Patents

Literature

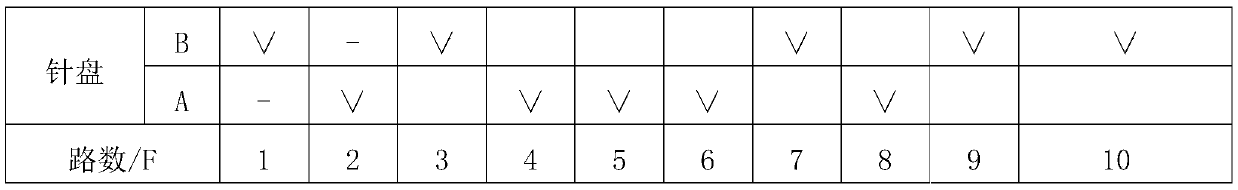

30results about How to "Bite smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium/aluminum/titanium composite board cladding-rolling method

InactiveCN105436203AEffectively Constrains Deformation BehaviorEasy to transformForging/pressing devicesMetal rolling arrangementsTitaniumShape optimization

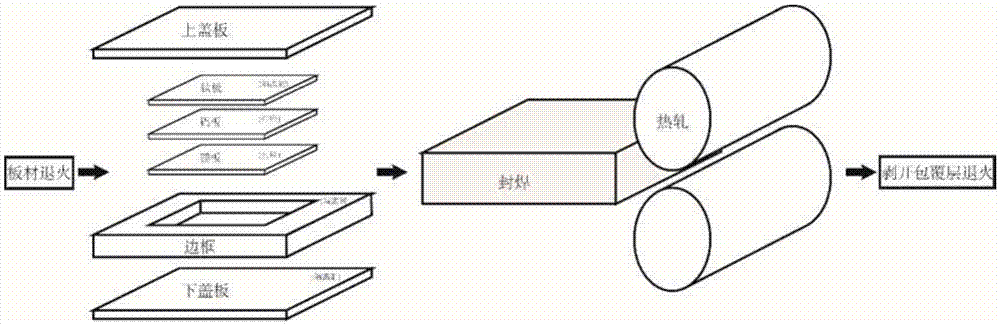

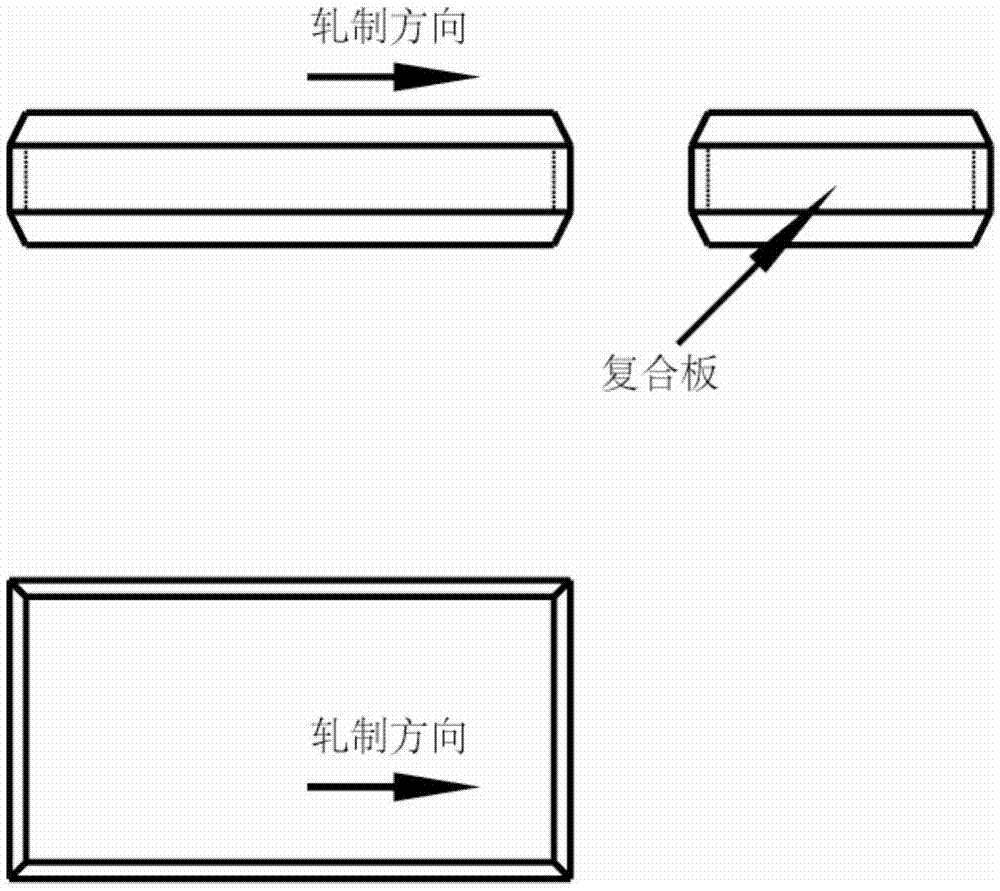

The invention discloses a magnesium / aluminum / titanium composite board cladding-rolling method. According to the method, a cladding layer is used for the composite board during rolling, and through shape optimization of upper and lower cover plates of the cladding layer and design of rolling process parameters, the cladding layer and the cladded composite board can achieve coordinated deformation during rolling, so that the deformation behavior of the cladded composite board can be effectively restrained, the composite interface of the composite board is straight, and the bonding strength of the composite board is improved; the cladding layer can effectively reduce invasion of impurities and harmful gas to the composite interface, so that the bonding strength of the composite board can be further improved; and meanwhile, the use of the cladding layer can slow down loss of heat, so that metal is easy to deform during rolling.

Owner:CHONGQING UNIV

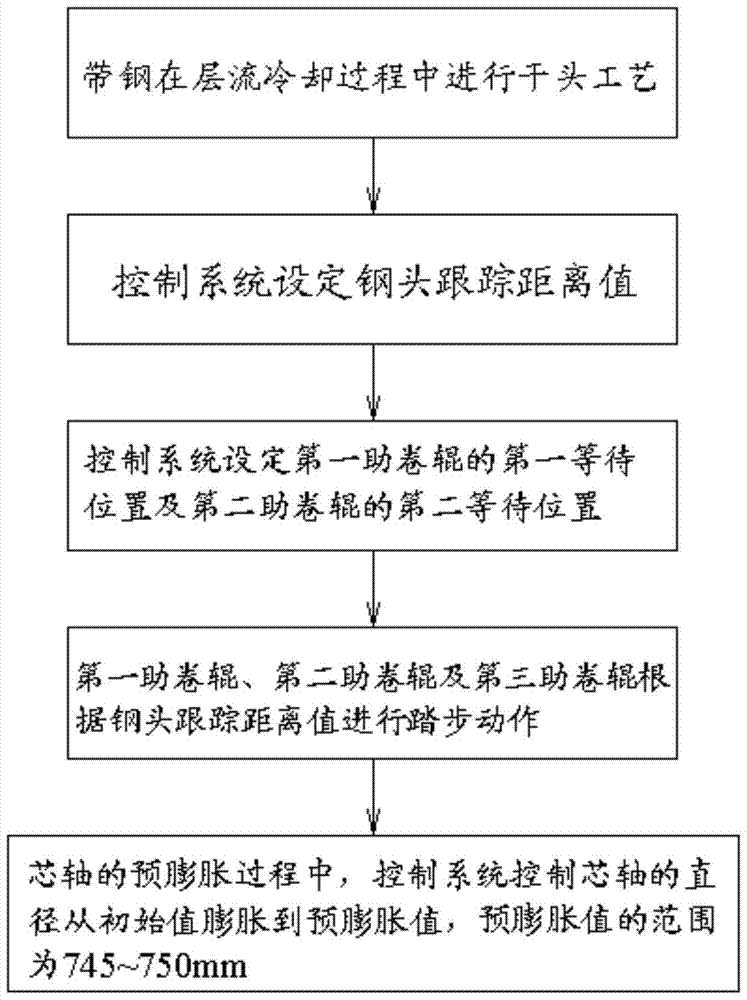

Control method for stable coiling of head of hot-rolled high-strength steel

ActiveCN105013860ASolve the problem that the temperature is relatively low and the bending performance is not idealImproved bending propertiesRoll mill control devicesMetal rolling arrangementsPre expansionControl system

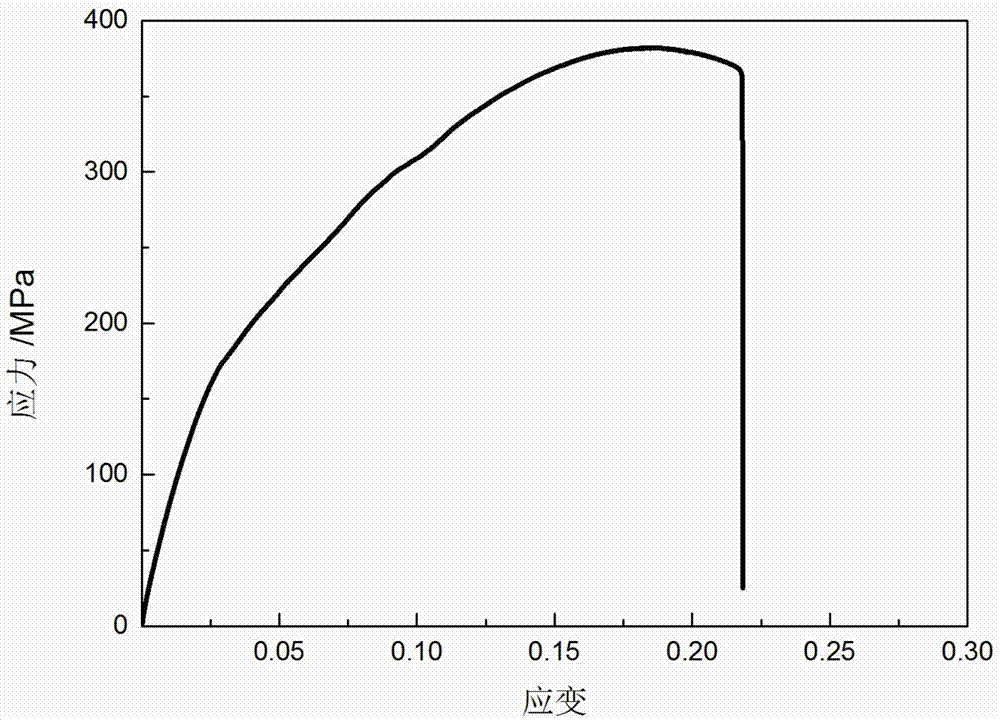

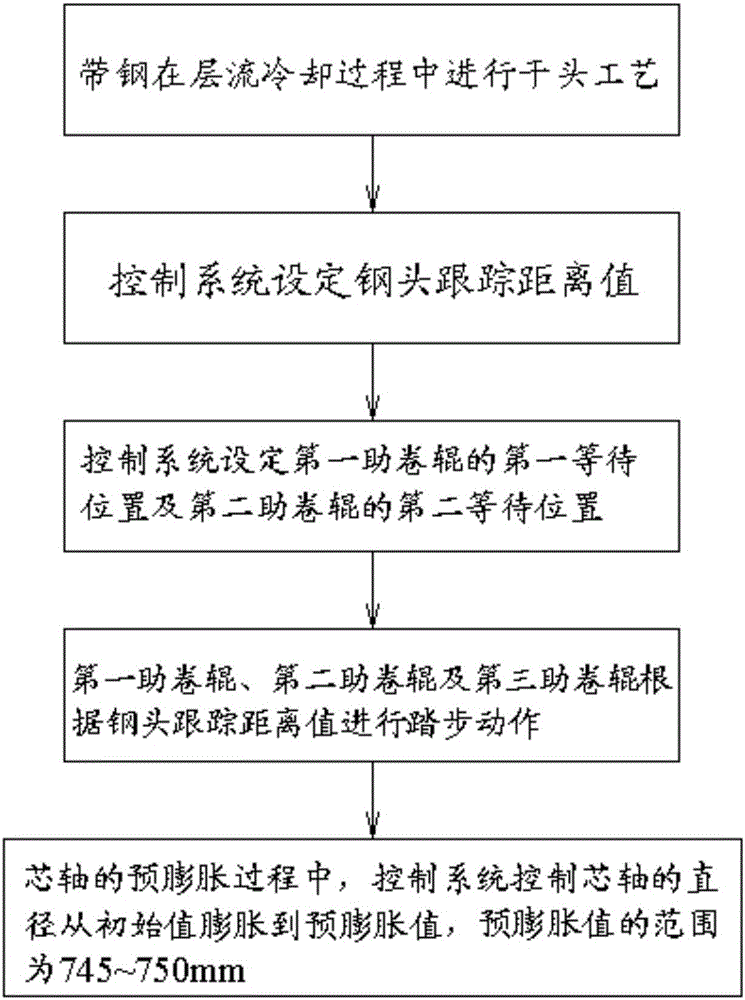

The invention relates to a control method for stable coiling of the head of hot-rolled high-strength steel. The method includes the following steps that head drying is performed on the strip steel in the laminar cooling process; a control system sets steel head tracking distance values; the control system sets the first waiting position of a first assistant coiling roll and the second waiting position of a second assistant coiling roll; the first assistant coiling roll, the second assistant coiling roll and a third assistant coiling roll conduct stepping according to the steel head tracking distance values; and in the pre-expansion process of a central spindle, the control system controls the central spindle to expand to a pre-expansion diameter value ranging from 745 mm to 750 mm from an initial diameter value. By means of the control method, it can be guaranteed that the head of the high-strength steel enters a coiling machine stably and smoothly, the situation that the head is abutted or rubs against relevant equipment, and consequently the steel strip halts is avoided, and therefore the steel heaping accident is avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

