FHM-based (fuzzy hyperbolic model-based) cold-rolling mill working roll emulsion sectional cooling control method

A fuzzy hyperbolic, segmented cooling technology, applied in the direction of rolls, metal rolling, temperature control, etc., can solve problems such as inability to describe and accurately control, meet real-time requirements, the method is simple and feasible, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

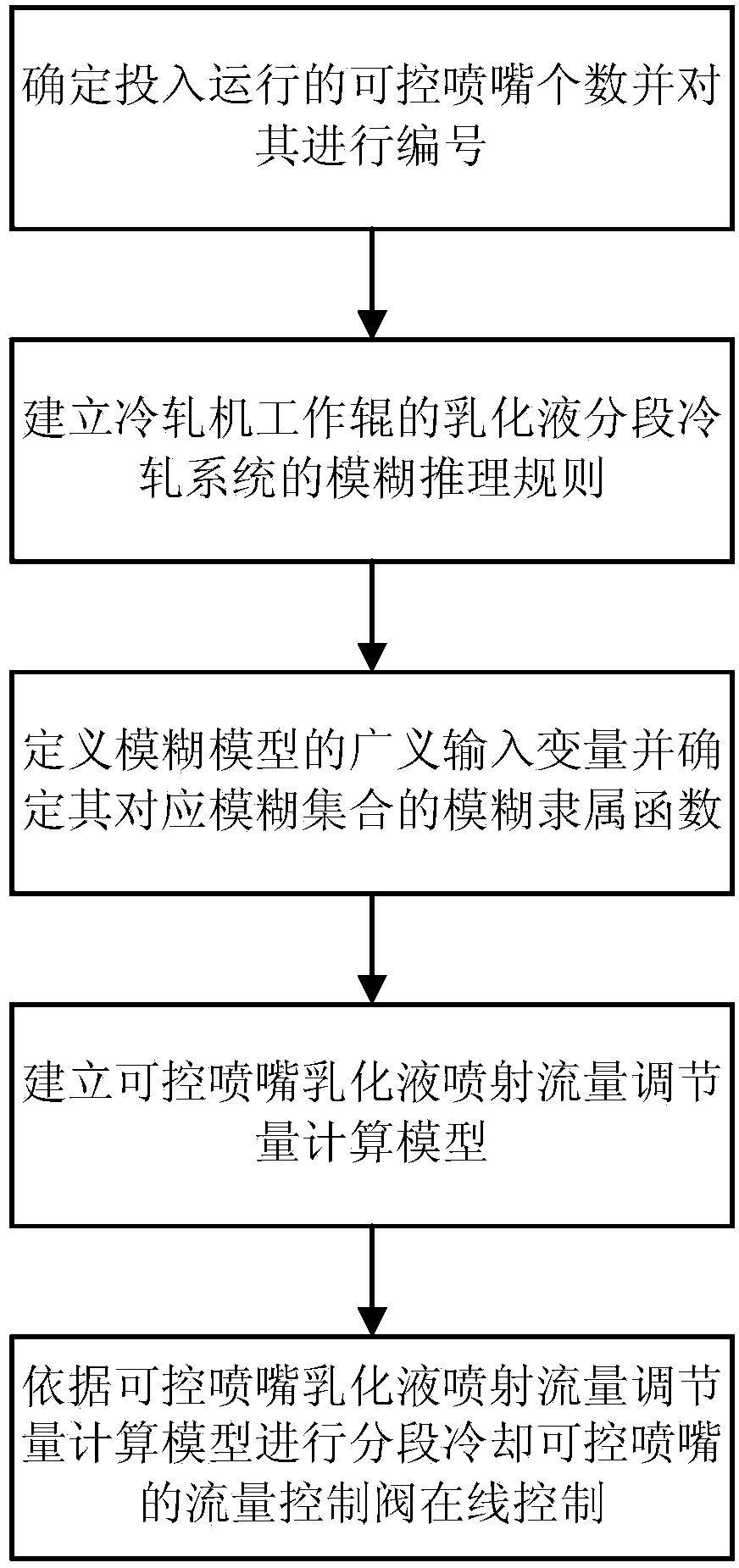

[0030] figure 1 It is a method flowchart of an embodiment of the present invention, based on the fuzzy hyperbolic model cold rolling mill work roll emulsion subsection cooling control method, it is characterized in that: it comprises the following steps:

[0031] 1) Determine the number of nozzles covering the strip according to the width of the strip and the layout of the controllable nozzles for the segmental cooling of the upper and lower work rolls of the rolling mill, and sequentially number the controllable nozzles from the operating side to the transmission side of the strip along the transverse direction of the strip, in order: The controllable nozzles of the upper work rolls from No. 1 to No. m and the corresponding controllable nozzles of the lower work rolls from No. 1 to No. m;

[0032] 2) In order to ensure the uniform temperature distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com