsShape deviation

The invention relates to a system for cold roll profiling profiles having variable cross-sections, comprising a plurality of roll stands arranged in a row, each comprising a pair of rolls, between which a sheet metal strip (2) is guided according to the length (X), wherein the roll stands are moved translationally transversely to the length of the sheet metal strip during cold roll profiling and are moved rotationally about an axis of the roll stand. According to the invention, a reforming device (8, 10, 12) is arranged behind at least one of the roll stands and has at least one drive for generating a movement of the reforming device in a plane transversely to the length (X) of the sheet metal strip.; On the basis of data calculated from data relating to the material and thickness of the sheet metal strip, the configuration and control data of the roll stands and the CAD data of the profiles to be shaped, the drive is controlled in such a way that, during ongoing operation of the system, the reforming device automatically cancels any shape deviations in the sheet metal strip leaving the at least one roll stand.

Owner:DATA M SHEET METAL SOLUTIONS

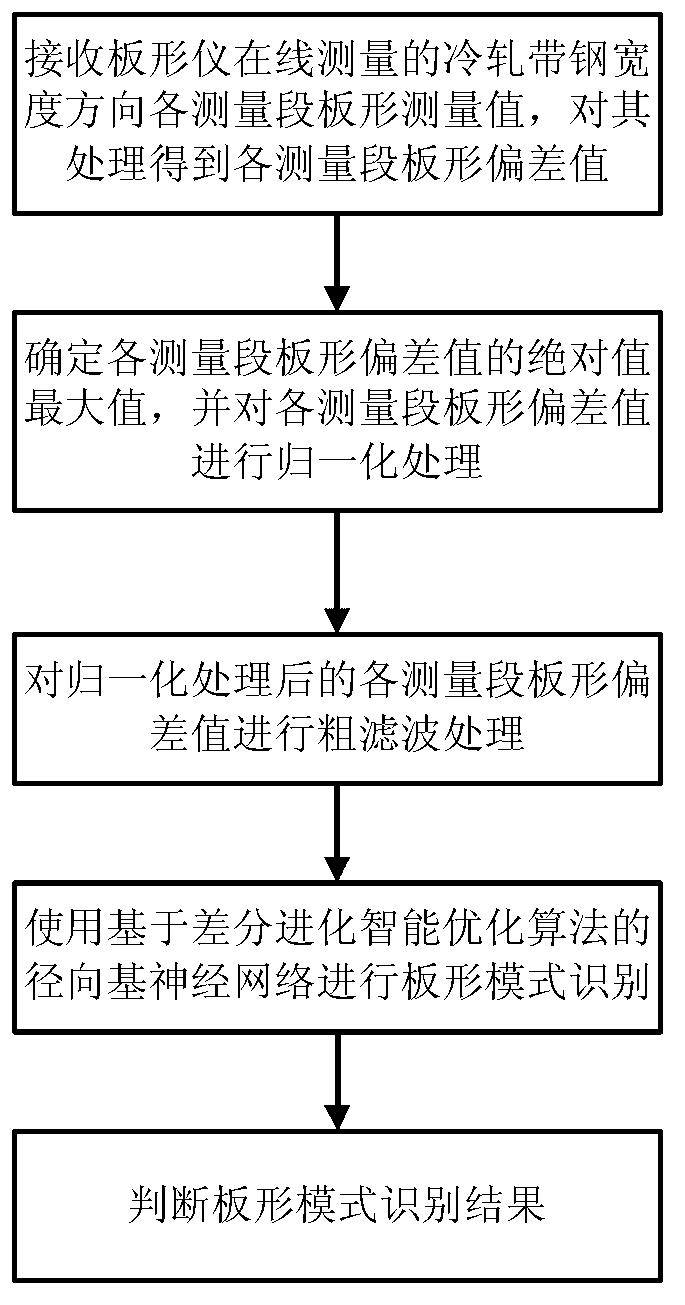

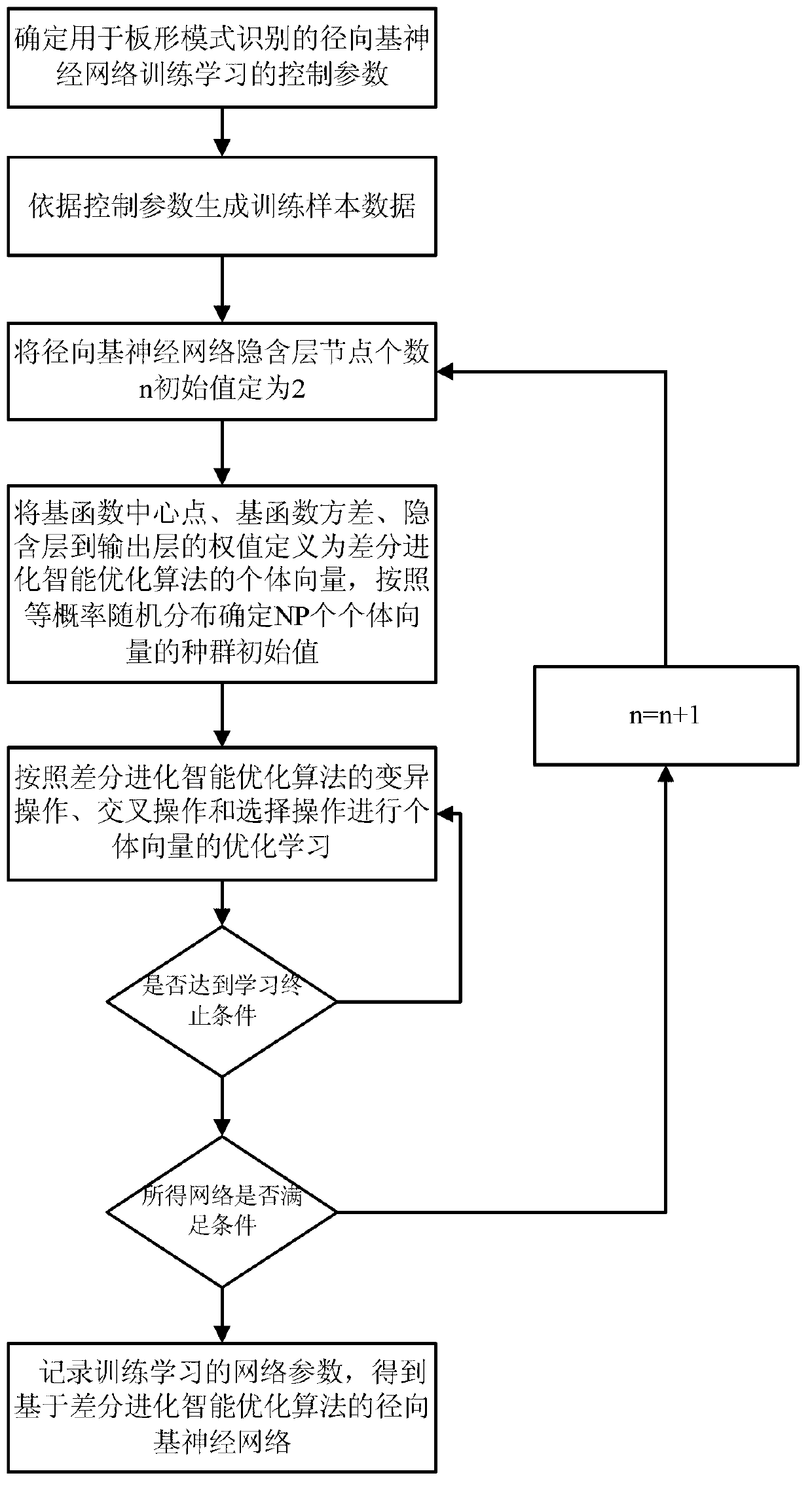

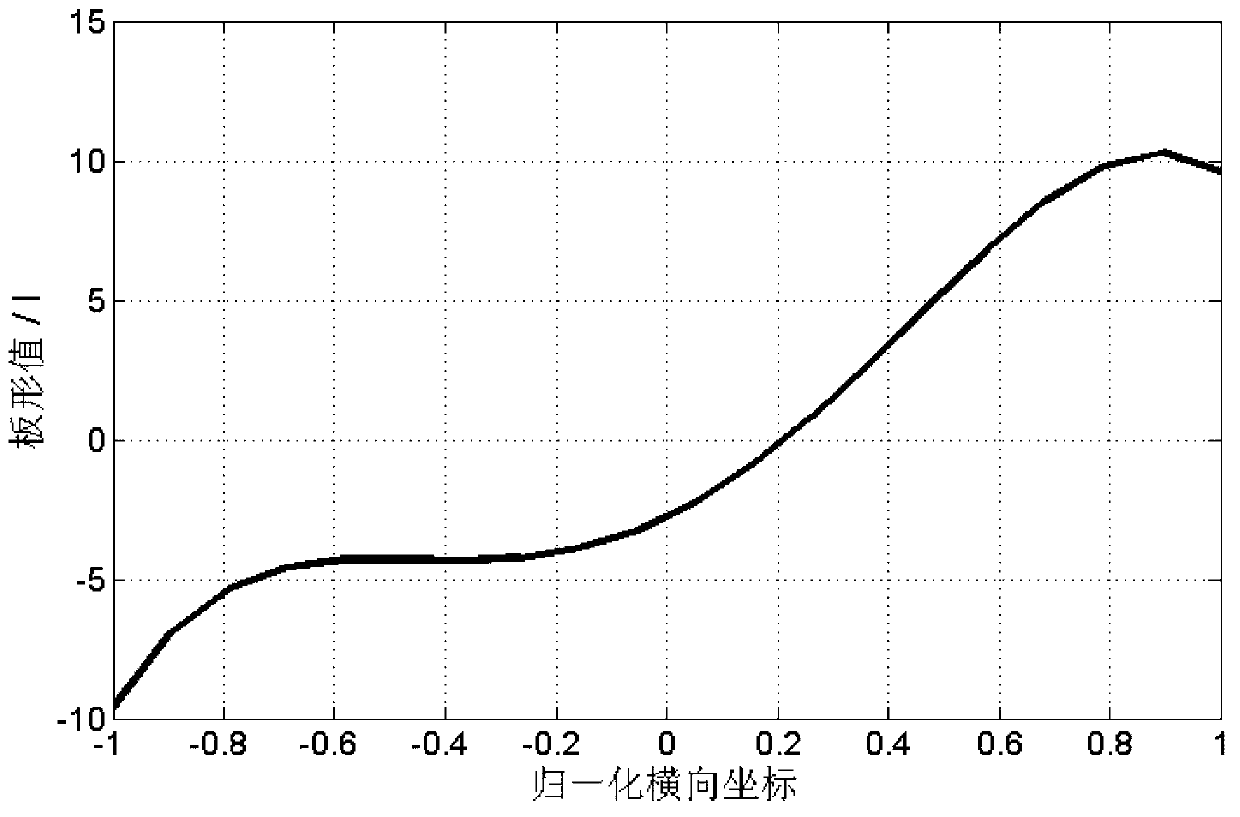

Cold-rolled sheet shape signal online mode recognition method

InactiveCN103341505AReduce adverse effectsHigh precisionMeasuring devicesProfile control deviceRadial basis function neuralShape deviation