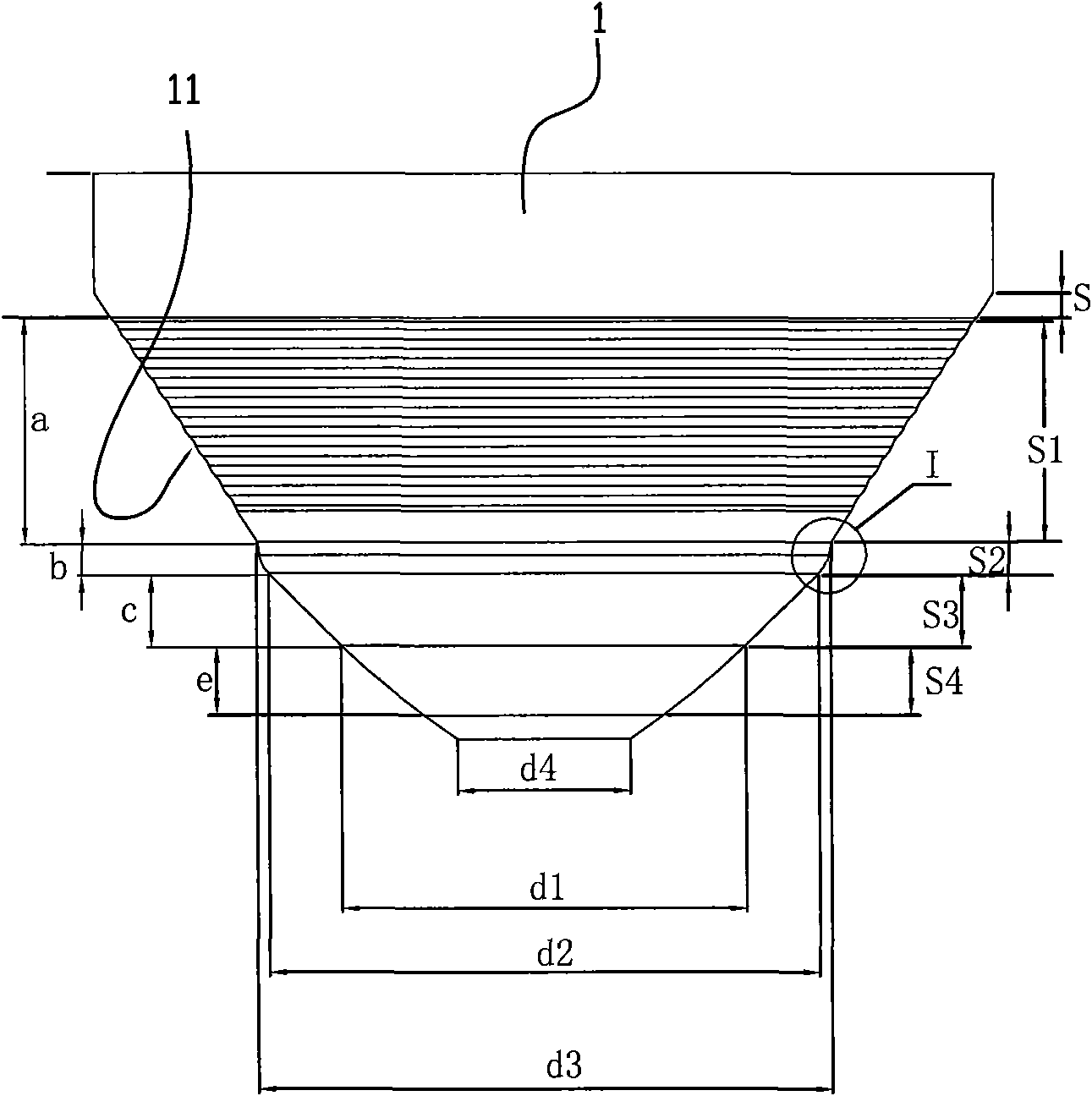

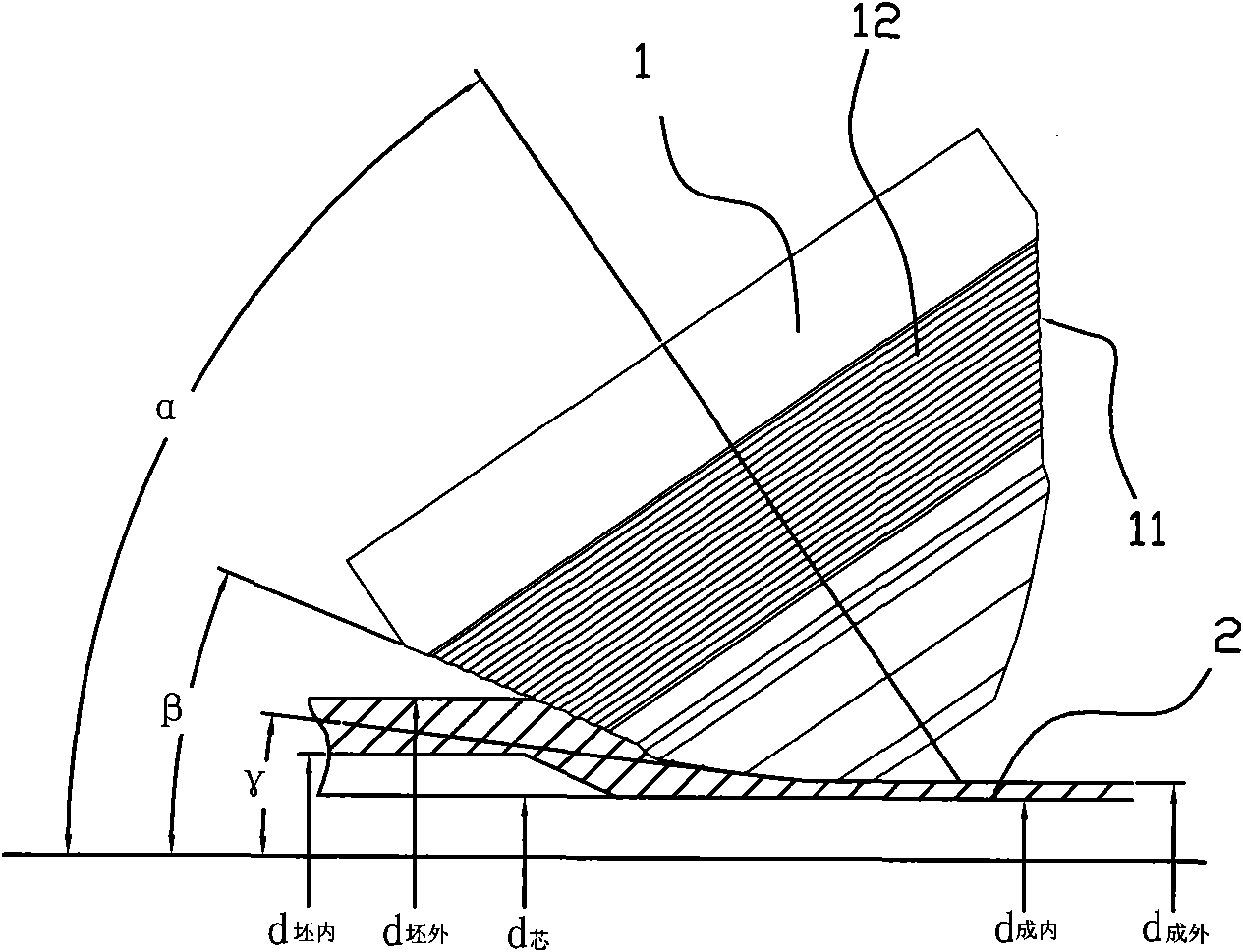

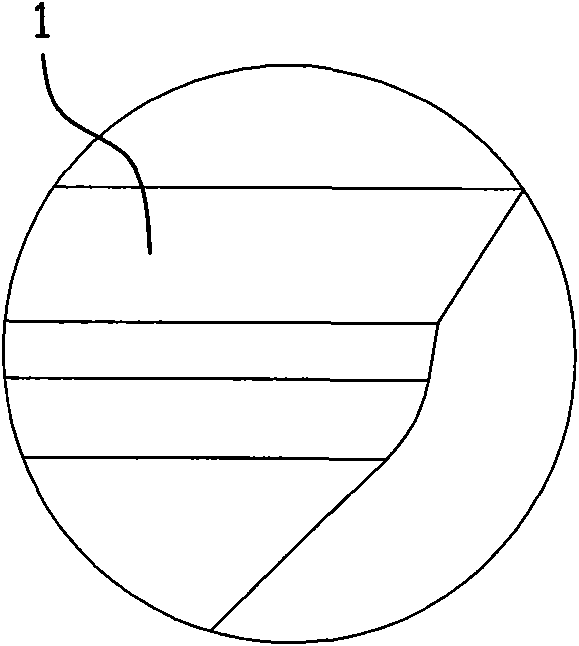

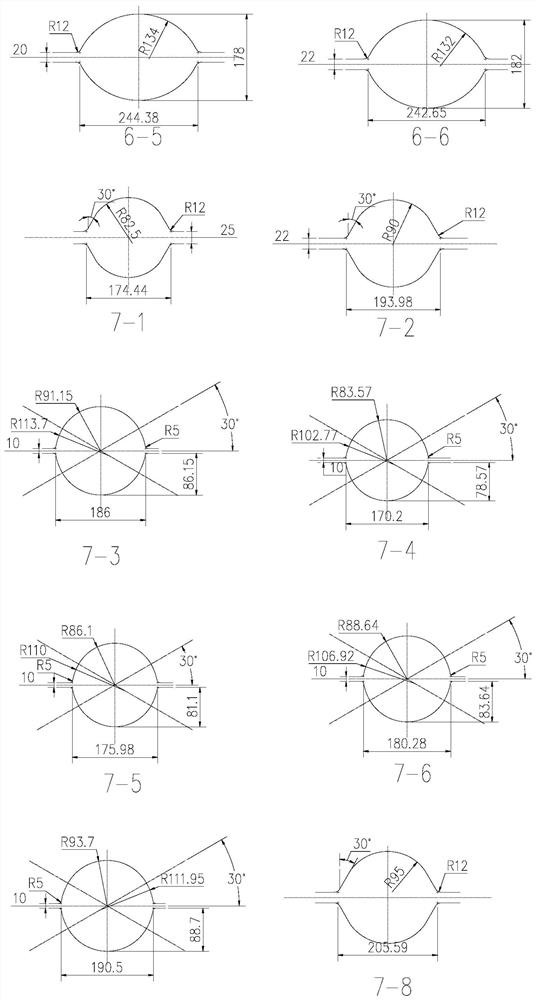

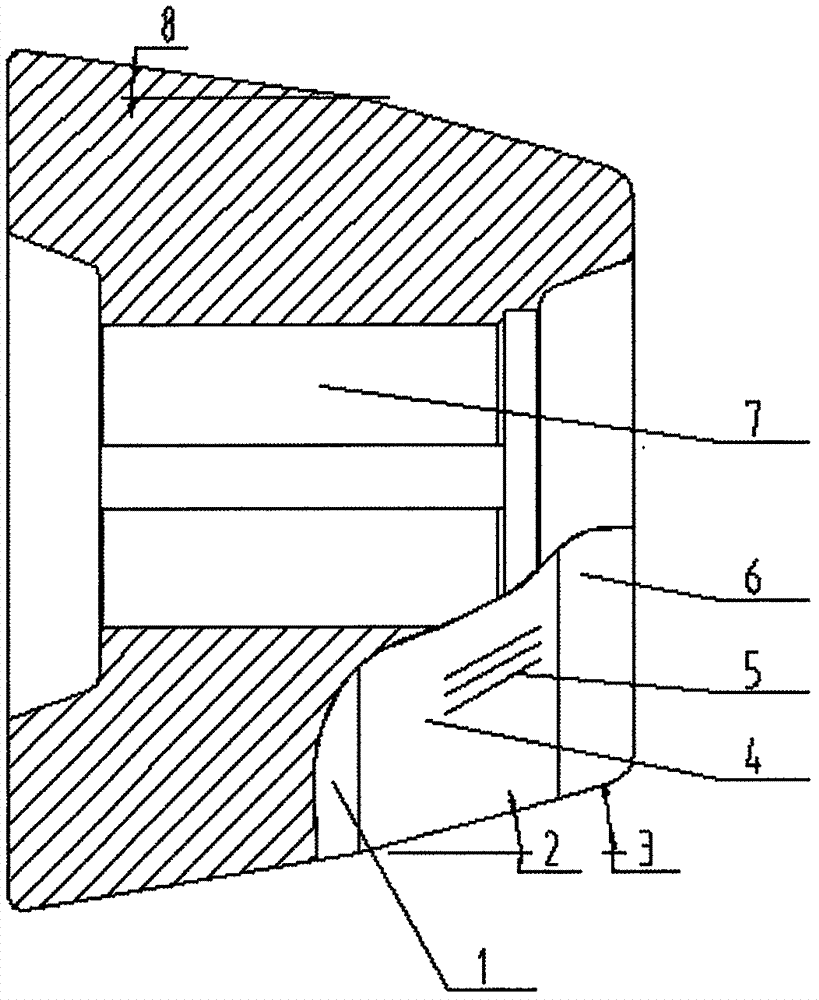

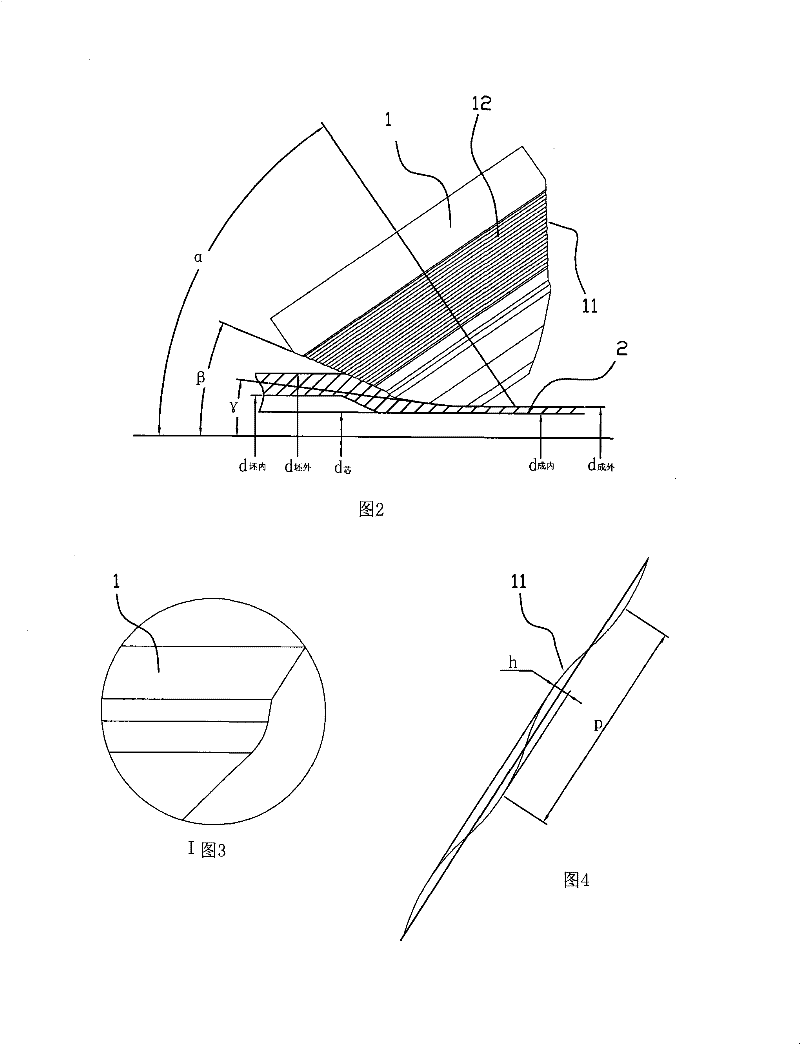

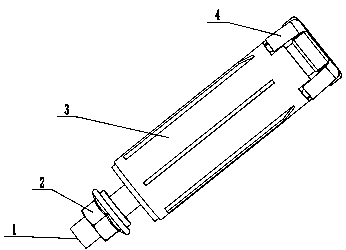

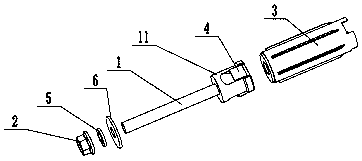

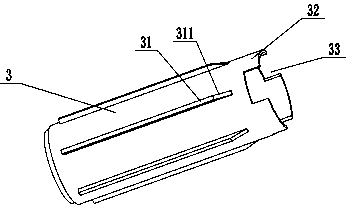

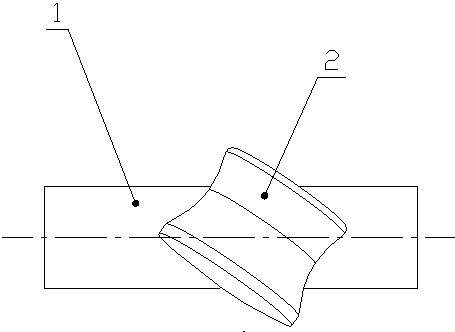

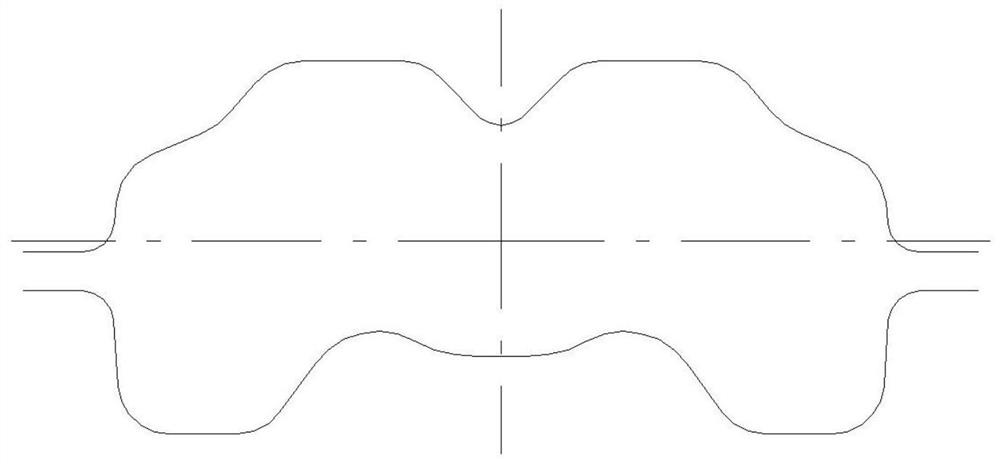

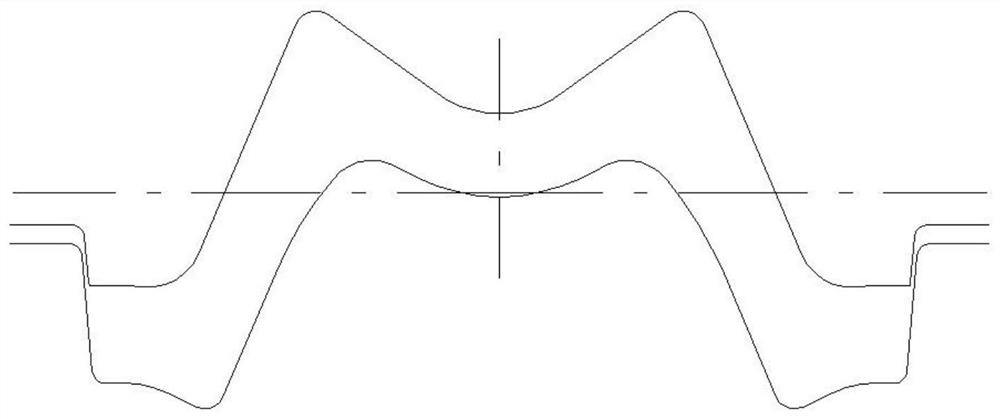

Roller of three-roller planetary rolling mill

ActiveCN101862754AExtended service lifeBite smoothlyRollsMetal rolling arrangementsProcess regionEngineering

The invention relates to a roller of a three-roller planetary rolling mill. The roller (1) is basically in a conical shape. The invention is characterized in that the roller (1) is divided into five regions from the tail part to the head part, and the five regions are sequentially a material inlet region (S), a deformation region (S1), a process region (S2), a sizing region (S3) and a material outlet region (S4), annular concavo-convex lines (12) are uniformly distributed in the radial direction on the conical surface of the roller (1) in the deformation region (S1) at intervals, and in addition, inclined lines (11) formed by the axial projection of the concavo-convex lines (12) are sinusoidal curves. Compared with the prior art, the invention has the advantages that the smooth feeding and continuous stable and efficient rolling of rolling element blanks can be ensured in the rolling process, in addition, the influence of the rolling element surface quality caused by the severe vibration of the blank deformation can be avoided, the thread pitch of the rolled pipe materials in actual operation is uniform and stable, and the service life of the roller is greatly prolonged.

