An acid concentration controlling method for a continuous annealing furnace

A continuous annealing furnace and control method technology, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve the problems of ensuring the quality of pickling, cumbersome test operations, and inability to carry out online measurement methods, and achieve the effect of improving quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

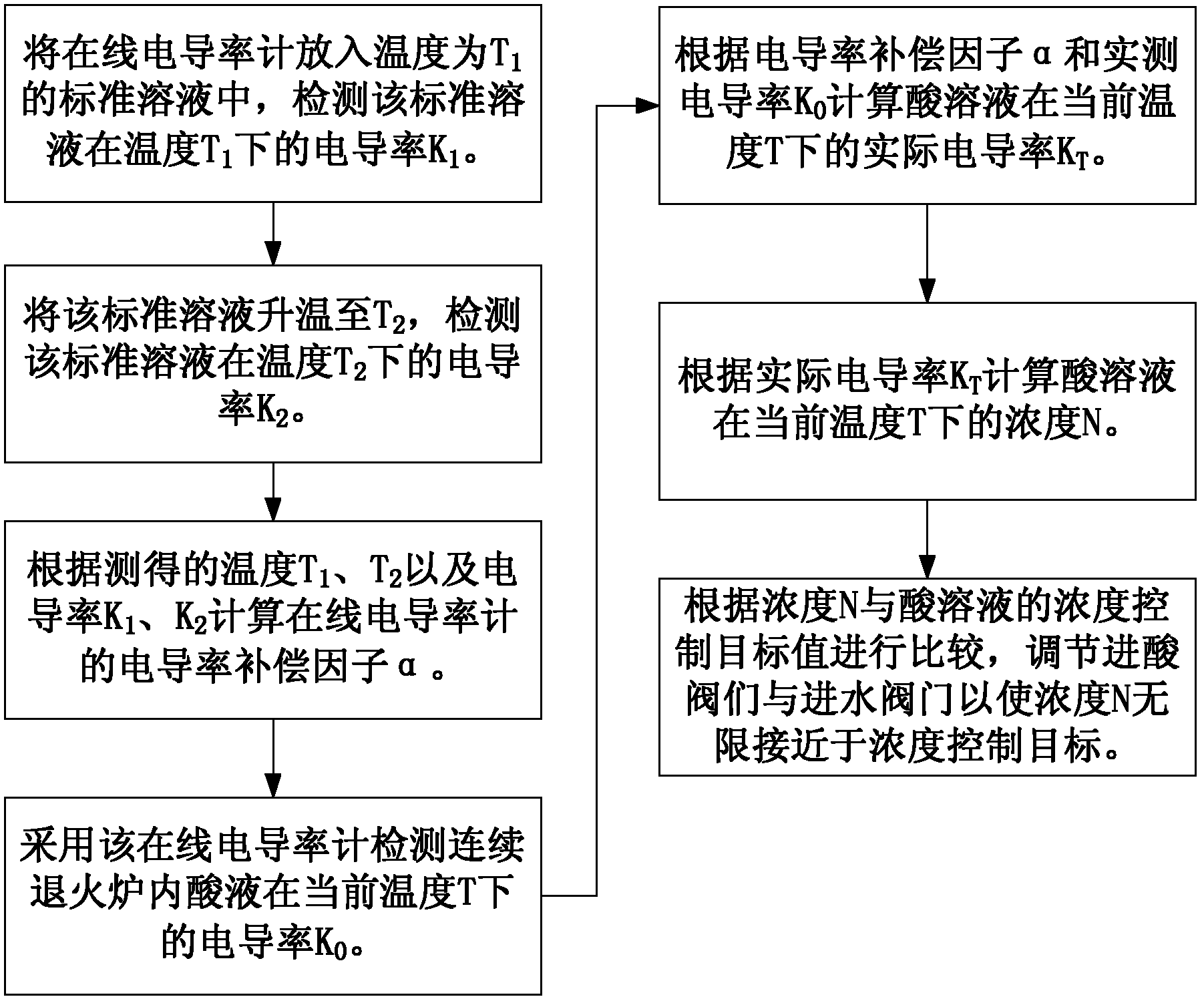

[0018] The method for controlling the acid concentration of the continuous annealing furnace according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