The invention provides a cold-rolled sheet shape signal online mode recognition method. The method includes the steps of receiving sheet shape measurement values of measurement segments in the width direction of a cold-rolled strip steel measured by a sheet shape instrument in an online mode, comparing the measurement values with a set distribution value of a corresponding target sheet shape, obtaining sheet shape deviation values of all measurement segments, determining the largest value of the absolute values of the sheet shape deviation values, carrying out the normalization processing on the sheet shape deviation values of all measurement segments, carrying out the rough-filtering processing on deviation values, after the normalization processing, of the measurement segments, recognizing sheet shape modes through a radial basis function neural network based on the differential evolution intelligent optimization algorithm, and judging a sheet shape mode recognition result. Through the normalization processing and the rough-filtering processing of the sheet shape deviation values of all measurement segments, the adverse influence of bad point data of the sheet shape measurement values on sheet shape mode recognition can be obviously eliminated, and recognition accuracy of the sheet shape mode is improved. Molding accuracy and network training efficiency are obviously improved due to the fact that the differential evolution intelligent optimization algorithm is applied to the sheet shape mode recognition based on the radial basis function neural network.

Owner:WISDRI ENG & RES INC LTD

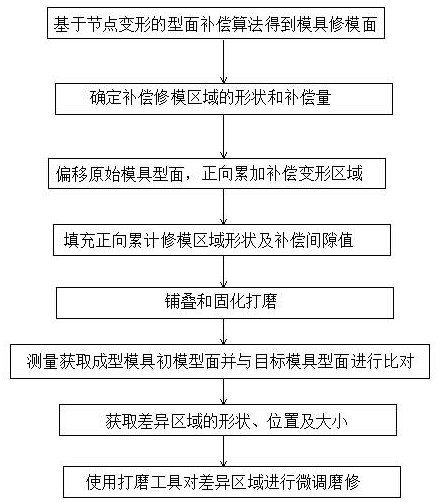

Compensation mold-repairing method for profile deformation of composite material component mold

The invention discloses a compensation mold-repairing method for the profile deformation of a composite material component mold, and belongs to the technical field of curing and forming for compositematerial components. The compensation mold-repairing method for the profile deformation of the composite material component mold is characterized by comprising the following steps: a, obtaining a moldrepairing surface based on a profile compensation algorithm for joint deformation; b, determining the shape and compensation amount of a compensation mold-repairing area, deviating from an original mold profile, and accumulating forwards a compensation deformation area; c, adopting a glass fiber reinforced plastic material for filling the shape of the forwards-accumulated mold repairing area andcompensating a gap value, and then carrying out laying and curing grinding to obtain an initial profile mold of the target forming mold; and d, obtaining the initial mold profile of the forming mold through digital measurement, comparing the initial mold profile with a target mold profile, obtaining the shape, the position and the size of a difference area, and carrying out fine adjustment and grinding on the difference area by using a grinding tool to finish mold profile qualification correction. According to the invention, the forming mold can greatly reduce the shape deviation between an actual part and a theoretical part, shorten the correction period and reduce the cost.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com