Owner:NINGBO JINTIAN COPPER TUBE

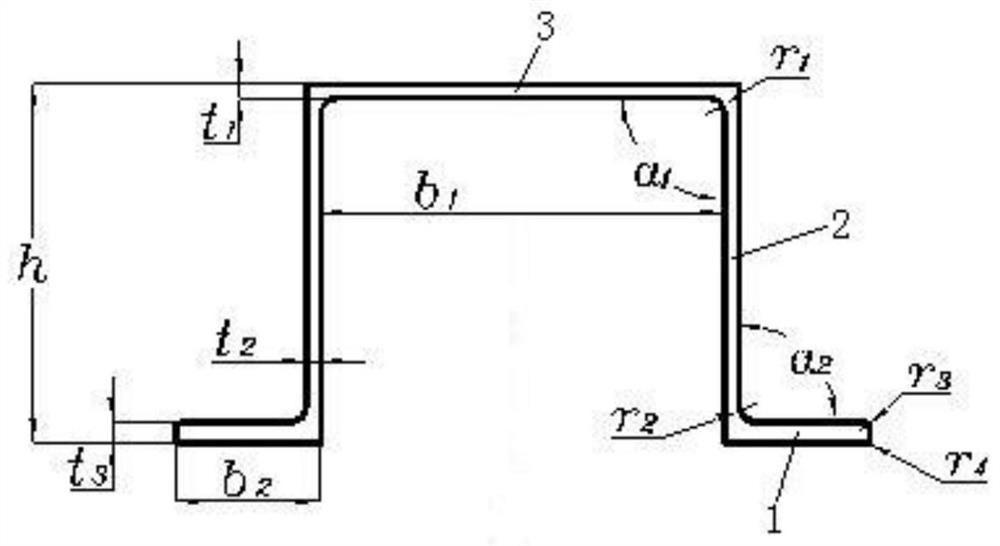

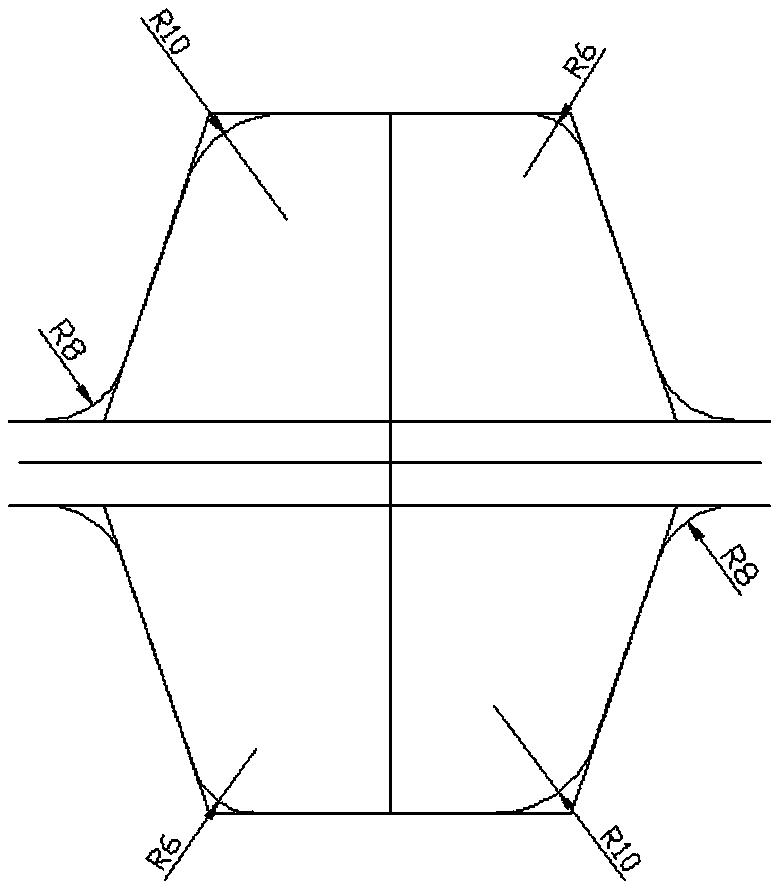

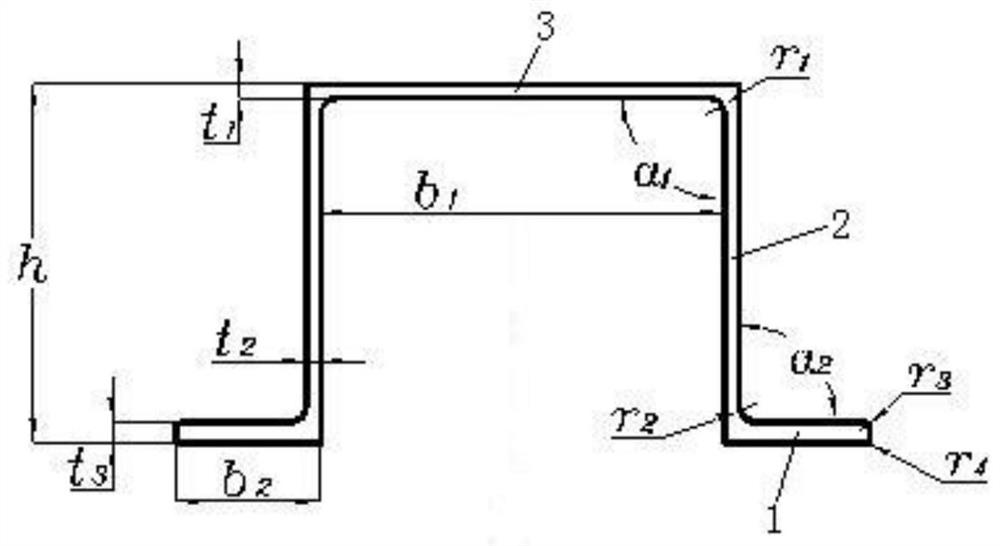

Hat shape steel rolling method and hat shape steel

ActiveCN112474794AReduce lossIncrease productivityTemperature control deviceRolling mill drivesStructural engineeringMechanical engineering

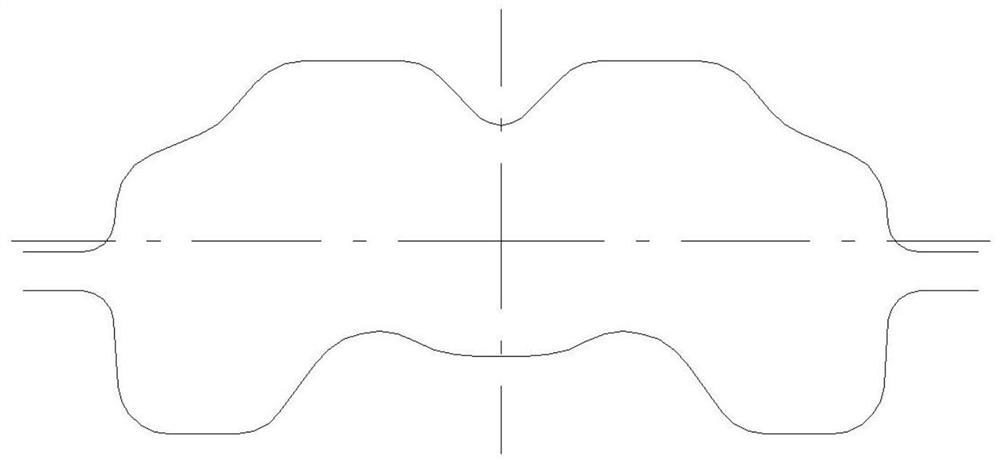

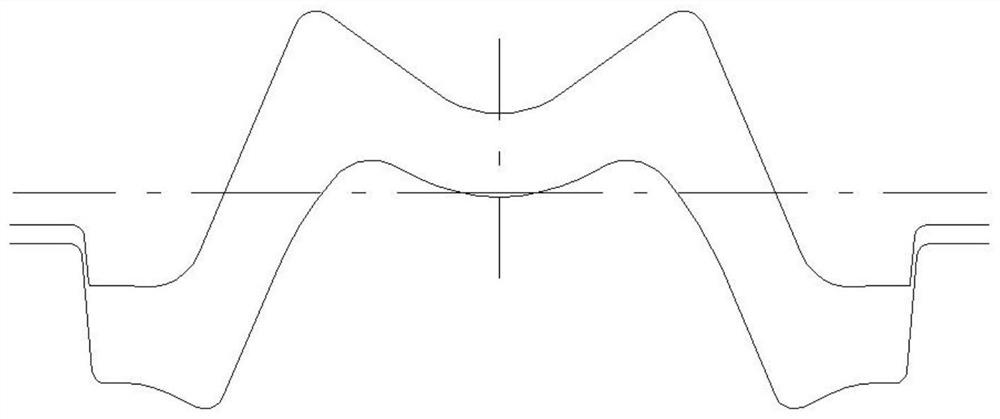

The invention discloses a hat shape steel rolling method and hat shape steel. The technological process of rolling comprises the steps of heating, high-pressure water descaling, cogging rough rolling,reciprocating type continuous rolling, cooling and straightening. A rolling hole pattern comprises a wavy flat arc-shaped pre-segmentation hole, an M-shaped n-type segmentation hole, an n-type finishrolling hole and a hot rolling finished product hole, arc-shaped sections are arranged in the middles of the n-type finish rolling hole and the hot rolling finished product hole, upper leg parts andlower leg parts are symmetrically arranged at the two ends of each arc-shaped section, and the upper ends of the upper leg parts and one ends of the arc-shaped sections intersect to form included angles; the lower leg parts are arranged at the lower ends of the sides, away from the arc-shaped sections, of the upper leg parts and intersect with the upper leg parts to form included angles; and the hat shape steel comprises a horizontal waist, vertical straight legs and horizontal flat legs are symmetrically arranged at the two ends of the waist respectively, and the flat legs are located at thesides, away from the waist, of the straight legs. According to the method, the production efficiency of the hat shape steel can be effectively improved, the rolling stability is improved, the processdesign difficulty is reduced, and the roller equipment loss is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

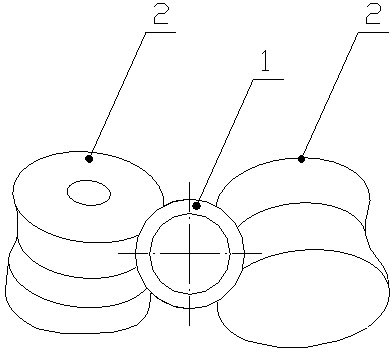

Fixing cutter group with positioning device

The invention discloses a fixed cutter group with a positioning device. The fixed cutter group comprises an upper cutter part and a lower cutter part, wherein the upper cutter part comprises an upper cutter shaft, and a cutting disc I and a cutter pad I which are arranged on the middle part of the upper cutter shaft at a uniform interval; the lower cutter part comprises a lower cutter shaft, and a cutter pad II and cutting disc II which are arranged on the middle part of the lower cutter shaft at a uniform interval; a guide cutter pad I, a guide cutter I and a positioning cutter pad are arranged on the left part of the upper cutter shaft; the guide cutter pad I is positioned on the left side of the guide cutter I; the positioning cutter pad is positioned on the right side of the guide cutter I; the cutting disc I, the cutter pad I, the guide cutter pad I, the guide cutter I and the positioning cutter pad are fixedly connected into a whole; a guide cutter II, a guide cutter pad II and a positioning cutter are arranged on the left part of the lower cutter shaft; the guide cutter II is positioned on the left side of the guide cutter pad II; the positioning cutter is positioned on the right side of the guide cutter pad; and the cutter pad II, the cutting disc II, the guide cutter II, the guide cutter pad II and the positioning cutter are fixedly connected into a whole. The fixed cutter group has a reasonable design, high processing accuracy and high processing efficiency, and is convenient to detach and use.

Owner:THE NORTHWEST MACHINE

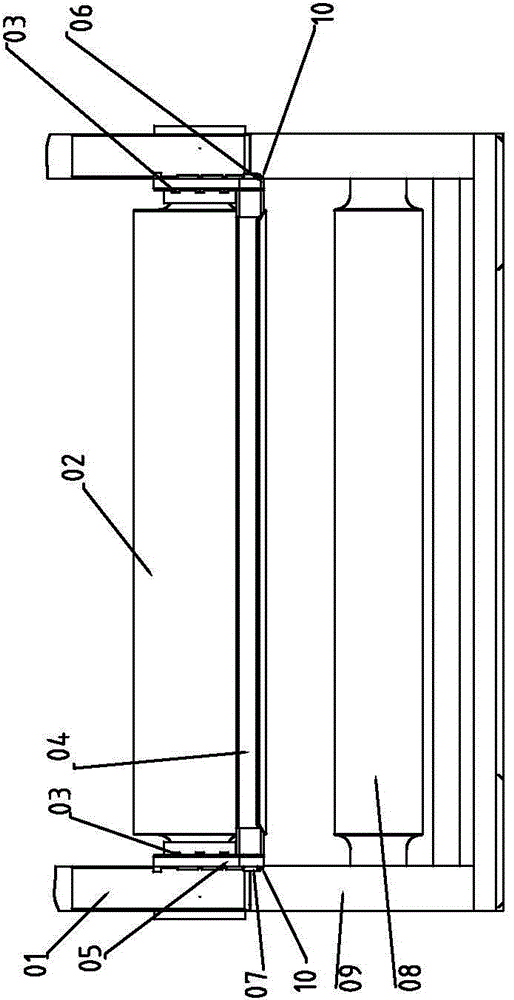

Vertical mill inlet shared induction device

ActiveCN102728628BExtended service lifeImprove physical qualityGuiding/positioning/aligning arrangementsRolling millSpare part

The invention provides a vertical mill inlet shared induction device, which consists of a fixing bracket, a guide body, an upper supporting arm, a lower supporting arm, a guide roller, a guide roller opening adjusting mechanism and a guide body horizontal movement mechanism, wherein the billet moves in a space formed by the upper and lower supporting arms and a side baffle, is guided by the guide roller and the side baffle and is correctly engaged with a rolling mill; when the milling specification is changed, an adjusting handle is rotated, the upper supporting arm drives the upper guide roller to lift to meet the novel specification requirement; the supporting arm stretches into two rollers on an inner frame, the guide plate body moves backwards in the process of replacing the rollers, and the supporting arms and the guide rollers retract the rollers and the arch of the inner frame; and therefore, the guide device is not required to be replaced in the process of replacing the rollers, the roller replacing time can be obviously shortened, the operate rate of the rolling mill is improved, the service life of the guide device is greatly prolonged, the storage and consumption of spare parts are reduced, and the production cost is reduced; and meanwhile, the scratch defect on the surface of a rolled piece can be overcome, and the quality of the finished rolled product is improved.

Owner:ANGANG STEEL CO LTD

Rolling method of small and medium shipbuilding flat-bulb steel

InactiveCN108787742ALess investmentImprove rolling conditionsMetal rolling arrangementsStrip millSteel mill

The invention relates to a rolling method of small and medium shipbuilding flat-bulb steel. A direct rolling method is used for rolling the small and medium shipbuilding flat-bulb steel, and relevantrolling equipment includes 3-5 three-roller section steel mills, and all the three-roller section steel mills are horizontally arranged. The rolling process comprises the steps of (1) rough rolling, specifically, a box-type hole is rolled, and a special-shaped flat-bulb steel section is rolled on a rolled piece; (2) intermediate rolling, specifically, metal of a bulb and a web is distributed, thespecial-shaped rolled piece subjected to rough rolling is forced to be widened through large reduction to complete metal distribution of the bulb and the web at a time, and the metal proportion is setaccording to the proportion of finished flat-bulb steel; and (3) finish rolling, specifically, the rolled piece subjected to intermediate rolling and approximate to the flat-bulb steel is variably rolled to obtain an inclination angle of the bulb, and the aspect ratio of the bulb and the web of the finished flat-bulb steel is ensured. By adoption of the rolling method of the small and medium shipbuilding flat-bulb steel, the objectives of high yield and low consumption can be achieved during batch production of the shipbuilding flat-bulb steel, the work efficiency can be improved, the marketrequirement is met, and the benefits of enterprises are increased.