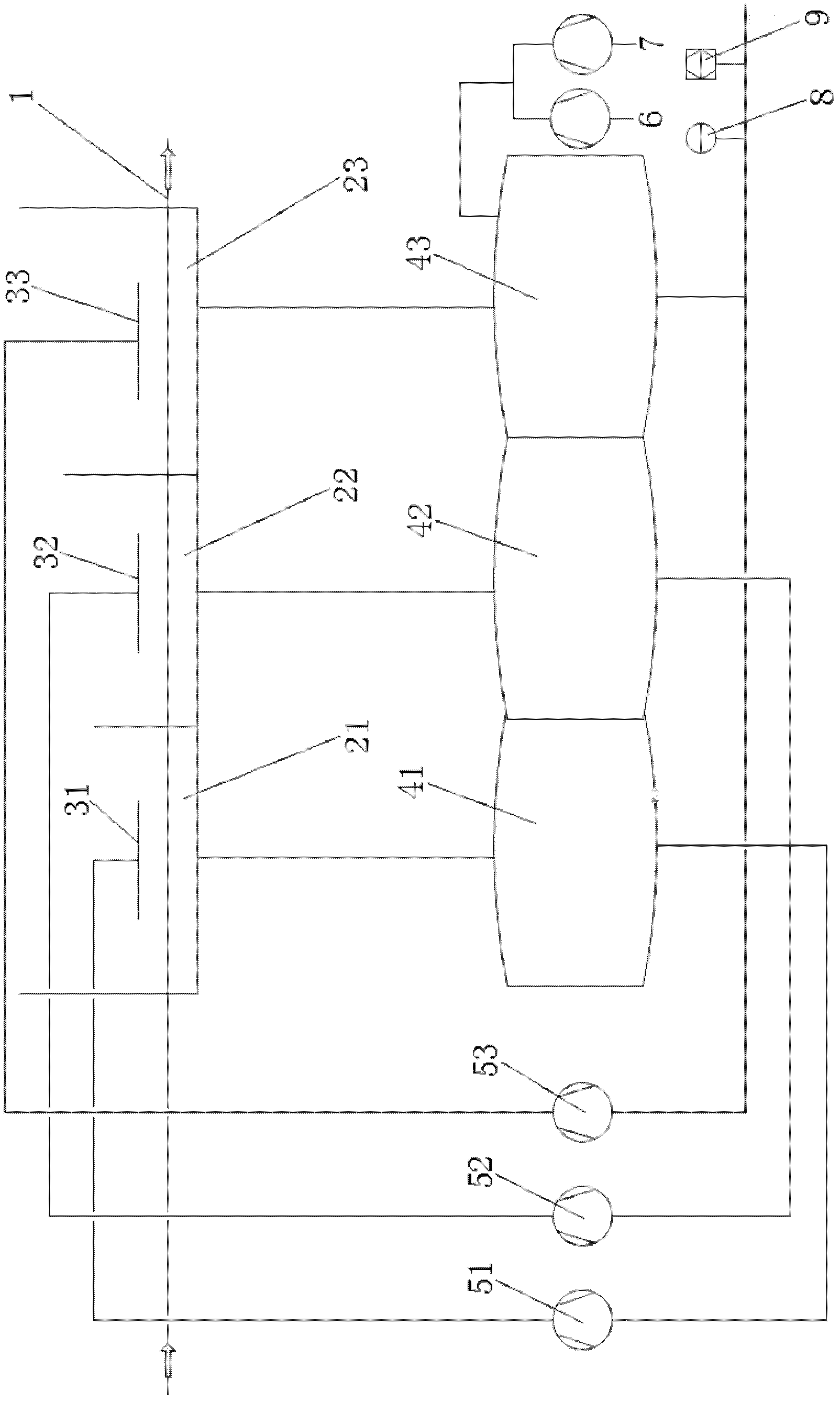

[0019] figure 1 It is a schematic diagram of the concentration monitoring system in this embodiment of the continuous annealing furnace acid concentration control method according to the present invention. Such as figure 1 As shown, the steel strip 1 passes through the acid tanks 21, 22, and 23 successively in the direction of the arrows, and the acid solution is sprayed onto the steel strip 1 through the spray beams 31, 32, and 33 respectively corresponding to the acid tanks 21, 22, and 23. Strip 1 is pickled. The acid solution after pickling flows back into the acid tanks 41, 42, 43 respectively corresponding to the acid tanks 21, 22, 23 through the acid tanks 21, 22, 23 and the corresponding pipelines, and then passes through the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com