Molten iron stirring desulfurization hot state test system

A stirring desulfurization and thermal test technology, which is applied in the direction of stirring devices, material thermal analysis, lighting and heating equipment, etc., can solve the problems of inability to greatly expand, difficulty in process stability control, limited industrial production conditions, etc., and achieve cycle time Short, adaptable, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

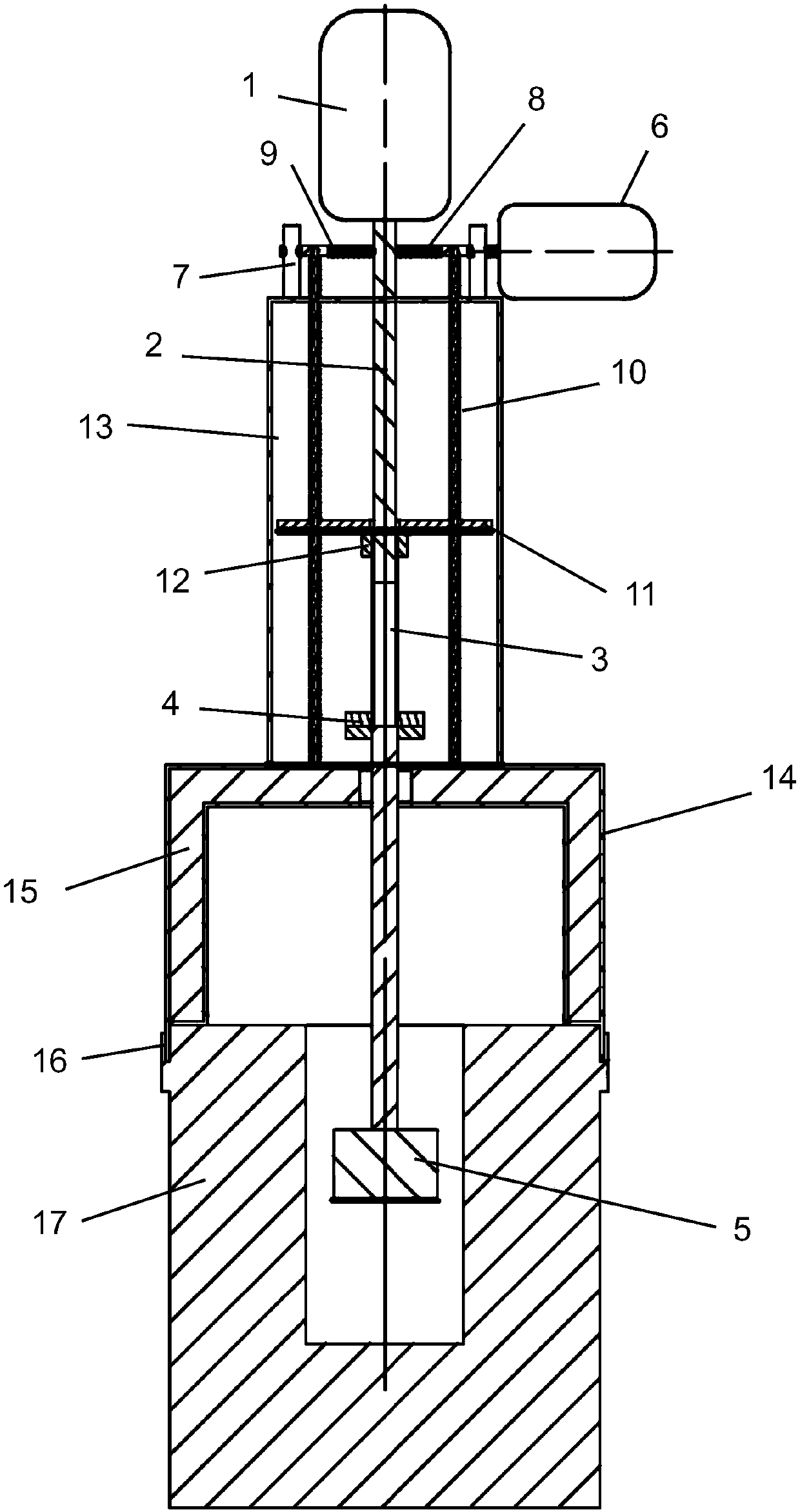

[0017] Such as figure 1 As shown, the molten iron stirring desulfurization thermal test system of the present invention mainly includes a stirring device, a lifting device, an equipment support, a heat radiation protection device, a furnace mouth fast fixing device and a non-vacuum induction furnace, wherein:

[0018] The stirring device includes a stirring rotating motor 1, a main shaft 2, an output shaft 3, a connecting flange 4 and an agitating paddle 5 connected sequentially from top to bottom. Nested connection with the output shaft 3, this design can adjust the height of the stirring paddle 5, and drive the output shaft 3 to rotate, the output shaft 3 and the stirring paddle 5 are connected by the connecting flange 4, and drive the stirring paddle 5 to rotate;

[0019] The lifting device includes a lifting motor 6, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com