Owner:ANGANG STEEL CO LTD

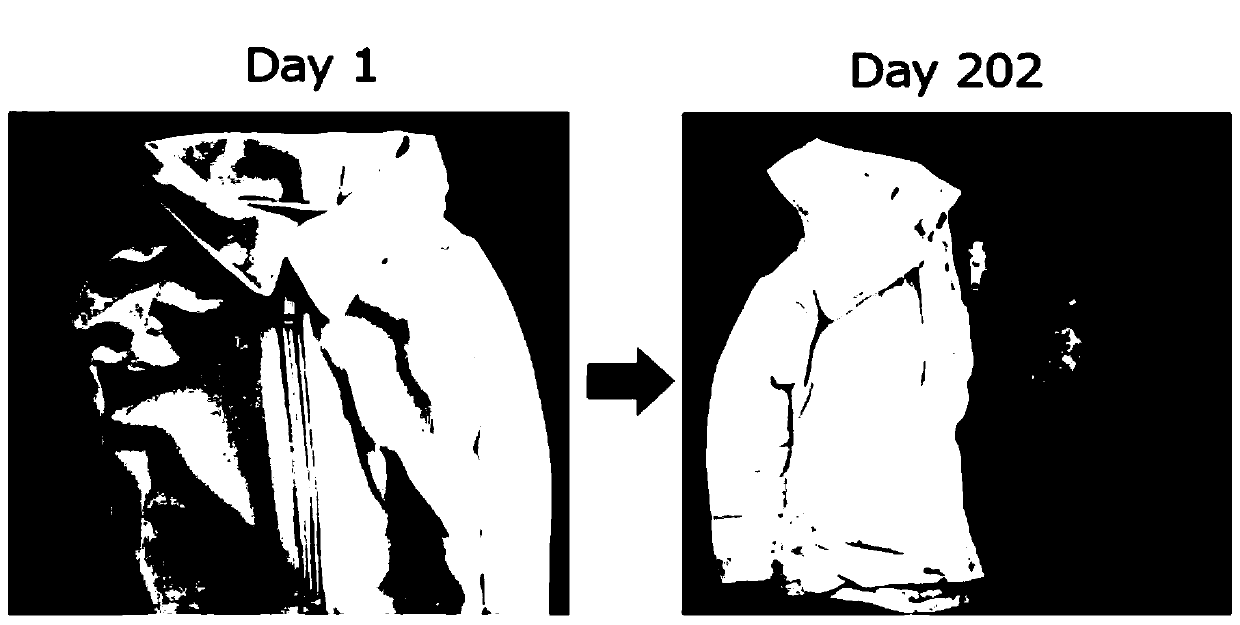

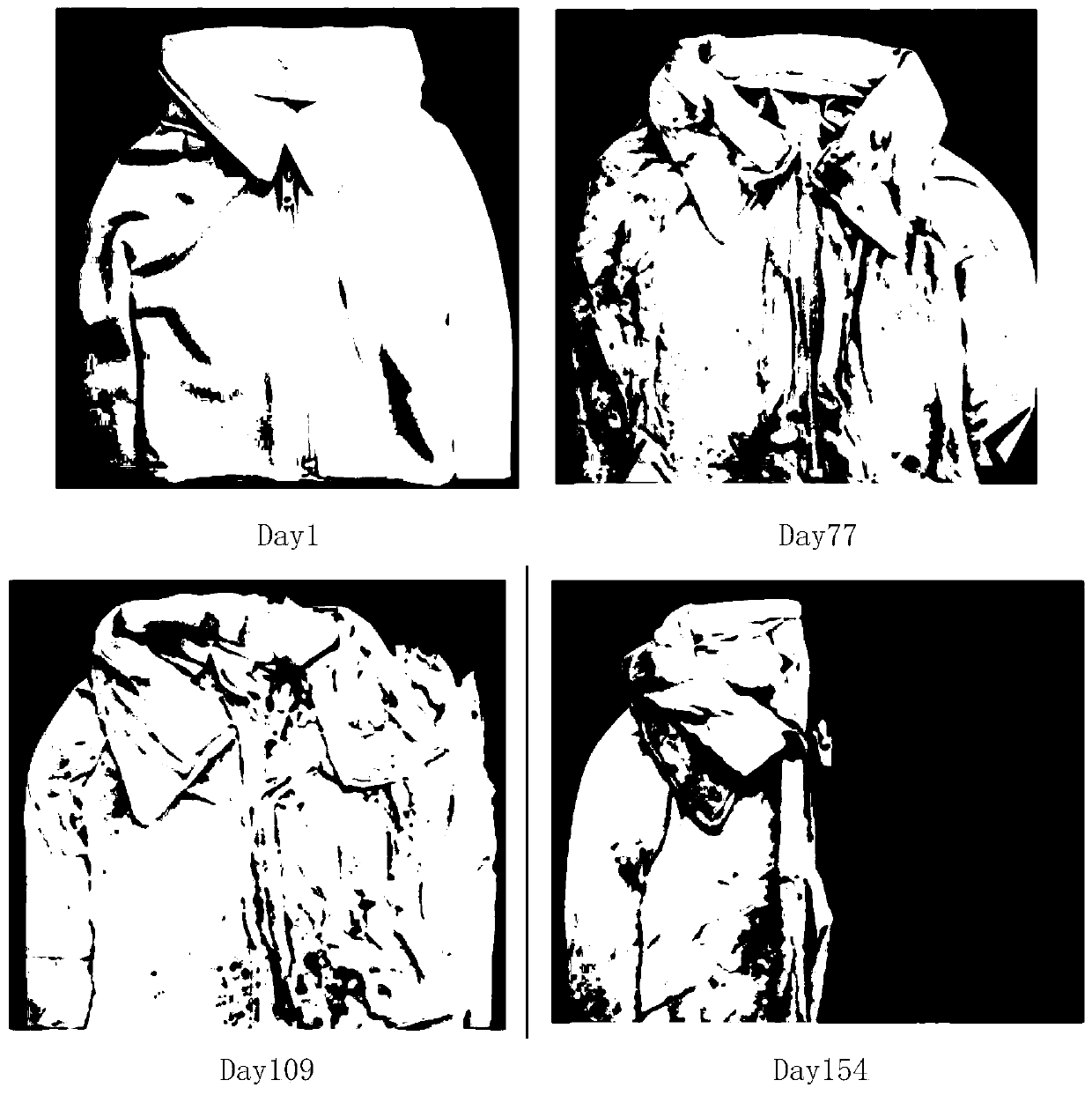

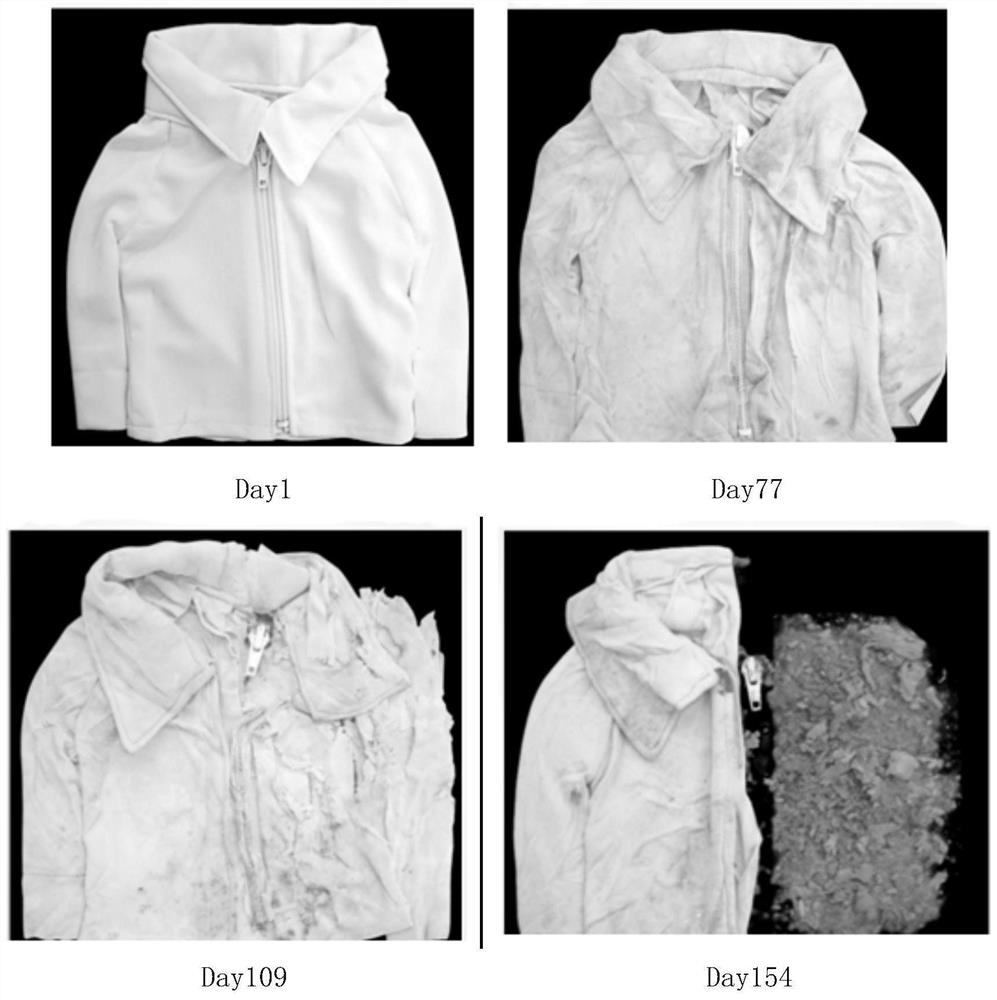

Composite polyester and preparation method thereof

ActiveCN110983480AContent will not decreaseAchieve fully biodegradable functionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention discloses composite polyester and a preparation method thereof. The composite polyester comprises a fiber body and microcapsules uniformly formed in the fiber body; each microcapsule comprises a microcapsule core material and a microcapsule wall material coated outside the microcapsule core material; the microcapsule core material comprises the following components in percentage by weight of 20-40 wt% of polyester enzyme bacteria, 10-60wt% of mixed plant oil and 10-20wt% of sucrose ester; the polyester enzyme bacteria can be metabolized to generate polyester enzyme; and the microcapsule wall materials are edible natural polymer materials. The preparation method of the composite polyester comprises the following steps of preparing microcapsule wall material hydrosol, preparingthe polyester enzyme bacteria, preparing a microcapsule core material water emulsion, preparing the microcapsules and preparing the polyester. The composite polyester obtained by adopting the technical scheme has high stability in the fiber body in the microcapsule, and the composite polyester product can attract microorganisms in the environment to eat the micro-fibers after being discarded, sothat the problem that the polyester cannot be degraded and the hidden danger of the ecological environment exists is solved.

Owner:ANTA CHINA

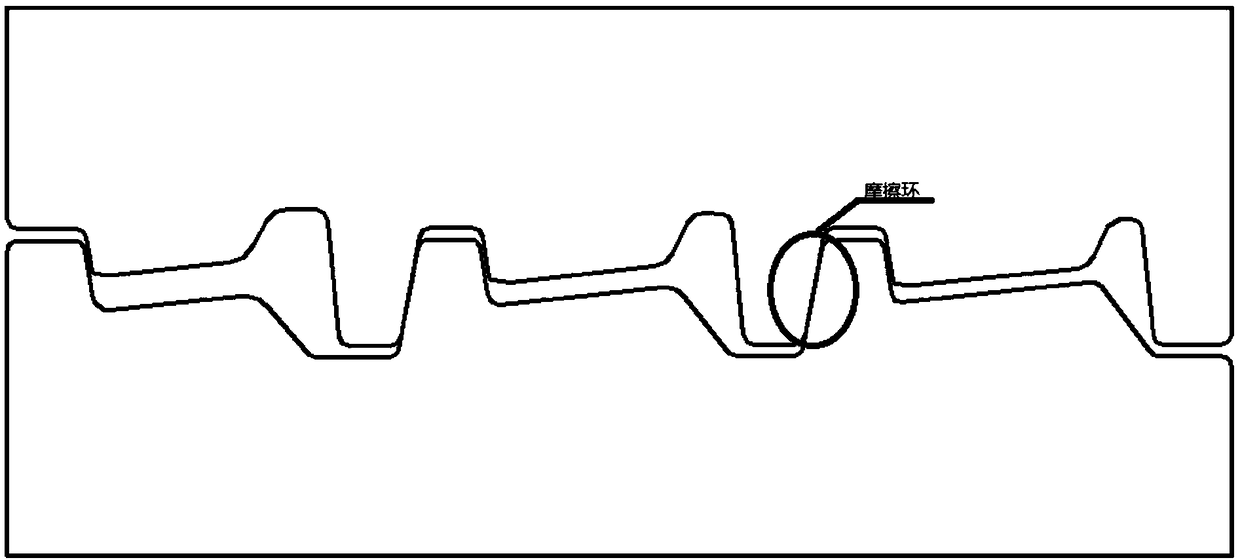

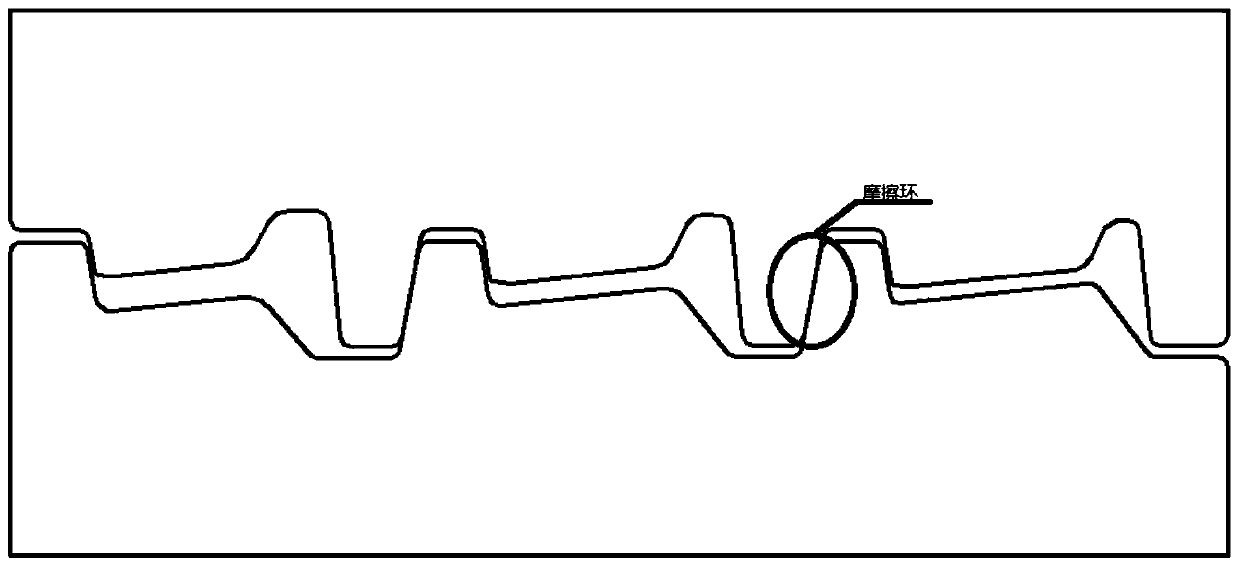

Rolling method of symmetric flat-bulb steel for large-scale shipbuilding

ActiveCN109261714AImprove mechanical propertiesEliminate organizational defectsWork cooling devicesMetal rolling arrangementsHigh pressure waterWater cooling

The invention relates to the technical field of flat-bulb steel rolling, in particular to a rolling method of symmetric flat-bulb steel for large-scale shipbuilding. The oblique rolling method is adopted for rolling. A rolling device comprises a two-roller type section mill, three to five three-roller type section mills, wherein the three-roller type section mills are arranged transversely. The specific rolling process comprises the following steps of rough rolling, moderate rolling, frictional ring arrangement, fine rolling and forced cooling after rolling, wherein high-pressure water mist issprayed by using a water cooling device, and accurate cooling is performed by accurately adjusting a bulb and the flow of web plate water mist. By adopting the oblique rolling method, the installingdifficulty of a foreplate and the labor intensity of steel rolling workers are reduced on the premise that the problem of insufficient length of each roller body is solved; the bulb metal filling amount and web plate width precision are ensured; by arranging frictional rings, web plate waves are avoided, and the surface quality of rolled pieces is improved.

Owner:ANGANG STEEL CO LTD

Novel anti-wrap guide plate device for pinch roller of steckel mill

The invention relates to a novel anti-wrap guide plate device for a pinch roller of a steckel mill. The novel anti-wrap guide plate device for the pinch roller of the steckel mill is characterized in that a left support and a right support are respectively fastened on an upper pinch roller support through bolts; a scraper blade is respectively connected with the left support and the right support through pin shafts; the pin shafts are clamped by baffles; the tip end of the scraper blade is tangent to and tightly fit to the outer circumference of the cross section of the upper pinch roller. With the novel anti-wrap guide plate device for the pinch roller of the steckel mill adopting the technical scheme, thin strip steel can be effectively prevented from wrapping on the pinch roller, oxidized scales adhered to the surface of the pinch roller can be effectively removed, impurities such as the oxidized scales can be prevented from being fed into the pinch roller, and the strip steel can be ensured to be smoothly bitten and rolled, so that high-quality strip steel can be ensured to be produced.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

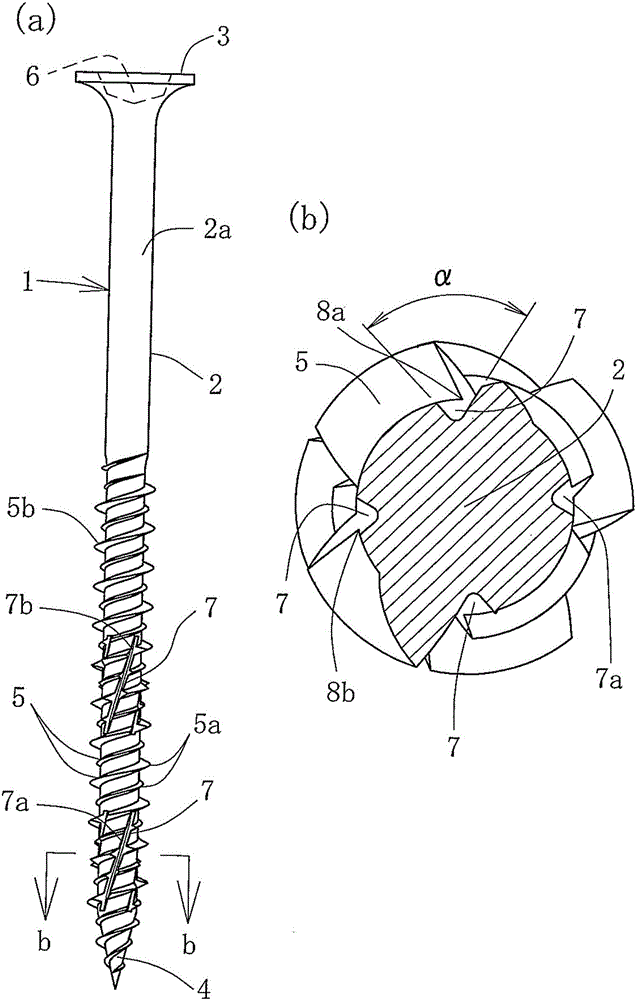

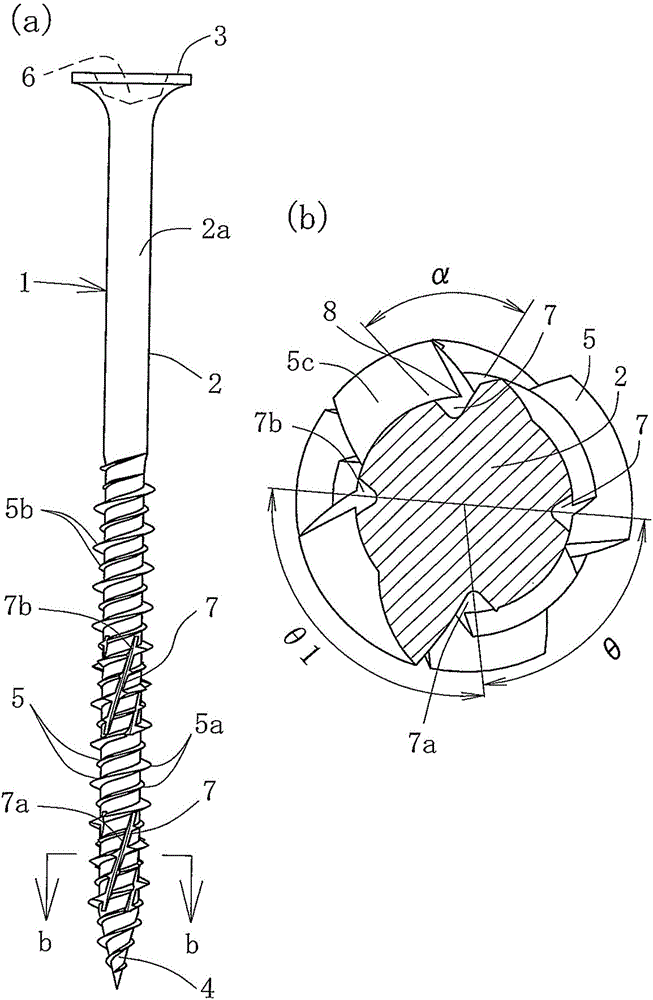

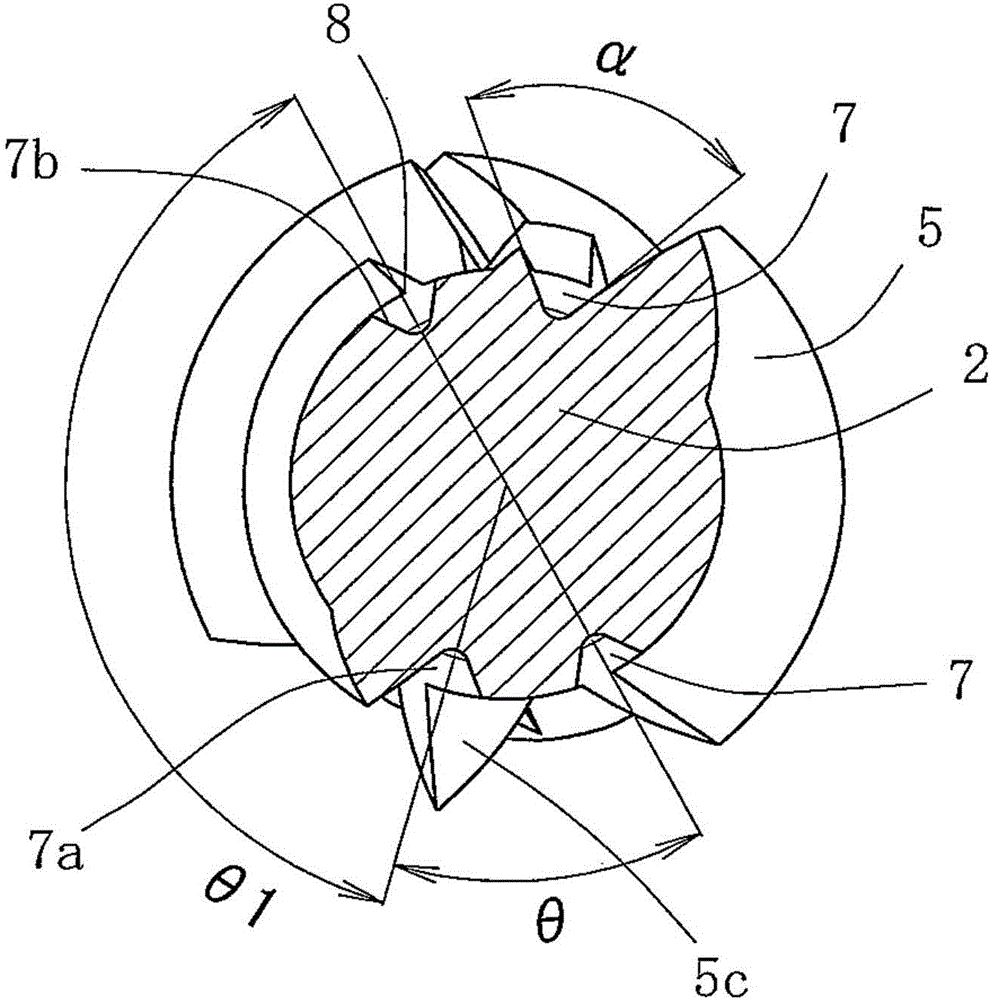

Wood screw

The invention provides a wood screw which cannot damage tightening performance in fastening state and can restrain the reduction of pulling resistance strenth after tightening. The wood screw (1) comprises a head (3) on one side of a shaft (2) and comprises a front end (4) on the other side, screw thread (5) spreads from the front end (4) of the shaft (2), cutting grooves (7) are respectively arranged with intervals on a plurality of axial positions along the shaft (2) and on the screw thread (5) of the shaft (2), the cutting grooves (2) have lengths which can make a plurality of scread threads (5) to be cut and are deeper than grooves of the scread threads (5), and grooveless screw thread (5a) are left between the ends of the cutting grooves (7) abutted along the axial direction of the shaft (2).

