Method for automatically controlling plate shape of continuous annealing leveling mill based on stability index

A tempering machine and stability technology, applied in the direction of contour control, etc., can solve the problems of reducing the shape quality of the finished strip steel plate, and the dynamic effect of the automatic control of the shape is not good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

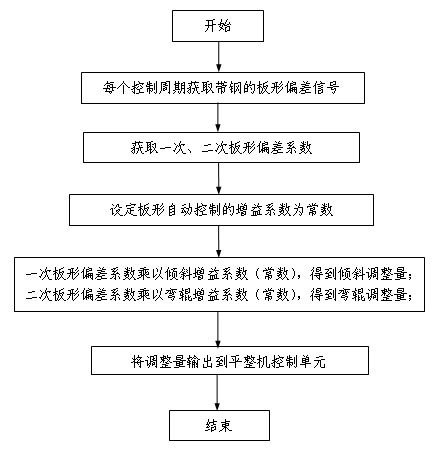

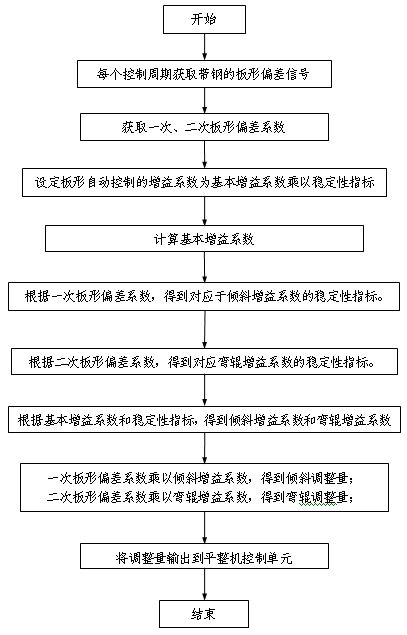

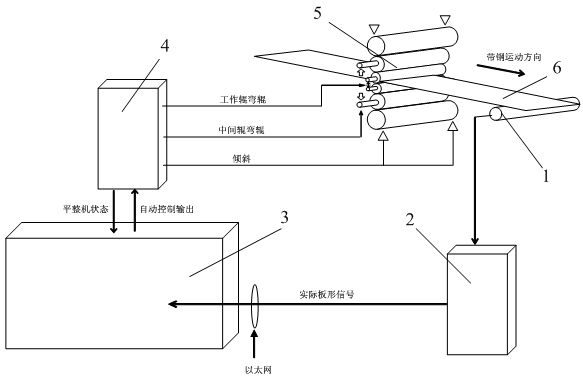

[0064] like figure 2 As shown, an automatic control method for continuous annealing and tempering machine shape based on stability index, including the following steps:

[0065] Step 1. Using the five sets of measured flatness data measured by the flatness measuring roller within one control period, performing sliding average processing on the five groups of actually measured flatness data to obtain smooth measured flatness data. The difference between the smoothed measured shape data and the target shape is fitted by the least square method to obtain the shape deviation equation in the form of a quadratic polynomial ,

[0066] (1)

[0067] From the shape deviation equation Obtain the shape deviation coefficient once in , Secondary shape deviation coefficient ;

[0068] Step 2. The control ability of the continuous tempering machine is limited. When the inclination changes from 0 to the limit value (1.0), there is a value corresponding to the cha...

Embodiment 2

[0140] The flatness measurement computer 2 receives the actual flatness signal, performs sliding average processing on the measured flatness signal, and obtains smooth measured flatness data, and then obtains smoothed actual flatness data σ p for:

[0141] σ p ={1.0000, 0.6970, 0.4404, 0.2305, 0.0670, -0.0499, -0.1202, -0.1440, -0.1213, -0.0521,

[0142] 0.0637, 0.2260, 0.4349, 0.6903, 0.9922, 1.3407, 1.7357, 2.1773, 2.6654, 3.2000};

[0143] The target shape σ stored in the shape controller s ={0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0,

[0144] 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0, 0.0};

[0145] Subtract the target shape from the measured shape data to get the shape deviation

[0146] Δσ p ={1.0000, 0.6970, 0.4404, 0.2305, 0.0670, -0.0499, -0.1202, -0.1440, -0.1213, -0.0521,

[0147] 0.0637, 0.2260, 0.4349, 0.6903, 0.9922, 1.3407, 1.7357, 2.1773, 2.6654, 3.200};

[0148] According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com