Owner:WAKAI & CO LTD

Gripping control method in rolling process of heavy rail

ActiveCN103157669AEnough kinetic energyBite smoothlyRoll speed control deviceEngineeringIntelligent control

The invention relates to the field of control of a rolling process, in particular to a gripping control method in a rolling process of a heavy rail. The gripping control method in the rolling process of the heavy rail is characterized in that the rotation speed of a main motor of a universal rolling mill is adjusted, so that a rolling piece obtains enough kinetic energy and grips a hole of a UR roller. The particular operation steps are as follows: (1) before the rolling piece enters the UR roller of the universal rolling mill, hole water is closed, and an automatic rolling program of the universal rolling mill is stopped; (2) after the rolling piece arrives transversely, the rotation speed of the main motor of the universal rolling mill is improved to 100-110 turns per minute; (3) the rolling piece is abraded on the UR roller for 30-40 seconds, and then the rotation speed of the main motor of the universal rolling mill is reduced to 10-20 turns per minute until the rolling piece grips the hole; and (4) after the rolling piece grips the hole by 2-3 meters, the rolling pieces is poured out by hand, and the automatic rolling program of the universal rolling mill is recovered. Compared with the prior art, the gripping control method in the rolling process of the heavy rail has the advantages of enabling the rolling piece to grip the hole of the UR roller smoothly, achieving intelligent control, and being suitable for the heavy rail with the level of more than 50 kilos.

Owner:ANGANG STEEL CO LTD

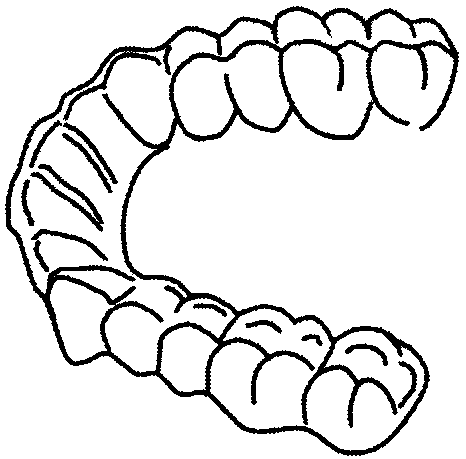

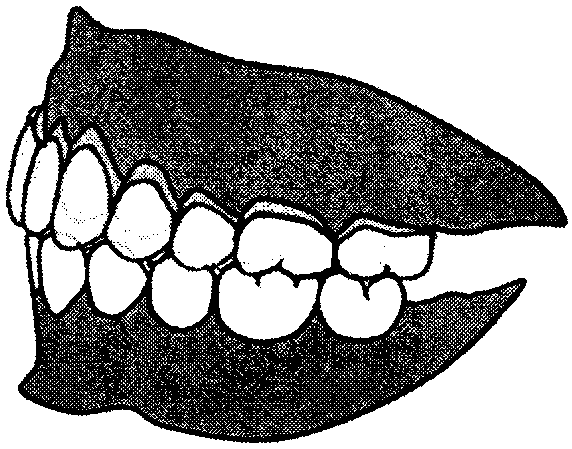

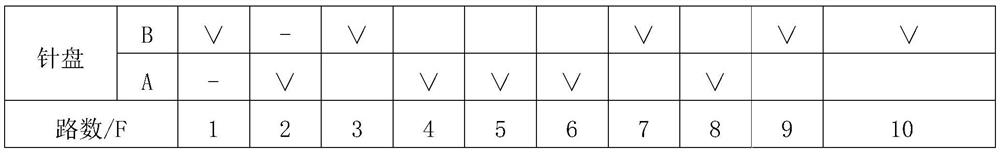

Whole-process digital designed produced personalized sleep bruxism protective occlusal splint

PendingCN110353868AHigh precisionSave materialNon-surgical orthopedic devicesComputer-aidedDentition

In view of the shortage of manufacturing methods and materials of a conventional sleep bruxism protective occlusal splint, the invention provides a sleep bruxism protective occlusal splint prepared byapplying digital impression, computer-aided design and computer-aided manufacturing. The sleep bruxism protective occlusal splint is characterized in that upper and lower jaw dentition data and the occlusal relationship after occlusal elevation are obtained by an intraoral scanning technology, and upper and lower jaw dentition digital models and the occlusal relationship are matched with a virtual occlusal frame system of a computer; with computer-aided design software, front and rear dental cusps can be guaranteed to be in even contact with the occlusal splint; a material is cut through a computer-aided manufacturing device, medical-grade engineering plastic polyether-ether-ketone (PEEK), polyether ether sulfone (PEES) or polyether sulfone (PES) with excellent performance is used, the selected material can be determined according to the order of severity of sleep bruxism and the type of a restoration body of teeth of a patient, a final restoration body is obtained and is worn into amouth, and the dentition is protected and abnormal wear is prevented. The method aims at simplifying and optimizing the manufacturing process of the sleep bruxism protective occlusal splint, reduces discomfort, saves cost, and is beneficial to environmental protection.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

A slider type expansion bolt

The present invention provides a slider-type expansion bolt, comprising: a bolt body, an outer casing, and a nut; the outer casing is arranged outside the bolt body; the nut cooperates with the bolt body; A washer and a spring pad are provided, wherein the outer sleeve is provided with a sliding hole, and a slider is installed in the sliding hole, and when the nut drives the bolt body to move, the bolt body can push the slider The block slides outward to lock. The present invention drives the bolt body to rotate outward through the nut, and the front part of the bolt body pushes the slider to slide outward so that the slider can be inserted into the wall. Since the slider of the device slides outward and is inserted into the wall, the depth is relatively deep. , When used on materials with low hardness such as: hollow bricks, wood, cardboard, rubber, etc., it can also produce deeper bites and can be firmly fixed.

Owner:金华市荣创五金工具有限公司

A kind of composite polyester and preparation method thereof

ActiveCN110983480BContent will not decreaseAchieve fully biodegradable functionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPolymer science

A composite polyester fiber and a preparation method thereof have been disclosed. The composite polyester fiber includes a fiber body and a microcapsule uniformly formed in the fiber body; the microcapsule includes a microcapsule core material and a microcapsule wall material coated on the microcapsule core material; The capsule core material includes the following components by weight percentage: 20-40wt% of polyester enzyme bacteria, 10-60wt% of vegetable sesame oil, 10-20wt% of sucrose ester; polyester enzyme bacteria can metabolize to produce polyester enzyme; microcapsule wall material is edible of natural polymer materials. The preparation method of composite polyester comprises the following steps of preparing microcapsule wall material hydrosol, preparing polyester enzyme bacteria, preparing microcapsule core material water emulsion, preparing microcapsule and preparing polyester. The composite polyester obtained by the above technical solution has good stability in the presence of microcapsules in the fiber body, and the composite polyester product can attract microorganisms in the environment to eat the microfibers after being discarded, thus solving the problem that polyester cannot be degraded. However, there are problems that endanger the ecological environment.

Owner:ANTA CHINA

A control method of automatic pressure head for aluminum hot rolling rough rolling

ActiveCN105834216BReduce labor loadReduced risk of roll wrappingRoll mill control devicesMetal rolling arrangementsProduction lineAutomatic control

The invention relates to an aluminum hot rolling and rough rolling head pressing technology and an automatic head pressing control method. According to the site production conditions that when rolling is conducted on a heavy shearing pass, the head of a blank is seriously opened; a roller bed between a rough mill and a finishing mill is short; and when five-system aluminum alloy is rolled, the head rises seriously in the pass which is conducted after the heavy shearing pass, the control method that automatic head pressing is conducted on the heavy shearing pass, the end pass and the pass (not containing the end pass) which is conducted after the heavy shearing pass when the five-system aluminum alloy is rolled is provided. According to the aluminum hot rolling and rough rolling automatic head pressing control method, by controlling head pressing automatically, impact of the head of the blank on equipment is reduced, successful biting of the finishing mill is ensured, the risk that the blank is wound when the five-system aluminum alloy is rolled is reduced, and guarantee is supplied to successful operation of the whole production line.

Owner:UNIV OF SCI & TECH BEIJING

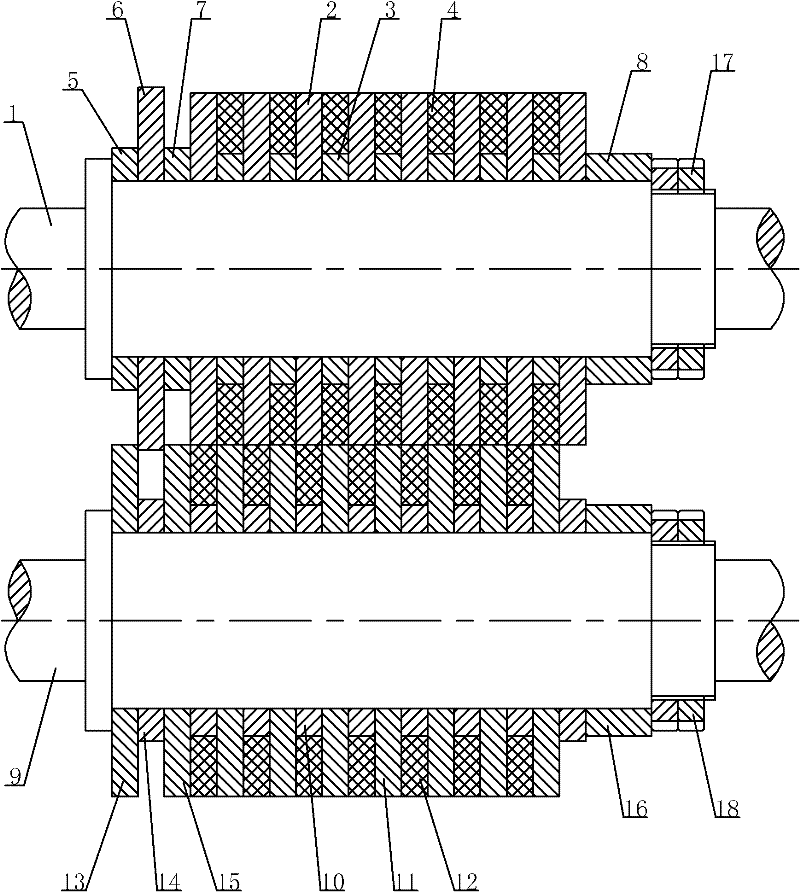

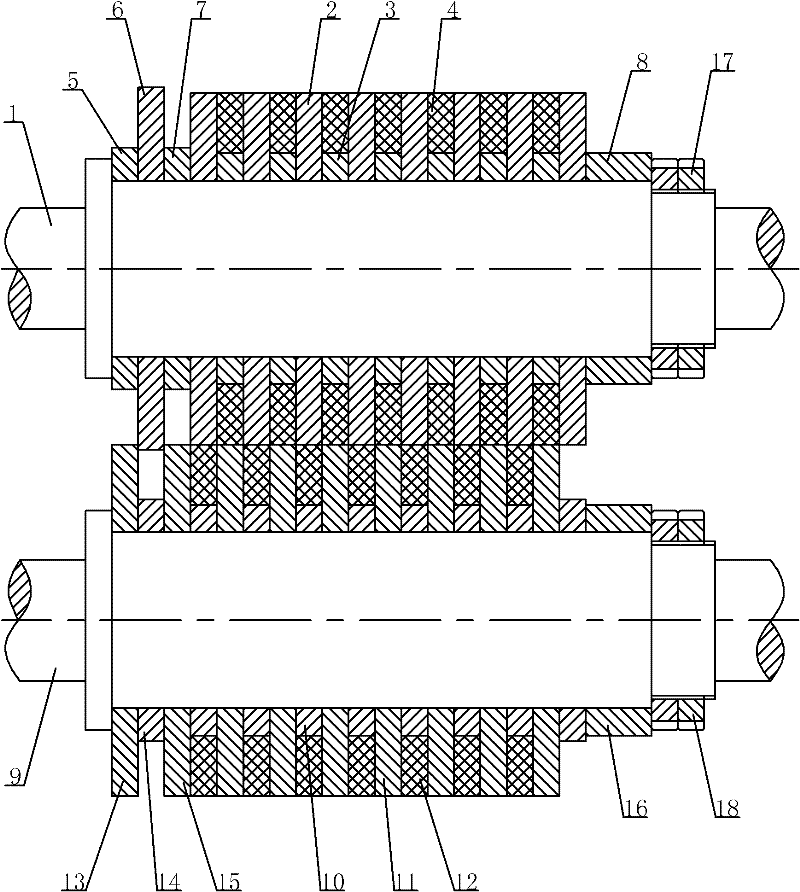

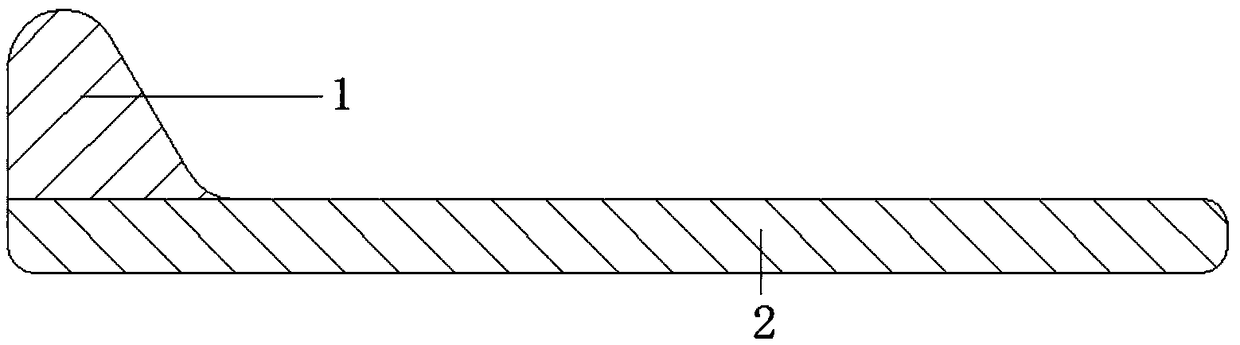

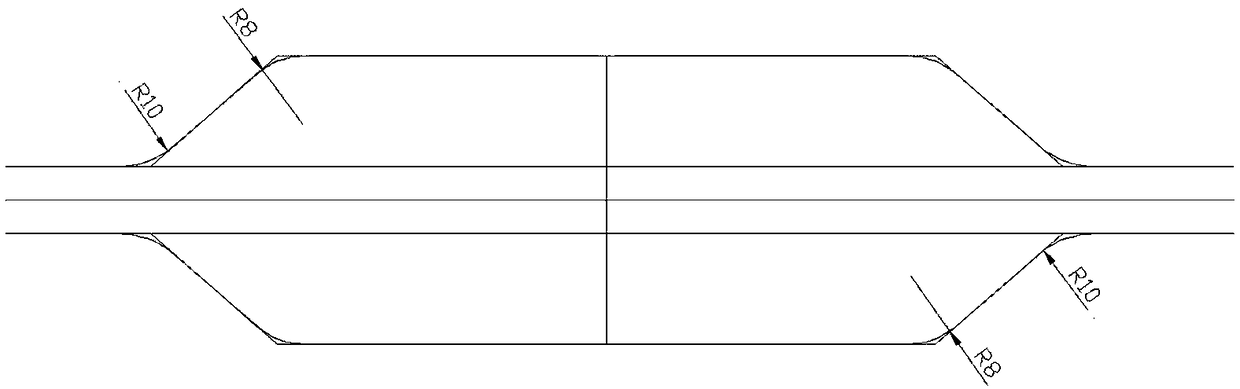

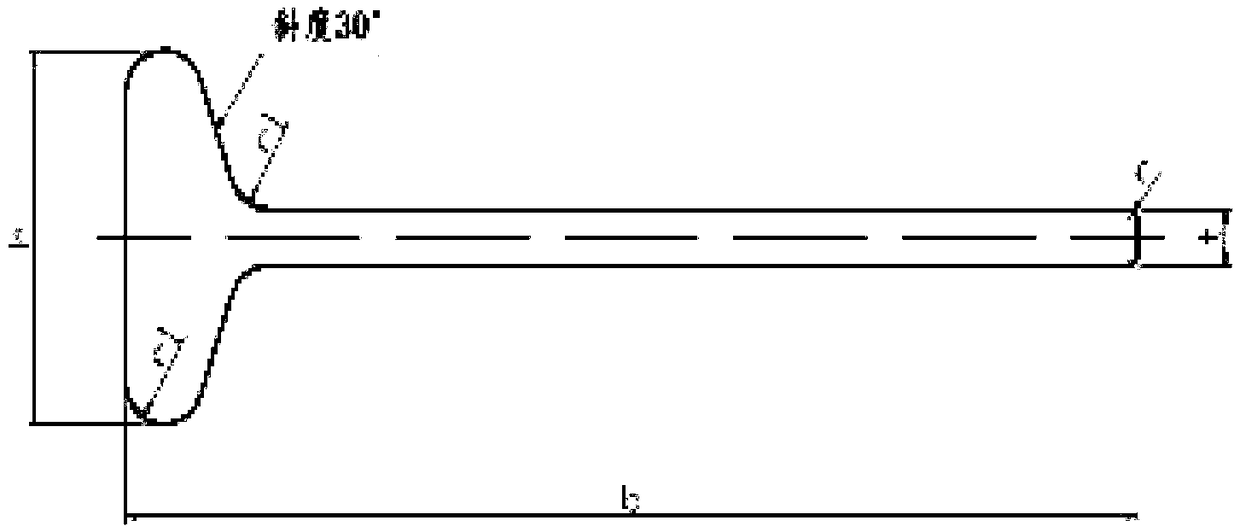

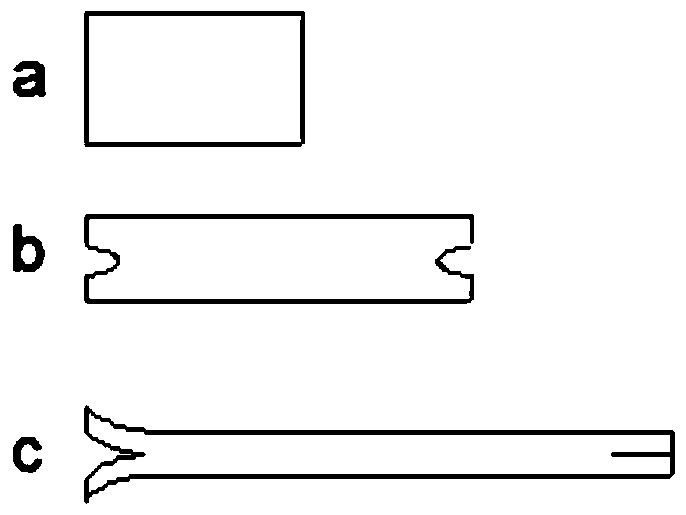

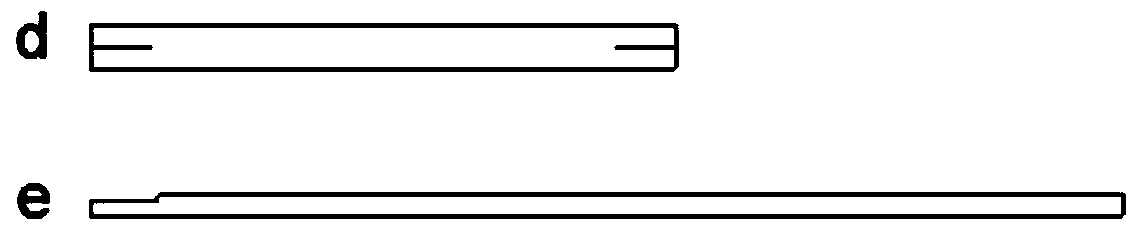

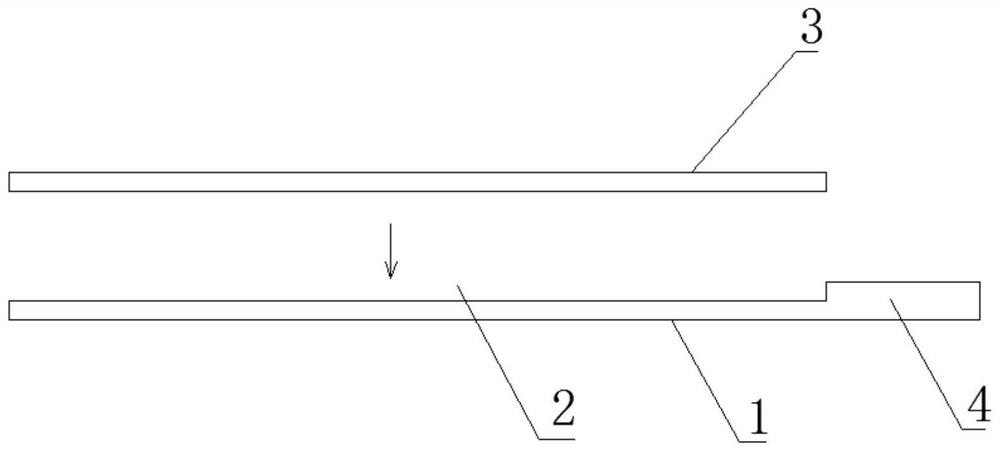

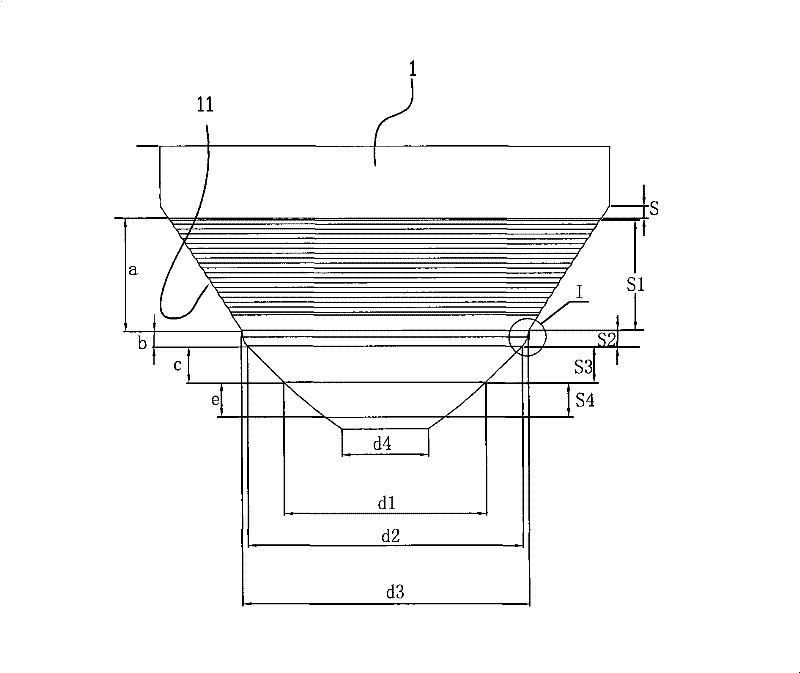

Preparation method of composite board assembly capable of ensuring smooth biting of roll and rolling method

PendingCN114505343AReduce the difficulty of productionBite smoothlyMetal rolling arrangementsComposite platePumping vacuum

The invention relates to the technical field of hot rolling of composite plates, in particular to a preparation method of a composite plate assembly capable of ensuring smooth biting of a rolled plate and a rolling method. Comprising the following steps: S1, selecting a base material and a composite material; s2, processing a processing surface at one end of the base material into a sunken plane, and forming a base material end head at the other end; s3, the sunken plane at one end of the base material and the clean surface of the composite material are attached and assembled, after the composite material and the base material are pressed and short edges of the composite material and the base material are welded, the composite material and the base material are fed into a vacuum chamber to be vacuumized, electron beam welding is conducted on the rest edges of the composite material and the base material under the high vacuum degree, and a composite plate assembly is obtained; and S4, the end of the heated composite board assembly base material is rolled in front of the composite board assembly base material. The rolling production difficulty of the thin-specification single-face stainless steel composite plate is reduced, and the equipment safety and the production efficiency are improved.

Owner:SD STEEL RIZHAO CO LTD

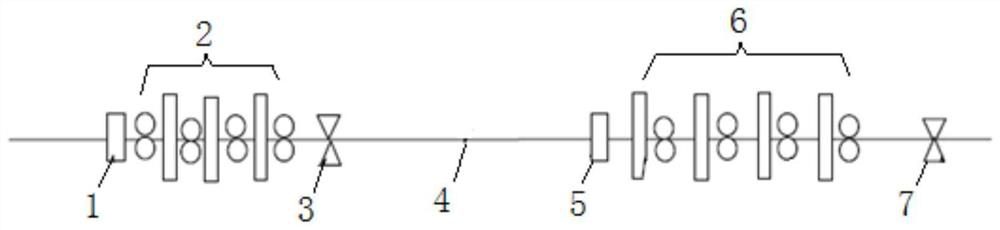

A special steel large bar rolling line and rolling method

ActiveCN111330971BIncrease production costIncrease productivityMetal rolling arrangementsPearliteContinuous rolling

The invention discloses a special steel large bar rolling line and rolling method, using a semi-continuous rolling rolling production line of "7 racks rough rolling + head-off roller table + 8 racks intermediate finishing rolling", specifically including sequentially setting The 1# pinch roll, rough rolling unit, hydraulic shear, head-off roller table, 2# pinch roll, middle finishing rolling unit and double-length shear. The 7 rough rolling stands are arranged alternately, using two-roller short stress line rolling mill, 1#-2# roll diameter φ950mm, cast steel rolls that can be surfacing, and 3#-4# roll diameter φ800mm, cast steel can be surfacing Roll, 5#-7# rolling mill roll diameter φ700mm, using pearlitic nodular molybdenum cast iron II roll. The 8 middle finishing mills are alternately arranged horizontally and vertically and all adopt two-high short stress line rolling mills. The rolling process based on this rolling line can not only ensure the quality of special steel large bars, but also improve the production efficiency of the large bar production line, and greatly reduce the investment cost of the production line.

Owner:ZENITH STEEL GROUP CORP CO LTD

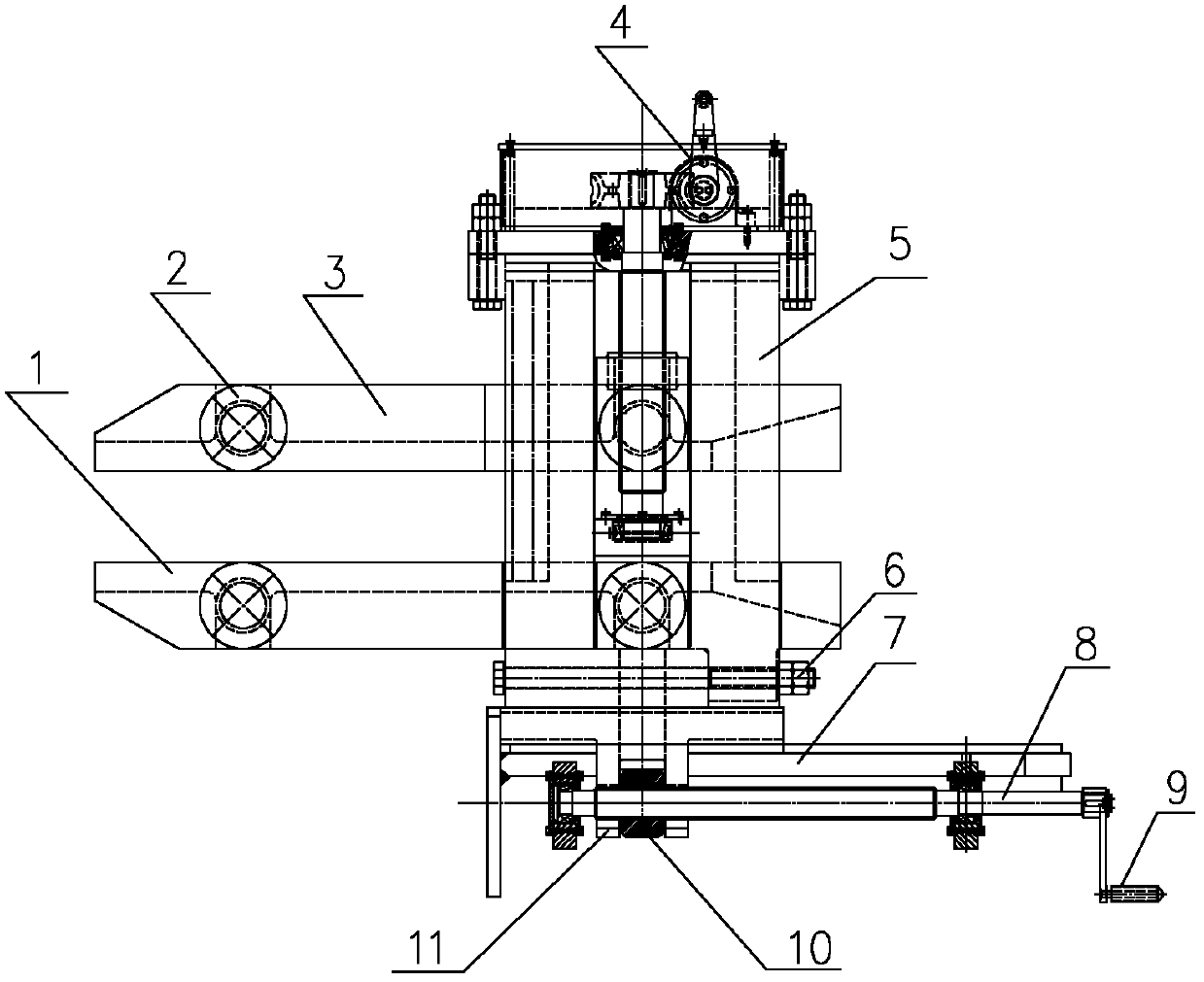

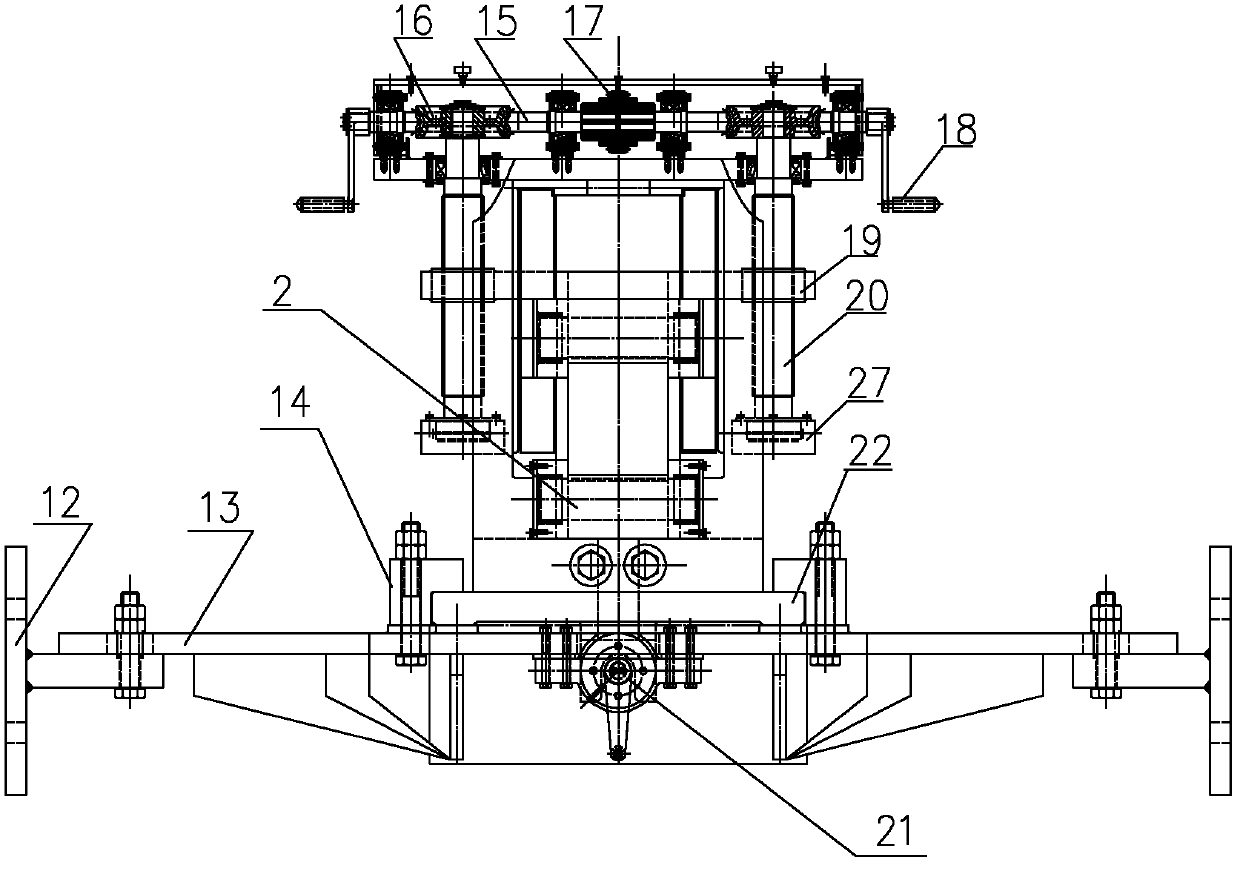

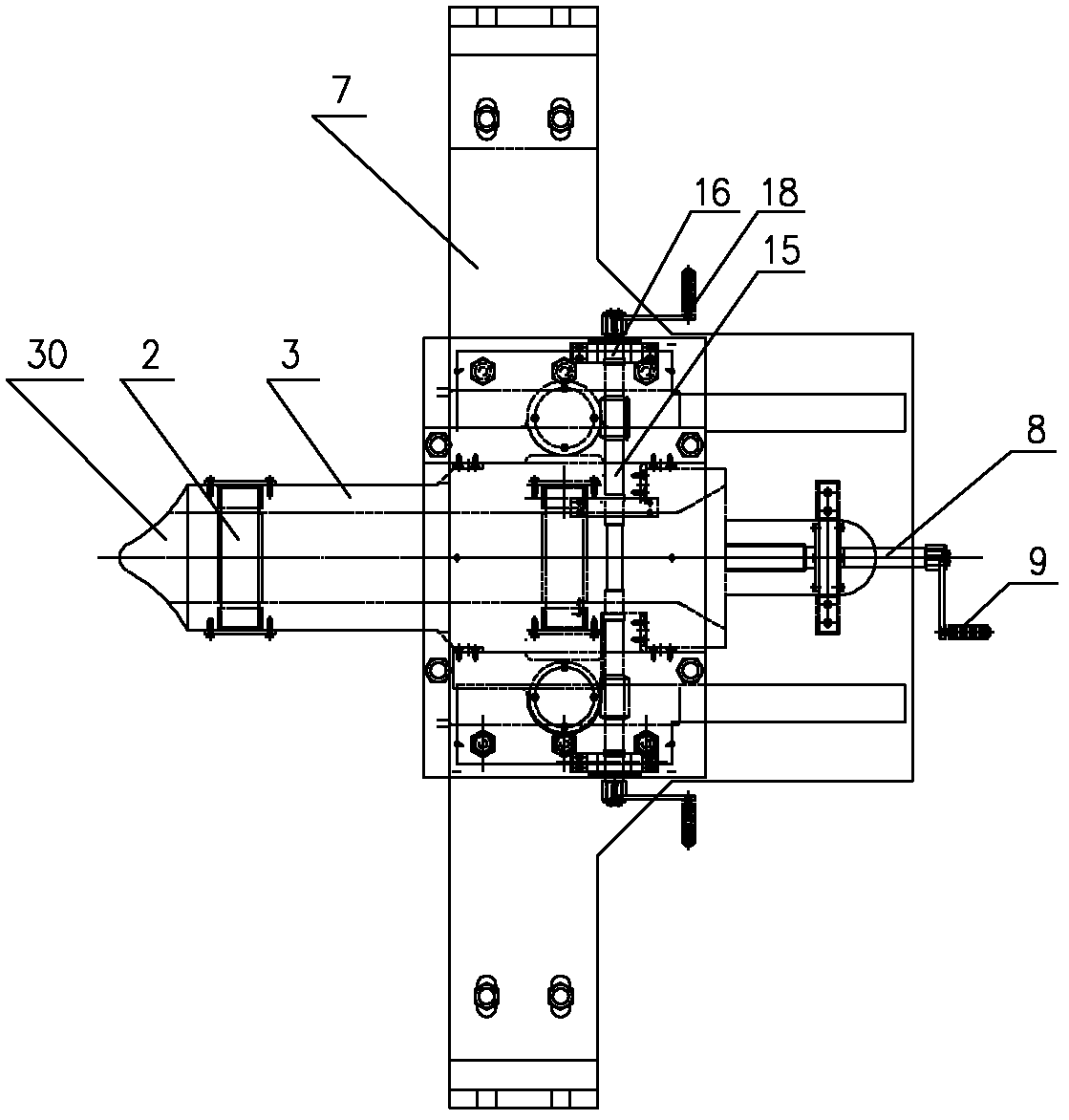

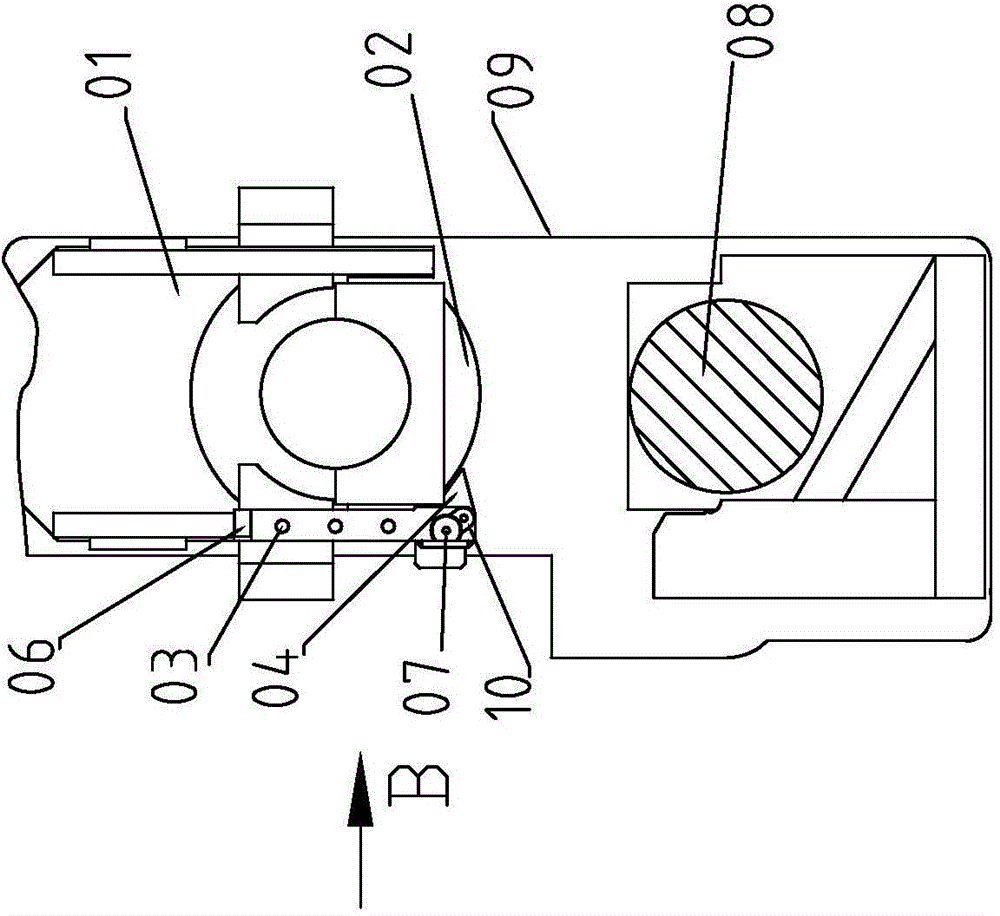

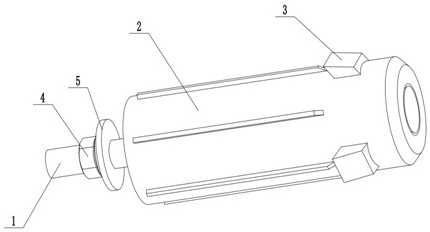

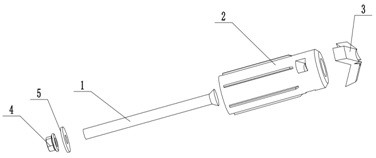

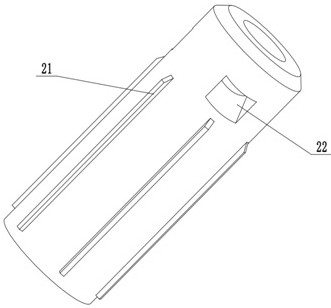

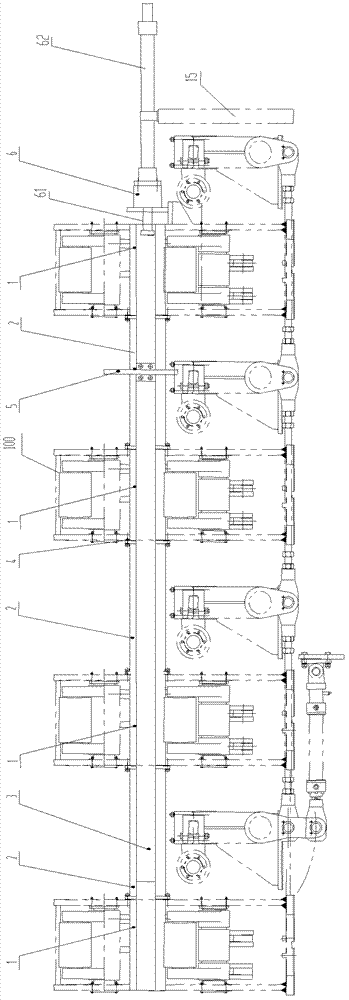

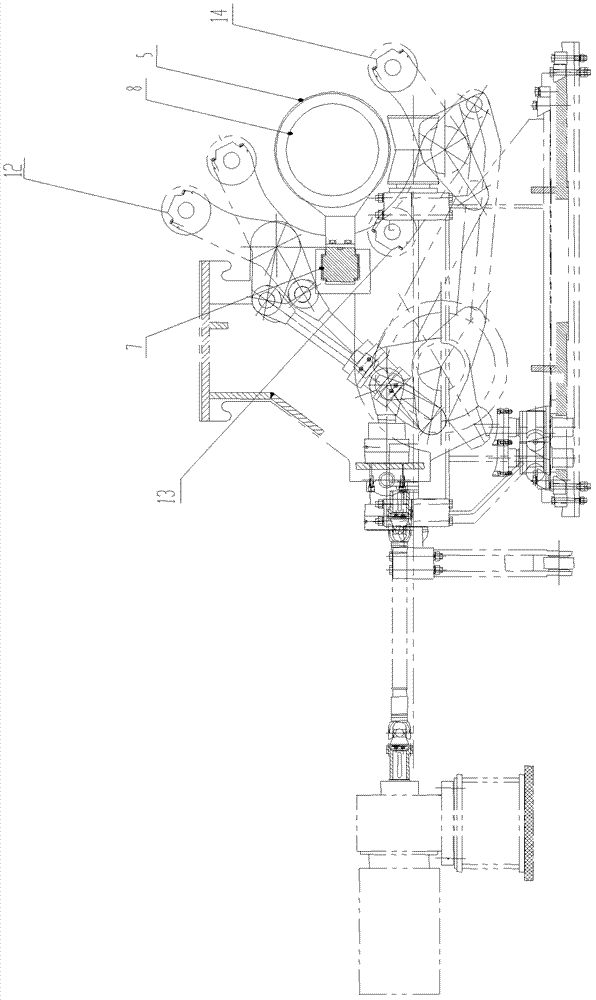

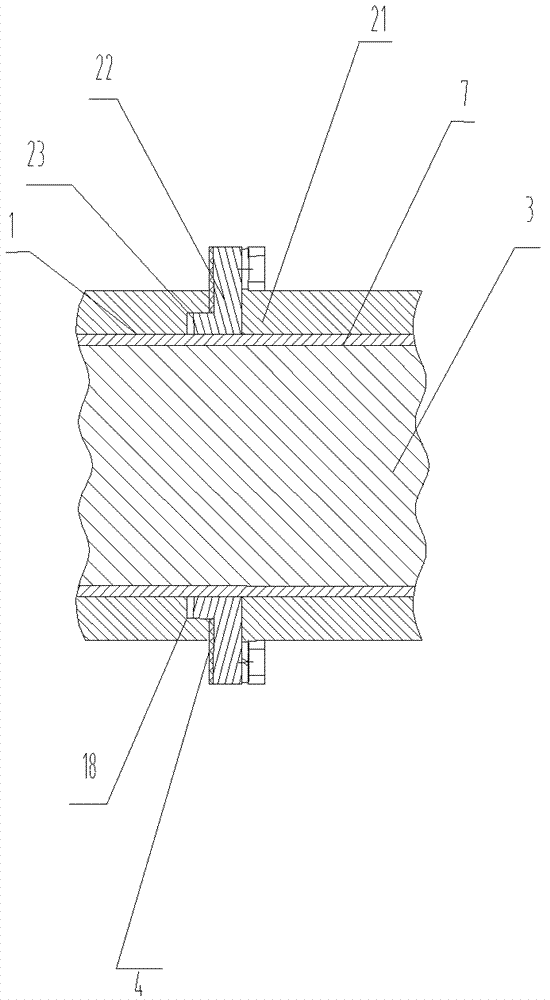

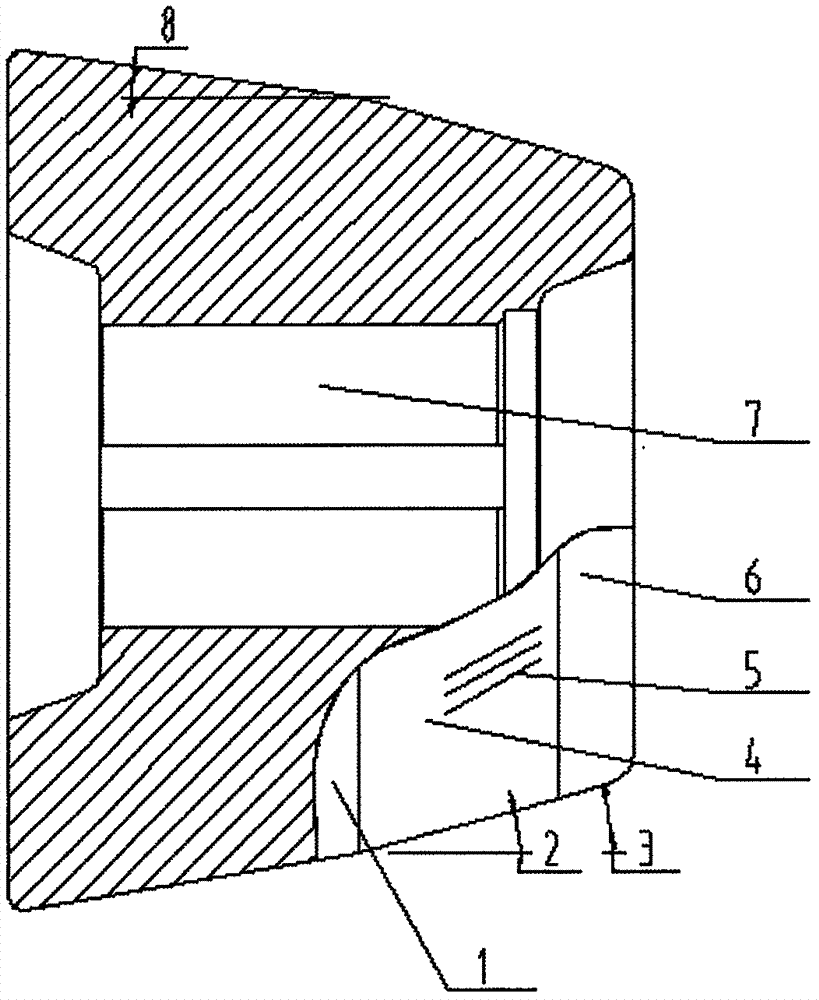

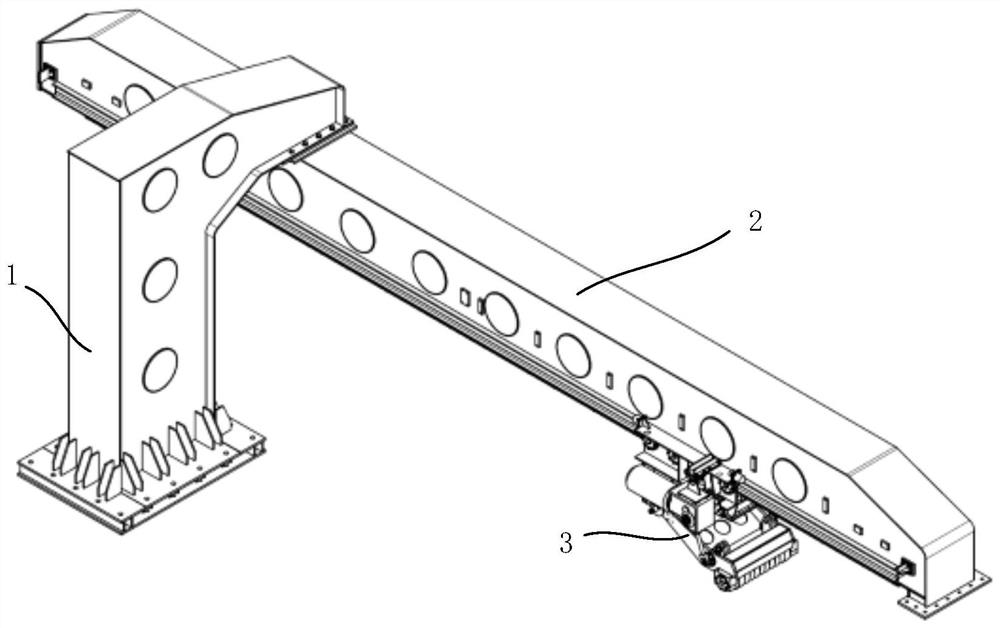

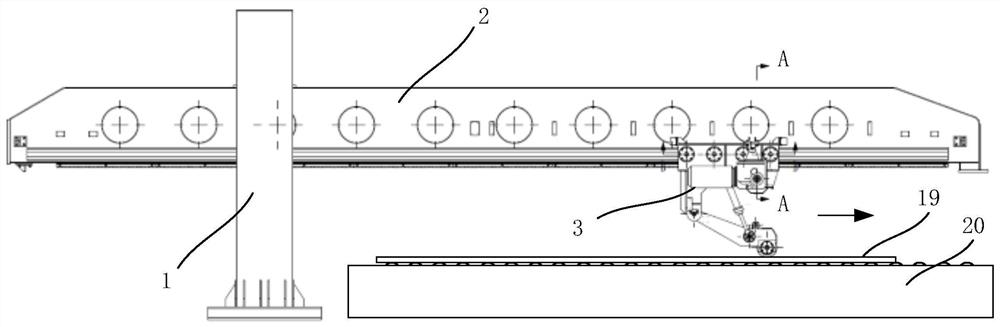

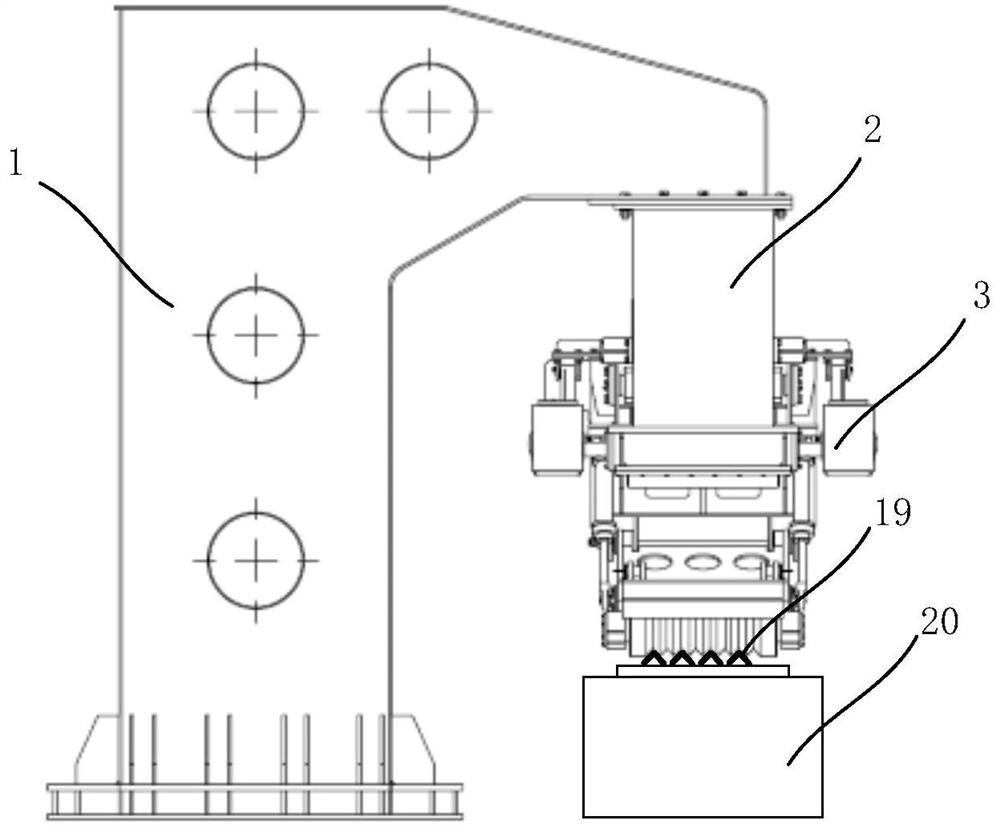

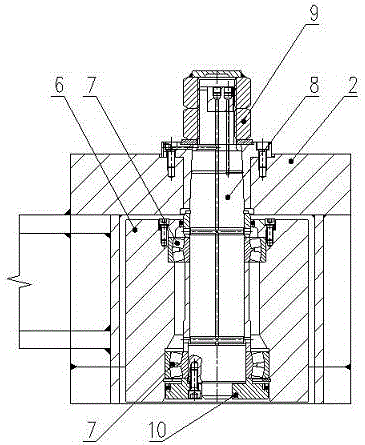

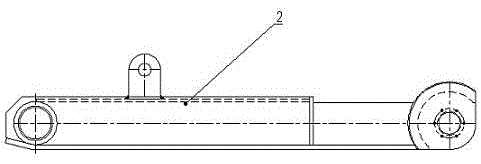

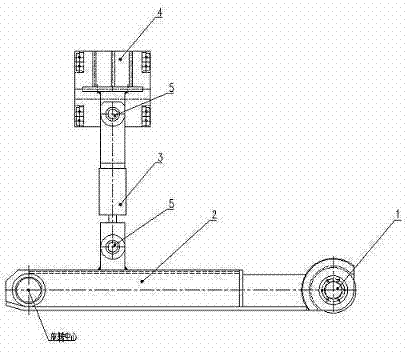

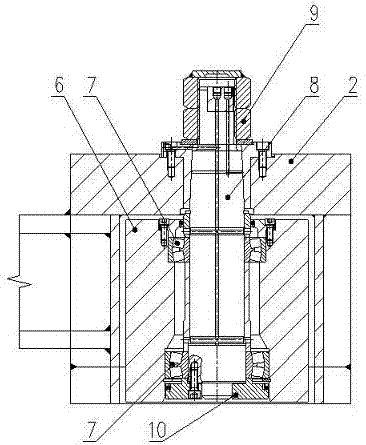

Feeding device on front stand of ASSEL tube mill

The invention relates to a tube mill, in particular to a feeding device on the front stand of an ASSEL tube mill, which comprises a guide rail part, a feeding part and a driving mechanism, wherein the guide rail part is arranged on the front stand of the ASSEL tube mill; the feeding part can move reciprocally along the guide rail part and is positioned on the outer side of the front stand of the ASSEL tube mill in a horizontal direction; and the driving mechanism can drive the feeding part. The feeding device of the ASSEL tube mill has a simple structure and is convenient for installation and regulation; in a horizontal direction, the feeding device is positioned on the outer side of the front stand of the ASSEL tube mill, which is very favorable for the conveying of tubular billets and prevents tubular billets with a diameter phi of more than 270 millimeters from sliding during conveying; and in a rolling process, the feeding device ensures the smooth biting of the tubular billets and the normal tube rolling and improves production efficiency.

Owner:TAIYUAN HEAVY IND

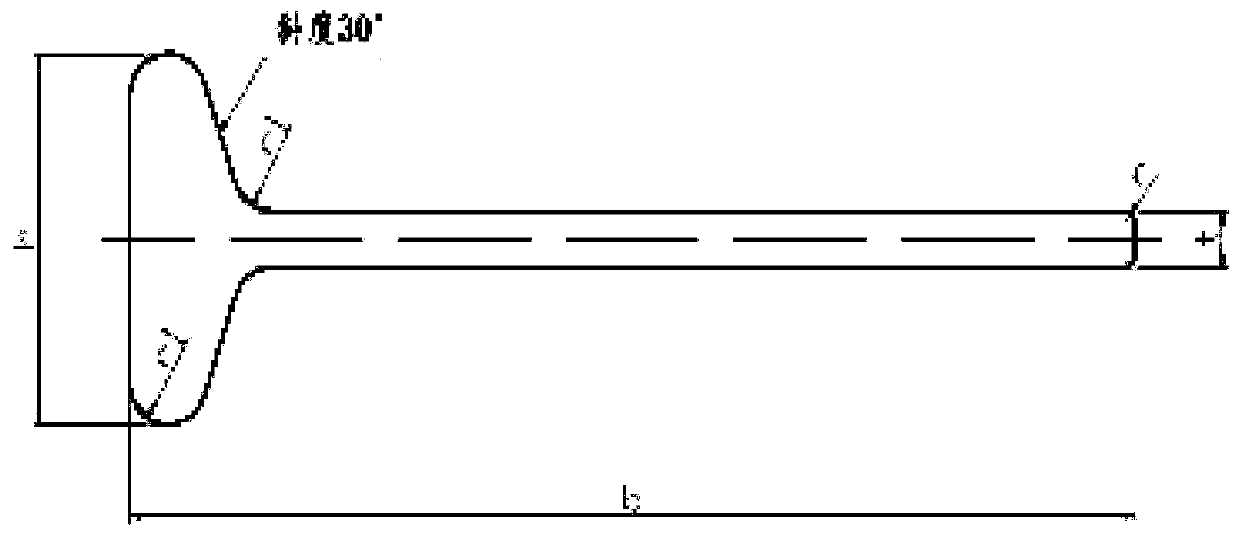

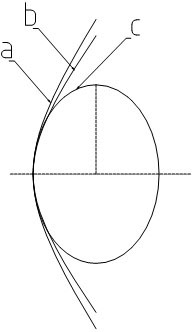

Piercer roller for extra-thick walls

PendingCN107999540ABite smoothlyUniform penetrationRollsMetal rolling arrangementsEngineeringKnurling

The invention discloses a piercer roller for extra-thick walls. The piercer roller comprises an entrance cone, a first exit cone and a second exit cone which are connected to each other in sequence, and the center position of the roller body is provided with a through hole; the half cone angle of the entrance cone is 7-8 DEG, and the half cone angle of the first exit cone is 14-16 DEG; and the half cone angle of the second exit cone is 16.5-18.5 DEG. According to the piercer roller for the extra-thick walls, the outer edge of the end of the entrance cone is provided with a chamber with the radius of 20 mm, and the smooth engagement of tube blanks in the rolling process is ensured. By arranging the roller surface angles of the entrance cone, the first exit cone and the second exit cone andthe outer edge chamber of the end of the second exit cone, the position of an ejector rod is closer to the front part, and the top extension is increased; and the penetrability and uniform wall thickness of seamless tubes with the extra-thick walls in the piercing process are ensured. The roller surface is provided with knurling, and the friction force of the roller and the tube blanks is increased; and the engagement force in the rolling process is increased.

Owner:XINPENGYUAN INTELLIGENT EQUIP GRP

Roller of three-roller planetary rolling mill

ActiveCN101862754BExtended service lifeBite smoothlyRollsMetal rolling arrangementsConical formsProcess region

The invention relates to a roller of a three-roller planetary rolling mill. The roller (1) is basically in a conical shape. The invention is characterized in that the roller (1) is divided into five regions from the tail part to the head part, and the five regions are sequentially a material inlet region (S), a deformation region (S1), a process region (S2), a sizing region (S3) and a material outlet region (S4), annular concavo-convex lines (12) are uniformly distributed in the radial direction on the conical surface of the roller (1) in the deformation region (S1) at intervals, and in addition, inclined lines (11) formed by the axial projection of the concavo-convex lines (12) are sinusoidal curves. Compared with the prior art, the invention has the advantages that the smooth feeding and continuous stable and efficient rolling of rolling element blanks can be ensured in the rolling process, in addition, the influence of the rolling element surface quality caused by the severe vibration of the blank deformation can be avoided, the thread pitch of the rolled pipe materials in actual operation is uniform and stable, and the service life of the roller is greatly prolonged.

Owner:NINGBO JINTIAN COPPER TUBE

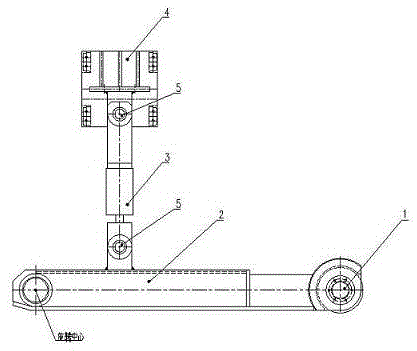

Row-shaped steel carding device

PendingCN112441399AImprove reliabilityHigh degree of automationMetal-working feeding devicesPositioning devicesElectric machineryManufacturing engineering

The invention discloses a row-shaped steel carding device. The row-shaped steel carding device comprises a stand column, a cross beam and a carding vehicle, wherein the cross beam comprises a cross beam body, a first groove-shaped guide rail, a second groove-shaped guide rail, a first rack and a second rack; the carding vehicle comprises a vehicle body, a guide wheel, a first gear motor, a secondgear motor, a gear shaft assembly, a first oil cylinder, a second oil cylinder, a proximity switch, a swing support and a carding roller assembly; one end of the stand column is arranged on an installation foundation, and the other end of the stand column is connected with the cross beam; the carding vehicle is connected with the cross beam through the guide wheel and a gear and rack pair; and thecarding vehicle can reciprocate along the cross beam under the drive of the motors, and the operation that row-shaped steel is carded at the same time through a carding roller is achieved. The row-shaped steel carding device is high in reliability and automation degree, and carding and alignment of multiple pieces of section steel running on a front roller way of a row straightening machine can be achieved so that the row straightening machine can smoothly bite the multiple pieces of section steel in rows.

Owner:HUATIAN ENG & TECH CORP MCC

Large bar hydraulic shear front hydraulic automatic guide device

ActiveCN104259552BReduce scratchesExtended service lifeGuiding/positioning/aligning arrangementsMetal rolling arrangementsHydraulic cylinderContinuous rolling

The invention relates to a hydraulic automatic guide device before hydraulic shearing of large bars, which comprises a rotating guide wheel mechanism, a guide arm, a hydraulic cylinder, and a hydraulic cylinder base. The rotating guide wheel mechanism and the guide arm are assembled together, and the guide arm and the guide arm The hydraulic cylinder and the hydraulic cylinder are connected with the hydraulic cylinder base through the movable connection structure, and the hydraulic cylinder base is fixed on the foundation through chemical anchor bolts. The design of the whole technical scheme is ingenious and practical, which can not only make the rolled piece enter the hydraulic shear smoothly, but also enable the rolled piece to automatically move in the same direction as the shear blade moves when the hydraulic shear blade cuts. In this way, the bending caused by the interference of the rolled piece with the fixed guide device is avoided, so that the rolled piece can smoothly enter the continuous rolling mill for the production of the next process. The device can adapt to the guidance requirements of intermediate billets of various specifications and sizes, and can ensure that the continuous rolling mill always bites into the billet smoothly, which significantly improves the productivity of the continuous rolling mill, speeds up the rolling rhythm, and reduces costs and energy consumption.

Owner:JIANGSU LIANFENG ENERGY EQUIP

A rolling method of symmetrical spherical flat steel for large shipbuilding

ActiveCN109261714BImprove mechanical propertiesEliminate organizational defectsWork cooling devicesMetal rolling arrangementsEngineeringHigh pressure water

The invention relates to the technical field of flat-bulb steel rolling, in particular to a rolling method of symmetric flat-bulb steel for large-scale shipbuilding. The oblique rolling method is adopted for rolling. A rolling device comprises a two-roller type section mill, three to five three-roller type section mills, wherein the three-roller type section mills are arranged transversely. The specific rolling process comprises the following steps of rough rolling, moderate rolling, frictional ring arrangement, fine rolling and forced cooling after rolling, wherein high-pressure water mist issprayed by using a water cooling device, and accurate cooling is performed by accurately adjusting a bulb and the flow of web plate water mist. By adopting the oblique rolling method, the installingdifficulty of a foreplate and the labor intensity of steel rolling workers are reduced on the premise that the problem of insufficient length of each roller body is solved; the bulb metal filling amount and web plate width precision are ensured; by arranging frictional rings, web plate waves are avoided, and the surface quality of rolled pieces is improved.

Owner:ANGANG STEEL CO LTD

Backstop high-expansion expansion bolt

The invention provides a backstop high-expansion expansion bolt which comprises a bolt body, an outer sleeve and a nut. A pushing block is arranged at the front part of the bolt body; the outer sleeveis arranged outside the bolt body; the nut is matched with the bolt body; a spring pad and a washer are further arranged between the nut and the outer sleeve; a clamping block is installed on the pushing block, a clamping plate and a pushing groove are arranged at the front part of the outer sleeve, and the pushing block moves to enable the clamping block to rotate and simultaneously enable the clamping plate to expand, so that the clamping block and the clamping plate can be bidirectionally locked. The pushing block moves to enable the clamping block and the clamping plate to expand in two opposite directions simultaneously, therefore the device can limit outward and inward movement in the axial direction simultaneously, high expansion force can be generated, and falling is not likely tooccur.

Owner:马娜

A control method for stable coiling of hot-rolled high-strength steel head

ActiveCN105013860BImproved bending propertiesBite smoothlyRoll mill control devicesMetal rolling arrangementsPre expansionControl system

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Pinch roll for pipes and bars

ActiveCN101862757BIncrease contactDoes not affect teleportationMetal rolling arrangementsNumerical rangeMinor axis

The invention relates to a pinch roll for pipes and bars. The shape of the circumferential surface of the roll comprises an improved hyperbolic curve as the upper part and an oval curve smooth transition as the lower part, wherein the improved hyperbolic curve of the upper part is as follows: cos<2>alphaX<2>-deltaY<2>=deltad<2>; and the oval curve of the lower part is as follows: cos<2>alphaX<2>+Y<2>=d<2>; wherein d is the diameter of a cylindrical blank, alpha is the included angle between the central axis of the roll and the central axis of the cylindrical blank, delta is a coefficient witha numerical range of 0.5-1, X represents a major axis, and Y represents a minor axis. In the pinch roll, two rollers of the pinch roll device and the cylindrical blank are arranged crosswise, and theself rotation of the rollers drives the cylindrical blank to move forward. By using the technical scheme, the roll curved surfaces of the rollers are brought in good contact with the blank. Thereby, the contact rate is ensured to the greatest extent, and the roll bite is smooth in the rolling process.

Owner:JINAN HEAVY MACHINERY JOINT STOCK

Automatic front hydraulic guiding device for big stick hydraulic shear

ActiveCN104259552AReduce scratchesExtended service lifeGuiding/positioning/aligning arrangementsMetal rolling arrangementsHydraulic cylinderControl engineering

The invention relates to an automatic front hydraulic guiding device for a big stick hydraulic shear. The automatic front hydraulic guiding device for the big stick hydraulic shear comprises a rotary guiding wheel mechanism, a guiding arm, a hydraulic cylinder and a hydraulic cylinder base; the rotary guiding wheel mechanism and the guiding arm are assembled together; the guiding arm and the hydraulic cylinder and the hydraulic cylinder and the hydraulic cylinder base are connected through a flexible connecting structure; the hydraulic cylinder base is fixed on foundation through a chemical anchor bolt. The integral technical scheme is skillful and practical in design, a rolled piece which smoothly enters the hydraulic shear automatically moves in the same direction along with shear blade actions during cutting of a hydraulic shear blade, bending caused by interference between the rolled piece and a fixed guiding device is avoided, and the rolled piece can smoothly enter a continuous mill to perform production of next procedure. The automatic front hydraulic guiding device for the big stick hydraulic shear is suitable for guiding requirements of middle square billets in various sizes, the continuous mill is guaranteed smoothly clamping blanks all the time, the production efficiency of the continuous mill is obviously improved, the milling pace is quickened, and costs and energy consumption are reduced.

Owner:JIANGSU LIANFENG ENERGY EQUIP

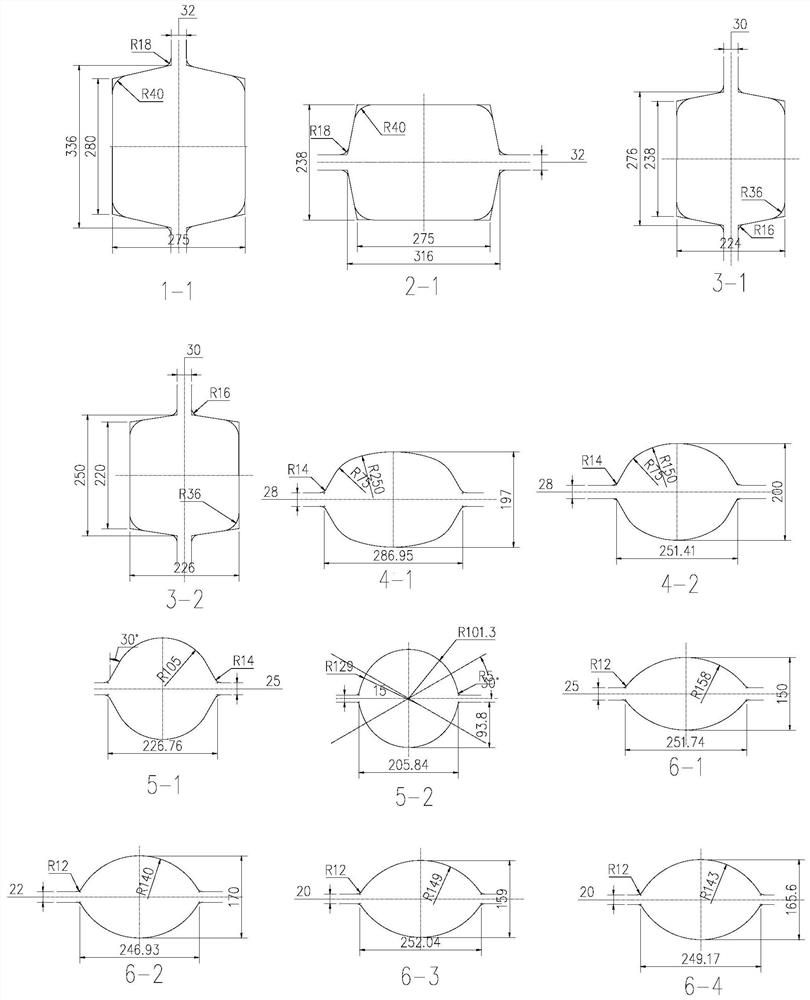

A hat-shaped steel rolling method and hat-shaped steel

ActiveCN112474794BReduce lossIncrease productivityTemperature control deviceRolling mill drivesClassical mechanicsStructural engineering

The invention discloses a hat-shaped steel rolling method and a hat-shaped steel; the rolling process of the invention comprises: heating → high-pressure water descaling → billet rough rolling → reciprocating continuous rolling → cooling → straightening; rolling pass Including wavy flat arc pre-slit holes, M-shaped cut holes, finish-rolled holes and hot-rolled finished holes, the middle of finish-rolled holes and hot-rolled finished holes have arc segments, Both ends of the shape segment are symmetrically provided with an upper leg and a lower leg, the upper end of the upper leg intersects with one end of the arc segment to form an included angle, and the lower leg is arranged at the lower end of the side away from the arc segment of the upper leg and is connected to the upper leg. The hat-shaped steel includes a horizontal waist, and two ends of the hat-shaped steel are symmetrically provided with a vertical straight leg and a horizontal flat leg respectively, and the flat leg is located on the side of the straight leg away from the waist; the invention can effectively improve the hat-shaped steel. Production efficiency, improve rolling stability, reduce the difficulty of process design, and reduce the loss of roll equipment.

Owner:MAANSHAN IRON & STEEL CO LTD

A Biting Control Method in Heavy Rail Rolling

ActiveCN103157669BEnough kinetic energyBite smoothlyRoll speed control deviceEngineeringIntelligent control

The invention relates to the field of control of a rolling process, in particular to a gripping control method in a rolling process of a heavy rail. The gripping control method in the rolling process of the heavy rail is characterized in that the rotation speed of a main motor of a universal rolling mill is adjusted, so that a rolling piece obtains enough kinetic energy and grips a hole of a UR roller. The particular operation steps are as follows: (1) before the rolling piece enters the UR roller of the universal rolling mill, hole water is closed, and an automatic rolling program of the universal rolling mill is stopped; (2) after the rolling piece arrives transversely, the rotation speed of the main motor of the universal rolling mill is improved to 100-110 turns per minute; (3) the rolling piece is abraded on the UR roller for 30-40 seconds, and then the rotation speed of the main motor of the universal rolling mill is reduced to 10-20 turns per minute until the rolling piece grips the hole; and (4) after the rolling piece grips the hole by 2-3 meters, the rolling pieces is poured out by hand, and the automatic rolling program of the universal rolling mill is recovered. Compared with the prior art, the gripping control method in the rolling process of the heavy rail has the advantages of enabling the rolling piece to grip the hole of the UR roller smoothly, achieving intelligent control, and being suitable for the heavy rail with the level of more than 50 kilos.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com